Abstract

A novel and green approach was adopted for the synthesis of 3,4-dihydropyrimidin-2(1H)-one/thiones derivatives using Punica granatum peel as an inexpensive, efficient and mild catalyst under solvent-free condition. The methodology is characterized by high efficiency, short reaction time, high yields, simple experimental procedure, availability of catalyst and environmentally friendly reaction conditions. Further, the catalyst can be reused and recovered seven times without significant decrease in its activity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

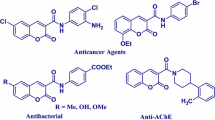

Dihydropyrimidinones and dihydropyrimidine thiones derivatives as Biginelli adducts have received great attention from synthetic and medicinal chemists due to their various promising activities such as antihypertensive, potassium channel antagonist, anti-epileptic, antimalarial, antimicrobial, antitumor, antibacterial, anticancer, and anti-inflammatory properties [1, 2]. The first synthesis of dihydropyrimidinones, which was originally reported by P. Biginelli in 1893, involves heating a mixture of an aldehyde, ethyl acetoacetate and urea, though yields are somewhat low [3]. The Biginelli reaction is remarkable for its simplicity and also for the fact that it represents one of the early examples of a multicomponent reaction (MCR) [4–6]. Since the 1990s, several new methods have been developed to improve the reaction yield, lower the reaction time, and/or broaden the scope of the Biginelli reaction by using microwave irradiation, ultrasound irradiation, Lewis and protic acid promoters such as lanthanide triflate [3], H3BO3, VCl3, Sr(OTf)2, PPh3, indium(III) halides, Mn(OAc)3·2H2O, Y(NO3)3·6H2O, In(OTf)3, TaBr5, Ce(NO3)3·6H2O, BF3EtOH/CuCl, LaCl3·7H2O with a catalytic amount of concentrated HCl, CeCl3.7H2O, Cu(OTf)2, LiClO4, LiBr, ceric ammonium nitrate (CAN), FeCl3.6H2O/HCl, Fe(HSO4)3, TMSI, CdCl2, PPE, LaCl3, 1-n-butyl-3-methyl imidazolium tetrafluoroborate (BMImBF4), ZrCl4, H4PMo11VO40, MgBr2, ZrOCl2·8H2O, CaF2, CuCl2, 12H2O supported on silica, silica chloride, H3PW12O40/SiO2, covalently anchored sulfonic acid onto silica, silica triflate, KSF clay, Dowex-50 W, natural HEU type zeolite [3], ionic liquids [3, 7], Zn(BF4)2 [8], NiCl2 [9], Fe(OTs)3.6H2O [10], CAN/HCl [11], TCICA [12], [bmim]BF4-immobilized Cu(II) acetylacetonate [13], [bmim][FeCl4] [14], Zn(OTf)2 [15], p-TsOH [16], ZnO [17], KAl(SO4)2. silica sulfuric acid [3, 18], silica gel-supported L-pyrrolidine-2-carboxylic acid-4-hydrogen sulphate [19], SBA-15 sulfonic acid [20], NaHSO4/SiO2 [21], mercaptopropyl silica [22], PEG–SO3 [23], p-dodecylbenzenesulfonic acid (DBSA) [24], Fe3O4@mesoporous SBA-15 [25], HCOOH [26], H2SO4 [27], l-proline [28], carbon-based solid acid [29], and so on.

Although a handful of the catalytic methodologies (by using metal Lewis acids, Brønsted acids or bases, heterogeneous catalysts, and nonconventional techniques, such as microwave, ultrasound, high pressure, and grindstone chemistry) have been promoted by environmentally friendly catalysts, many others at a practical level require relatively harsh reaction conditions such as high reaction temperatures, expensive, toxic or highly corrosive acidic catalysts, and prolonged reaction times. In most of the cases, stoichiometric amounts of catalyst are required in order to achieve good yields. Moreover, most of the reactions suffer from narrow substrate scope, tedious work-up procedures, metal leaching, solubility of the catalyst in the reaction medium, and column chromatography purification, which ultimately results in diminished yields [3, 30–35].

Catalysis lies at the heart of countless chemical protocols, from academic research laboratories to the chemical industry. In recent years, in the field of chemical and materials research, there has been increasing awareness of the right approach for the maintenance of “greenness” in the catalyst design and catalytic processes, which have encouraged chemists to design greener reaction pathways and methodologies that reduce and prohibit the pollution of nature and ensure perpetual life on the earth [36–40]. In the field of synthetic organic chemistry, metal-free organocatalysis is one of the green catalytic methodological approaches. As separation of homogeneous organocatalysts from the reaction mixture is very difficult, the use of a heterogeneous organocatalyst is a smart choice which brought the reusability of the catalyst and improved efficiency. Also, heterogeneous catalysis, in particular, addresses the goals of green chemistry by providing the ease of separation of the product and catalyst, thereby eliminating the need for separation through distillation or extraction.

Punica granatum as an ancient fruit cultivated in Iran, Spain, Egypt, Russia, France, Argentina, China, Japan, USA and India [41]. Modern science shows that Punica granatum contains anticarcinogenic [42], antimicrobial [43], antiviral [44], anticancer, potent anti-oxidant and antimutagenic compounds [45, 46]. Punica granatum peel (pericarp) is well known for its astringent properties and is rich in ellagitannins (ETs) (such as punicalagin (A) and its isomers), as well as lesser amounts of punicalin (B), gallagic acid, ellagic acid (EA) and EA-glycosides [47] (Scheme 1). Ellagitannins (ETs) are esters of hexahydroxydiphenic acid and a polyol, usually glucose or quinic acid [48]. Punicalagin (A) as a part of ellagitannins family is derived biosynthetically from gallic acid and glucose. Also, punicalagin (A) is unique to Punica granatum peel and includes the minor tannins called punicalin (B) and gallic acid, which are characterized by good water solubility. Another important class of phenolic natural products in Punica granatum peel is anthocyanins. These are water-soluble polyphenolic compounds that are derivatives of anthocyanidins. Punica granatum peel has been used for the direct removal of blue dye [49], 2,4-dichlorophenol from aqueous solutions [50] and also the removal of metals from wastewater such as lead, copper [51], chromium [52, 53], iron [54] and nickel [55].

In continuation of our green chemistry program [56–71], we present a simple and economic method to synthesize a library of 3,4-dihydropyrimidin-2(1H)ones/thiones derivatives performing the Biginelli reaction under solvent-free conditions in the presence of Punica granatum peel (an organocatalyst) as an efficient and low cost environmentally benign catalyst.

Experimental

General

All chemical reagents and solvents were purchased from Merck and Sigma-Aldrich and were used as received without further purification. The purity determinations of the products were accomplished by TLC on silica gel polygram STL G/UV 254 plates. The melting points of products were determined with an Electrothermal Type 9100 melting point apparatus. The FT-IR spectra were provided on pressed KBr pellets using an AVATAR 370 FT-IR spectrometer (Therma Nicolet, USA) at room temperature in the range between 4000 and 400 cm−1 with a resolution of 4 cm−1. TGA analysis was carried out on a Shimadzu Thermogravimetric Analyzer (TG-50) in the temperature range of 50–592 °C at a heating rate of 10 °C min−1 under air atmosphere. Elemental compositions were determined with a Leo 1450 VP scanning electron microscope equipped with an SC7620 energy dispersive spectrometer (SEM–EDS) presenting a 133-eV resolution at 20 kV. The NMR spectra were obtained in Brucker Avance 300 MHz instruments in CDCl3 and DMSO-d 6. Mass spectra were recorded with a CH7A Varianmat Bremem instrument at 70-eV electron impact ionization, in m/z (rel%). All the products were known compounds and they were characterized by FT-IR, 1H NMR, 13C NMR, and mass spectrometry, and comparison of their melting points with known compounds. All yields refer to isolated products after purification by recrystallization.

