Abstract

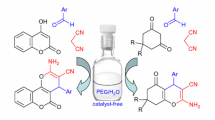

Tartaric acid is a highly effective and efficient catalyst for the one-pot synthesis of highly substituted piperidines through a combination of 1,3-dicarbonyl compounds, aromatic aldehydes, and various amines in methanol at room temperature. The advantages of this protocol are good yields, short reaction time, mild reaction conditions, no need for column chromatography, easy access, simple work-up procedure, and a cheap and biodegradable catalyst.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Multi-component (MCRs) reactions allow compounds to be synthesized in short steps and usually in a one-pot manner [1]. These reaction MCRs play an efficient role in chemistry because of their ability to synthesize small drug-like molecules with several degrees of structural diversity. This group of reactions offers a considerable number of advantages including being time and energy saving while having simple procedures, high bond forming efficiency, low expenditures, very environmentally friendly, and easy access to large compound libraries with the avoidance of protection and deprotection steps, and diverse functionalities, for possible combinatorial investigating of structural variations [2–5]. One-pot multi-component reactions including domino processes with three different starting materials like aldehydes, 1,3-dicarbonyl compounds, and nucleophile compounds have been carried out in recent years [6–9].

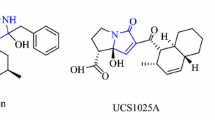

Poly-functionalized piperidines are widely distributed in naturally occurring monocyclic and bicyclic alkaloids and synthetic drugs [10]. Also, piperidine and its derivatives have an important role in drug discovery exhibiting various biological activities such as anti-hypertensive [11], antimalarial [12], neuro-protective [13, 14], antibacterial [15], anticonvulstant [16], and anti-inflammatory activities [17]. Furthermore, it is noteworthy that the substituted piperidines are important therapeutic agents in the treatment of influenza [18–20], diabetes [21, 22], viral infections including AIDS [23, 24], and cancer metastatis [25, 26]. In addition, some of the tetrahydropyridine (THP) derivatives have been found to possess enzyme inhibitory activity versus farnesyltransferase [27] (Fig. 1).

In recent years, the syntheses of functionalized piperidines were reported using a plethora of reagents, such as a combination of l-proline/TFA [12], InCl3 [28, 29], tetrabutylammoniumtribromide (TBATB) [30], bromodimethylsulfonium bromide (BDMS) [31], cerium ammonium nitrate (CAN) [32], iodine [33], ZrOCl2·8H2O [34], VCl3 [35], Bi(NO3)3·5H2O [36], BF3·SiO2 [37], and LaCl3·7H2O [38] as a catalyst. But some of these procedures have disadvantages, such as long reaction times, unsatisfactory yields, highly toxic catalysts, being difficult to prepare, harsh reaction conditions, or the use of expensive catalysts. Therefore, there is a need for a simple and high-yielding environmentally benign method for the one-pot multi-component synthesis of piperidines without these problems.

It is well known that tartaric acid has many applications in the pharmacy, food, and textile industries [39]. Tartaric acid is added to foods in order to give a sour taste, and is usually used as an antioxidant [40]. This compound is also used in the production of jams, sweets, jelly, tinned fruit and vegetables, coca powder and frozen dairy produce, mainly as an acidity adjuster but also in the form of an emulsifier [41]. In regard to acid adjustment, it is one of the strongest naturally occurring acids in fruit and is the strongest acid in grapes and wine (pKa1 = 2.90) [42]. Tartaric acid is relatively microbiologically stable compared to the other naturally occurring organic acids, such as malic and citric acids in the wine industry [41].

As a part of our current studies on the development of efficient multi-component reactions for the preparation of interesting bioactive molecules [43–49], we report here a simple and efficient procedure for the synthesis of highly substituted piperidines via a one-pot five-component reaction between aromatic aldehydes, anilines and β-ketoesters in the presence of tartaric acid as a catalyst in methanol at ambient temperature (Scheme 1).

Experimental

General

Melting points and IR spectra were measured on an Electrothermal 9100 apparatus and a JASCO FT/IR-460 plus spectrometer, respectively. The 1H NMR spectra were recorded on a Bruker DRX-400 Avance instrument with CDCl3 as solvent at 400 MHz. The aromatic aldehydes, anilines, β-ketoesters, and tartaric acid were obtained from Merck (Darmstadt, Germany), Acros (Geel, Belgium), and Fluka (Buchs, Switzerland), and used without further purification.

