Abstract

A simple, efficient, and eco-friendly aerobic procedure for synthesis of 2-substituted benzothiazoles catalyzed by facile prepared [N2222][Pro] in a biomass medium (ethyl lactate) has been developed. The reactions afford the target 2-arylbenzothiazoles in good to excellent yields (>80 %) under air condition and was observed without use of chromatography. In addition, this proline-based ionic liquid catalyst can be easily recycled six times without loss of catalytic activity in gram scale synthesis.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Benzothiazoles are the most important class of heterocyclic compounds because of their various applications in biology and functional materials [1, 2]. In industry, benzothiazoles are also used as antioxidants and vulcanization accelerators. These special utilities of benzothiazoles highlight the importance of their synthesis [3].

Numerous methods have been reported in the literature for the synthesis of benzothiazoles [4–9]. Generally, the most popular approaches involve condensation with aldehydes under oxidative conditions [10, 11] (Scheme 1). Many oxidants have been employed in the synthesis of benzothiazoles such as DDQ [12], PhI (OAc)2 [13], CAN [14], BaMnO4 [15]. Although these oxidants are effective, they usually require excess or stoichiometric amounts of strong oxidants resulting in a large amount of waste.

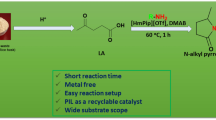

Recently, renewed interests have focused on aerobic oxidations by employing oxygen as the ultimate oxidant. Several examples have been reported in the synthesis of benzo-fused azole compounds under aerobic oxidation conditions [16–20]. With the requirement of sustainable chemistry, some green approaches for the preparation of 2-arylbenzothiazoles via aerobic condensation reaction have also been reported, such as “on water” synthesis [21], catalyst-free synthesis [22], photocatalytic synthesis [23]. Room temperature ionic liquids (ILs) as reusable, homogeneous catalysts, reaction media, and reagents with "green" aspects have been applied to the synthesis of heterocyclic compounds due to their remarkable properties such as designable structure, low volatility, and chemical and high thermal stability [24, 25].

As our interests in developing organic synthesis with better sustainability by ionic liquids catalysts, we report herein a green and facile aerobic procedure for preparation of 2-arylbenzothiazoles in biomass medium using proline-based ionic liquids as a catalyst (Scheme 1).

Results and discussion

A series of tetraethylammonium amino acid ionic liquids ([N2222][AA]) were synthesized via simple neutralization reactions. In order to investigate the performances of [N2222][AA] catalysts and establish the optimum conditions in this aerobic condensation reaction, we took the reaction of benzaldehyde 1a with o-aminothiophenol as model reaction.

Firstly, the effect of catalysts on synthesis of 2-phenylbenzothiazole was tested and is summarized in Table 1. The target products were almost not formed in the present of common inorganic and organic bases (Table 1, entries 1–6). In addition, the 2-arylbenzothiazoles could be obtained in the present of [N2222][AA], l-proline, glycine, and NaPro as catalysts (Table 1, entries 7–20). This can be ascribed to the formation of imino intermediates from the amino group of catalysts and aldehyde. Compared with other amino acid ILs, [N2222][Pro] showed superior catalytic activity in this reaction. In other words, the secondary amine group showed a relatively high catalytic activity. This is probably because the imium intermediates that are formed from the aldehyde group and secondary amine gives more reactivity [26]. In order to verify the better catalytic performance of secondary amine, we also tested the catalytic activities of l-proline and glycine (Table 1, entries 17–18). This result further confirmed that the secondary amine gave a better yield than the primary amino acid. But in this condensation reaction, it seemed that l-proline was not a very ideal catalyst because it is weakly alkaline. For comparison, NaOH and [N2222][OH] as base were added to the reaction mixture (Table 1 entries 19–20). The results indicated that the catalytic performance of l-proline by using NaOH as base was not improved, probably due to the poor solubility of NaPro in organic solvent. Therefore, [N2222][Pro] was finally chosen as the catalyst for further studies.

