Abstract

A simple and highly efficient method has been developed for the construction of polyhydroquinoline derivatives via one-pot, four-component Hantzsch condensation of various aldehydes, dimedone, ethyl acetoacetate, and ammonium acetate in the presence of an ionic liquid, 1-sulpopyridinium chloride, as a catalyst under solvent-free conditions. This methodology has an advantage of high yields, short reaction times, a clean reaction profile, and reusability of the catalyst.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Multicomponent reactions (MCRs) are efficient synthetic tools for the construction of chemically and biological active compounds. They have unique advantages such as the generation of highly diverse and complex products from readily available substrates in a single synthetic operation without isolation of intermediates, and with maximum selectivity in minimal time, high atom economy, and high purity with excellent yields [1–3]. Nowadays, ionic liquid catalyzed reactions have gained considerable attention because of their interesting properties like high thermal stability, non-flammability, an ability to dissolve a wide range of materials, eco-friendly nature, and reusability, all contributing to carrying out reactions more effectively [4, 5]. Moreover, reactions under solvent-free conditions are also increasingly attractive to researchers due to the fact that without solvent, reactions usually need shorter reaction times, simpler reactors, and require simple and efficient workup procedures [6, 7].

1,4-Dihydropyridine (1,4-DHP) derivatives are well known as calcium channel modulators and have emerged as one of the most important classes of drugs for the treatment of cardiovascular diseases (e.g. amlodipine, nifedipine, nimodipine, nicardipine, and efonidipine, etc.; Fig. 1) [8–11]. Thus, in recent years an increasing interest has been focused on their syntheses. 1,4-DHPs were also found to possess antiviral [12], antioxidant [13], antitumour [14], anti-inflammatory [15], antimalarial [16], antibacterial [17], and antitubercular [18] activities. They also act as NADH coenzymes for the reduction of carbonyl compounds and their derivatives [19], as neuroprotectants, with platelet anti-aggregatory activity and cerebral anti-ischemic activity in the treatment of Alzheimer’s disease, and as chemosensitizers in tumor therapy [20].

In view of their pharmacological activities, numerous methods have been reported for the synthesis of structurally related polyhydroquinoline derivatives. The classical method involves the condensation of an aldehyde with ethyl acetoacetate and ammonia in acetic acid or in refluxing alcohol [21–23]. However, these methods suffer from several drawbacks such as long reaction times, use of large quantities of volatile organic solvents, low yields, and harsh reaction conditions. Thus, chemists have developed more competent methods including conventional heating [24], microwave irradiation [25], ultrasound irradiation [26], and also using various catalytic systems such as ionic liquids [27], l-proline [28], magnetic Fe3O4 nanoparticles [29], molecular iodine [30], Sc(OTf)3 [31], HClO4–SiO2 [32], PPA–SiO2 [33], PTSA [34], FeF3 [35], CAN [36], P(4-VPH)HSO4 [37], cellulose sulphuric acid [38], cross-linked poly(AMPS-co-AA) [39] and 1,3-bromo/chloro-5,5-dimethylhydantoin [40]. However, most of these methods have one or several draw backs such as low yields, long reaction times, tedious workup procedures, and the use of expensive and large quantities of reagents. Thus, to overcome these limitations and in continuation of our previous studies on the development of eco-friendly methodologies [41], we herein report the synthesis of polyhydroquinoline derivatives utilizing an efficient, eco-friendly, and reusable ionic liquid, 1-sulfopyridinium chloride [pyridine–SO3H]Cl, as a catalyst under solvent-free conditions.

Experimental

Materials and methods

All the solvents and chemicals were purchased from Aldrich/Merck/Fisher and used without further purification. The melting points were determined on a Buchi melting point apparatus and are uncorrected. The progress of the reaction as well as the purity of the compounds were checked using F 254 silica-gel pre-coated TLC plates with hexane and ethyl acetate as eluent. IR spectra were recorded on a Perkin Elmer FT-IR spectrophotometer using KBr pellets. 1H NMR spectra were recorded on a Bruker 400 MHz spectrometer and mass spectra were obtained using a Jeol JMSD-400 spectrometer. Elemental analyses were performed on a Carlo-Erba model EA1108 analytical unit.