General procedure for the synthesis of highly functionalized piperidine 4

A solution of aromatic amine 2 (2.0 mmol) and β-ketoester 3 (1.0 mmol) in MeOH (5 mL) was stirred for 20 min in the presence of 0.075 g tartaric acid at room temperature. Next, the aromatic aldehyde 1 (2.0 mmol) was added and the reaction mixture was stirred for the time indicated in Table 2. The progress of the reaction was monitored by thin-layer chromatography (TLC). After completion of the reaction, the thick precipitate was filtered off and washed with ethanol (3 × 2 mL) to give the pure product 4.

Results and discussion

For optimizing the reaction conditions, the one-pot five-component reaction between 4-methyl benzaldehyde, aniline and methyl acetoacetate was chosen as a model reaction (Table 1). A survey of solvents revealed methanol to be the best choice, used directly without rigorous drying. It is noteworthy that no product was obtained in the absence of the catalyst even after 48 h (Table 1, Entry 17), which indicated that the catalyst’s presence is necessary for this transformation. Also, the effect of different solvents and the amount of catalyst were investigated on the yield and rate of reaction. The best result was achieved in the presence of 0.075 g of catalyst in methanol at ambient temperature (Table 1, Entry 14). When the reaction was performed under solvent-free conditions, the product was generated in a moderate yield (25 %) that may be relevant to the lack of catalyst (Table 1, Entry 16).

Different reactions between substituted anilines, benzaldehydes, and methyl/ethyl acetoacetate were examined under the optimized conditions reaction, and the results are summarized in Table 2. These results show that the aldehydes with electron-withdrawing groups reacted effectively with anilines as did electron-donating groups to give the corresponding piperidines in good to high yields. Various substituents on the benzene ring such as OMe, Me, NO2, F, Cl, and Br were tolerated during the reaction. In all cases, the reaction proceeded to obtain piperidines in good yields. However, the reaction of 4-(dimethylamino) benzaldehyde, p-anisidine, and methyl acetoacetate did not produce any piperidine (Table 2, Entry 33).

The structures of all the compounds were characterized by a comparison of their IR and NMR spectra with authentic samples. Also, the relative stereochemistry of these piperidines has been confirmed by single X-ray crystallography analysis in previously reported literature [28–34, 36, 37, 44], and the relative stereochemistry of the products in the present work was proved by comparison of spectroscopic data of some products with those authentic samples.

The formation of piperidines through a Knoevenagel-type intermediate followed by [4 + 2] aza-Diels–Alder reaction has been reported in the literature [12, 31, 34, 35, 38, 45]. The possible reaction mechanism for this five-component reaction is described in Scheme 2. Tartaric acid is a Brønsted acid, which serves as an acid catalyst for the construction of imine 5, formed by the reaction of aromatic aldehyde with aniline. Subsequently, ethyl acetoacetate reacts with aniline to give β-enaminone 6. Benzaldehyde which is retained in the reaction mixture undergoes Knoevenagel condensation with β-enaminone leading to the formation of intermediate 7 and reactive form 8. Due to the diene core present in intermediate 8, it proceeds towards an intramolecular [4 + 2] aza-Diels–Alder reaction with imine 5 (serves as dienophile) which affords the foreseen functionalized piperdine 4 (Scheme 2).

To compare the applicability and efficiency of our catalyst with catalysts reported for the synthesis of piperidine 4e, we have tabulated results for these catalysts (Table 3). It is apparent from Table 3 that tartaric acid remarkably improved the synthesis of piperidine 4e, in terms of reaction time and yield.

Conclusion

In summary, an efficient and simple method has been developed for the formation of highly functionalizaed piperidines via one-pot five-component under mild conditions using tartaric acid as the catalyst in methanol. This reaction can be employed as an efficient approach for the preparation of synthetically and pharmaceutically important piperidine systems. This methodology offered several advantages, such as mild reaction conditions, easy work-up, simple procedure, clean reaction profiles, no need to column chromatography, high yields, and cheap and biodegradable catalyst.

