Abstract

Advanced oxidation process is a promising technology for the treatment of azo dye wastewater, owing to its high degradation performance and less secondary contamination. Herein, the mineralization of azo dye Reactive Black 5 (RB5) by the heterogeneous photo-Fenton process was investigated in a three-phase fluidized bed reactor. The waste iron oxide (denoted as BT) obtained from tannery wastewater process with Fenton’s reagent was selected as a heterogeneous catalyst. The introduction of BT to the UV/H2O2 process (UV/H2O2/BT) shows obviously higher mineralization efficiency because ferric complexes of carboxylic acid, the degradation intermediates of RB5, could be readily decomposed by UV irradiation. The decolorization was achieved by homogenous photo-Fenton reaction induced by leached iron, while the mineralization was contributed to heterogeneous oxidation. Under the conditions of 254 nm UV irradiation, 19.00 mM H2O2, 2.0 g L–1 catalyst loading and natural pH0 of 5.0, 90.2% TOC removal of RB5 could be achieved. The catalyst indicated an acceptable stability and reusability after four cycles. The proposed heterogeneous photo-Fenton process with stable performance is environmental-friendly for the mineralization of RB5.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Azo dyes, which constitute a significant proportion of dye production in the world, have been identified as hazardous agents with potential genotoxicity and carcinogenicity [1]. Characterized by azo groups (–N=N–) [2], azo dyes are widely used in textile, printing and leather industries. Generally, these dyes have complex aromatic structures which are resistant to biodegradation [3]. The release of this type of industrial sewage is a troublesome problem to both aquatic life and human, mainly due to high color, organic loads and refractory of these effluents [4]. Therefore, effective and economical methods are needed for the treatment of dye industrial wastewater before its discharge [3].

Compared with the traditional dye wastewater treatment such as adsorption, coagulation and flocculation, advanced oxidation processes (AOPs) are preferable option, due to the advantages of high efficiency and less secondary pollution [5]. AOPs are characterized by the in-situ generation of powerful oxidizing species, such as hydroxyl radicals (·OH), which are suitable for achieving the complete abatement and mineralization of toxic or refractory substances [6, 7].

Conventional Fenton process is one of the homogeneous AOPs, in which peroxide (usually H2O2) is catalyzed to form ·OH by ferrous ion as given in Eq. (1) [6, 8]. Generally, Fenton’s reagent is relatively inexpensive and the process is easy to operate [9], and the generated ·OH with a high redox potential (E0 = 2.8 V) [10] can degrade most refractory organic pollutants under appropriate conditions [11]. Nevertheless, the practical application of conventional homogeneous Fenton process is limited owing to the consumption of large iron input, the formation of ferric hydroxide sludge and the narrowly acidic pH range [9]. Therefore, by using cheap, efficient and recyclable catalyst, heterogeneous Fenton process can be an alternative for the treatment of dye wastewaters [12].

Normally, the heterogeneous Fenton catalysts are fabricated from pure chemicals. In order to save material cost, a novel “wastes-treat-wastes” strategy has been proposed by using iron-containing wastes as Fenton catalysts [13, 14]. In our previous studies, the waste iron oxide obtained from tannery wastewater process with Fenton’s reagent was employed as heterogeneous photo-Fenton catalyst for the treatment of Orange G [12], bisphenol A [15] and N-methyl-2-pyrrolidone [16]. However, it has not been applied to the degradation of Reactive Black 5 (RB5). More importantly, the contribution of heterogeneous and homogenous photo-Fenton reaction to the organic degradation was not investigated. Therefore, in this study, the decolorization and mineralization of RB5 in the heterogeneous photo-Fenton system was investigated using waste iron oxide (named as BT) as catalyst. To enhance mass transfer in the UV/H2O2/BT process, the degradation of RB5 was performed in a three-phrase (gas–liquid-solid) fluidized bed reactor. The contribution of homogenous photo-Fenton reaction induced by leached iron and heterogeneous photo-Fenton process to the decolorization and mineralization of RB5 was discriminated. The effects of initial pH, H2O2 concentration and catalyst dosage on the mineralization of RB5 were evaluated. The stability and reusability of the catalyst were tested by four consecutive cycles.