General procedure for the synthesis of Hantzsch polyhydroquinolines (5a–m)

Ionic liquid, [pyridine–SO3H]Cl (10 mol%, 0.1 mmol, 19.56 mg) was added to a mixture of dimedone (1 mmol, 140.18 mg), aldehyde (1 mmol), ethyl acetoacetate (1 mmol, 127.46 µL), and ammonium acetate (3 mmol, 231.25 mg), and heated at 110 °C under neat conditions for an appropriate time, as described in Table 1. After completion of the reaction shown by TLC, the mixture was diluted with water and the product was extracted with ethyl acetate (3 × 10 mL). The combined organic layer was dried over Na2SO4 and concentrated under reduced pressure, and then purified by recrystallization from ethanol to obtain the pure polyhydroquinoline derivatives. The recovered catalyst was washed with ethyl acetate, dried under vacuum at 90 °C for about 2.5 h, and reused for consecutive reactions.

Spectral data of representative compounds

Ethyl 4-(4-bromophenyl)-2,7,7-trimethyl-5-oxo-1,4,5,6,7,8-hexahydroquinoline-3-carboxylate ( 5b )

White solid; IR (KBr, υ max, cm−1): 3285, 2962, 1701, 1606, 1510, 1382, 1231, 1023, 765; 1H NMR (400 MHz, CDCl3); δ (ppm) 0.94 (s, 3H), 1.07 (s, 3H), 1.24 (t, 3H, J = 7.2 Hz), 2.21–2.24 (m, 3H), 2.35–2.41 (m, 4H), 4.09 (q, 2H, J = 7.2 Hz), 5.07 (s, 1H), 5.92 (s, 1H), 7.30 (d, 2H, J = 8.0 Hz), 7.39 (d, 2H, J = 8.0 Hz); Mass (ESI) m/z: 417 (M+); Anal. Calcd. for C21H24BrNO3: C, 60.29; H, 5.78; N, 3.35. Found: C, 60.36; H, 5.71; N, 3.42.

Ethyl 4-(5-chloro-2-hydroxyphenyl)-2,7,7-trimethyl-5-oxo-1,4,5,6,7,8-hexahydroquinoline-3-carboxylate ( 5f )

Pale yellow solid; (KBr, υ max, cm−1): 3317, 3253, 3096, 2961, 1654, 1608, 1591, 1490, 1368, 1230, 1122, 819, 643; 1H NMR (400 MHz, DMSO-d 6): δ 0.84 (s, 3H), 1.01–1.05 (m, 6H), 2.06 (d, J = 16.0 Hz, 1H), 2.21–2.45 (m, 6H), 3.88–3.95 (m, 2H), 4.91 (s, 1H), 6.71 (d, J = 8.4 Hz, 1H), 6.85 (d, J = 8.4 Hz, 1H), 6.96–6.98 (m, 1H), 9.30 (s, 1H), 9.58 (s, 1H); Mass (ESI) m/z: 390 (M+H)+; Anal. Calcd. for C21H24ClNO4: C, 64.69; H, 6.20; N, 3.59. Found: C, 64.58; H, 6.32; N, 3.76.

Ethyl 2,7,7-trimethyl-5-oxo-4-styryl-1,4,5,6,7,8-hexahydroquinoline-3-carboxylate ( 5i )

White solid; IR (KBr, υ max, cm−1): 3312, 2962, 1674, 1601, 1482; 1H NMR (400 MHz, CDCl3): δ (ppm) 1.08 (s, 3H), 1.12 (s, 3H), 1.24–1.32 (m, 3H), 2.27 (t, 3H, J = 7.3 Hz), 2.32–2.36 (m, 4H), 4.11–4.20 (m, 2H), 4.71 (d, 1H, J = 7.0 Hz), 5.74 (s, 1H), 6.22 (d, 2H, J = 7.1 Hz), 7.22–7.31 (m, 5H). Mass (ESI) m/z: 366 (M+H)+; Anal. Calcd. For C23H27NO3: C, 75.59; H, 7.45; N, 3.83. Found: C, 75.72; H, 7.33; N, 3.91.

