Abstract

Bimetallic Fe0-based catalysts have been shown to be effective heterogeneous catalysts for elimination of organic pollutants by activating persulfate (PS). In this study, copper ferrite (CuFe2O4) was isothermally treated under a reducing atmosphere in order to load Fe0/Cu0 bimetallic nanoparticles on the surface of CuFe2O4. The reduced CuFe2O4 was then used as a magnetically separable catalyst for PS activation to remove methyl orange (MO) from aqueous solution. The experimental data followed well the pseudo-first-order kinetic model, and the reaction rate of the reduced CuFe2O4/PS system was 5.6 times greater than that of the CuFe2O4/PS system. The key operating parameters such as PS concentration, catalyst dosage and solution pH were investigated. Catalyst stability of reduced CuFe2O4 was also tested by consecutive reuse cycles. Quenching experiments and electron spin resonance (ESR) spectroscopy revealed that the main reactive species was sulfate radical (SO ·−4 ). Intermediate products of MO degradation were determined by high performance liquid chromatography coupled with a high-resolution hybrid quadrupole time-of-flight mass spectrometer (LC-Q-TOF–MS) and the MO degradation pathways were proposed. Based on the analysis of catalytic activity and surface characteristics of reduced CuFe2O4, the enhanced reactivity of reduced CuFe2O4 was mainly attributed to rapid corrosion of Fe0/Cu0 bimetallic nanoparticles by PS. These findings illustrated that the reduced CuFe2O4/PS system may be an efficient technology for MO removal from wastewaters.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Water pollution caused by synthetic dyes is of great environmental concern all over the world, since most dyes are bio-recalcitrant, toxic, carcinogenic and mutagenic [1]. Thus, it is inevitable to remove dyes from wastewater before they are discharged into water resources. In recent decades, considerable attention has been paid to advanced oxidation processes (AOPs) as an efficient and versatile approach to degrade recalcitrant organic pollutants in wastewaters [2, 3]. AOPs, involving highly reactive oxygen species like hydroxyl radical (·OH), offer several advantages over conventional methods [2]. One significant advantage is the rapid transformation of recalcitrant organic compounds to biodegradable organic matter or to CO2 and H2O. Compared to the classic AOPs, sulfate radical (SO ·−4 ) related AOPs have attracted increasing research attention for decontamination of organic pollutants from water due to the fact that SO ·−4 possesses a high oxidation selectivity, strong oxidation potential (2.5–3.1 V) and wide operational pH range [4,5,6]. Therefore, SO ·−4 could be expected to be an excellent oxidant for the degradation of recalcitrant organic compounds in polluted water.

Generally, SO ·−4 can be generated from activating peroxymonosulfate (PMS) or persulfate (PS) by a variety of methods such as homogenous and heterogeneous metal-based catalysts, metal-free heterogeneous catalysts, heat, UV and alkaline [6,7,8]. Among the activation methods, heterogeneous catalysts have received more attention due to their simplicity and reusability. Moreover, PS ($0.74 per kg) is much cheaper than PMS (sold as Oxone (2KHSO5–KHSO4–K2SO4), $2.2 per kg) and even less expensive than H2O2 ($1.5 per kg) [9]. Thus, PS is considered to have a better application potential. Currently, metal oxides such as CuO [9], Fe3O4 [10], Co3O4 [11] and CuFe2O4 [12] have been employed as heterogeneous catalysts for PS activation. Particularly, magnetic materials are more attractive due to their easy separation from water under a magnetic field. Yet, the application of these catalysts still suffers from the low efficiency of organic pollutants removal. For example, greater than [PS]/[SMX] = 800 dose is requested to degrade sulfamethoxazole (SMX) in the Fe3O4/PS oxidation [10] and only 33% of diethyl phthalate is removed within 30 min in the CuFe2O4/PS oxidation [12]. Consequently, the development of efficient and magnetically recyclable heterogeneous catalysts for PS activation remains a priority.

