Abstract

An easy and convenient method is reported for the synthesis of polyhydroquinoline derivatives in solvent-free conditions under microwave irradiation in the presence of magnetic nickel ferrite nanoparticles (NiFe2O4 MNPs) as a catalyst. Excellent yields (82–94 %), facile work-up, achieving high purity of products via simple recrystallization, and short reaction times (2–5 min) are some advantages of this procedure. It is worth noting, the catalyst is magnetically removed without significant loss of activity for reuse a few times.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

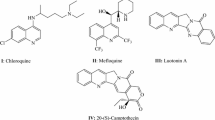

Polyhydroquinolines derivatives, 4-substituted 1,4-dihydropyridines (1,4-DHPs) compounds (Fig. 1), are an essential framework of a great category of biologically active heterocycles [1]. They are well-known compounds as an important class of drugs and analogues of NADH co-enzymes [2]. The therapeutic usages of 1,4-DHPs include significant biological activity [3, 4], various drugs such as nifedipine, nicardipine, benidipine, amolodipine, lacidipine, (Fig. 2) and other related derivatives for treatment of hypertension as an effective cardiovascular agent [5, 6], and having a variety of biological properties such as vasodilator, antitumour, antidiabetic, anti-atherosclerotic, bronchodilator, anti-oxidant, geroprotective and heptaprotective agents [7, 8].

Quinoline derivatives with 1,4-dihydropyridine scaffolding have pharmacological properties. Some compounds of this family are antimalarial, anti-asthmatic, anti-inflammatory, antibacterial, and tyrosine kinase inhibiting agents [9, 10]. Other researches indicate that 1,4-DHPs express different medical functions as neuroprotectants, having platelet anti-aggregatory activity, cerebral anti-ischemic agents, and chemosensitizers [11, 12]. Also, numerous synthetic methods by MCRs have been reported for the preparation of 1,4-dihydropyridine derivatives under different conditions [13–18].

In view of the importance of polyhydroquinolines derivatives, numerous and various methods by MCRs have been reported for synthesis of these compounds, which include the use of grinding [19], solar thermal energy [20], microwave irradiation by Ni nanoparticles [21], ZnO-Beta Zeolite [22], PEG 4000-bound acetoacetate [23], composite-A (ZnFe0.2Al1.8O4) [24], and silica sulfuric acid [25]; and also using different catalysts such as l-proline [26], montmorillonite K-10 clay [27], molecular iodine [28], Scolecite (CaAl2Si3O10·3H2O) [29], ZnO nanoparticles [30], HClO4–SiO2 [31], nanocrystalline copper(II) oxide [32], ionic liquids [33], and metal triflates such as Yb(OTf)3 [34]. In addition, these MCRs have been performed by use of BINOL-phosphoric acid [35], Carbon-based Solid acid (CBSA) [36], DBH or DCH [37], and SO3H-functionalized ILs under ultrasound irradiation [38].

However, in past reports, the existence of some drawbacks such as long reaction times, harsh conditions, toxic organic solvents, high temperatures, high costs, low product yields, being expensive, having difficulty to reuse, and unecofriendly catalysts limit the use of these methods.

In recent years, magnetic nanoparticles (MNPs) have emerged as an attracting class of catalysts, because of the increasing need to develop low-cost, green, efficient, and reusable catalysts. Their nano-size property maximizes the contact between reactants and the catalyst, thus mimicking a heterogeneous catalyst. Use of magnetically separable catalysts is one of the most promising strategies. These systems combine the advantages of nanosized catalysts and magnetic properties, thus, providing the opportunity for quantitative recovery of the catalyst by the use of an external magnet, making it cost-effective and potentially applicable for industrial application [39, 40].

In this regard, iron-based materials, which benefit their terrestrial abundance and low toxicity, have been extensively exploited as catalysts in many organic transformations. Nickel ferrite MNPs are inexpensive, air-stable, magnetically separable, and economical catalysts [41–44]. There are very limited and there are less references about catalytic properties of nickel ferrite MNPs [45–47]. These spinel-type bimetal oxides, have shown great potential in the field of use for catalysis, although they have so far been less investigated.

In recent years, the organic reactions on solid supports in the absence of a solvent and in solvent-free conditions have received considerable attention of synthetic chemists because of their high efficiency, environmentally benign conditions, convenient workup procedures, enhanced selectivity, milder reaction conditions, much improved reaction rates and formation of cleaner products [48]. Aiming to use these advantages, we planned to develop a solvent-free protocol for synthesis of polyhydroquinoline derivatives in solvent-free conditions.