Pre-preparation of Punica granatum peel

In order to remove pollution on the surface of the catalyst, the Punica granatum peel was washed with distilled water, dried in an oven for 2 h at 90 °C, ground in a ball mill and sieved to particle size range 0.3–0.6 mm.

Typical procedure for preparation of ethyl 6-methyl-2-oxo-4-phenyl-1,2,3,4-tetrahydropyrimidine-5-carboxylate in the presence of Punica granatum peel

To a mixture of benzaldehyde (1 mmol, 0.106 g), ethyl acetoacetate (1 mmol, 0.130 g) and Punica granatum peel (0.03 g) at 100 °C, urea (1 mmol, 0.060 g) was added with stirring. The progress of the reaction was monitored by thin layer chromatography (TLC). After completion of the reaction, the reaction mixture was cooled to room temperature. Then, cold distilled water (5 mL) was poured into the reaction flask, and the resultant mixture was decanted. The brown precipitate was dissolved in hot EtOH (3 mL) and the catalyst was separated by filtration. Then, the filtrate was distilled under reduced pressure and finally the crude product was recrystallized by EtOH to give the pure product (0.247 g, 95%).

Spectral data

Ethyl 6-methyl-2-oxo-4-phenyl-1,2,3,4-tetrahydropyrimidine-5-carboxylate [72] (Table 2, 4a)

White solid; yield 95%; mp 202–204 °C (Lit. 203–205 °C); FT-IR (KBr): νmax/cm−1 3243.96 (NH str.), 3116.42 (aromatic CH str.), 2979.04 (aliphatic CH str.), 1725.42 (C=O str.), 1648.50 and 1464.45 (aromatic C=C str.); 1H NMR (300 MHz, CDCl3, ppm) δ: 8.49 (s, 1H, NH), 7.34–7.27 (m, 5H, ArH), 5.99 (s, 1H, NH), 5.42 (d, J = 2.7 Hz, 1H, CH), 4.10 (q, J = 8.0 Hz, 2H, OCH2CH3), 2.36 (s, 3H, CH3), 1.18 (t, J = 7.2 Hz, 3H, OCH2CH3); 13C NMR (75 MHz, CDCl3, ppm) δ: 165.68, 153.62, 146.45, 143.75, 128.71, 127.94, 126.61, 101.30, 60.01, 55.68, 18.61, 14.15; MS (EI): m/z (%) 260 (5) [M+], 258 (70) [M+–2H], 182 (100) [M+–C6H6], 171 (60) [M+–C7H5], 110 (60) [M+–C5H6N2O], 77 (65) [M+–C8H11N2O3], 28 (65) [M+–C12H12N2O3].

Ethyl 6-methyl-2-oxo-4-(p-tolyl)-1,2,3,4-tetrahydropyrimidine-5-carboxylate [72] (Table 2, 4b)

White solid; yield 95%; mp 214–216 °C (Lit. 215–216 °C); 1H NMR (300 MHz, DMSO-d 6 , ppm) δ: 9.19 (s, 1H, NH), 7.72 (s, 1H, NH), 7.13 (s, 4H, ArH), 5.12 (d, J = 2.7 Hz, 1H, CH), 3.99 (q, J = 7.1 Hz, 2H, OCH2CH3), 2.52 (s, 3H, CH3), 1.11 (t, J = 7.1 Hz, 3H, OCH2CH3); MS (EI): m/z (%) 274 (5) [M+], 271 (85) [M+–3H], 182 (100) [M+–C7H8], 154 (80) [M+–C9H12], 110 (95) [M+–C10H12O2], 91 (80) [M+–C8H11N2O3], 28 (85) [M+–C12H12N2O3].

Ethyl 4-(4-methoxyphenyl)-6-methyl-2-oxo-1,2,3,4-tetrahydropyrimidine-5-carboxylate [73] (Table 2, 4c)

White solid; yield 97%; mp 201–202 °C (Lit. 200–202 °C); FT-IR (KBr): νmax/cm−1 3240.68 (NH str.), 3112.59 (aromatic CH str.), 2956.35 (aliphatic CH str.), 1727.34 (C=O str.), 1651.51 and 1461.28 (aromatic C=C str.); 1H NMR (300 MHz, DMSO-d 6 , ppm) δ: 9.17 (s, 1H, NH), 7.68 (s, 1H, NH), 7.15 (d, J = 8.4 Hz, 2H, ArH), 6.88 (d, J = 8.7 Hz, 2H, ArH), 5.10 (d, J = 3.0 Hz, 1H, CH), 3.99 (q, J = 7.1 Hz, 2H, OCH2CH3), 3.73 (s, 3H, OCH3), 2.25 (s, 3H, CH3), 1.11 (t, J = 7.2 Hz, 3H, OCH2CH3); 13C NMR (75 MHz, DMSO-d 6 , ppm) δ: 165.84, 158.90, 152.61, 148.49, 137.52, 127.86, 114.17, 100.02, 59.62, 55.53, 53.78, 18.22, 14.58; MS (EI): m/z (%) 290 (5) [M+], 287 (85) [M+–3H], 258 (100) [M+–CH4O], 182 (90) [M+–C7H8O], 154 (85) [M+–C9H12O], 136 (85) [M+–C8H10NO], 110 (82) [M+–C10H12O3], 28 (85) [M+–C13H14N2O4].

Ethyl 4-(4-hydroxyphenyl)-6-methyl-2-oxo-1,2,3,4-tetrahydropyrimidine-5-carboxylate [72] (Table 2, 4d)

White solid; yield 95%; mp 226–227 °C (Lit. 227–228 °C); 1H NMR (300 MHz, DMSO-d 6 , ppm) δ: 9.41 (br s, 1H, OH), 9.13 (s, 1H, NH), 7.64 (s, 1H, NH), 7.04 (d, J = 8.7 Hz, 2H, ArH), 6.71 (d, J = 8.4 Hz, 2H, ArH), 5.06 (d, J = 3.0 Hz, 1H, CH), 3.98 (q, J = 7.0 Hz, 2H, OCH2CH3), 3.39 (s, 3H, OCH3), 2.25 (s, 3H, CH3), 1.11 (t, J = 7.1 Hz, 3H, OCH2CH3); 13C NMR (75 MHz, DMSO-d 6 , ppm) δ: 165.89, 157.03, 152.66, 148.21, 135.88, 127.86, 115.45, 100.21, 59.57, 53.90, 18.21, 14.57; MS (EI): m/z (%) 276 (5) [M+], 273 (85) [M+–3H], 258 (45) [M+–H2O], 201 (100) [M+–C3H7O2], 182 (100) [M+–C6H6O], 110 (80) [M+–C9H10O3], 30 (80) [M+–C12H10N2O4].

Ethyl 4-(2-hydroxyphenyl)-6-methyl-2-oxo-1,2,3,4-tetrahydropyrimidine-5-carboxylate [74] (Table 2, 4e)

White solid; yield 96%; mp 202–203 °C (Lit. 201–203 °C); MS (EI): m/z (%) 276 (0) [M+], 273 (100) [M+–3H], 201 (100) [M+–C3H7O2], 182 (100) [M+–C6H6O], 159 (55) [M+–C4H9N2O2], 111 (100) [M+–C9H9O3], 28 (100) [M+–C12H12N2O4].

Ethyl 4-(4-(dimethylamino)phenyl)-6-methyl-2-oxo-1,2,3,4-tetrahydropyrimidine-5 carboxylate [75] (Table 2, 4f)

White solid; yield 80%; mp 231–232 °C (Lit. 230–232 °C); MS (EI): m/z (%) 303 (5) [M+], 300 (100) [M+–3H], 257 (25) [M+–C2H6O], 228 (100) [M+–C3H7O2], 174 (45) [M+–C4H5N2O3], 154 (40) [M+–C10H15N], 120 (90) [M+–C8H11N2O3], 29 (85) [M+–C14H16N3O3].