Subsequently, the effect of catalyst loading on this reaction was evaluated. It was found that catalyst loading had an obvious influence on the formation of product (Table 1, entries 7–12). The yield of 2-phenylbenzothiazole increased significantly (50–90 %) with the rise of catalyst loadings from 5 to 20 mol%. However, while the catalyst loading further increased to 30 mol%, the yield was almost no change (from 9 to 91 %). Thus, considering the cost of ILs, 20 mol% was taken as the optimum catalyst loading for further investigation. In addition, excellent yield (90 %) of 2-phenylbenzothiazole has been obtained at a 1.1 molar ratio of o-aminothiophenol to benzaldehyde. Further increase on the molar ratio is not necessary.

As is well known, many organic solvents are harmful to the environment. Thus, it is necessary to seek an eco-friendly solvent for this reaction. It can be seen that alcohols showed better results than other organic solvents in the presence of [N2222][Pro] (Table 2, entries 1–6). Ethyl lactate (EL) gave the best yield (90 %) in the synthesis of 2-phenylbenzothiazole. This may be the reason for the good solubility of the raw materials and catalyst in alcohols. Except for high product yield, ethyl lactate can be completely biodegraded and is easily obtained from the biomass at low cost [27]. Thus, ethyl lactate as a biodegradable and facile solvent was finally chosen in this aerobic condensation reaction.

The following examination on reaction time showed that the yield of 2-phenylbenzothiazole was almost no change, even when the reaction time was extended from 4 to 8 h (Table 2, entries 6–9), but 2 h of reaction time was not enough for complete conversion by TLC analysis. Therefore, the reaction time was preferably 4 h.

Reaction temperature is very important for this aerobic condensation reaction. Thus, the investigation on the effect of temperature is essential for the synthesis of 2-arylbenzothiazoles. The model reaction was performed in the presence of [N2222][Pro] catalyst at temperatures ranging from 20 to 100 °C (Table 2, entries 10–13). The yield increased obviously from 7 to 90 % with the rise of temperature from 20 to 80 °C. While the reaction temperature was further increased to 100 °C, the yield was only improved with a limited extent. Therefore, an optimized reaction temperature was chosen to be 80 °C.

With the optimized reaction condition in hand, the scope of application by using [N2222][Pro] as catalyst was also explored. The reaction of o-aminothiophenol with various aromatic aldehydes was further examined. The results are summarized in Table 3. It was observed that all aromatic aldehydes can be successfully converted to the corresponding 2-arylbenzothiazoles. Most of these products could be obtained with excellent yield simply by crystallization. It was also observed that the electronic nature of the substituents on the phenyl ring had some impact on the yield of products. Excellent yields of the 2-arylbenzothiazoles with electron-withdrawing substituents were obtained, possibly because benzaldehydes with electron-withdrawing substituents were more activated than other substituents. The n-butylaldehyde was also tested in this catalytic system. It seemed that this procedure was not very conducive to aliphatic aldehydes. The structures of all products were confirmed by 1H NMR, mass spectrometry and comparing the melt points with literature results.

The recovery and reuse of catalysts is highly preferable for sustainable chemical process. Thus, the [N2222][Pro] catalyst was recycled and reused for gram scale synthesis. It was shown that this catalytic system is typically recovered and the catalyst can be easily reused for subsequent reactions with little decrease in yields because of catalyst loss in the recycling process (Table 4). After completion of the reaction, water was added to the reaction mixture. The reaction mixture was then filtered off and the IL catalyst was recovered by evaporating the solvent under vacuum. The catalytic activity of recovered catalyst was retained up to the sixth cycle. In addition, compared with the fresh [N2222][Pro] catalyst, the characteristic bands of reused [N2222][Pro] catalyst was the same in the IR spectrum (Fig. 1). This result proved that [N2222][Pro] catalyst is very stable in this condensation reaction for several runs.