Recently, zero-valent metal catalysts such as Fe0 [13,14,15], Cu0 [16], Zn0 [17], Al0 [18] and Mn0 [19] have been investigated as PS activators. The current research trend is dominated by the Fe0 because it is cost effective, nontoxic and more reactive [8]. Moreover, the application of Fe0 nanoparticles as PS activator has shown an outstanding performance of organic pollutants oxidation [20]. However, due to their high surface energy, Fe0 nanoparticles trend to aggregate, which leads to an apparent decrease in surface active sites [21]. Hence, several methods have been proposed to improve the performance of Fe0/PS process such as coupled with ultrasound [22] and ultraviolet [23], sulfidized Fe0 [24] and supported Fe0 [25, 26]. Among these methods, supported Fe0 has a great advantage because it is simple and does not need an extra energy source. Besides supported Fe0, bimetallic Fe0-based catalysts are found to have significantly higher reactivity and stability compared to the single Fe0 catalyst [27, 28]. For instance, the combination of copper with iron exhibits an improved catalytic activity due to synergic effect [27, 28]. Therefore, it is meaningful to load Fe0/Cu0 bimetallic nanoparticles on supports to enhance oxidation of organic pollutants by activating PS.

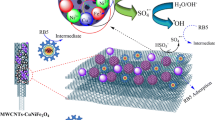

CuFe2O4, a kind of magnetic material, has been widely investigated in water treatment [29, 30]. It can also be used to activate PS for organic pollutants removal. However, the removal efficiency is relatively lower compared to several catalysts [12]. CuFe2O4 has both Fe and Cu elements. Therefore, to improve the catalytic activity of CuFe2O4 as PS activator, we used the hydrogen-thermal reduction method to load Fe0/Cu0 bimetallic nanoparticles on the surface of CuFe2O4. Then, the reduced CuFe2O4 and raw CuFe2O4 were examined as catalysts for PS activation. A common organic dye, methyl orange (MO), was selected as a model compound. The kinetics and impact factors of MO degradation were comprehensively evaluated. The catalytic mechanism for PS activation by reduced CuFe2O4 was further discussed and possible MO degradation pathways were also proposed.

Materials and methods

Reagents and materials

Unless otherwise specified, all chemicals and reagents were of reagent grade and used as received. Potassium persulfate (K2S2O8) and MO were of analytical grade and supplied by Aladdin (China). The deionized water (DI water) with a resistivity of 18.2 MΩ cm was used in this study.

Preparation and characterization of reduced CuFe2O4

Reduced CuFe2O4 was prepared by thermal treatment of CuFe2O4 under a reducing gas atmosphere [29]. Exactly, 4.26 g CuCl2·2H2O and 13.52 g FeCl3·6H2O were added to 100 mL DI water. Then, a total of 75 mL NaOH solution (4 M) was added dropwise into the solution with continuous magnetic stirring. The solution was heated at 90 ◦C for 2 h. The precipitates were washed by DI water several times and dried at 70 °C overnight. Later, the precipitates were calcined at 400 °C for 4 h to obtain CuFe2O4. Finally, CuFe2O4 was treated in a H2 stream for 4 h at 400 °C.

The morphologies of CuFe2O4 and reduced CuFe2O4 were observed by transmission electron micrograph (TEM, H-8100, Hitachi). The crystallinity was characterized by X-ray powder diffraction (XRD, PW1710, Philips) using Cu Kα radiation. Nitrogen adsorption–desorption isotherms were measured by Micromeritics ASAP 2020 and the specific surface area (SSA) was calculated. The magnetic property (M–H curve) was measured by a vibrating sample magnetometer (VSM, Lakeshore 7407, USA). The structural information was measured by a Fourier transform spectrophotometer (FTIR, IR Affinity-1, Shimadzu) from 400 to 4000 cm−1 using the standard KBr disk method. The surface elemental compositions were analyzed by X-ray photoelectron spectroscopy (XPS, Perkin-Elmer PHI-5300/ESCA, USA) with an Al Kα X-ray source.