Material and methods

The target contaminant, RB5 was purchased from Sigma-Aldrich Co. (St Louis, Missouri). H2O2 (analytical grade, 50% w/w) was purchased from Union Chemical in Taiwan. All solutions were prepared with pure water from a laboratory-grade RO-ultrapure water system.

The waste iron oxide (BT), a by-product of the Fenton reaction in a three-phase fluidized bed reactor (3P-FBR) for the treatment of the bio-effluent from tannery wastewater, was characterized using X-ray powder diffraction (XRD, Rigaku, RX3). Figure 1 shows the main diffraction peaks of BT at 2θ = 21.22°, 26.33°, 33.24°, 34.06°, 36.65°, 39.98°, 41.19°, 50.61° and 53.24° match well with the standard XRD card of goethite (α-FeOOH, PDF#29-0713).

All experiments were carried out in a three-phase fluidized bed reactor (3P-FBR, 7.5 cm-diameter and 45 cm-height), which was similar to our previous study [12]. As depicted in Fig. 2, from the bottom of 3P-FBR, compressed air (1 L min–1) was continuously injected through the porous sintered plate. The UV lamp (254 nm, 15 W) was fixed inside the inner coaxial cylinder (3.5 cm-diameter and 45 cm-height). To completely prevent the penetration of visible light from outside, aluminum foil was used to hood the 3P-FBR. The UV lamp was turned on firstly for 10–15 min, and then 1 L RB5 solution and a certain amount of BT were added into the 3P-FBR, respectively, which were circulated by aeration. Initial pH value of dye solution was adjusted by 0.1 M H2SO4 or 0.1 M NaOH if needed. Reaction was started right after dropping of H2O2 and performed at ambient temperature (28 ± 2 °C). Samples were taken with syringes at specific time points and filtered through 0.22 μm syringe filters for further analysis.

The absorbance of RB5 was analyzed by using a UV–Vis spectrometer (Jasco 7850) at maximum wavelength of 597 nm. The TOC was determined by a TOC analyzer (InnovOx Laboratory, GE). The total iron released into aqueous phase was quantified by an inductively coupled plasma optical emission spectrometer (ICP-OES). Similar analytical procedures were previously reported by many authors [17,18,19,20,21,22,23,24]. This shows the reliability of the results presented in this study.

Results and discussion

Decolorization and mineralization of RB5 in different processes

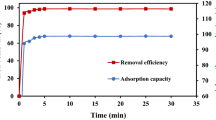

To determine feasibility and superiority of the UV/H2O2/BT process, a batch of RB5 degradation experiments were carried out. Figure 3 shows BT alone had no obvious elimination towards RB5, illustrating the low adsorptive capability of BT. The dye was hardly bleached when UV irradiation alone was applied since most of the dyes are designed to resist photochemical degradation [25]. The combination of BT and UV (UV/BT) did not improve the decay of RB5, indicating the low photocatalytic activity of BT.

With H2O2 alone, the removal of RB5 was also negligible due to the limited oxidation potential of H2O2 (E0 = 1.76 V) [26]. The addition of BT into the H2O2 alone system (H2O2/BT) achieved about 28.8% decolorization of RB5 in 180 min, which is owing to the reaction as given in Eq. (2) [27] and the sequent Fenton reaction induced by ≡Fe2+ (≡ denotes solid state) as presented in Eq. (3). However, the corresponding TOC removal efficiency was only 10.3% due to insufficient radicals formed in the H2O2/BT system. In parallel, the coupling of UV with H2O2 (UV/H2O2) attained a relatively efficient decomposition of RB5 (90.2%). This can be explained by that UV irradiation induced the generation of ·OH from H2O2 via photolysis reaction as illustrated in Eq. (4). Nevertheless, only a small amount of TOC (23.1%) was obtained, implying that the degradation products of RB5 such as carboxylic acids are more difficult to oxidize [28].