Ethyl 4-(4-chlorophenyl)-6-methyl-2-oxo-1,2,3,4-tetrahydropyrimidine-5-carboxylate [72] (Table 2, 4g)

White solid; yield 95%; mp 207–209 °C (Lit. 208–210 °C); MS (EI): m/z (%) 294 (50) [M+], 291 (75) [M+–3H], 182 (100) [M+–C6H5Cl], 154 (75) [M+–C8H9Cl], 136 (70) [M+–C6H11N2O3], 110 (68) [M+–C9H9ClO2], 28 (70) [M+–C12H11ClN2O3].

Ethyl 4-(2-chlorophenyl)-6-methyl-2-oxo-1,2,3,4-tetrahydropyrimidine-5-carboxylate [72] (Table 2, 4h)

White solid; yield 90%; mp 214–215 °C (Lit. 214–216 °C); FT-IR (KBr): νmax/cm−1 3353.04 and 3228.55 (NH str.), 3113.46 (aromatic CH str.), 2977.10 (aliphatic CH str.), 1702.46 (C=O str.), 1642.23 and 1454.87 (aromatic C=C str.); 1H NMR (300 MHz, CDCl3, ppm) δ: 8.89 (s, 1H, NH), 7.40–7.22 (m, 4H, ArH), 5.90 (s, 2H, NH and CH), 4.03 (q, J = 7.1 Hz, 2H, OCH2CH3), 2.44 (s, 3H, CH3), 1.08 (t, J = 7.1 Hz, 3H, OCH2CH3); 13C NMR (75 MHz, CDCl3, ppm) δ: 165.35, 153.28, 148.51, 139.57, 132.59, 129.80, 129.29, 128.04, 127.56, 98.87, 59.99, 52.13, 18.31, 14.00; MS (EI): m/z (%) 294 (25) [M+], 292 (78) [M+–2H], 220 (85) [M+–C3H6O2], 182 (100) [M+–C6H5Cl], 154 (85) [M+–C8H9Cl], 136 (82) [M+–C6H11N2O3], 110 (65) [M+–C9H9ClO2], 28 (85) [M+–C12H11ClN2O3].

Ethyl 4-(3-bromophenyl)-6-methyl-2-oxo-1,2,3,4-tetrahydropyrimidine-5-carboxylate [73] (Table 2, 4i)

White solid; yield 85%; mp 193–194 °C (Lit. 192–194 °C); MS (EI): m/z (%) 338 (65) [M+], 309 (70) [M+–C2H5], 263 (70) [M+–C3H7O2], 182 (100) [M+–C6H5Br], 136 (72) [M+–C8H11BrO], 110 (70) [M+–C9H9BrO2], 28 (70) [M+–C12H11BrN2O3].

Ethyl 4-(4-fluorophenyl)-6-methyl-2-oxo-1,2,3,4-tetrahydropyrimidine-5-carboxylate [75] (Table 2, 4j)

White solid; yield 85%; mp 183–185 °C (Lit. 182–186 °C); FT-IR (KBr): νmax/cm−1 3243.64 (NH str.), 3117.56 (aromatic CH str.), 2979.18 (aliphatic CH str.), 1729.31 (C=O str.), 1647.80 and 1468.83 (aromatic C=C str.); 1H NMR (300 MHz, DMSO-d 6 , ppm) δ: 9.23 (s, 1H, NH), 7.75 (s, 1H, NH), 7.28–7.11 (m, 4H, ArH), 5.15 (d, J = 2.7 Hz, 1H, CH), 3.97 (q, J = 7.0 Hz, 2H, OCH2CH3), 2.25 (s, 3H, CH3), 1.08 (t, J = 7.1 Hz, 3H, OCH2CH3); 13C NMR (75 MHz, DMSO-d 6 , ppm) δ: 170.47, 168.14, 164.93, 157.21, 153.74, 146.33, 133.52, 120.47, 120.19, 104.34, 64.43, 58.56, 23.00, 19.27; MS (EI): m/z (%) 278 (5) [M+], 275 (85) [M+–3H], 231 (70) [M+–C2H7O], 203 (90) [M+–C3H7O2], 182 (100) [M+–C6H5F], 154 (80) [M+–C8H9F], 121 (70) [M+–C6H10N2O3], 95 (70) [M+–C8H11N2O3], 29 (85) [M+–C12H10FN2O3].

Ethyl 6-methyl-4-(4-nitrophenyl)-2-oxo-1,2,3,4-tetrahydropyrimidine-5-carboxylate [72] (Table 2, 4k)

White solid; yield 98%; mp 210–211 °C (Lit. 210–211 °C); MS (EI): m/z (%) 305 (0) [M+], 303 (10) [M+–2H], 230 (10) [M+–C3H7O2], 182 (35) [M+–C6H5NO2], 149 (15) [M+–C7H10NO3], 77 (10) [M+–C8H10N3O5], 28 (100) [M+–C12H11N3O5].

Ethyl 6-methyl-2-oxo-4-(thiophen-2-yl)-1,2,3,4-tetrahydropyrimidine-5-carboxylate [74] (Table 2, 4m)

White solid; yield 70%; mp 215–216 °C (Lit. 215–217 °C); MS (EI): m/z (%) 266 (10) [M+], 263 (100) [M+–3H], 219 (80) [M+–C2H7O], 192 (100) [M+–C3H6O2], 182 (85) [M+–C4H4S], 154 (85) [M+–C6H8S], 136 (85) [M+–C6H10SO], 110 (90) [M+–C7H8SO2], 84 (75) [M+–C8H10N2O3], 28 (85) [M+–C10H10N2O3S].

Ethyl 6-methyl-4-phenyl-2-thioxo-1,2,3,4-tetrahydropyrimidine-5-carboxylate [72] (Table 2, 5a)

Yellow solid; yield 90%; mp 209–210 °C (Lit. 208–210 °C); 1H NMR (300 MHz, DMSO-d 6 , ppm) δ: 10.36 (s, 1H, NH), 9.68 (s, 1H, NH), 7.44–7.23 (m, 5H, ArH), 5.20 (d, J = 3.6 Hz, 1H, CH), 4.02 (q, J = 7.0 Hz, 2H, OCH2CH3), 2.31 (s, 3H, CH3), 1.11 (t, J = 3.4 Hz, 3H, OCH2CH3); 13C NMR (75 MHz, DMSO-d 6 , ppm) δ: 174.71, 165.60, 145.50, 143.97, 129.03, 128.15, 126.86, 101.19, 60.06, 54.52, 17.63, 14.47; MS (EI): m/z (%) 276 (5) [M+], 273 (95) [M+–3H], 202 (90) [M+–C3H6O2], 198 (100) [M+–C6H6], 170 (90) [M+–C8H10], 152 (60) [M+–C8H12O], 130 (60) [M+–C5H10N2OS], 77 (90) [M+–C8H11N2O2S], 29 (100) [M+–C12H11N2O2S].

Ethyl 6-methyl-2-thioxo-4-(p-tolyl)-1,2,3,4-tetrahydropyrimidine-5 -carboxylate [72] (Table 2, 5b)

Yellow solid; yield 90%; mp 191–192 °C (Lit. 190–192 °C); MS (EI): m/z (%) 290 (5) [M+], 287 (95) [M+–3H], 243 (20) [M+–C2H7O], 215 (100) [M+–C3H7O2], 198 (95) [M+–C7H8], 170 (35) [M+–C9H12], 91 (40) [M+–C8H11N2O2S], 76 (95) [M+–C9H14N2O2S], 29 (100) [M+–C13H13N2O2S].