Catalytic degradation experiments

Batch experiments were carried out in 100 mL conical flasks in the dark to examine the catalytic degradation of catalysts. In a typical procedure, the required amount of catalyst was dispersed in 50 mg L−1 MO solutions with a final volume of 50 mL under vigorous magnetic stirring at 25 °C. The pH of the reaction solution was adjusted by NaOH or HCl in most of the reactions. Then, a known concentration of PS was added to the solution to initiate the reaction. Samples of 1 mL were taken out at set intervals, filtered immediately through a 0.22 µm membrane filter and quenched with excess methanol. For the investigation of reduced CuFe2O4 reusability, after each run the catalyst was filtrated, washed with DI water, dried under vacuum, and then used for the next reaction under identical experimental conditions.

Analytical methods

The concentration of MO was analyzed with a Persee T6-1610E automatic scanning UV–Vis spectrophotometer. The maximum absorbance–wavelength of MO was observed at 510 nm. The concentration of leached ions was determined by the inductively coupled plasma mass spectrometry (ICP-MS) method. Mineralization of MO was measured using a Shimadzu TOC-5000 total organic carbon (TOC) analyzer. Electron spin resonance (ESR) spectroscopy was performed by using 5,5-dimethyl-1-pyrroline-N-oxide (DMPO) as trapping agent to examine reactive oxygen species produced in the heterogeneous reaction. The intermediates of MO degradation were detected using high performance liquid chromatography (HPLC; Agilent Technologies, Waldbronn, Germany) coupled with a high-resolution hybrid quadrupole time-of-flight mass spectrometer (Triple TOF 5600, AB Sciex, Foster City, CA) with an electrospray ionization (ESI) source operating in positive and negative ion modes (LC-Q-TOF–MS). A BEH C18 column (2.1 mm × 50 mm, 2.5 μm, Waters, USA) was used to separate chemicals. The mobile phases used were 2 mM ammonium acetate in 5% methanol aqueous solution (A) and methanol (B).

Results and discussion

Characterization of reduced CuFe2O4

The TEM images (Fig. 1a) showed the surface morphologies of CuFe2O4 and reduced CuFe2O4. It was obvious that the surface of the CuFe2O4 was relatively smooth. Meanwhile, the surface of the reduced CuFe2O4 was relatively rough and composed of many nanoparticles, implying that Fe0/Cu0 bimetallic nanoparticles were well loaded onto the surface of CuFe2O4. XRD patterns of the synthesized samples are presented in Fig. 1b. The XRD patterns illustrated that the CuFe2O4 was highly crystallized, which was in agreement with PDF #77-0010. In the pattern of the reduced CuFe2O4, two characteristic peaks for Fe0 (PDF #99-0064) and two characteristic peaks for Cu0 (PDF #70-3039) were observed simultaneously, indicating the formation of Fe0 and Cu0 on the CuFe2O4 surface. The SSA of CuFe2O4 and reduced CuFe2O4 was obtained from the N2 physisorption isotherms (Fig. 1c). CuFe2O4 and reduced CuFe2O4 had the SSA of 15.6 and 51.8 m2 g−1, respectively. The relatively higher SSA of the reduced CuFe2O4 tended to provide abundant active sites for PS activation. The pore size distribution of 2–8 nm guaranteed efficient transportation of pollutants to the reduced CuFe2O4. The magnetization curve of reduced CuFe2O4 showed a typical superparamagnetic S-like curve with the saturated magnetization of 6.3 emu g−1, indicating the magnetic property of reduced CuFe2O4 (Fig. 1d). Meanwhile, the specific saturation magnetization value of reduced CuFe2O4 was higher than that of CuFe2O4. This is because the higher amount of iron in reduced CuFe2O4, which will give rise to a high magnetization value [31]. The FTIR spectra of CuFe2O4 and reduced CuFe2O4 are presented in Fig. 1e. For the CuFe2O4, the peak at 568 cm−1 was assigned to the symmetric stretching vibration of the Fe–O band in the tetrahedral FeO6 groups of spinel-type compounds [32]. After reduction, a remarkable shift to 602 cm−1 was observed, suggesting the change of CuFe2O4 surface structure.