Furthermore, the combination of UV, H2O2 and BT (UV/H2O2/BT) was much more efficient than other processes. In the UV/H2O2/BT process, ·OH radicals can be generated via the decomposition of H2O2 by ≡Fe2+ catalysis (Eq. 3) and by direct photolysis (Eq. 4) [29]. Figure 3 indicates that 99.9% of decolorization efficiency was obtained in 40 min reaction and 95.6% TOC removal could be achieved when the reaction time was extended to 120 min. It illustrates the advantage of UV/H2O2/BT over UV/H2O2 for RB5 mineralization though both processes could achieve almost complete decolorization. As mentioned above, the formed intermediates, carboxylic acids, are hardly oxidized by ·OH in the UV/H2O2 process. When BT was introduced, carboxylic acids would complex with ≡Fe3+ on the surface of BT. The formed ferric carboxylate complexes could be readily decomposed by UV irradiation (Eq. 5), accompanied by the regeneration of ≡Fe2+ [12] to enhance Fenton reaction (Eq. 3).

To investigate the contribution of homogeneous photo-Fenton process to the degradation of RB5, BT was replaced by 3.0 mg L−1 of Fe2+, which was detected in the UV/H2O2/BT process. Figure 3a shows 95.5% of RB5 was oxidized by the UV/H2O2/Fe2+ process, indicating the homogeneous photo-Fenton process plays a role in the decolorization of RB5. However, the corresponding TOC removal efficiency was only 22.3% (Fig. 3b), which was much lower than that by UV/H2O2/BT process. It reveals heterogeneous oxidation contributed much more significantly to the mineralization of RB5 than homogenous oxidation. Considering that the mineralization performance is corresponding to completely oxidation of RB5 and its intermediates, it was selected as an evaluation criterion in the following experiments.

Effects of reaction parameters on RB5 mineralization

The effect of initial pH on TOC removal of RB5 was examined over a wide pH range from 3.0 to 11.0, and results are shown in Fig. 4a. At initial pH of 3.0, 4.0, 5.0 and 7.0, the TOC removal efficiencies of RB5 were 96.2%, 96.3%, 96.1% and 95.7%, respectively, which exhibited nearly the same mineralization trend of RB5. Further increasing the pH0 value to 9.0 and 11.0, the mineralization efficiencies dropped by 6.5% and 27.1%, respectively. To some extent, excess of OH– in the alkaline environment would inhibit the heterogeneous Fenton reaction of Eq. (3). As previously reported, the oxidation potential of ·OH could decrease with the increase in pH [30]. Thus, acidic and neutral conditions are preferred for RB5 mineralization in the UV/H2O2/BT process. Based on the results above, pH0 5.0 (natural pH of RB5 solution) was chosen as the initial pH for the subsequent experiments.

As the source of ·OH generation, H2O2 plays a significant role in the UV/H2O2/BT process. The effect of H2O2 concentration on RB5 mineralization was investigated in the range of 4.75–38.00 mM. As observed from Fig. 4b, the mineralization of RB5 was accelerated along with increase in H2O2 concentration. In the heterogeneous photo-Fenton process, more ·OH radicals could be generated as the concentration of H2O2 increased. However, the improvement in TOC removal was not so obvious when H2O2 concentration was doubled from 19.00 to 38.00 mM. As reported in the previous study, excessive H2O2 would consume ·OH radicals by the side reaction as presented in Eq. (6) [31]. According to the obtained results, 19.00 mM was selected as the optimal H2O2 concentration for the following experiments.