Based on experimental observations and literature reports of similar reaction [28–30], a plausible reaction mechanism was proposed for proline-based ILs catalyzed the aerobic condensation of aromatic aldehydes with o-aminothiophenol (Scheme 2). Firstly, proline-based ILs reacted with the aldehydes group to form intermediate A. The next step involved nucleophilic addition with an amine to generate tetrahedral intermediate B. The thiol of intermediate B is activated by the formation of intramolecular hydrogen bond between the thiol and carboxylate anion in the alkaline condition leading to the formation of intermediate C. This activated thiol group makes nucleophilic attack more easily. Subsequently, cyclization resulted in another intermediate D, then the catalyst [N2222][Pro] was regenerated. Finally, its oxidative dehydrogenation provided the product. Therefore, it is obviously demonstrated that the [N2222][Pro] catalyst are highly favorable for this aerobic condensation and have good yields of 2-arylbenzothiazoles.

Conclusions

We have developed an efficient, green, and gram-scale methodology for the synthesis of 2-arylbenzothiazoles by using proline-based ILs as catalyst. The advantages of this procedure are the simplicity of reaction conditions, nontoxic solvents, and easy workup. This [N2222][Pro] IL catalyst can be also simply recovered and reused for six runs without loss of catalytic activities on the gram-scale synthesis.

Experimental

Apparatus and analysis

Thin-layer chromatography (TLC) was used to monitor the reaction progress. Melting points were recorded in open capillaries and are uncorrected. IR spectra were recorded on an Nicolet 6700 FT-IR spectrophotometer (Thermo Nicolet). 1H NMR spectra were recorded at 400 MHz on a BRUKER AVANCE 400 MHz spectrophotometer using D2O, CDCl3 and DMSO-d6 as solvent and tetramethylsilane (TMS) as internal standard. Elemental analyses were recorded on a EuROVECTOR EA3000 CHNS/O elemental analyzer. High resolution mass spectrometry (HRMS) spectra analysis was performed by electrospray ionization (ESI-micrOTOF). Tetraethylammonium hydroxide (25 % aq) and ethyl lactate (EL) (purity ≥ 99 %) were purchased from Aladdin (Shanghai, China). Other reagents such as aromatic aldehydes, o-aminothiophenol, amino acid, and solvents were of analytical grade and used without any further purification.

Preparation and characterization of [N2222][AA]

Five [N2222][AA] ILs, [N2222][Ser], [N2222][Pro], [N2222][Val], [N2222][Gly], and [N2222][Ala] were synthesized via simple acid–base neutralization reactions with a slight excess of amino acid by stirring at room temperature for 10 h (Fig. 1). The mixture was dried at 60 °C under vacuum, and ethanol was added to the residue. The solution was agitated completely so that the excess amino acids were deposited. After filtration, the solvent was removed by evaporation. The pure [N2222][AA] (≥80 % yields) was obtained in a vacuum oven containing P2O5 at 90 °C for 48 h. The structures of [N2222][AA] ILs were confirmed by 1H NMR, elemental analysis, FT-TR (Fig. 2), and HRMS.

[N 2222 ][Pro]: 1H NMR (D2O) 1.23 (12H, CH 3), 1.68 (3H, NCH2CH 2CH 2CH), 2.06 (1H, NCH2CH2CH 2CH), 2.71 (1H, NCH 2CH2CH2CH), 3.00 (1H, NCH 2CH2CH2CH), 3.22 (8H, CH3CH 2N), 3.43 (1H, NCH2CH2CH2CH) ppm. Elemental analyses: calculated for C13H28N2O2: C, 63.93; H, 11.48; N, 11.48 %. Found: C, 64.10; H, 11.32; N, 11.61 %. HRMS for C13H28N2O2 [M], [M + H-Proline]+ calculated: 130.1590; found: 130.1596. [M–N2222]− calculated: 114.0561; found: 114.0565. Yield: 87 %.

[N 2222 ][Gly]: 1H NMR (D2O) δ = 1.24 (12H, CH 3 CH2N), 3.15 (2H, NCH 2 COO), 3.24 (8H, CH3CH 2 N) ppm. Elemental analyses: calculated for C10H24N2O2: C, 58.82; H; 11.76; N; 13.72 %. Found: C, 59.87; H; 11.69; N; 13.83 %. HRMS for C10H24N2O2 [M], [M + H-Glycine]+ calculated: 130.1590; found: 130.1594. [M-N2222]− calculated: 74.0248; found: 74.0251. Yield: 86 %.