As part of our ongoing program to develop efficient and robust methods for the synthesis of heteroatom-containing organic compounds [49–52], we report an easy and convenient method for synthesis of polyhydroquinoline derivatives in solvent-free conditions under microwave irradiation in the presence of magnetic nickel ferrite nanoparticles (NiFe2O4 MNPs) as a catalyst. According to the best of our knowledge, there is no report on the use of NiFe2O4 MNPs as a magnetic nanocatalyst. Therefore, this fact has caused us to apply the new catalyst for the synthesis of polyhydroquinoline derivatives with a facile and appropriate method under eco-friendly conditions, as shown in Scheme 1.

Experimental

Materials and methods

Starting materials were obtained from Merck, Fluka, and Aldrich and were used without further purification. The methods used to follow the reactions are TLC. The microwave-assisted procedures were carried out in a Milestone Microwave Oven operating at 1600 W. Melting points were measured on an Electrothermal 9100 apparatus (LABEQUIP LTD., Markham, Ontario, Canada) and are uncorrected. 1H (DMSO-d6) and 13C NMR (DMSO-d6) spectra were recorded on a Bruker DRX-250 Avance spectrometer at 250.13 and 62.90 MHz, respectively. IR spectra were measured on a Jasco 6300 FTIR spectrometer. Elemental analysis was performed using inductively coupled plasma optical emission spectroscopy (ICP-OES, Model: VISTA-PRO).

The structural properties of NiFe2O4 MNPs were analyzed by X-ray powder diffraction (XRD) with a X’Pert-PRO advanced diffractometer using Cu (Kα) radiation (wavelength: 1.5406 Å), operated at 40 kV and 40 mA at room temperature in the range of 2θ from 20° to 80°. The particle size and morphology of the surfaces of the sample were analyzed by a scanning electron microscopy) KYKY Co., China, Model: EM 3200). The disc was coated with gold in an ionization chamber. Transmission electron microscopy was studied using a Zeiss-EM10C TEM instrument with an accelerating voltage of 80 kV.

Preparation of catalyst (NiFe2O4 MNPs)

Nickel ferrite nanoparticles were prepared via the auto-combustion assisted sol–gel method of Fe(III) and Ni(II) ions (molar ratio 2:1) in ammonia solution [53, 54]. Briefly, Fe(NO3)3·9H2O (2 mol), Ni(NO3)2·6H2O (1 mol) and citric acid as chelating agent (3 mol) were dissolved in deionized water. The pH value was controlled at 7 by dropwise adding ammonia solution (28 %) to the reaction mixture under fixed stirring. Then, the solution was vaporized in a water bath (60 °C) to form a sticky gel. The temperature was increased to 80 °C in order to obtain a thick gel. The thick gel was held on a hot plate for auto combustion and the temperature was increased to ca. 200 °C. A large amount of gases such as CO2, H2O, and N2 were released and auto combustion occurred, giving rise to a dark brown ferrite powder. The powder was washed with deionized water and acetone three times and separated by using a strong external magnet.

General experimental procedure for the synthesis of polyhydroquinoline derivatives

A mixture of aldehyde 1a–r (1 mmol), dimedone 2 (1 mmol), ammonium acetate 3 (1.5 mmol), ethylacetoacetate 4 (1 mmol), and 23.4 mg of NiFe2O4 nanoparticles (10 mol%) were taken in a glass rod and irradiated in a microwave oven (500 W; when the reaction mixtures were placed under microwave irradiation, MW heating causes melting reactants that led to the partially liquefied reaction mixture and achieved fairly good mixing of the reactants with the catalyst). The progress of the reaction was checked by TLC (n-Hexane: EtOAc, 10:4). After completion, the resulting product was heated in ethanol. The catalyst was magnetically removed from the mixture and washed several times with ethanol for reuse. Then, the residue was poured into crushed ice and stirred for several minutes. The solid product was filtered and the pure product was obtained by recrystallization from hot ethanol–water.

Physical and spectral data of ethyl 4-(4-hydroxyphenyl)-2,7,7-trimethyl-5-oxo-1,4,5,5,7,8-hexahydroquinoline-3-carboxylate (5m, Table 3, Entry 13): Yield: 94 %; M.P. 233–235 °C (Ref. [42] 232–234 °C). IR (KBr): 3488, 3277, 3073, 2958, 2930, 1683, 1491, 1590, 1480, 1194 cm−1. 1H NMR (DMSO-d6, 250.13 MHz) δ 0.83 (3H, s, CH3), 0.98 (3H, s, CH3), 1.12 (3H, t, CH3, J = 6.5 Hz), 1.91–2.42 (4H, m, 2 × CH2), 2.38 (3H, s, CH3), 3.94 (2H, q, CH2, J = 6.2 Hz), 4.71 (1H, s, CH), 6.54 (2H, d, J = 6.8 Hz, Arom.), 6.91 (2H, d, J = 7.0 Hz, Arom.), 8.96 (1H, s, OH), 9.04 (1H, s, NH). 13C NMR (DMSO-d6, 62.90 MHz) δ 14.60, 18.68, 26.89, 29.61, 32.56, 35.21, 50.73, 59.39, 104.56, 110.76, 114.87, 128.77, 138.86, 144.82, 149.59, 155.67, 167.45, 194.76.