Ethyl 4-(4-hydroxyphenyl)-6-methyl-2-thioxo-1,2,3,4-tetrahydropyrimidine-5-carboxylate [76] (Table 2, 5d)

White solid; yield 95%; mp 204–205 °C (Lit. 203–205 °C); 1H NMR (300 MHz, DMSO-d 6 , ppm) δ: 10.26 (s, 1H, NH), 9.57 (s, 1H, NH), 9.47 (br s, 1H, OH), 7.02 (d, J = 8.4 Hz, 2H, ArH), 6.73 (d, J = 8.4 Hz, 2H, ArH), 5.08 (d, J = 3.3 Hz, 1H, CH), 4.01 (q, J = 7.0 Hz, 2H, OCH2CH3), 2.29 (s, 3H, CH3), 1.11 (t, J = 7.1 Hz, 3H, OCH2CH3); 13C NMR (75 MHz, DMSO-d 6 , ppm) δ: 174.31, 165.69, 157.39, 144.97, 134.56, 128.11, 115.62, 101.60, 59.99, 54.03, 17.59, 14.49; MS (EI): m/z (%) 292 (10) [M+], 289 (85) [M+–3H], 245 (70) [M+–C2H7O], 217 (100) [M+–C3H7O2], 198 (75) [M+–C6H6O], 170 (55) [M+–C8H10O], 91 (35) [M+–C8H13N2O2S], 76 (70) [M+–C8H12N2O3S], 29 (75) [M+–C12H11N2O3S].

Ethyl 4-(2-hydroxyphenyl)-6-methyl-2-thioxo-1,2,3,4-tetrahydropyrimidine-5-carboxylate [77] (Table 2, 5e)

White solid; yield 90%; mp 207–208 °C (Lit. 206–209 °C); MS (EI): m/z (%) 292 (0) [M+], 276 (25) [M+–CH4], 245 (90) [M+–C2H7O], 229 (50) [M+–C2H7O2], 202 (90) [M+–C3H6O3], 198 (100) [M+–C6H6O], 170 (85) [M+–C8H10O], 152 (40) [M+–C8H12O2], 128 (65) [M+–C9H8O3], 77 (85) [M+–C8H11N2O3S], 29 (95) [M+–C12H11N2O3S].

Ethyl 4-(4-chlorophenyl)-6-methyl-2-thioxo-1,2,3,4-tetrahydropyrimidine-5-carboxylate [72] (Table 2, 5g)

White solid; yield 95%; mp 196–198 °C (Lit. 197–199 °C); MS (EI): m/z (%) 310 (30) [M+], 308 (75) [M+–2H], 251 (80) [M+–CHNS], 236 (80) [M+–C3H6O2], 199 (80) [M+–C6H4Cl], 112 (75) [M+–C8H10N2O2S], 77 (100) [M+–C8H10ClN2O2S], 29 (80) [M+–C12H10ClN2O2S].

Ethyl 4-(2-chlorophenyl)-6-methyl-2-thioxo-1,2,3,4-tetrahydropyrimidine-5-carboxylate [78] (Table 2, 5h)

Yellow solid; yield 85%; mp 218–219 °C (Lit. 218–220 °C); MS (EI): m/z (%) 310 (10) [M+], 308 (30) [M+–2H], 250 (25) [M+–CH2NS], 198 (50) [M+–C6H5Cl], 170 (15) [M+–C8H9Cl], 76 (100) [M+–C6H4], 29 (75) [M+–C12H10ClN2O2S].

Ethyl 4-(3-bromophenyl)-6-methyl-2-thioxo-1,2,3,4-tetrahydropyrimidine-5-carboxylate [79] (Table 2, 5i)

Yellow solid; yield 90%); mp 182–183 °C (Lit. 182–184 °C); MS (EI): m/z (%) 354 (90) [M+], 325 (90) [M+–C2H4], 307 (30) [M+–C2H6O], 281 (95) [M+–C3H4O2], 250 (100) [M+–C3H7N2S], 223 (75) [M+–C5H10N2S], 198 (95) [M+–C6H5Br], 170 (85) [M+–C8H9Br], 154 (55) [M+–C8H9BrO], 76 (90) [M+–C8H11BrN2O2S], 29 (90) [M+–C12H10BrN2O2S].

Ethyl 4-(4-fluorophenyl)-6-methyl-2-thioxo-1,2,3,4-tetrahydropyrimidine-5-carboxylate [80] (Table 2, 5j)

Yellow solid; yield 80%; mp 186–187 °C (Lit. 186–187 °C); 1H NMR (300 MHz, DMSO-d 6 , ppm) δ: 10.39 (s, 1H, NH), 9.69 (s, 1H, NH), 7.28–7.07 (m, 4H, ArH), 5.18 (d, J = 3.3 Hz, 1H, CH), 4.02 (q, J = 7.0 Hz, 2H, OCH2CH3), 2.31 (s, 3H, CH3), 1.09 (t, J = 7.1 Hz, 3H, OCH2CH3); MS (EI): m/z (%) 294 (5) [M+], 291 (65) [M+–3H], 247 (55) [M+–C2H7O], 219 (100) [M+–C3H7O2], 198 (65) [M+–C6H5F], 152 (55) [M+–C8H11FO], 95 (40) [M+–C6H4F], 28 (70) [M+–C12H11FN2O2S].

Ethyl 6-methyl-4-(4-nitrophenyl)-2-thioxo-1,2,3,4-tetrahydropyrimidine-5-carboxylate [76] (Table 2, 5k)

Yellow solid; yield 95%; mp 110–111 °C (Lit. 110–112 °C); MS (EI): m/z (%) 321 (5) [M+], 319 (15) [M+–2H], 248 (20) [M+–C3H5O2], 198 (25) [M+–C6H5NO2], 76 (100) [M+–C8H11N3O4S], 28 (95) [M+–C12H11N3O4S].

Ethyl 4-(4-cyanophenyl)-6-methyl-2-thioxo-1,2,3,4-tetrahydropyrimidine-5-carboxylate [81] (Table 2, 5l)

Yellow solid; yield 95%; mp 239–241 °C (Lit. 240–242 °C); FT-IR (KBr): νmax/cm−1 3374.80 and 3274.87 (NH str.), 3174.54 (aromatic CH str.), 2980.07 (aliphatic CH str.), 2229.04 (CN str.), 1688.69 (C=O str.), 1608.96 and 1462.86 (aromatic C=C str.), 1183.47 (C=S str.); 1H NMR (300 MHz, DMSO-d 6 , ppm) δ: 10.48 (s, 1H, NH), 9.75 (s, 1H, NH), 7.87–7.33 (m, 4H, ArH), 5.25 (d, J = 3.6 Hz, 1H, CH), 4.02 (q, J = 3.3 Hz, 2H, OCH2CH3), 2.52 (s, 3H, CH3), 1.13 (t, J = 7.5 Hz, 3H, OCH2CH3); 13C NMR (75 MHz, DMSO-d 6 , ppm) δ: 184.30, 174.90, 165.36, 148.95, 146.35, 133.21, 127.92, 119.12, 110.97, 100.22, 60.23, 17.70, 14.45; MS (EI): m/z (%) 301 (5) [M+], 299 (50) [M+–2H], 254 (25) [M+–C2H7O], 226 (90) [M+–C3H7O2], 198 (30) [M+–C7H5N], 127 (34) [M+–C10H9NO2], 76 (100) [M+–C9H11N3O2S], 28 (75) [M+–C13H11N3O2S].

Ethyl 6-methyl-4-(thiophen-2-yl)-2-thioxo-1,2,3,4-tetrahydropyrimidine-5-carboxylate [74] (Table 2, 5m)

Yellow solid; yield 75%; mp 216–217 °C (Lit. 218–217 °C); MS (EI): m/z (%) 282 (30) [M+], 279 (100) [M+–3H], 235 (55) [M+–C2H7O], 207 (100) [M+–C3H7O2], 170 (40) [M+–C6H8S], 136 (65) [M+–C5H10N2OS], 109 (65) [M+–C6H10N2O2S] 28 (80) [M+–C10H10N2O2S2].