[N 2222 ][Ala]: 1H NMR (D2O) δ = 1.20 (3H, CH 3 CH), 1.25 (12H, CH 3 CH2N), 3.24 (8H, CH3CH 2 N), 3.29 (1H, CH3CH) ppm. Elemental analyses: calculated for C11H26N2O2; C, 57.78; H, 11.40; N, 12.28 %. Found: C, 58.01; H, 11.32; N, 12.33 %. HRMS for C11H26N2O2 [M], [M + H-Alanine]+ calculated: 130.1590; found: 130.1593. [M-N2222]− calculated: 88.0404; found: 88.0406. Yield: 85 %.

[N 2222 ][Val]: 1H NMR (D2O) δ = 0.85 (3H, CH 3CH), 0.93 (3H. CH 3CH), 1.24 (s, 12H, CH 3 CH2N), 1.93 (1H, CH(CH3)2), 3.06 (1H, CHNH2), 3.25 (8H, CH3CH 2 N) ppm. Elemental analyses: calculated for C13H30N2O2: C, 63.41; H, 12.19; N, 11.38 %. Found: C, 63.56; H, 12.12; N, 11.43 %. HRMS for C13H30N2O2 [M], [M + H-Valine]+ calculated: 130.1590; found: 130.1593. [M–N2222]− calculated: 116.0717; found: 116.0722. Yield: 84 %.

[N 2222 ][Ser]: 1H NMR (D2O) δ = 1.25 (12H, CH 3 CH2N), 3.26 (8H, CH3CH 2 N), 3.37 (1H, HOCH2CHCOO), 3.74 (2H, HOCH 2 CHCOO) ppm. Elemental analyses: calculated for C11H26N2O3: C, 56.41; H, 11.11; N, 11.97 %. Found: C, 56.55; H, 10.95; N, 12.07 %, HRMS for C11H26N2O3 [M], [M + H-Serine]+ calculated: 130.1590; found: 130.1594. [M–N2222]− calculated: 104.0353; found: 104.0358. Yield: 88 %.

General procedures for the synthesis of 2-arylbenzothiazoles

[N2222][AA] catalysts (0.4 mmol), benzaldehydes (1.98 mmol), o-aminothiophenol (2.28 mmol), and solvent (5 ml) were added into a round-bottom flask (25 ml) with a magnetic stirrer and condenser. The temperature of the reaction mixture was controlled by using a temperature controller with an accuracy of ±0.01 °C. Then, the reactor was heated to the designated temperature in an oil bath with stirring. After the reaction was completed, deionized water (10 ml) was added to the reaction mixture. The products were precipitated out, and the aqueous phase containing [N2222][AA] ILs was isolated simply by filtration, thus were recovered and reused in the next run after heat treatment to remove water under vacuum at 90 °C for 12 h. The pure products were obtained by recrystallization with EL/water or silica gel column chromatography.

2-Phenylbenzothiazole(2a)

1H NMR (400 MHz, CDCl3) δ = 7.34–7.38 (m, 1H), 7.47–7.51 (m, 4H), 7.85–7.88 (m, 1H), 8.07–8.09 (m, 3H) ppm; MS m/z (MH)+ calcd.: 212.3, found: 212.5; m.p. (°C): 114–116, (lit. 110–112) [1].

2-(4′-Methylphenyl)benzothiazole(2b)

1H NMR (400 MHz, CDCl3) δ = 2.43 (s, 3H) 7.31 (d, J = 8 Hz, 2H) 7.36–7.40 (m, 1H) 7.47–7.51 (m, 1H) 7.89–7.91 (m, 1H) 7.99 (d, J = 8 Hz, 2H) 8.06–8.08 (m, 1H) ppm. MS m/z (MH)+ calcd.: 226.3, found: 226.6; m.p. (°C): 99–101, (lit. 100–102) [1].

2-(4′-Fluorophenyl)benzothiazole(2c)

1H NMR (400 MHz, CDCl3) δ = 6.57–6.61 (m, 2H) 6.70–6.72 (m, 2H) 7.14–7.17 (m, 4H) ppm. MS m/z (MH)+ calcd.: 230.3, found: 230.1; m.p. (°C): 78–79, (lit. 85–86) [1].