Catalytic activity of reduced CuFe2O4

MO removal efficency in the presence of PS, reduced CuFe2O4, PS + CuFe2O4 and PS + reduced CuFe2O4 was examinated, respectively. As shown in Fig. 2a, greater than 72.5% of MO was removed in the reduced CuFe2O4/PS system after 30 min reaction, whereas only 28.4% of MO was removed in the CuFe2O4/PS system, which demonstrated a significant enhancement of catalytic activity of CuFe2O4 by use of H2 reduction. Moreover, no remarkable degradation of MO was observed in the presence of PS and the adsorption of MO by reduced CuFe2O4 was less than 16%. These findings clearly indicated that the removal of MO in the reduced CuFe2O4/PS system was most likely due to the activation of PS by reduced CuFe2O4. The remaining TOC in solution was also measured after 30 min of reaction in the reduced CuFe2O4/PS system. The TOC was removed less than 5% in 30 min. The relatively low TOC removal efficiency is probably due to the low PS dose and the short reaction time [14, 28].

It has been reported that the heterogeneous activation of PS is controlled by both the catalyst surface structure and composition [33]. The higher SSA will provide more active sites, which is expected to accelerate the reactions of PS decomposition. Therefore, to better evaluate the catalytic reactivity, the reaction rates were normalized by SSA. Here, the pseudo-first-order kinetic model (C = C0exp(− kt)) was used to describe the concentration profile of MO degradaion (Fig. 2b). The reaction rate k (min−1) of CuFe2O4 and reduced CuFe2O4 was calculated to be 0.011 (R2 = 0.999) and 0.062 (R2 = 0.989) min−1, respectively. After normalization, the constant for the reduced CuFe2O4 (1.20 × 10−3 g m−2 min−1) was more than 1.7 times higher than that for CuFe2O4 (0.71 × 10−3 g m−2 min−1), indicating the active sites on the reduced CuFe2O4 surface were more reactive. It also suggested that Fe0 and Cu0 bimetallic particles in the reduced CuFe2O4 surface played important roles for effective PS activation.

In general, the PS activation mechanism by Fe0 involves a slow-releasing of dissolved Fe2+ from Fe0 through corrosion (Eq. 1) [13]. Fe2+ then activates PS through electron transfer to produce SO ·−4 (Eq. 2) [13, 14]. Similarly, Cu0 corrodes to form dissolved Cu+ in the presence of PS (Eq. 3) [16]. Thereafter, Cu+ activates PS via one-electron transfer to generate SO ·−4 (Eq. 4).

Hence, the in situ generation of total dissolved metal ions in the reduced CuFe2O4/PS system was measured. As shown in Fig. 3, the amount of soluble iron and copper ions gradually increased as reaction time increased. The concentrations of iron and copper ions were 36.9 and 6.6 mg L−1 after 30 min reaction, respectively. In order to confirm the formation of metal ions associated with PS reaction, the leached metal ions were also measured without PS addition. The results showed that the leached iron and copper ions were 0.37 and 1.1 mg L−1 after 30 min reaction, respectively, which were much lower than addition of PS. This observation revealed that PS accelerated the corrosion of Fe0 and Cu0 to release metal ions during the reduced CuFe2O4/PS oxidation process (Eqs. 1–4).

Effects of parameters on MO degradation

Figure 4a illustrates the effect of PS concentration on the removal of MO using reduced CuFe2O4. It was clearly observed that the removal of MO increased while increasing the PS concentration. The higher the PS concentration, the faster the degradation rate that was obtained. The reaction rate increased from 0.041 to 0.112 min−1 when PS increased from 0.5 to 2.0 mM. This was likely that the generation of highly reactive oxygen species (SO ·−4 and/or ·OH) would increase along with the increase in PS initial concentration, leading to a high MO degradation rate.

Figure 4b shows the effect of reduced CuFe2O4 dose on MO degradation. It can be seen that the removal of MO increased with the increase in reduced CuFe2O4 dose due to the availability of more active sites. However, when its dose increased from 0.1 to 0.2 g L−1, a slight decline in the final degradation after 30 min reaction was noticed. This decline was probably due to the scavenging effect of Fe(II) [6]. At a high catalyst dose, a large amount of Fe(II) will form, which will scavenge SO ·−4 through undesirable reactions (Eq. 5). In addition, excessive amounts of SO ·−4 will be generated at an excess addition of catalyst. Then, SO ·−4 will disappear by the combination between SO ·−4 themselves (Eq. 6). Similar phenomena were also found in other studies with a high catalyst dose [26, 34, 35].