5-Acetyl-6-methyl-4-phenyl-3,4-dihydropyrimidin-2(1H)-one [82] (Table 2, 6a)

Yellow solid; yield 95%; mp 264–265 °C (Lit. 264–265 °C); 1H NMR (300 MHz, DMSO-d 6 , ppm) δ: 9.22 (s, 1H, NH), 7.86 (s, 1H, NH), 7.36–7.23 (m, 5H, ArH), 5.28 (d, J = 3.3 Hz, 1H, CH), 2.31 (s, 3H, CH3), 2.12 (s, 3H, CH3); 13C NMR (75 MHz, DMSO-d 6 , ppm) δ: 194.74, 152.64, 148.60, 144.72, 128.99, 127.82, 126.91, 110.06, 54.30, 30.79, 19.39; MS (EI): m/z (%) 230 (70) [M+], 228 (90) [M+–2H], 186 (80) [M+–C2H4O], 152 (100) [M+–C6H6], 143 (70) [M+–C3H7N2O], 130 (50) [M+–C3H4N2O2], 110 (70) [M+–C8H8O], 29 (80) [M+–C11H9N2O2].

5-Acetyl-4-(4-methoxyphenyl)-6-methyl-3,4-dihydropyrimidin-2(1H)-one [82] (Table 2, 6b)

White solid; yield 90%; mp 200–202 °C (Lit. 201–202 °C); 1H NMR (300 MHz, DMSO-d 6 , ppm) δ: 9.20 (s, 1H, NH), 7.81 (s, 1H, NH), 7.20 (d, J = 8.4 Hz, 2H, ArH), 6.90 (d, J = 8.4 Hz, 2H, ArH), 5.24 (d, J = 2.7 Hz, 1H, CH), 3.73 (s, 3H, OCH3), 2.31 (s, 3H, CH3), 2.09 (s, 3H, CH3); 13C NMR (75 MHz, DMSO-d 6 , ppm) δ: 194.87, 159.00, 152.64, 148.26, 136.84, 128.13, 114.32, 110.10, 55.51, 53.84, 30.61, 19.31; MS (EI): m/z (%) 260 (5) [M+], 258 (100) [M+–2H], 215 (100) [M+–CH3NO], 152 (100) [M+–C7H8O], 109 (20) [M+–C8H9O], 29 (70) [M+–C12H11N2O3].

5-Acetyl-4-(4-chlorophenyl)-6-methyl-3,4-dihydropyrimidin-2(1H)-one [82] (Table 2, 6c)

White solid; yield 98%; mp 258–259 °C (Lit. 258–260 °C); 1H NMR (300 MHz, DMSO-d 6 , ppm) δ: 9.25 (s, 1H, NH), 7.88 (s, 1H, NH), 7.40 (d, J = 8.1 Hz, 2H, ArH), 7.27 (d, J = 8.4 Hz, 2H, ArH), 5.27 (d, J = 2.4 Hz, 1H, CH), 2.30 (s, 3H, CH3), 2.14 (s, 3H, CH3); 13C NMR (75 MHz, DMSO-d 6 , ppm) δ: 194.58, 152.53, 148.94, 143.68, 132.31, 128.94, 128.78, 109.98, 53.54, 30.90, 19.45; MS (EI): m/z (%) 264 (50) [M+], 262 (100) [M+–2H], 219 (95) [M+–C2H5O], 152 (100) [M+–C6H4Cl], 110 (40) [M+–C8H7ClO], 29 (100) [M+–C11H8ClN2O2].

1-(6-Methyl-4-phenyl-2-thioxo-1,2,3,4-tetrahydropyrimidin-5-yl)ethanone [83] (Table 2, 7a)

White solid; yield 90%; mp 230–231 °C (Lit. 230–231 °C; 1H NMR (300 MHz, DMSO-d 6 , ppm) δ: 10.29 (s, 1H, NH), 9.78 (s, 1H, NH), 7.39–7.23 (m, 5H, ArH), 5.31 (d, J = 3.9 Hz, 1H, CH), 2.35 (s, 3H, CH3), 2.17 (s, 3H, CH3); 13C NMR (75 MHz, DMSO-d 6 , ppm) δ: 195.26, 174.55, 145.05, 143.38, 129.11, 128.17, 127.03, 110.94, 54.23, 30.90, 18.73; MS (EI): m/z (%) 246 (60) [M+], 244 (100) [M+–2H], 201 (85) [M+–C2H5O], 185 (65) [M+–CH3NS], 168 (100) [M+–C6H6], 143 (70) [M+–C3H7N2S], 110 (70) [M+–C9H12O], 91 (60) [M+–C6H7N2OS2], 77 (70) [M+–C7H9N2OS], 29 (60) [M+–C11H9N2OS].

1-(4-(4-Methoxyphenyl)-6-methyl-2-thioxo-1,2,3,4-tetrahydropyri midin-5-yl)ethanone [84] (Table 2, 7b)

White solid; yield 90%; mp 168–170 °C (Lit. 169–170 °C); 1H NMR (300 MHz, DMSO-d 6 , ppm) δ: 10.25 (s, 1H, NH), 9.72 (s, 1H, NH), 7.18–6.89 (m, 4H, ArH), 5.25 (d, J = 3.6 Hz, 1H, CH), 3.73 (s, 3H, CH3), 2.34 (s, 3H, CH3), 2.13 (s, 3H, CH3); 13C NMR (75 MHz, DMSO-d 6 , ppm) δ: 195.36, 174.29, 159.25, 144.72, 135.54, 128.33, 114.45, 110.92, 55.57, 53.81, 30.73, 18.66; MS (EI): m/z (%) 276 (10) [M+], 273 (100) [M+–3H], 243 (80) [M+–CH5O], 231 (95) [M+–C2H5O], 168 (80) [M+–C7H8O], 110 (80) [M+–C10H14O2], 29 (80) [M+–C12H11N2O2S].

Spectral data of intermediates II and II′

Ethyl 2-(hydroxy(phenyl)methyl)-3-oxobutanoate (II) [85]

Yield 70%; Oil; FT-IR (KBr): νmax/cm−1 3440.18 (OH str.), 3063.60 (aromatic CH str.), 2926.21 (aliphatic CH str.), 1724.74 (C=O str.), 1642.22 and 1450.14 (aromatic C=C str.); MS (EI): m/z (%) 236 (2) [M+], 209 (22) [M+–C2H3], 166 (35) [M+–C4H6O], 142 (45) [M+–C6H6O], 130 (65) [M+–C8H10], 122 (70) [M+–C56H11O3], 105 (100) [M+–C6H11O3], 77 (70) [M+–C7H11O4], 28 (65) [M+–C11H12O4].

1-Benzylideneurea (II′) [86]

White solid; yield 80%; mp 224–226 °C (Lit. 225–226 °C); FT-IR (KBr): νmax/cm−1 3615.89 and 3314.90 (NH2 str.), 3064.25 (aromatic CH str.), 1647.31 (C=O str.), 1596.71 and 1448.99 (aromatic C=C str.); MS (EI): m/z (%) 148 (10) [M+], 147 (40) [M+–H], 131 (80) [M+–NH3], 104 (100) [M+–CH2NO], 77 (85) [M+–C2H3N2O], 60 (62) [M+–CH4N2O], 29 (65) [M+–C6H3N2O].

Results and discussion

Characterization of catalyst

FT-IR spectroscopy was carried out to identify the structure of Punica granatum peel. As shown in Fig. 1a, the broad stretching and bending vibrations of the OH groups in Punica granatum peel were detected around 3700–3000 and 1360 cm−1, respectively (polyphenolic, alcoholic and acidic groups). Also, the alkyl C–H groups of punicalagin (A) appeared at 2970–2800 cm−1. An absorption band at 1740 cm−1 is due to the C=O groups of ester and acid. Furthermore, the appearance of two absorption bands at 1620 and 1430 cm−1 is attributed to the stretching frequencies of the C=C aromatic rings and the strong absorption band at 1052 cm−1 is ascribed to the C–OH stretching vibration. The absorption bands at 1229 and 637 cm−1 are known to be associated to the C–O stretching bond of ester and aromatic C–H bending frequencies, respectively.