2-(4′-Cyanophenyl) benzothiazole(2d)

1H NMR (400 MHz, CDCl3) δ = 7.25–7.27 (m, 2H) 7.57–7.60 (m, 2H) 7.69 (d, J = 8 Hz, 2H) 8.10 (d, J = 8 Hz, 2H) ppm. MS m/z (MH)+ calcd.: 237.3, found: 237.6; m.p. (°C): 91–92, (lit. 94–96) [6].

2-(4′-Methoxylphenyl)benzothiazole(2e)

1H NMR (400 MHz, CDCl3) δ = 3.89 (s, 3H) 7.01 (d, J = 8 Hz, 2H) 7.34–7.38 (m, 1H) 7.46–7.50 (m, 1H) 7.87–7.89 (m, 1H) 8.05 (d, J = 8 Hz, 2H) 8.06–8.08 (m, 1H) ppm. MS m/z (MH)+ calcd.: 242.3, found: 242.2; m.p. (°C): 121–123, (lit. 120–124) [2].

2-(4′-dimethylaminophenyl)benzothiazole(2f)

1H NMR (400 MHz, d6-DMSO) δ = 3.00 (s, 6H) 6.84 (d, J = 8 Hz, 2H) 7.12–7.15 (m, 2H) 7.50–7.52 (m, 2H) 7.99 (d, J = 8 Hz, 2H) ppm. MS m/z (MH)+ calcd.: 255.4, found: 255.8; m.p. (°C): 61–62, (lit. 63–65) [3].

2-(2′-Chlorophenyl)benzothiazole(2g)

1H NMR (400 MHz, CDCl3) δ = 7.38–7.43 (m, 4H) 7.51–7.56 (m, 2H) 8.12–8.14 (m, 1H) 8.21–8.23 (m, 1H) ppm. MS m/z (MH)+ calcd.: 246.7, found: 246.5; m.p. (°C): 82–83, (lit. 83–84) [4].

2-(4′-Bromophenyl)benzothiazole(2h)

1H NMR (400 MHz, CDCl3) δ = 7.39–7.42 (m, 1H) 7.49–7.53 (m, 1H) 7.63 (d, J = 8 Hz, 2H) 7.91 (d, J = 8 Hz, 1H) 7.96 (d, J = 8 Hz, 2H) 8.077.91 (d, J = 8 Hz, 1H) ppm. MS m/z (MH)+ calcd.: 291.2, found: 291.0; m.p. (°C): 133–135, (lit. 129–131) [1].

2-(Thiophen-2′-yl)benzothiazole(2i)

1H NMR (400 MHz, CDCl3) δ = 7.05–7.08 (m, 1H) 7.27–7.31 (m, 1H) 7.38–7.44 (m, 2H) 7.58–7.60 (m, 1H) 7.78 (d, J = 8 Hz, 1H) 7.96 (d, J = 8 Hz, 1H) ppm. MS m/z (MH)+ calcd.: 218.3 found: 218.2; m.p. (°C): 99–100, (lit. 99) [5].

2-Butylbenzothiazole(2j)

1H NMR (400 MHz, CDCl3, ppm): δ 7.92 (d, J = 8.0 Hz 1H), 7.80 (d, J = 8.0 Hz, 1H), 7.40 (t, J = 7.5 Hz, 1H), 7.30 (t, J = 7.3 Hz, 1H), 3.08 (t, J = 7.6 Hz, 2H), 1.86–1.80 (m, 2H), 1.45 (t, J = 7.6 Hz, 2H), 0.92 (t, J = 7.6 Hz, 3H); MS m/z (MH)+ calcd.: 192.3 found: 192.6. Yellow oil.