The effect of BT dosage was investigated under the conditions of pH0 5.0 and 19.00 mM H2O2. As observed in Fig. 4c, when BT dosage rose from 0.5 to 2.0 g L–1, the TOC removal efficiency gradually increased from 73.1 to 90.2%. The more dosage of BT means more active sites available for the decomposition of H2O2 to generate ·OH. Nevertheless, a further increase in catalyst dosage from 2.0 to 5.0 g L–1 only caused a slight increase in TOC removal by 1.1%, probably because excessive BT catalyst increased turbidity of the reaction mixture and lowered the penetration of UV light, which could possibly suppress photolysis of H2O2 and photo-reduction in ≡Fe3+. This side effect would partly offset the positive effect of abundant BT dosage. From the above result, the catalyst dosage of BT was chosen as 2.0 g L–1 for the subsequent tests.

Reusability of the catalyst BT

Undoubtedly, the reusability of heterogeneous catalyst is a crucial parameter for practical application. Thus, a batch of reuse experiments were carried out to assess the reusability of the catalyst in the UV/H2O2/BT process. After each experiment, the used catalyst was recycled by filtering, washing and drying and then reused for the next run. Figure 5a shows TOC removal during the four consecutive cycles. Even after three cycles, BT still exhibited good catalytic stability and achieved 70.4% TOC removal at the fourth cycle. The dissolved iron of each recycle is presented in Fig. 5b. The detected concentrations of leached Fe were all in a low level. The calculated leaching percentage of Fe in each cycle was also subtle, being 0.055%, 0.094%, 0.067% and 0.057%, respectively, which indicates the stability and corrosion resistance of catalyst BT.

Conclusions

In this study, the waste iron oxide BT was selected as heterogeneous catalyst of the UV/H2O2/BT process for the degradation of RB5. The proposed process shows the advantages of high treatment performance, low iron leaching and “wastes-treat-wastes” strategy. In contrast with other processes, UV/H2O2/BT was proved to be a promising approach for the decolorization and mineralization of RB5. The optimal conditions of the UV/H2O2/BT process were determined as 254 nm UV irradiation, natural pH0 5.0, 19.00 mM H2O2 and 2.0 g L–1 catalyst dosage. Under the optimal conditions, 90.2% TOC removal was achieved in 180 min. The catalyst reuse experiment shows recyclable and stable performance of the heterogeneous catalyst BT. These results indicate that the proposed UV/H2O2/BT process is an efficient and environmental-friendly solution for the mineralization of RB5.

References

Y. Sha, I. Mathew, Q. Cui, M. Clay, F. Gao, X.J. Zhang, Z. Gu, Chemosphere 144, 1530 (2016)

C. Cai, H. Zhang, X. Zhong, L. Hou, J. Hazard. Mater. 283, 70 (2015)

M. Punzi, A. Anbalagan, R.A. Börner, B.-M. Svensson, M. Jonstrup, B. Mattiasson, Chem. Eng. J. 270, 290 (2015)

Z.G. Aguilar, E. Brillas, M. Salazar, J.L. Nava, I. Sirés, Appl. Catal. B 206, 44 (2017)

Y. Wang, Y.W. Gao, L. Chen, H. Zhang, Catal. Today 252, 107 (2015)

A. Boucenna, N. Oturan, M. Chabani, S. Bouafia-Chergui, M.A. Oturan, Environ. Sci. Pollut. Res. 26, 23149 (2019)

A. Sharfalddin, E. Alzahrani, M. Alamoudi, Res. Chem. Intermed. 43, 2587 (2017)

N. Masomboon, C.-W. Chen, J. Anotai, M.-C. Lu, Chem. Eng. J. 159, 116 (2010)

Y.W. Gao, Y. Wang, H. Zhang, Appl. Catal. B 178, 29 (2015)

Z. Ye, I. Sirés, H. Zhang, Y.-H. Huang, Chemosphere 217, 475 (2019)

L.F.O. Silva, X. Querol, K.M. da Boit, S.F.-O. Vallejuelo, J.M. Madariaga, J. Hazard. Mater. 186, 516 (2011)