Figure 5 shows the effect of initial pH on the removal of MO by reduced CuFe2O4/PS oxidation. It can be seen that the degradation of MO was significantly influenced by solution pH. The degradation of MO decreased with the increased pH of the solution. The degradation of MO was 72.5%, 56.0%, 41.0% and 22.5% at pH 3.2, 5.6, 7.1 and 9.2 after 30 min, indicating it more favorable for the degradation of MO at acidic pH. The relatively slow degradation of MO at higher pH values may be attributed to a repulsive force prevailing between the S2O82− and the negatively charged surface of reduced CuFe2O4. The pH of the point of zero charge (pHPZC) of reduced CuFe2O4 was assumed to be less than 8.0 since the pHPZC of Fe0, Cu0 and CuFe2O4 was 7.8 [36], 5.17 [16] and 7.9 [30], respectively. Thus, the reduced CuFe2O4 surface has a negative charge at pH higher than its pHPZC. The repulsive force between the reduced CuFe2O4 surface and S2O82− would inhibit S2O82− to reach the catalyst surface and accelerate the electron transfer [37]. Moreover, metal ions will form precipitates at higher pH, and the precipitates can not provide new active sites [38]. On the other hand, as Fe0 and Cu0 were loaded onto the surface of reduced CuFe2O4, the lower pH will favor the generation of Fe2+ and Cu+ (Eqs. 7, 8), which could promote the decomposition of PS into SO ·−4 [16, 39]. Similar degradation profiles were also observed by other researchers using Fe0 or Cu0 as PS activator to degrade organic compounds [15, 16, 38, 39].

Reusability of reduced CuFe2O4

For stability evaluation of the catalyst, the reduced CuFe2O4 was collected after the degradation reaction, washed with DI water and dried under vacuum. Figure 6 shows the degradation of MO for three consecutive runs. As observed, the removal of MO gradually decreased during three runs. The overall removals of MO after 30 min at each run were 72.5%, 68.9% and 58.1%, respectively. The main reason for this decrease can be attributed to the active constituent leaching from catalyst and/or catalyst poisoning caused by intermediates. The total concentration of metal ions remained in the solution was detected to be greater than 30 mg L−1 at each 30 min reaction, which suggested the loss of catalyst activity was mainly caused by metal leaching. Further studies are still required to diminish the leaching of active components from the catalyst. The XRD patterns of the reduced CuFe2O4 before and after reaction are presented in Fig. 7. The crystal phase of the used catalyst was almost the same as that of the fresh catalyst, indicating that no new product was generated. Ji et al. [27] also have found the similar result that no new peak was observed in XRD spectrum of the Fe0/Cu0-PS system. Overall, reduced CuFe2O4 exhibited a fairly good PS activation efficiency for reuse in several runs without any significant drop in catalytic activity.

The reaction mechanism

In order to investigate the major reactive species responsible for MO degradation, classical quenching tests using ethanol and tert-butyl alcohol (TBA) as quenching agents were carried out [40]. Ethanol and TBA are usually used to differentiate SO ·−4 from ·OH as the reaction rates of TBA with SO ·−4 and ·OH are distinguishable. The effects of ethanol and TBA on reduced CuFe2O4/PS oxidation are shown in Fig. 8. It can be seen that ethanol had a much higher inhibition effect on the degradation of MO compared with TBA. When TBA was added, no significant decrease in MO degradation was observed, suggesting that ·OH was subsequently ruled out in this system. However, when 50 mM ethanol was added in the original reaction solution, the removal of MO was significantly inhibited. Therefore, the dominant reactive species for MO degradation were suggested to be SO ·−4 based on the quenching experiments.