References

L.W. Xu, C.G. Xia, L. Li, J. Org. Chem. 69, 8482 (2004)

A. Domling, Chem. Rev. 106, 17 (2006)

F. Liéby-Muller, C. Simon, T. Constantieux, J. Rodriguez, QSAR Comb. Sci. 25, 432 (2006)

G.V.M. Sharma, K.L. Reddy, P.S. Lakshmi, P.R. Krishn, Synthesis 1, 55 (2006)

L.M. Wang, J. Sheng, L. Zhang, J.W. Han, Z.Y. Fan, H. Tian, C.T. Qian, Tetrahedron 61, 1539 (2005)

S. Benetti, R. Romagnoli, C. De Risi, G. Spalluto, V. Zanirato, Chem. Rev. 95, 1065 (1995)

P. Langer, Chem. Eur. J. 7, 3858 (2001)

P. Langer, Synthesis. 2002, 441 (2002)

C. Simon, T. Constantieux, J. Rodriguez, Eur. J. Org. Chem. 2004, 4957 (2004)

P.S. Watson, B. Jiang, B.A. Scott, Org. Lett. 2, 3679 (2000)

S. Petit, J.P. Nallet, M. Guillard, J. Dreux, R. Chermat, M. Poncelet, C. Bulach, P. Simon, C. Fontaine, M. Barthelmebs, J.L. Imbs, Eur. J. Med. Chem. 26, 19 (1991)

M. Misra, S.K. Pandey, V.P. Pandey, J. Pandey, R. Tripathi, R.P. Tripathi, Bioorg. Med. Chem. 17, 625 (2009)

I. Borza, G. Domany, Curr. Top. Med. Chem. 6, 687 (2006)

L. Mony, J.N. Kew, M.J. Gunthorpe, P. Paoletti, Br. J. Pharmacol. 157, 1301 (2009)

Y. Zhou, V.E. Gregor, B.K. Ayida, G.C. Winters, Z. Sun, D. Murphy, G. Haley, D. Bailey, J.M. Froelich, S. Fish, S.E. Webber, T. Hermann, D. Wall, Bioorg. Med. Chem. Lett. 17, 1206 (2007)

H. Bin, A.M. Crider, J.P. Stables, Eur. J. Med. Chem. 36, 265 (2001)

R. Gitto, L. De Luca, S. Ferro, F. Occhiuto, S. Samperi, G. De Sarro, E. Russo, L. Ciranna, L. Costa, A. Chimirri, Chem. Med. Chem. 3, 1539 (2008)

C.U. Kim, W. Lew, M.A. Williams, H. Liu, L. Zhang, S. Swaminathan, N. Bischofberger, M.S. Chen, D.B. Mendel, C.Y. Tai, W.G. Laver, R.C. Stevens, J. Am. Chem. Soc. 119, 681 (1997)

M. Von Itzstein, W.-Y. Wu, G.B. Kok, M.S. Pegg, J.C. Dyason, B. Jin, T.V. Phan, M.L. Smythe, H.F. White, S.W. Oliver, P.M. Colman, J.N. Varghese, D.M. Ryan, J.M. Woods, R.C. Bethell, V.J. Hothman, J.M. Camreon, C.R. Penn, Nature 363, 418 (1993)

P. Chand, P.L. Kotian, A. Dehghani, Y. El-Kattan, T.H. Lin, T.L. Hutchison, Y. Sudhakar Babu, S. Bantia, A.J. Elliott, J. Montgomery, J. Med. Chem. 44, 4379 (2001)

G.S. Jacob, Curr. Opin. Struct. Biol. 5, 605 (1995)

J.L. Treadway, P. Mendys, D.J. Hoover, Opin. Invest. Drugs 10, 439 (2001)

J.E. Groopman, Rev. Infect. Dis. 12, 931 (1990)

G.B. Karlsson, T.D. Butters, R.A. Dwek, F.M. Platt, J. Biol. Chem. 268, 570 (1993)

Y. Nishimura, T. Satoh, H. Adachi, S. Kondo, T. Takeuchi, M. Azetaka, H. Fukuyasu, Y. Iizuka, J. Med. Chem. 40, 2626 (1997)