Thermogravimetric analysis (TGA) of the Punica granatum peel was also performed to investigate the thermal stability of the catalyst. As is obvious in Fig. 2, the TGA thermogram showed three major weight loss stages. The first stage of degradation represents the loss of water (weight loss 5.0%, from 50 to 200 °C). The major weight loss took place in the second step (weight loss 90.0%, from 200 to 445 °C) which was followed by a further weight loss in the third step (weight loss 98.0%, from 445–592 °C). The second stage represents some chain scission of Punica granatum peel. In the third stage, complete decomposition of the Punica granatum peel main chains occurred.

The energy-dispersive X-ray analysis (EDX) of catalyst indicates the presence of C, O, Fe, Na, K and Ca as the main components of the Punica granatum peel (Fig. 3).

The scanning electron microscopy (SEM) images were recorded to determine the exact size and shape of the Punica granatum peel (Fig. 4). The SEM analysis proved the porous surface of Punica granatum peel with particle size of around 10–20 μm.

Catalytic synthesis of 3,4-dihydropyrimidin-2(1H)ones/thiones derivatives

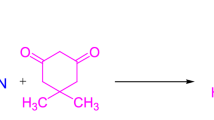

The present study as a part of our ongoing research program [56–71] on the exploration of green transformations and domino/sequential multicomponent reactions reports the synthesis of a library of 3,4-dihydropyrimidin-2(1H)ones/thiones derivatives by performing the Biginelli reaction under solvent-free conditions in the presence of an environmentally benign organocatalyst (Scheme 2). Organocatalysis offers many advantages for synthetic organic chemistry. In contrast to many transition metal catalysts, most organocatalysts are stable to air and water, easily handled, non-toxic and robust compounds and most of them are readily separated from the crude reaction mixture. In general, a large number of them are commercially available and/or easily synthesized.

The results of optimization experiments for the three-component Biginelli condensation reaction involving benzaldehyde, ethyl acetoacetate and urea in the presence of Punica granatum peel as catalyst are presented in Table 1. One important aspect of green chemistry is the elimination of solvents in the chemical processes or the replacement of hazardous solvents with relatively benign solvents [87]. Thus, our initial work started by performing the condensation reaction in solvent-free condition. It could be seen that, in the presence of 0.1 g of Punica granatum peel ethyl 6-methyl-2-oxo-4-phenyl-1,2,3,4-tetrahydropyrimidine-5-carboxylate was obtained rapidly in high isolated yield, whereas in the absence of Punica granatum peel and under the same reaction conditions, the condensation reaction does not proceed even after a long period of time (Table 1, compare entries 1 and 2). In order to improve the performance of the reaction, the influence of temperature on the yield and reaction time was investigated. It was found that at 100 °C a higher yield of desired product was rapidly obtained (Table 1, entries 3–6). In order to fine-tune the reaction conditions, we also examined the effect of molar ratio of reactants on the reaction rate. Interestingly, it was observed that, by applying a 1/1/1 molar ratio of aldedyde/ethylacetoactate/urea, the desired product was obtained in a short reaction time and in high yield (Table 1, entry 7). The catalytic activity of Punica granatum peel in condensation reaction was then studied in different solvents (Table 1, entries 8–14). The findings indicate that there is no crucial outcome in H2O, EtOH, PEG, DMSO, DMF, toluene and glycerol. Then, the condensation reaction occurs more efficiently in solvent-free conditions than it does in solution since the reactants and catalyst are arranged more tightly when a solvent is not used. Therefore, without a solvent, the reactions usually need shorter reaction times, simpler reactors, simple and efficient workup procedures, and are often more environmentally friendly. We further found that the yields are obviously affected by the amount of catalyst. Punica granatum peel (0.03 g) was found to be effective in stitching of all starting substrates to ethyl 6-methyl-2-oxo-4-phenyl-1,2,3,4-tetrahydropyrimidine-5-carboxylate with high yield (Table 1, entries 15–21). It is remarkable to note that higher amounts of catalyst did not boost the yields, while lower amounts were proved to be less effective.

Encouraged by these results, we studied the Biginelli condensation reaction of several aromatic aldehydes with 1,3-dicarbonyl compounds and urea/thiourea in the presence of Punica granatum peel (Table 2). In all cases, the three-component reaction proceeded smoothly to give the corresponding 3,4-dihydropyrimidin-2(1H)-ones/thiones in good to excellent yields. Various substituted aldehydes bearing electron-donating and electron-withdrawing groups at different positions of aromatic rings have been employed for the one-pot three-component condensation reactions under solvent-free conditions. According to the results of Table 2, the nature and position of substitution on the aromatic ring have little effect on the reaction rate or on the final yield of 3,4-dihydropyrimidin-2(1H)-ones/thiones. In comparison, the condensation reaction with thiourea required relatively more time for completion than did urea. This was probably due to the lower electronegativity of sulfur compared with oxygen which caused weak hydrogen bonding with the catalyst and then rendered slow cyclization of intermediate III (Scheme 3) due to the more weakened nucleophile(–NH2).

The yields of condensation reactions are measured by weighing the final products which were purified by recrystallization from ethanol. All the products were known compounds and they were characterized by comparison of their physical (color, melting points) and spectral (mass spectrometry) data with those of authentic compounds. The selected compounds were further identified by FT-IR, 1H NMR and13C NMR spectroscopy which compared them with literature data.

Key features in the FT-IR spectra of the products include the absorption bands at 3353–3228 cm−1 (related to the N–H stretching vibration), 1729–1702 cm−1 and 1183–1050 cm−1 (due to the C=O and C=S stretching vibrations). In all cases, the formation of 3,4-dihydropyrimidin-2(1H)-one/thiones was established by the disappearance of two sharp absorption bands at 2850 and 2750 cm−1 (related to the –CHO stretching vibrations of aldehyde). The 1HNMR spectra of 3,4-dihydropyrimidin-2(1H)-one/thiones exhibited a singlet resonating at around 10.48–8.49 (due to the NH proton at position 1) and 9.78–5.99 ppm (due to NH proton at position 3). In addition, click condensations were confirmed by the appearance of a doublet resonating at around 5.42–5.06 ppm in the 1H NMR spectra, which corresponds to the hydrogen on position 4 of the dihydropyrimidin ring and confirms the regioselective synthesis of 4-disubstituted dihydropyrimidin regioisomers. Also in the 13C NMR spectra, a signal at 195–165 ppm corresponds to the carbonyl carbon at position 5 and another signal at 164–152/184–174 ppm to the C = X at position 2 (X = O/S) of 3,4-dihydropyrimidin-2(1H)-one/thiones, which can be beneficial for further confirming the structure of the desired products.

On the basis of the above observations and the literature reports, we have proposed a reaction mechanism for the Punica granatum peel-catalyzed Biginelli condensation reaction under solvent-free condition in Scheme 3. The catalytic activity of Punica granatum peel in the Biginelli condensation reaction was established by performing the reaction in the absence of Punica granatum peel. After a long reaction time, a lower yield of product (trace) was obtained (Table 1, entry 1). Although the role of Punica granatum peel in the Biginelli condensation reaction is not definitively clear, as shown in Scheme 3, it is speculated that the phenolic hydroxyl groups of punicalagin (A) and punicalin (B) (two essential components of Punica granatum peel) through hydrogen bonding activate the carbonyl group of aldehyde towards the nucleophilic attack of I (enolic form of 1,3-dicarbonyl compound which was produced upon treatment with catalyst) and urea. The condensed product II was produced more quickly than II′, but in a reversible manner. To understand which component (ethylacetoacetate or urea) is more reactive toward aldehyde, benzaldehyde was treated in two separate flasks by ethyl acetoacetate and urea under optimized reaction conditions. Subsequently, addition of urea/thiourea to II, while forwarding the equilibrium to the right and to more formation of II, led to the formation of III. On the other hand, addition of I to II′ produced III which upon dehydration led to the corresponding 3,4-dihydropyrimidin-2(1H)-one/thiones as IV. Further investigation on the elucidation of the mechanism was undertaken in our laboratory by performing the simultaneous reaction of aldehyde with the 1,3-dicarbonyl compound and urea/thiourea under optimized reaction conditions. When the progress of the reaction was followed precisely, intermediate II was produced as the major product in the first step of the Biginelli condensation reaction along with trace amounts of II′. According to the results obtained from Table 2, as condensation of II with urea was completed faster than condensation with thiourea, cyclization of III may be referred to as a rate-determining step in the Biginelli condensation reaction. So, we can conclude that 3,4-dihydropyrimidin-2(1H)-one/thiones derivatives in the presence of Punica granatum peel were produced through the formation of intermediate II (pathway a), and the re-generated catalyst re-enters the catalytic cycle. The structure of intermediates II and II′ were confirmed by FT-IR spectroscopy, mass spectrometry and comparison of their melting points with known compounds [85, 86]. FT-IR spectroscopy of intermediate II revealed two absorption bands at 3440 and 1724 cm−1 due to vibration stretching of the hydroxyl (OH) and carbonyl groups (C=O), respectively. The presence of the NH2 group of II′ was established by two strong absorption bands at 3615 and 3314 cm−1 (due to asymmetric and symmetric stretching vibration of NH2), and C=O vibration stretching was revealed as a strong absorption band at 1647 cm−1. Also, the existence of a molecular ion peak at m/z 236 and 148 in the mass spectra confirmed the formation of intermediates II and II′, respectively (see Supporting Information, pages 75–78).