To further confirm the major reactive species, ESR experiments were conducted to monitor the types of radicals generated during the degradation of MO. As shown in Fig. 9, the signals of DMPO radical adducts in the reduced CuFe2O4 catalyzed PS system were much stronger than the pure PS system, indicating that the generation of radicals was significantly facilitated by the addition of reduced CuFe2O4 into the PS system. Furthermore, signals of both ·OH and SO ·−4 radicals were observed in the reduced CuFe2O4 catalyzed PS system. It has been well reported in many studies that Fe0 and Cu0 mainly activated PS to generate SO ·−4 [8, 13, 16, 26]. In addition, the dominant reactive species for MO degradation were SO ·−4 based on quenching experiments in this study. Therefore, the observed strong signals of DMPO-OH adducts were possibly attributed to the fast transformation from DMPO-SO4 to DMPO-OH via nucleophilic substitution [41]. These phenomena were also observed in Fe0/PS and Co3O4/PS systems [11, 42].

Previous studies suggested that PS can be activated by Fe0 and Cu0 to produce SO ·−4 via Eqs. (1)–(4) [13, 14, 16]. The leached metal ions result in this study revealed that PS could accelerate the corrosion of Fe0 and Cu0 to release metal ions. Therefore, the surface characteristics of reduced CuFe2O4 may be changed during reaction. Then, XPS technique was used to characterize the chemical compositions of reduced CuFe2O4 after reaction. As shown in Fig. 10a, the binding energy at 710.2 and 712.3 eV can be assigned to Fe(II) and Fe(III), respectively. After reaction, the peak at 706.1 eV assigned to Fe0 disappeared, and the percentage of Fe(III) increased from 18.0 to 52.3%, suggesting the oxidation of Fe(II) to Fe(III) via reacting with PS. Wu et al. [26] proposed that Fe0 could react with S2O82− to generate Fe(II), which activated PS to yield SO ·−4 and conduced to the oxidation of atrazine. As shown in Fig. 10b, the atomic ratio of Cu0 decreased from 10.6 to 6.8% after reaction, suggesting the reaction of Cu0 in aqueous solution. Zhou et al. [16] concluded that Cu0 could react with H+ in acidic conditions to produce Cu+, and the presence of PS also could strongly enhance the corrosion and Cu+ release. Then, the generated Cu+ further decomposed PS to produce SO ·−4 . Accordingly, a possible mechanism of MO degradation by reduced CuFe2O4 was proposed as illustrated in Fig. 11.

Degradation pathways

Usually, SO ·−4 oxidation of aromatic compounds in the first step includes: (1) single electron transfer; (2) hydrogen atom abstraction; and (3) radical adduct formation [43]. To investigate the degradation pathway of MO, LC-Q-TOF–MS was used to identify the intermediates including protonated ion ([M + H]+). As shown in Fig. 12, five products were tentatively identified. The intermediate products included 4-[(4-methyl amino) phenyl diazenyl] benzene sulphonate (m/z 290), 4-hydroxybenzenesulfonic acid (m/z 173), benzenesulfonic acid (m/z 157), 2-N,N-dimethyl aniline diazine (m/z 150) and N-methyl aniline diazine (m/z 136). According to the chemical structures of the identified oxidation intermediates, pathways for the degradation of MO were postulated (Fig. 13). The degradation was primarily achieved by attack of SO ·−4 on MO. The compound with m/z 290 was formed by demethylation of MO, which further underwent breaking of the –C–N– bond. Demethylation of MO by attack of SO ·−4 was also observed in the copper nanoparticles/PMS system [44]. Compounds with m/z 157 and 150 were formed by cleavage of the –C–N– bond near the azo bond in MO. The compound with m/z 136 was derived from the compound with m/z 290 after azo bond cleavage. Moreover, the compound with m/z 173 was another transformation pathway of the MO transformation. First, SO ·−4 attacked the compounds (m/z 304 and m/z 290), producing a radical cation at the carbon center. Then, subsequent addition of H2O led to the production of 4-hydroxybenzenesulfonic acid. This intermediate has been also observed in oxidation of Acid Orange 7 by reaction with SO ·−4 [45]. Overall, these identified intermediates clearly indicated that MO degradation mainly underwent SO ·−4 oxidation.