Y. Wang, R. Priambodo, H. Zhang, Y.-H. Huang, RSC Adv. 5, 45276 (2015)

M.E.M. Ali, T.A. Gad-Allah, M.I. Badawy, Applied Water Science 3, 263 (2013)

J.M. Zheng, Z.Q. Gao, H. He, S.G. Yang, C. Sun, Chemosphere 150, 40 (2016)

H.Y. Li, R. Priambodo, Y. Wang, H. Zhang, Y.-H. Huang, J. Taiwan Inst. Chem. Eng. 53, 68 (2015)

F.Z. Liu, J. Ai, H. Zhang, Y.-H. Huang, Environ. Technol. 41, 539 (2020)

A.C. Dalmora, C.G. Ramos, X. Querol, R.M. Kautzmann, M.L.S. Oliveira, S.R. Taffarel, T. Moreno, L.F.O. Silva, Chemosphere 144, 2013 (2016)

A.C. Dalmora, C.G. Ramos, M.L.S. Oliveira, E.C. Teixeira, R.M. Kautzmann, S.R. Taffarel, I.A.S. de Brum, L.F.O. Silva, Sci. Total Environ. 539, 560 (2016)

M.S. Civeira, C.G. Ramos, M.L.S. Oliveira, R.M. Kautzmann, S.R. Taffarel, E.C. Teixeira, L.F.O. Silva, Chemosphere 145, 142 (2016)

M. Civeira, M.L.S. Oliveira, J.C. Hower, D.M. Agudelo-Castañeda, S.R. Taffarel, C.G. Ramos, R.M. Kautzmann, L.F.O. Silva, Environ. Sci. Pollut. Res. 23, 6535 (2016)

J.L. Sehn, F.B. de Leão, K. da Boit, M.L.S. Oliveira, G.E. Hidalgo, C.H. Sampaio, L.F.O. Silva, Chemosphere 147, 439 (2016)

A. Rodriguez-Iruretagoiena, S. F.-O. de Vallejuelo, A. de Diego, F. B. de Leão, D. de Medeiros, M. L. S. Oliveira, S. R. Tafarel, G. Arana, J. M. Madariaga and L. F. O. Silva, Sci. Total Environ. 565 (2016).

J. Wilcox, B. Wang, E. Rupp, R. Taggart, H. Hsu-Kim, M.L.S. Oliveira, C.M.N.L. Cutruneo, S. Taffarel, L.F.O. Silva, S.D. Hopps, G.A. Thomas, J.C. Hower, Energy Fuels 29, 7168 (2015)

C.G. Ramos, X. Querol, M.L.S. Oliveira, K. Pires, R.M. Kautzmann, L.F.S. Oliveira, Sci. Total Environ. 512–513, 371 (2015)

H. Zhang, L.J. Duan, D.B. Zhang, J. Hazard. Mater. 138, 53 (2006)

T.-K. Kim, T. Kim, A. Jo, S. Park, K. Choi, K.-D. Zoh, Chemosphere 208, 441 (2018)

Y. Lee, C. Lee, J. Yoon, Chemosphere 51, 963 (2003)

H. Zhang, J.H. Zhang, C.Y. Zhang, F. Liu, D.B. Zhang, Ultrason. Sonochem. 16, 325 (2009)

Y.H. Zhong, X.L. Liang, Y. Zhong, J.X. Zhu, S.Y. Zhu, P. Yuan, H.P. He, J. Zhang, Water Res. 46, 4633 (2012)

B.G. Kwon, D.S. Lee, N. Kang, J. Yoon, Water Res. 33, 2110 (1999)

A. Khataee, S. Bozorg, B. Vahid, Res. Chem. Intermed. 43, 3989 (2017)

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tan, W., Ai, J., Fan, Y. et al. Enhanced mineralization of Reactive Black 5 by waste iron oxide via photo-Fenton process. Res Chem Intermed 46, 4423–4431 (2020). https://doi.org/10.1007/s11164-020-04212-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-020-04212-w