References

S. Noël, S. Cadet, E. Gras, C. Hureau, Chem. Soc. Rev. 42, 7747 (2013)

S. Massari, D. Daelemans, M.L. Barreca, A. Knezevich, S. Sabatini, V. Cecchetti, A. Marcello, C. Pannecouque, O. Tabarrini, J. Med. Chem. 53, 641 (2010)

I. Navizet, Y.J. Liu, N. Ferreo, H.Y. Xiao, W.H. Fang, R. Lindh, J. Am. Chem. Soc. 132, 706 (2010)

D. Ma, S. Xie, P. Xue, X. Zhang, J. Dong, Y. Jiang, Angew. Chem. Int. Ed. 48, 4222 (2009)

X.J. Mu, J.P. Zou, R.S. Zeng, J.C. Wu, Tetrahedron Lett. 46, 4345 (2005)

J. Hyvl, J. Srogl, Eur. J. Org. Chem. 75, 2849 (2010)

A. Yokooji, T. Okazawa, T. Satoh, M. Miura, M. Nomura, Tetrahedron 59, 5685 (2003)

X.F. Wu, P. Anbarasan, H. Neumann, M. Beller, Angew. Chem. Int. Ed. 49, 7316 (2010)

J. Wang, X.-Z. Zhang, S.-Y. Chen, X.-Q. Yu, Tetrahedron 70, 70245 (2014)

K. Bahrami, M.M. Khodaei, F. Naali, J. Org. Chem. 17, 6835 (2008)

B.S. Londhe, U.R. Pratap, J.R. Mali, R.A. Mane, Bull. Korean Chem. Soc. 31, 2329 (2010)

J. Chang, K. Zhao, S. Pan, Tetrahedron Lett. 43, 951 (2002)

R.S. Varma, R.K. Saini, O. Prakash, Tetrahedron Lett. 38, 2621 (1997)

H.-L. Jin, T.-X. Cheng, J.-X. Chen, Appl. Organomet. Chem. 25, 238 (2011)

R.G. Srivastava, P.S. Venkataramani, Synth. Commun. 18, 1537 (1988)

N. Parikh, D. Kumar, S.R. Roy, A.K. Chakraborti, Chem. Commun. 47, 1797 (2011)

M. Lei, L. Ma, L. Hu, Synth. Commun. 42, 2981 (2012)

W.-H. Chen, Y. Pang, Tetrahedron Lett. 50, 6680 (2009)

W.-J. Yoo, H. Yuan, H. Miyamura, S. Kobayashi, Adv. Synth. Catal. 353, 3085 (2011)

M. Behrooz, S. Hafezeh, Eur. J. Chem. 1, 377 (2010)

A.K. Chakraborti, S. Rudrawar, K.B. Jadhav, G. Kaur, S.V. Chankeshwara, Green Chem. 9, 1335 (2007)

K.U. Sadek, R.A. Mekheimer, A.M.A. Hameed, F. Elnahas, M.H. Elnagdi, Molecules 17, 6011 (2012)

S. Samanta, S. Das, P. Biswas, J. Org. Chem. 78, 11184 (2013)

C. Maton, N. De Vos, C.V. Stevens, Chem. Soc. Rev. 42, 5963 (2013)

P.J. Hallett, T. Welton, Chem. Rev. 111, 3508 (2011)

F. Ouyang, Y. Zhou, Z.-M. Li, N. Hu, D.J. Tao, Korean J. Chem. Eng. 31, 1377 (2014)

Y.Y. Liu, H. Wang, C.P. Wang, J.-P. Wan, RSC Adv. 3, 21369 (2013)

S.N. Rao, D.C. Mohan, S. Adimurthy, Org. Lett. 15, 1496 (2013)

M. Venkatanarayana, P.K. Dubey, Synth. Commun. 42, 1746 (2012)

M.K. Ghorai, S. Samanta, S. Das, Asian J. Org. Chem. 2, 1026 (2013)

Acknowledgments

This work is supported by the Department of Education of Jiangxi Province and Key Laboratory of Functional Small Organic Molecules, Ministry of Education (No. GJJ13214, KLFS-KF-201229).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, ZY., Fang, QS., Zhou, J. et al. Reusable proline-based ionic liquid catalyst for the simple synthesis of 2-arylbenzothiazoles in a biomass medium. Res Chem Intermed 42, 2035–2045 (2016). https://doi.org/10.1007/s11164-015-2133-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-015-2133-z