Ethyl 2,7,7-trimethyl-5-oxo-4-propyl-1,4,5,6,7,8-hexahydroquinoline-3-carboxylate ( 5j )

White solid; IR (KBr, υ max, cm−1): 3283, 3206, 3082, 2963, 1703, 1606, 1494, 1379, 1279, 1213, 843; 1H NMR (400 MHz, CDCl3): δ (ppm) 0.83 (t, 3H, J = 6.9 Hz), 1.09 (s, 6H), 1.18–1.22 (m, 2H), 1.29 (t, 3H, J = 6.9 Hz), 1.33–1.40 (m, 2H), 2.22 (d, J = 17.2 Hz, 2H), 2.30 (s, 3H), 2.37 (d, J = 17.2 Hz, 2H), 4.02 (t, 1H, J = 5.5 Hz), 4.10–4.22 (m, 2H), 6.32 (s, 1H); Mass (ESI) m/z: 306 (M+H)+; Anal. Calcd. For C18H27NO3: C, 70.79; H, 8.91; N, 4.59. Found: C, 70.92; H, 8.70; N, 4.66.

4-(5-Chloro-pyridin-2-yl)-2,7,7-trimethyl-5-oxo-1,4,5,6,7,8-hexahydro-quinoline-3-carboxylic acid ethyl ester ( 5l )

Pale yellow solid; IR (KBr, υ max, cm−1): 3321, 3250, 3090, 1595, 1242, 1070; 1H NMR (400 MHz, CDCl3): δ (ppm) 0.86 (s, 3H), 1.01–1.06 (m, 6H), 2.06 (d, 1H, J = 16.4 Hz), 2.25 (d, 1H, J = 16.3 Hz), 2.29–2.46 (m, 5H), 3.89–3.99 (m, 2H), 5.06 (s, 1H), 5.92 (s, 1H), 7.14 (d, 2H, J = 8.7 Hz), 7.29 (s, 1H); Mass (ESI) m/z: 375 (M+H)+; Anal. Calcd. For C20H23ClN2O3: C, 64.08; H, 6.18; N, 7.47. Found: C, 64.18; H, 6.01; N, 7.56.

Results and discussion

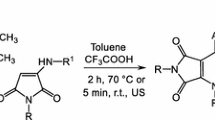

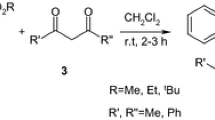

Polyhydroquinoline derivatives (5a–m) were synthesized via Hantzsch multicomponent condensation of various aryl/alkyl/heteryl aldehydes (2a–m) with dimedone (1), ethyl acetoacetate (3), and ammonium acetate (4) under neat conditions at 110 °C in the presence of an eco-friendly ionic liquid, [pyridine–SO3H]Cl, as a catalyst with excellent yields. The schematic representation is shown in Scheme 1. The ionic liquid [pyridine–SO3H]Cl was prepared according to the published procedure [42] from readily available starting materials, as shown in Scheme 2.

We initially investigated the reaction of benzaldehyde (2a) with dimedone (1), ethyl acetoacetate (3), and ammonium acetate (4) as a model reaction in the absence as well as in the presence of an ionic liquid (5, 10 and 15 mol%) at different temperatures ranging from room temperature to 140 °C under solvent-free conditions. The observations are as follows: Without catalyst at room temperature the formation of product (5a) was not observed; as the temperature increases to 140 °C, only 35 % of the product was observed (Table 1, entries 1–4). In the presence of 5 mol% of catalyst, at room temperature only 36 % of the product was formed; as the temperature increased to 110 °C the yield of the product dramatically increased to 82 %, however, further increments of temperature up to 140 °C did not show any affect on product yield and reaction time (Table 1, entries 5–8). To achieve better yields, the above reaction was conducted with 10 and 15 mol % of the catalyst, and observed the maximum yield (93 %) in shorter reaction times (25 min) with 10 mol % of the catalyst. We also observed that as the amount of the catalyst increased to 15 mol % the yield slightly decreased due to the formation of unidentified impurities. Thus, the optimum condition is 10 mol% of the catalyst at 110 °C under solvent-free conditions.