Results and discussion

Catalyst characterization

Magnetic nickel ferrite nanoparticles were synthesized by the auto-combustion assisted sol–gel method [43, 44]. The structural properties of the NiFe2O4 MNPs were investigated by X-ray diffraction (XRD), scanning electron microscopy (SEM), transmission electron microscopy (TEM), inductively coupled plasma (ICP), and IR. The X-ray diffraction (XRD) pattern of catalyst powder presented the average diameter of that was determined to be 59.2 nm by the Debye–Scherrer equation (Fig. 3). The diffraction peaks at 30.45°, 35.76°, 37.30°, 43.43°, 53.84°, 57.34°, and 63.01° corresponded with Miller indices observed in (2 2 0), (3 1 1), (2 2 2), (4 0 0), (4 2 2), (5 1 1), and (4 4 0) planes, respectively. These results show the cubic spinel structure of nickel ferrite (JCPDS: 01-074-2081).

The grain size and morphology of the NiFe2O4 MNPs powder were determined by scanning electron microscopy (SEM) (Fig. 4). SEM images show the average size of the grains with spherical morphology is 59 nm and that has good agreement with the XRD pattern.

Also, the grain and size morphology of the NiFe2O4 MNPs were investigated by transmission electron microscopy (TEM) (Fig. 5). They had spherical morphology with a size distribution from 20 to 84 nm and a mean grain size of 46 nm. The presence of some larger particles could be attributed to aggregating (it may be a result of a long time (ca. 20 months) holding the NiFe2O4 MNPs in their pure form at the laboratory conditions) or overlapping of smaller particles.

Inductively coupled plasma (ICP) analysis of nickel ferrite presented the atomic ratio of Ni–Fe at about 0.53, which is close to NiFe2O4 and 24.8 % of its weight contains the nickel element.

Also, the FT-IR spectrum of the NiFe2O4 MNPs is demonstrated in Fig. 6. Two principle absorption bands in the range of 400–600 cm−1 are seen. The first band is around 469 cm−1 and the second one is around 580 cm−1, attributed to the long bond length of oxygen metal ions in the octahedral sites and the shorter bond length of oxygen–metal ions in the tetrahedral sites in the spinel structure, respectively. A large number of OH groups are presented on the surface of the MNPs that show a broad absorption band at about 3439 cm−1 for the stretching mode of H2O molecules.

The role of prepared catalyst in the synthesis of polyhydroquinoline derivatives was investigated under microwave irradiation in solvent-free conditions. We optimized the reaction conditions such as catalyst amount, microwave power, and reaction times. First, the efficiency and amount of the NiFe2O4 MNPs catalyst were investigated in a model reaction of 4-hydroxy benzaldehyde 1m (1 mmol), dimedone 2 (1 mmol), ammonium acetate 3 (1.5 mmol), and ethylacetoacetate 4 (1 mmol) for the synthesis of compound 5m (Table 3, entry 13). As shown in Table 1, the optimum yield of the product was obtained when 23.4 mg of catalyst (10 mol%) was used.

The effect of microwave power inputs from 400 to 600 W on the synthesis of compound 5m (Table 3, entry 13) as a model reaction was evaluated (Table 2). The reaction yield increased with the microwave power at 500 W in comparison to 400 and 450 W but decreased at 600 W. Also, we investigated this reaction in thermal conditions without microwave irradiation in the absence of catalyst and with catalyst in solvent-free conditions for the synthesis of compound 5m (Table 3, entry 13). Ultimately, solvent-free conditions under microwave irradiation were preferred due to short reaction times and high yields.

Then, various aromatic aldehydes carrying electron-donating and electron-withdrawing groups on the aromatic ring in the ortho, meta, and para positions and heterocyclic aldehydes were evaluated. Yields of the all reactions were good to excellent. It was found that the aldehydes with electron-donating groups reacted longer than in comparison to aldehydes with electron-withdrawing groups (Table 3).