The relationship between the number of cycles of the model reaction and the catalytic activity in terms of conversion and isolated yield of product is presented in Fig. 5. Upon completion of the reaction in the specified time, the mixture was washed with water (15 mL). After decantation of the washing water, the solid mixture was dissolved in hot EtOH (15 mL) and the catalyst was separated, washed with ethanol and finally dried at 90 °C for 2 h prior to the next run. During the recycling experiment with fresh reactants, under the same reaction conditions, no considerable change in the activity of the Punica granatum peel was observed for at least 7 consecutive runs, which clearly demonstrates the stability of the catalyst for these conditions in the Biginelli reaction (Fig. 5). The identity of the recovered catalyst was checked by FT-IR spectroscopy (Fig. 1b), and it was observed that there were no considerable changes in the chemical structure of the functional groups and the hydrogen bonding network of the catalyst as compared to fresh catalyst (Fig. 1a).

A comparative study was performed for the use of Punica granatum peel with some of the reported catalysts for the Biginelli condensation reaction (Table 3). The reaction with different catalysts required long reaction times for completion compared with Punica granatum peel which afforded the desired product rapidly. Moreover, in most methods, the reaction was performed in solvents such as H2O, acetic acid, ethanol, methanol, acetonitrile, dioxane and toluene. The Punica granatum peel promoted the reaction more effectively under mild conditions than the other catalysts, and it can be considered as one of the best choices for selecting an environmentally benign and user-friendly catalyst.

Conclusion

Here, we have elaborated a new green and rapid Biginelli condensation reaction in the presence of Punica granatum under solvent-free condition. Punica granatum is shown to be an effective heterogeneous organocatalyst for the multicomponent one-pot condensation of aldehydes,1,3-dicarbonyl compounds and urea/thiourea to produce 3,4-dihydropyrimidin-2(1H)-one/thiones in high to excellent yields, which could be regenerated up to seven cycles without any considerable loss of efficiency. The noteworthy merits of this protocol are the simple operation, short reaction time, high yields, mild and clean reaction conditions, avoiding hazardous catalysts or corrosive or toxic solvents, easy work-up procedure and green sustainable conditions. We believe that these features will enable this protocol to find widespread applications in the field of organic synthesis.

References

D.L. da Silva, F.S. Reis, D.R. Muniz, A.L.T.G. Ruiz, J.E. de Carvalho, A.A. Sabino, L.V. Modolo, A. de Fatima, Bioorg. Med. Chem. 20, 2645 (2012)

C.O. Kappe, Eur. J. Med. Chem. 35, 1043 (2000)

K. Singh, K. Singh, Adv. Heterocycl. Chem. 105, 223 (2012)

B.B. Tour, D.G. Hall, Chem. Rev. 109, 4439 (2009)

L.F. Tietze, Chem. Rev. 96, 115 (1996)

A. Dmling, I. Ugi, Angew. Chem. Int. Ed. Engl. 32, 563 (1993)

A. Hasaninejad, A. Zare, M. Shekouly, J.A. Rad, J. Comb. Chem. 12, 844 (2010)

S.K. Kundu, A. Majee, A. Hajra, Indian J. Chem. 48B, 408 (2009)

U.B. More, Asian J. Chem. 24, 1906 (2012)

J.T. Starcevich, T.J. Laughlin, R.S. Mohan, Tetrahedron Lett. 54, 983 (2013)

H.N. Karade, J. Acharya, M.P. Kaushik, Tetrahedron Lett. 53, 5541 (2012)

F. Shirini, M.A. Zolfigol, E. Mollarazi, Lett. Org. Chem. 2, 718 (2005)

S.L. Jain, J.K. Joseph, B. Sain, Catal. Lett. 115, 52 (2007)

X. Chen, Y. Peng, Catal. Lett. 122, 310 (2008)

X. Hui, W. Yan-Guang, Chin. J. Chem. 21, 327 (2003)

R.H. Shoar, G. Rahimzadeh, F. Derikvand, M. Farzaneh, Synth. Commun. 40, 1270 (2010)

K. Bahrami, M.M. Khodaei, A. Nejati, Monatsh. Chem. 142, 159 (2011)

S. Rostamnia, K. Lamei, Chin. Chem. Lett. 23, 930 (2012)

A.G. Choghamarani, P. Zamani, Chin. Chem. Lett. 24, 804 (2013)

S. Rostamnia, F. Pourhassan, Chin. Chem. Lett. 24, 401 (2013)

M.A. Chari, K. Syamasundar, J. Mol. Catal. A Chem. 221, 137 (2004)

C. Mukhopadhyay, P.K. Tapaswi, M.G.B. Drew, Tetrahedron Lett. 51, 3944 (2010)

X.C. Wang, L.J. Zhang, Z. Zhang, Z.J. Quan, Chem. Lett. 23, 423 (2012)

M.A. Bigdeli, G. Gholami, E. Sheikhhosseini, Chem. Lett. 22, 903 (2011)

J. Mondal, T. Sen, A. Bhaumik, Dalton Trans. 41, 6173 (2012)

J. Cheng, D.Y. Qi, Chin. Chem. Lett. 18, 647 (2007)

K. Folkers, T.B. Johnson, J. Am. Chem. Soc. 55, 2886 (1933)

S. Samai, G.C. Nandi, P. Singh, M.S. Singh, Tetrahedron 65, 10155 (2009)

T.H. Niloofar, D. Abolghasem, Chin. J. Chem. 29, 203 (2011)

S. Tu, X. Zhu, F. Shi, J. Zhang, Y. Zhang, J. Heterocycl. Chem. 44, 837 (2007)

H. Sachdeva, R. Saroj, S. Khaturia, H.L. Singh, J. Chil. Chem. Soc. 57, 1012 (2012)

Y. Wang, H. Yang, J. Yu, Z. Miao, R. Chena, Adv. Synth. Catal. 351, 3057 (2009)

R.S. Bhosale, S.V. Bhosale, S.V. Bhosale, T. Wang, P.K. Zubaidha, Tetrahedron Lett. 45, 9111 (2004)

S.E. Hankari, B. Motos-Perez, P. Hesemann, A. Bouhaouss, J.J.E. Moreau, Chem. Commun. 47, 6704 (2011)

N. Prosa, R. Turgis, R. Piccardi, M.C. Scherrmann, Eur. J. Org. Chem. 11, 2188 (2012)

D. Tejedor, F. Garcia-Tellado, Chem. Soc. Rev. 36, 484 (2007)

L. Weber, Drug Discov. Today 7, 143 (2002)

C. Hulme, V. Gore, Curr. Med. Chem. 10, 51 (2003)

S.D. Sharma, P. Gogoi, D. Konwar, Green Chem. 9, 153 (2007)