Conclusions

Reduced CuFe2O4 showed a superior activity in PS activation for degradation of MO in water compared with raw CuFe2O4. The presence of Fe0 and Cu0 nanoparticles on the surface of reduced CuFe2O4 was proved to play an important role in the high catalytic activity. The catalyst stability tests revealed that reduced CuFe2O4 possessed a relatively good PS activation efficiency for reuse in several runs. The quenching experiments and ESR measurements verified that SO ·−4 was the major radical species to degrade MO in reduced CuFe2O4/PS oxidation. On the basis of XPS and LC-Q-TOF–MS results, the mechanisms and pathways were proposed for MO degradation. Although the catalytic and magnetic properties of reduced CuFe2O4 show a potential availability in wastewater treatment, further work is needed to diminish the leaching of active components from the catalyst.

References

P. Verma, S.K. Samanta, Environ. Chem. Lett. 16, 969 (2018)

J.L. Wang, L.J. Xu, Crit. Rev. Environ. Sci. Technol. 42, 251 (2012)

O. Acisli, A. Khataee, R.D.C. Soltani, S. Karaca, Ultrason. Sonochem. 35, 210 (2017)

P.D. Hu, M.C. Long, Appl. Catal. B Environ. 181, 103 (2016)

F. Ghanbari, M. Moradi, Chem. Eng. J. 310, 41 (2017)

I.A. Ike, K.G. Linden, J.D. Orbell, M. Duke, Chem. Eng. J. 338, 651 (2018)

J.L. Wang, S.Z. Wang, Chem. Eng. J. 334, 1502 (2018)

W.D. Oh, T.T. Lim, Chem. Eng. J. 358, 110 (2019)

T. Zhang, Y. Chen, Y.R. Wang, J. Le Roux, Y. Yang, J.P. Croue, Environ. Sci. Technol. 48, 5868 (2014)

Y.L. Wu, Y.H. Shi, H.C. Chen, J.F. Zhao, W.B. Dong, Process Saf. Environ. Protect. 116, 468 (2018)

J. Zhang, M.Y. Chen, L. Zhu, RSC Adv. 6, 758 (2016)

X.L. Zhang, M.B. Feng, R.J. Qu, H. Liu, L.S. Wang, Z.Y. Wang, Chem. Eng. J. 301, 1 (2016)

C. Kim, J.Y. Ahn, T.Y. Kim, W.S. Shin, I. Hwang, Environ. Sci. Technol. 52, 3625 (2018)

S.Y. Oh, S.G. Kang, P.C. Chiu, Sci. Total Environ. 408, 3464 (2010)

C.A.L. Graca, L.T.N. Fugita, A.C. de Velosa, A. Teixeira, Environ. Sci. Pollut. Res. 25, 5474 (2018)

P. Zhou, J. Zhang, Y.L. Zhang, G.C. Zhang, W.S. Li, C.M. Wei, J. Liang, Y. Liu, S.H. Shu, J. Hazard. Mater. 344, 1209 (2018)

C. Chen, Y.J. Han, J. Guo, L.X. Zhou, Y.Q. Lan, J. Taiwan Inst. Chem. Eng. 88, 169 (2018)

T.F. Ren, S.Y. Yang, Y.T. Jiang, X.R. Sun, Y.X. Zhang, Chem. Eng. J. 348, 350 (2018)

N.S. Shah, J.A. Khan, M. Sayed, Z.U. Khan, H.S. Ali, B. Murtaza, H.M. Khan, M. Imran, N. Muhammad, Chem. Eng. J. 356, 199 (2019)

H.X. Li, J.Q. Wan, Y.W. Ma, Y. Wang, M.Z. Huang, Chem. Eng. J. 237, 487 (2014)

R. Sharma, S. Bansal, S. Singhal, RSC Adv. 5, 6006 (2015)

T. Zhou, X.L. Zou, J. Mao, X.H. Wu, Appl. Catal. B Environ. 185, 31 (2016)

Y.W. Pan, Y. Zhang, M.H. Zhou, J.J. Cai, Y.S. Tian, Chem. Eng. J. 361, 908 (2019)

M.P. Rayaroth, C.S. Lee, U.K. Aravind, C.T. Aravindakumar, Y.S. Chang, Chem. Eng. J. 315, 426 (2017)