With the optimized conditions in hand, we proceeded to examine the scope of the reaction using a variety of different aromatic, aliphatic, and hetero aromatic aldehydes (Scheme 1), and obtained the desired polyhydroqunoline derivatives (5a–m) with excellent yields and in shorter reaction times (Table 2). After completion of the reaction, the catalyst was recovered by evaporating the aqueous layer, washed with warm ethyl acetate, dried under vacuum and at 90 °C for about 2.5 h, and reused for subsequent reactions for additional four cycles. In this process, we observed a slight decrease in its activity in terms of product yield. For example, the reaction of dimedone (1), benzaldehyde (2a) ethyl acetoacetate (3), and ammonium acetate (4) gave the desired product (5a) in 91, 89, 86, and 83 % yields over an additional four cycles. All the synthesized compounds were characterized by IR, 1H NMR and mass spectral data, as well as via elemental analyses studies, and the melting points of the known compounds were also compared with the literature values, where both were found to be in good agreement.

A plausible mechanism for the formation of polyhydroquinolines catalyzed by an ionic liquid, [pyridine–SO3H]Cl is described in Scheme 3. The carbonyl oxygen of aldehyde is activated in the presence of [pyridine–SO3H]Cl and readily reacts with the enolic form of dimedone, affording the corresponding chalcone type compound A. Intermediate A undergoes cyclization with ethyl-3-aminobut-2-enoate B, which is formed in situ by the reaction of ethyl acetoacetate with ammonium acetate followed by dehydration;this results in the corresponding polyhydroquinoline in excellent yields.

Conclusion

In conclusion, we have developed a simple, efficient, and eco-friendly protocol for the synthesis of polyhydroquinolines via Hantzsch multicomponent condensation of dimedone, aryl/alkyl/heteryl aldehydes, ethyl acetoacetate, and ammonium acetate utilizing 1-sulfopyridinium chloride as a catalyst. This method offers several advantages including high yields, short reaction times, a simple workup procedure, reusability of the catalyst, and the ability to avoid use of hazardous organic solvents.

References

B.H. Rotstein, S. Zaretsky, V. Rai, A.K. Yudin, Chem. Rev. 114, 8323 (2014)

A. Domling, W. Wang, K. Wang, Chem. Rev. 112, 3083 (2012)

J. Zhu, H. Bienayme, Multicomponent Reactions (Wiley, Weinheim, 2005)

J.E. Martyn, R.S. Kenneth, Pure Appl. Chem. 72, 1391 (2000)

Q. Zhang, S. Zhang, Y. Deng, Green Chem. 13, 2619 (2011)

K. Tanaka, F. Toda, Chem. Rev. 100, 1025 (2000)

M.S. Singh, S. Chowdhury, RSC Adv. 2, 4547 (2012)

J.L. Reid, P.A. Meredith, F. Pasanisi, J. Cardiovasc. Pharmacol. 7, S18 (1985)

R.H. Bocker, F.P. Guengerich, J. Med. Chem. 29, 1596 (1986)

F. Bossert, H. Meyer, E. Wehinger, Angew. Chem. Int. Ed. Engl. 20, 762 (1981)

D.J. Triggle, D.A. Langs, R.A. Janis, Med. Res. Rev. 9, 123 (1989)

A. Hilgeroth, Mini-Rev. Med. Chem. 2, 235 (2002)

H.S. Chung, W.S. Woo, J. Nat. Prod. 64, 1579 (2001)

M. Kawase, A. Shah, H. Gaveriya, N. Motohashi, H. Sakagami, A. Varga, J. Molnar, Bioorg. Med. Chem. 10, 1051 (2002)

O.A. El-Sayed, T.M. Al-Turki, H.M. Al-Daffiri, B.A. Al-Bassam, M.E. Hussein, Boll. Chim. Farm. 143, 227 (2004)

A. Ryckebusch, R. Derprez-Poulain, L. Maes, M.A. Debreu-Fontaine, E. Mouray, P. Grellier, C. Sergheraert, J. Med. Chem. 46, 542 (2003)