N. Zitzmann, A.S. Mehta, S. Carrouee, T.D. Butters, F.M. Platt, J. Mc Cauley, B.S. Blumberg, R.A. Dwek, T.M. Block, Proc. Natl. Acad. Sci. USA 96, 11878 (1999)

G. Balme, E. Bossharth, N. Monteiro, Eur. J. Org. Chem. 2003, 4101 (2003)

P.A. Clarke, A.V. Zaytzev, A.C. Whitwood, Tetrahedron Lett. 48, 5209 (2007)

P.A. Clarke, A.V. Zaytzev, A.C. Whitwood, Synthesis. 2008, 3530 (2008)

A.T. Khan, M. Lal, M.M. Khan, Tetrahedron Lett. 51, 4419 (2010)

A.T. Khan, T. Parvin, L.H. Choudhury, J. Org. Chem. 73, 8398 (2008)

H.-J. Wang, L.-P. Mo, Z.-H. Zhang, ACS. Comb. Sci. 13, 181 (2011)

A.T. Khan, M.M. Khan, K.K.R. Bannuru, Tetrahedron 66, 7762 (2010)

S. Mishra, R. Ghosh, Tetrahedron Lett. 52, 2857 (2011)

S. Pal, L.H. Choudhury, T. Parvin, Mol. Divers. 16, 129 (2012)

G. Brahamachari, S. Das, Tetrahedron Lett. 53, 1479 (2012)

R. Ramachandran, S. Jayanthi, Y.T. Jeong, Tetrahedron 68, 363 (2012)

B. Umamahesh, V. Sathesh, G. Ramachandran, M. Sathishkumar, K. Sathiyanarayanan, Catal. Lett. 142, 895 (2012)

K. Zhang, M. Wang, D. Wang, C. Gao, J. Membr. Sci. 341, 246 (2009)

N. Marchitan, C. Cojocaru, A. Mereuta, G. Duca, I. Cretescu, M. Gonta, Sep. Purif. Technol. 75, 273 (2010)

A.C. Clark, P.D. Prenzler, G.R. Scollary, Food Chem. 102, 905 (2007)

H.A. Azab, I.T. Ahmed, M.R. Mahmoud, J. Chem. Eng. Data 42, 593 (1997)

S.S. Sajadikhah, M.T. Maghsoodlou, N. Hazeri, S.M. Habibi-Khorassani, S.J. Shams-Najafi, Monatsh. Chem. 143, 939 (2012)

S.S. Sajadikhah, M.T. Maghsoodlou, N. Hazeri, S.M. Habibi-Khorassani, A.C. Willis, Chin. Chem. Lett. 23, 569 (2012)

M.R. Mousavi, J. Aboonajmi, M.T. Maghsoodlou, N. Hazeri, S.M. Habibi-Khorassani, M. Safarzaei, Lett. Org. Chem. 10, 171 (2013)

J. Aboonajmi, M.R. Mousavi, M.T. Maghsoodlou T.N. Hazeri, A. Masoumnia, Res. Chem. Intermed. doi:10.1007/s11164-013-1320-z

N. Hazeri, M.T. Maghsoodlou, S.M. Habibi-Khorassani, J. Aboonajmi, S.S. Sajadikhah, J. Chin. Chem. Soc. 60, 355 (2013)

M. Lashkari, M.T. Maghsoodlou, N. Hazeri, S.M. Habibi-Khorassani, S.S. Sajadikhah, R. Doostmohamadi, Synth. Commun. 43, 635 (2013)

S.S. Sajadikhah, N. Hazeri, M.T. Maghsoodlou, S.M. Habibi-Khorassani, A. Beigbabaei, M. Lashkari, J. Chem. Res. 36, 463 (2012)

Acknowledgment

We gratefully acknowledge financial support from the Research Council of University of Sistan and Baluchestan, Iran.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aboonajmi, J., Maghsoodlou, M.T., Hazeri, N. et al. Tartaric acid: a natural, green and highly efficient catalyst for the one-pot synthesis of functionalized piperidines. Res Chem Intermed 41, 8057–8065 (2015). https://doi.org/10.1007/s11164-014-1877-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-014-1877-1