M.B. Gu, U. Farooq, S.G. Lu, X. Zhang, Z.F. Qiu, Q. Sui, J. Hazard. Mater. 349, 35 (2018)

S.H. Wu, H.J. He, X. Li, C.P. Yang, G.M. Zeng, B. Wu, S.Y. He, L. Lu, Chem. Eng. J. 341, 126 (2018)

Q.Q. Ji, J. Li, Z.K. Xiong, B. Lai, Chemosphere 172, 10 (2017)

C.X. Wang, J.Q. Wan, Y.W. Ma, Y. Wang, Res. Chem. Intermed. 42, 481 (2016)

Q.D. Qin, Y.H. Liu, X.C. Li, T. Sun, Y. Xu, RSC Adv. 8, 1071 (2018)

T. Zhang, H.B. Zhu, J.P. Croue, Environ. Sci. Technol. 47, 2784 (2013)

M.T. Qiao, X.F. Lei, Y. Ma, L.D. Tian, K.H. Su, Q.Y. Zhang, Chem. Eng. J. 304, 552 (2016)

Y.B. Ding, L.H. Zhu, N. Wang, H.Q. Tang, Appl. Catal. B Environ. 129, 153 (2013)

Y. Feng, D.L. Wu, Y. Deng, T. Zhang, K.M. Shih, Environ. Sci. Technol. 50, 3119 (2016)

J.C. Yan, M. Lei, L.H. Zhu, M.N. Anjum, J. Zou, H.Q. Tang, J. Hazard. Mater. 186, 1398 (2011)

D.H. Ding, C. Liu, Y.F. Ji, Q. Yang, L.L. Chen, C.L. Jiang, T.M. Cai, Chem. Eng. J. 308, 330 (2017)

S.R. Kanel, B. Manning, L. Charlet, H. Choi, Environ. Sci. Technol. 39, 1291 (2005)

Y. Lei, C.S. Chen, Y.J. Tu, Y.H. Huang, H. Zhang, Environ. Sci. Technol. 49, 6838 (2015)

I. Hussain, Y.Q. Zhang, S.B. Huang, X.Z. Du, Chem. Eng. J. 203, 269 (2012)

M.H. Nie, C.X. Yan, M. Li, X.N. Wang, W.L. Bi, W.B. Dong, Chem. Eng. J. 279, 507 (2015)

G.P. Anipsitakis, D.D. Dionysiou, Environ. Sci. Technol. 38, 3705 (2004)

G.S. Timmins, K.J. Liu, E.J.H. Bechara, Y. Kotake, H.M. Swartz, Free Radic. Biol. Med. 27, 329 (1999)

X.G. Duan, H.Q. Sun, J. Kang, Y.X. Wang, S. Indrawirawan, S.B. Wang, ACS Catal. 5, 4629 (2015)

S. Luo, Z.S. Wei, D.D. Dionysiou, R. Spinney, W.P. Hu, L.Y. Chai, Z.H. Yang, T.T. Ye, R.Y. Xiao, Chem. Eng. J. 327, 1056 (2017)

N. Nagar, V. Devra, J. Environ. Chem. Eng. 5, 5793 (2017)

X.Y. Chen, J.W. Chen, X.L. Qiao, D.G. Wang, X.Y. Cai, Appl. Catal. B Environ. 80, 116 (2008)

Acknowledgements

This work was supported by the National Natural Science Foundation of China [41671468 and 51408119], Fundamental Research Funds for the Central Universities and State Key Laboratory of Pollution Control and Resource Reuse (PCRRF16020). The authors would like to thank the Analytical Center of NIGLAS for making this study possible by making laboratory facilities available. The authors are grateful to Dr. Nanyang Yu and Dr. Si Wei at Nanjing University for providing the LC-Q-TOF–MS method.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Qin, Q., Xu, J., Sun, T. et al. Reduced CuFe2O4 for catalytic oxidation of methyl orange by activation of persulfate: performances and mechanisms. Res Chem Intermed 45, 3541–3556 (2019). https://doi.org/10.1007/s11164-019-03807-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-019-03807-2