M.Q. Zhang, A. Haemers, D. Vanden Berghe, S.R. Pattyn, W. Bollaert, I. Levshin, J. Heterocycl. Chem. 28, 673 (1991)

H. Gevariya, B. Desai, V. Vora, A. Shah, Heterocycl. Commun. 7, 481 (2011)

M. Rueping, A.P. Antonchick, T. Theissmann, Angew. Chem. Int. Ed. 45, 3683 (2006)

R. Boer, V. Gekeler, Drugs Future 20, 499 (1995)

B. Love, K.M. Sander, J. Org. Chem. 30, 1914 (1965)

A. Hantzsch, Ber. Dtsch. Chem. Ges. 21, 942 (1888)

A. Hantzsch, Ber. Dtsch. Chem. Ges. 23, 1747 (1890)

J.B. Sainani, A.C. Shah, Indian J. Chem. Sect. B 33, 526 (1994)

S.J. Tu, J.F. Zhou, X. Deng, P.J. Cai, H. Wang, J.C. Feng, Chin. J. Org. Chem. 21, 313 (2001)

A. Maquestiau, A. Mayence, J.J. Vanden Eynde, Tetrahedron Lett. 32, 3839 (1991)

S.J. Ji, Z.Q. Jiang, J. Lu, T.P. Loh, Synlett 5, 831 (2004)

N.N. Karade, V.H. Budhewar, S.V. Shinde, W.N. Jadhav, Lett. Org. Chem. 4, 16 (2007)

M. Nasr-Esfahani, S.J. Hoseini, M. Montazerozohori, R. Mehrabi, H. Nasrabadi, J. Mol. Catal. A Chem. 382, 99 (2014)

S. Ko, M.N.V. Sastry, C. Linc, C.F. Yao, Tetrahedron Lett. 46, 5771 (2005)

J.L. Donelson, R.A. Gibbs, S.K. De, J. Mol. Catal. A Chem. 256, 309 (2006)

M. Maheswara, V. Siddaiah, G.L.V. Damu, C.V. Rao, Arkivoc 2, 201 (2006)

A. Khojastehnezhad, F. Moeinpour, A. Davoodnia, Chin. Chem. Lett. 22, 807 (2011)

S. Ko, C.F. Yao, Tetrahedron 62, 7293 (2006)

R. Surasani, D. Kalita, A.V.D. Rao, K. Yarbagi, K.B. Chandrasekhar, J. Fluor. Chem. 135, 91 (2012)

C.S. Reddy, M. Raghu, Chin. Chem. Lett. 19, 775 (2008)

B. Janardhan, B. Rajitha, P.A. Crooks, J. Saudi Chem. Soc. 18, 722 (2014)

J. Safari, S.H. Banitaba, S.D. Khalili, J. Mol. Catal. A Chem. 335, 46 (2011)

M. Behrooz, T. Reza, S. Zeinalabedin, K. Mina, Acta Chim. Slov. 59, 814 (2012)

M. Behrooz, T. Reza, K. Mina, S.A. Samaneh, J. Mex. Chem. Soc. 57, 290 (2013)

B. Sakram, B. Sonyanaik, K. Ashok, S. Rambabu, S.K. Johnmiya, Res. Chem. Intermed. 42, 1699 (2016)

A.R.M. Zare, M.A. Zolfigol, M. Zarei, A. Zare, V. Khakyzadeh, A. Hasaninejad, Appl. Catal. A Gen. 467, 61 (2013)

Acknowledgments

We gratefully acknowledge the head of the Department of Chemistry, Osmania University, for providing research facilities. One of the authors (B. Sonyanaik) thanks the University Grant Commission (UGC) New Delhi, India, for providing research fellowships.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Sakram, B., Sonyanaik, B., Ashok, K. et al. Polyhydroquinolines: 1-sulfopyridinium chloride catalyzed an efficient one-pot multicomponent synthesis via Hantzsch condensation under solvent-free conditions. Res Chem Intermed 42, 7651–7658 (2016). https://doi.org/10.1007/s11164-016-2559-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-016-2559-y