A proposed mechanism for the synthesis of polyhydroqunoline derivatives is shown in Scheme 2. A Knoevenagel reaction involves the evident coupling of aldehydes with active methylene compounds (dimedone and ethyl acetoacetate) in paths 2 and 2′. Also, in paths 3 and 3′ a Michael addition of intermediates gives the target products.

In addition, we compared the efficiency of catalytic activity of the NiFe2O4 MNPs with some known catalysts from the prior methods (Table 4). The result expresses that this work is superior to some of the previous methods in terms of magnetic separation of catalyst, reaction time, and yield.

Finally, the recyclability, reusability, and catalytic activity of the reaction catalyst were examined. After the magnetic separation of catalyst from the reaction mixture, the catalyst was washed with ethanol and dried to remove any remaining ethanol, and reused in the further reactions for several times. As shown in Table 5, NiFe2O4 MNPs could be reused at least five times without any inordinate reduction in of its activity.

Conclusions

To summarize, the reported method offers a new, simple, and efficient route for the synthesis of polyhydroquinolines derivatives via a four-component Hantzsch condensation without solvent under microwave irradiation using magnetic nickel ferrite nanoparticles as catalyst. Some important superiorities of this method are short reaction time, no use of hazardous solvents, easy work-up, high yields, and high purity. Furthermore, the use of the recyclable, reusable, inexpensive, and commercially available catalyst makes it a useful procedure in modern synthetic methodologies.

References

D. Mauzeral, F.H. Westheimer, J. Am. Chem. Soc. 77, 2261 (1955)

R.A. Jain, P.J. Silver, D. Triggle, Adv. Drug Res. 16, 309 (1987)

A. Di Stilo, S. Visentin, C. Clara, A.M. Gasco, G. Ermondi, A. Gasco, J. Med. Chem. 41, 5393 (1998)

M. Kawase, A. Shah, H. Gaveriya, N. Motohashi, H. Sakagami, A. Varga, J. Molnar, J. Bioorg. Chem. 10, 1051 (2002)

J.L. Reid, P.A. Meredith, F. Pasanisi, J. Cardiovasc. Pharmacol. 7(S18), 20 (1985)

S. Cosconati, L. Marinelli, A. Lavecchia, E. Novellino, J. Med. Chem. 50, 1504 (2007)

T. Godfraid, R. Miller, M. Wibo, Pharmacol. Rev. 38, 321 (1985)

R. Mannhold, B. Jablonka, W. Voigdt, K. Schoenafinger, K. Schravan, Eur. J. Med. Chem. 27, 229 (1992)

Y.L. Chen, K.C. Fang, J.Y. Sheu, S.I. Hsu, C.C. Tzeng, J. Med. Chem. 44, 2374 (2001)

G. Roma, M.D. Braccio, G. Grossi, F. Mattioli, M. Chia, Eur. J. Med. Chem. 35, 1021 (2000)

V. Klusa, Drugs Future 20, 135 (1995)

R.G. Bretzen, C.C. Bollen, E. Maeser, Drugs Future 17, 465 (1992)

H. Alinezhad, S. Mohseni Tavakkoli, Res. Chem. Intermed. (2014). doi:10.1007/s11164-014-1712-8

B.P. Reddy, S. Sarveswari, V. Vijayakumar, Res. Chem. Intermed. (2014). doi:10.1007/s11164-014-1784-5

M. Nikpassand, M. Mamaghani, Kh Tabatabaeian, Molecules 14, 1468 (2009)

S.S. Makone, D.B. Vyawahare, Int. J. Chem. Tech. Res. 5, 1550 (2013)

H. Kiyani, M. Ghiasi, Res. Chem. Intermed. (2014). doi:10.1007/s11164-014-1621-x

S. Naeim Ghattali, K. Saidi, H. Khabazzadeh, Res. Chem. Intermed. 40, 281 (2014)

S. Kumar, P. Sharma, K.K. Kapoor, M.S. Hundal, Tetrahedron 64, 536 (2008)

R.A. Mekheimer, A. Hameed, K.U. Sadek, Green Chem. 10, 592 (2008)

S.B. Sapkal, K.F. Shelke, B.B. Shingate, M.S. Shingare, Tetrahedron Lett. 50, 1754 (2009)

S.S. Katkar, B.R. Arbad, M.K. Lande, Arab. J. Sci. Eng. 36, 39 (2011)

X.L. Zhang, ShR Sheng, X.L. Liu, X.L. Liu, Arkivoc 13, 79 (2007)

V.M. Joshi, R.P. Pawar, Eur. Chem. Bull. 2(9), 679 (2013)