A.R. Gholap, K. Venkatesan, T. Daniel, R.J. Lahoti, K.V. Srinivasan, Green Chem. 6, 147 (2004)

A.V. Patil, A.R. Karade, In T.K. Bose and S.K. Mitra (Eds.), Fruits: Tropical, Subtropical (Naya Prakash, Calcutta, 1996)

C. Bell, S. Hawthorne, J. Pharm. Pharmacol. 60, 139 (2008)

M.K. Reddy, S.K. Gupta, M.R. Jacob, S.I. Khan, D. Ferreira, Planta Med. 73, 461 (2007)

G.J. Kotwal, Vaccine 26, 3055 (2007)

N.P. Seeram, L.S. Adams, S.M. Henning, Y. Niu, Y. Zhang, M.G. Nair, D. Heber, J. Nut. Biochem. 16, 360 (2005)

P.S. Negi, G.K. Jayaprakash, B.S. Jena, Food Chem. 80, 393 (2003)

N. Seeram, R. Lee, M. Hardy, D. Heber, Separ. Purif. Technol. 41, 49 (2005)

M.N. Clifford, A. Scalbert, J. Sci. Food Agric. 80, 1118 (2000)

N. Kamal, Amin. J. Hazard. Mater. 165, 52 (2009)

A. Bhatnagar, A.K. Minocha, J. Hazard. Mater. 168, 1111 (2009)

E.S.Z. El-Ashtoukhya, N.K. Amina, O. Abdelwahab, Desalination 223, 162 (2008)

A. El Nemr, Chem. Ecol. 23, 409 (2007)

A. El Nemr, J. Hazard. Mater. 161, 132 (2009)

M. Rohani Moghadam, N. Nasirizadeh, Z. Dashti, E. Babanezhad, Int. J. Ind. Chem. 4, 19 (2013)

A. Bhatnagar, A.K. Minocha, Colloids Surf. B Biointerfaces 76, 544 (2010)

N. Razavi, B. Akhlaghinia, RSC Adv. 5, 12372 (2015)

S.S.E. Ghodsinia, B. Akhlaghinia, RSC Adv. 5, 49849 (2015)

M. Zarghani, B. Akhlaghinia, Appl. Organomet. Chem. 29, 683 (2015)

Z. Zarei, B. Akhlaghinia, Chem. Pap. 69, 1421 (2015)

M. Zarghani, B. Akhlaghinia, RSC Adv. 5, 87769 (2015)

N. Razavi, B. Akhlaghinia, New J. Chem. 40, 477 (2016)

R. Jahanshahi, B. Akhlaghinia, RSC Adv. 5, 104087 (2015)

N. Yousefi Siavashi, B. Akhlaghinia, M. Zarghani, Res. Chem. Intermed. 42, 5789 (2016)

E. Karimian, B. Akhlaghinia, S.S.E. Ghodsinia, J. Chem. Sci. 128, 429 (2016)

R. Jahanshahi, B. Akhlaghinia, RSC Adv. 6, 29210 (2016)

M. Zarghani, B. Akhlaghinia, RSC Adv. 6, 31850 (2016)

M. Zarghani, B. Akhlaghinia, RSC Adv. 6, 38592 (2016)

S.S.E. Ghodsinia, B. Akhlaghinia, RSC Adv. 6, 63613 (2016)

M. Zarghani, B. Akhlaghinia, Bull. Chem. Soc. Jpn 89, 1192 (2016)

S. Memar Masjed, B. Akhlaghinia, M. Zarghani, N. Razavi, Aust. J. Chem. (2016). doi:10.1071/CH16126

Z. Zarei, B. Akhlaghinia, RSC Adv. 6, 106473 (2016)

M. Abbasi, Res. Chem. Intermed. 42, 3303 (2016)

A. Zare, Z. Nasouri, J. Mol. Liq. 216, 364 (2016)

J. Safari, S. Gandomi-Ravandi, S. Ashiri, New J. Chem. 40, 512 (2016)

Q. Song, X. An, F. Che, T. Shen, J. Heterocycl. Chem 52, 1496 (2015)

H. Kiyani, M. Ghiasi, Res. Chem. Intermed. 41, 5177 (2015)

F. Tamaddon, S. Moradi, J. Mol. Catal. A Chem. 370, 117 (2013)

A. Rajack, K. Yuvaraju, Ch. Praveen, Y.L.N. Murthy, J. Mol. Catal. A Chem. 370, 197 (2013)

C.J. Liu, J.D. Wang, Molecules 14, 763 (2009)

S. Nagarajan, T.M. Sheikh, E. Kandasamy, J. Chem. Sci. 127, 1539 (2015)

W. Li, G. Zhou, P. Zhang, Y. Lai, S. Xu, Heterocycles 83, 2067 (2011)

F. Shaghayeghi Toosi, A. Maghsoodi, F.S. Toosi, Synth. React. Inorg. M. 46, 168 (2016)

K. Akhter, K. Jahan, U.K.R. Romman, M.G. Ahmed, M.S. Rahman, M. Al-Amin, Asian J. Chem. 27, 2624 (2015)

J. Safari, Z. Zarnegar, RSC Adv. 3, 17962 (2013)

R.O.M.A. De Souza, E.T. Da Penha, H.M.S. Milagre, S.J. Garden, P.M. Esteves, M.N. Eberlin, O.A.C. Antunes, Chem. Eur. J. 15, 9799 (2009)

P.K. Sahu, P.K. Sahu, D.D. Agarwal, RSC Adv. 3, 9854 (2013)

J. Safari, Z. Zarnegar, M. Heydarian, J. Taibah Univ. Sci. 7, 17 (2013)

M. Kargar, R. Hekmatshoar, A. Mostashari, Z. Hashemi, Catal. Commun. 15, 123 (2011)

F. Damkaci, A. Szymaniak, J. Chem. Educ. 91, 943 (2014)

X.W. Liu, K.K. Pasunooti, H. Chai, C.N. Jensen, B.K. Gorityala, S. Wang, Tetrahedron Lett. 52, 80 (2011)

ChV Reddy, M. Mahesh, P.V.K. Raju, T.R. Babu, V.V.N. Reddy, Tetrahedron Lett. 43, 2657 (2002)

S. Rao Jetti, A. Bhatewara, T. Kadre, S. Jain, Chin. Chem. Lett. 25, 469 (2014)

D.L. da Silva, S.A. Fernandes, A.A. Sabino, A. de Fatima, Tetrahedron Lett. 52, 6328 (2011)

M. Moosavifar, C. R. Chim. 15, 444 (2012)

G.H. Mahdavinia, H. Sepehrian, Chin. Chem. Lett. 19, 1435 (2008)

F. Zamani, E. Izadi, Catal. Commun. 42, 104 (2013)

S. Patil, S.D. Jadhav, S.Y. Mane, Int. J. Org. Chem. 1, 125 (2011)

R. Tayebee, B. Maleki, M. Ghadamgahi, Chin. J. Catal. 33, 659 (2012)

M. Nasr-Esfahani, M. Montazerozohori, M. Aghel-Mirrezaee, H. Kashi, J. Chil. Chem. Soc. 59, 2311 (2014)

S. Besoluk, M. Kukukislamoglu, M. Zengin, M. Arsalan, M. Nebioglu, Turk. J. Chem. 34, 411 (2010)

K. Aswin, S.S. Mansoor, K. Logaiya, P.N. Sudhan, R.N. Ahmed, J. Taibah Univ. Sci. 8, 236 (2014)

Acknowledgement

The authors gratefully acknowledge the partial support of this study by Ferdowsi University of Mashhad Research Council.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Mohammadian, N., Akhlaghinia, B. Punica granatum peel: an organocatalyst for green and rapid synthesis of 3,4-dihydropyrimidin-2 (1H)-ones/thiones under solvent-free condition. Res Chem Intermed 43, 3325–3347 (2017). https://doi.org/10.1007/s11164-016-2828-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-016-2828-9