A. Mobinikhaledi, N. Foroughifar, M.A.B. Fard, H. Moghanian, S. Ebrahimi, M. Kalhor, Synth. Commun. 39, 1166 (2009)

N.N. Karade, V.H. Budhewar, S.V. Shinde, W.N. Jadhav, Lett. Org. Chem. 4, 16 (2007)

G. Song, B. Wang, X. Wu, Y. Kang, L. Yang, Synth. Commun. 35, 2875 (2005)

S. Ko, M.N.V. Sastry, C. Lin, C.F. Yao, Tetrahedron Lett. 46, 5771 (2005)

L.S. Gadekar, S.S. Katkar, ShR Mane, B.R. Arbad, M.K. Lande, Bull. Korean Chem. Soc. 30, 2532 (2009)

M.Z. Kassaee, H. Masrouri, F. Movahedi, Monatsh. Chem. 141, 317 (2010)

M. Maheswara, V. Siddaiah, G.L.V. Damu, C.V. Rao, Arkivoc 2, 201 (2006)

J. Safaei-Ghomi, M.A. Ghasemzadeh, J. Nanostruct. 1, 243 (2012)

S.J. Ji, Z.Q. Jiang, J. Lu, T.P. Loh, Synlett 5, 831 (2004)

L.M. Wang, J. Sheng, L. Zhang, J.W. Han, Z.Y. Fan, H. Tian, C.T. Qian, Tetrahedron 61, 1539 (2005)

C.G. Evans, J.E. Gestwicki, Org. Lett. 11, 2957 (2009)

A. Davoodnia, A. Khojastenezhad, J. Chil. Chem. Soc. 57, 1385 (2012)

B. Maleki, R. Tayebee, M. Kermanian, S. Sedigh Ashrafi, J. Mex. Chem. Soc. 57(4), 290 (2012)

B.L. Li, A.G. Zhong, A.G. Ying, J. Heterocycl. Chem. 52, 445 (2014)

D. Wang, D. Astruc, Chem. Rev. 114, 6949 (2014)

M.B. Gawande, R. Luque, R. Zboril, ChemCatChem 6, 3312 (2014)

R. Galindo, E. Mazario, S. Gutiérrez, M.P. Morales, P. Herrasti, J. Alloys Compd. 536S, S241 (2012)

P. Sivakumar, R. Ramesh, A. Ramanand, S. Ponnusamy, C. Muthamizhchelvan, Mater. Res. Bull. 46, 2204 (2011)

F. Moeinpour, A. Alimoradi, M. Kazemi, J. Environ. Health Sci. Eng. 12, 112 (2014)

A.-H. Lu, E.L. Salabas, F. Schüth, Angew. Chem. Int. Ed. 46, 122 (2007)

E. Karaoğlu, U. Özel, C. Caner, A. Baykal, M.M. Summaka, H. Sözeri, Mater. Res. Bull. 47, 4316 (2012)

P. Li, Z. Li, F. Zhai, Q. Wan, X. Li, X. Qu, A.A. Volinsky, J. Phys. Chem. C 117, 25917 (2013)

P.T.A. Santos, A.C.F.M. Costa, R.H.G.A. Kiminami, H.M.C. Andrade, H.L. Lira, L. Gama, J. Alloys Compd. 483, 399 (2009)

M.B. Gawande, V.D.B. Bonifacio, R. Luque, P.S. Branco, R.S. Varma, ChemSusChem 7, 24 (2014)

A. Souldozi, A. Ramazani, Tetrahedron Lett. 48, 1549 (2007)

A. Ramazani, A. Rezaei, Org. Lett. 12, 2852 (2010)

A. Ramazani, N. Shajari, A. Mahyari, Y. Ahmadi, Mol. Divers. 15, 521 (2011)

A. Souldozi, A. Ramazani, N. Bouslimani, R. Welter, Tetrahedron Lett. 48, 2617 (2007)

A.A. Thant, S. Srimala, P. Kaung, M. Itoh, O. Radzali, M.N. Ahmad Fauzi, J. Aust. Ceram. Soc. 46, 11 (2010)

I.V. Kasi Viswanath, Y.L.N. Murthy, K. Rao Tata, R. Singh, Int. J. Chem. Sci. 11, 64 (2013)

Acknowledgments

This work was supported by the “Iran National Science Foundation: INSF”.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Ahankar, H., Ramazani, A. & Joo, S.W. Magnetic nickel ferrite nanoparticles as an efficient catalyst for the preparation of polyhydroquinoline derivatives under microwave irradiation in solvent-free conditions. Res Chem Intermed 42, 2487–2500 (2016). https://doi.org/10.1007/s11164-015-2163-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-015-2163-6