Abstract

In the present work, a chitosanase was induced from a squid pen powder-containing Bacillus cereus TKU031 medium, and the addition of 0.05 % (w/v) boric acid or sodium tetraborate resulted in 195 and 177 % enhancement, respectively, in TKU031 chitosanase production. The purified TKU031 chitosanase exhibited optimum activity at pH 5 and 50 °C and was stable at pH 5–9 and <50 °C. The TKU031 chitosanase that was used for chitooligomers preparation was studied. The enzyme products revealed various chitooligomers with different degrees of polymerisation from 3 to 8, as determined by a MALDI-TOF–mass spectrometer, confirming the endo-type nature of the TKU031 chitosanase.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Chitosan is a polysaccharide of β-1,4-linked glucosamine (GlcN) residues, partially substituted with N-acetyl groups. Applications of chitosan have been developed in industries such as food production and pharmaceutics [1–3]. Recent studies on chitosan have attracted interest for oligosaccharide conversion because oligosaccharides are not only water-soluble but also possess versatile functional properties such as antitumor and antimicrobial activities [4–7]. Enzymatic processes to produce chitosan oligosaccharides is an ideal alternative to traditional chemical degradation which needs acid hydrolysis and results in low yields of oligosaccharides. Among the microbial chitosanases, most of the chitinase- or chitosanase-producing strains use chitin or chitosan as a major carbon source [8–10]. Among the natural chitinous resources, fishery wastes (shrimp/crab shells and squid pens) have an especially high content of chitin. Direct utilisation of shellfish waste as the sole carbon/nitrogen source to produce chitosanase not only solves environmental problems but also decreases microbial chitosanase production costs [1].

The use of boronic acids as inhibitors of bacterial enzymes has been reported recently [11]. However, in our previous study, we found that a small synthetic boron-containing molecule could enhance the growth of a chitosanase-producing strain in squid pen powder (SPP)-containing medium [12]. This result stimulated us to investigate whether common boric compounds could also enhance the growth of other Bacillus spp. chitosanase-producing strains and their chitosanase production. Therefore, the aim of this study was to investigate the culture conditions and effects of boric compounds for the production of chitosanase induced by SPP from a strain in soil, Bacillus cereus TKU031. Furthermore, the TKU031 chitosanase was purified and its biochemical features were also characterised. In addition, we also report the applications of the endo-type TKU031 chitosanase in functional chitooligomers production.

Materials and methods

Materials

The SPP used in these experiments was prepared as described previously [6]. The squid pens were purchased from Shin-Ma Frozen Food (I-Lan, Taiwan). During the preparation of the SPP, the squid pens were washed thoroughly with tap water and then dried. The resulting dried materials were milled to powders for use as the carbon source for chitosanase production. DEAE-Sepharose CL-6B was purchased from GE Healthcare UK (Little Chalfont, Buckinghamshire, UK). The weak base anion exchange Macro-prep DEAE was obtained from Bio-Rad (Hercules, CA, USA). All other reagents used were of the highest grade available.

Screening and identification of chitosanase-producing strains

The microorganisms isolated from soil samples collected at different locations in northern Taiwan were screened on agar plates containing 1 % SPP, 0.1 % K2HPO4, 0.05 % MgSO4·7H2O, and 1.5 % agar powder (pH 7). The plates were incubated at 30 °C for 2 days. The organisms obtained from this screening were subcultured in liquid media (containing 1 % SPP, 0.1 % K2HPO4, and 0.05 % MgSO4·7H2O) in shaking flasks at 30 °C on a rotary shaker (150 rpm; Yih Der LM-570R). After incubation for 2 days, the culture broth was centrifuged (4 °C at 12,000g for 20 min; Kubota 5922), and the supernatants were collected for the measurement of chitosanase activity using the procedure described below. The TKU031 strain showed the highest chitosanase activity, and it was isolated, maintained on SPP agar, and used throughout the study.

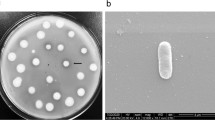

The bacterial strain TKU031 was identified using morphological, physiological, and biochemical parameters as well as a 16S rDNA-based sequence analysis after PCR amplification with specific primers. The nucleotide bases of the DNA sequence obtained were compiled and compared with sequences in the GenBank databases using the BLAST program. Further identification of strain TKU031 was performed using the analytical profile index (API).

Optimal chitosanase production

Different incubation periods (1–5 days) were employed to study chitosanase production. The SPP was used as a sole carbon/nitrogen source, and the boric compounds (boric acid and sodium tetraborate) were added in the liquid media containing 0.1 % (w/v) K2HPO4 and 0.05 % (w/v) MgSO4·7H2O (pH 7) to assess optimal chitosanase production from B. cereus TKU031. The optimal culturing temperature was investigated (25–37 °C). Similarly, the optimum pH was determined to be in the range from 4 to 11. After incubation with the optimal process, the culture broth was centrifuged (4 °C at 12,000g for 20 min), and the supernatant was used for further purification via chromatography.

Chitosanase activity measurement

Enzyme chitosanase activity was measured by incubating 0.2 mL enzyme solution with 1 mL 0.3 % (w/v) water-soluble chitosan (Kiotec, Hsinchu, Taiwan; with 60 % deacetylation) in 50 mM phosphate buffer, pH 7, at 37 °C for 30 min. The reaction was stopped by heating the reaction mixture to 100 °C for 15 min. The amount of reducing sugar produced was measured using the method of Imoto and Yagishita [13] with glucosamine as a reference compound; 1 U of enzyme activity was defined as the amount of enzyme that produced 1 μmol reducing sugars/min. The specific activity was expressed as units per mg protein (U/mg protein) of the enzyme extract.

Purification of TKU031 chitosanase

DEAE-Sepharose CL-6B chromatography

Ammonium sulphate (608 g/L) was added to the culture supernatant (950 mL). The resulting mixture was stored at 4 °C overnight, and the precipitate that had formed was collected by centrifugation at 4 °C for 20 min at 12,000g. The precipitate was then dissolved in a small amount of 50 mM sodium phosphate buffer (pH 7) and dialysed against the buffer. The resulting dialysate was loaded onto a DEAE-Sepharose CL-6B column (5 cm × 30 cm) that had been equilibrated with 50 mM sodium phosphate buffer (pH 7). One peak exhibiting chitosanase activity was washed from the column with the same buffer, and the other chitosanase was eluted with a linear gradient of 0–1 M NaCl in the same buffer. The fractions of the two peaks containing chitosanase activity were independently pooled and concentrated using ammonium sulphate precipitation. The resultant precipitate was collected by centrifugation and dissolved in 5 mL of 50 mM sodium phosphate buffer (pH 7).

Macro-prep DEAE chromatography

The obtained enzyme solution (the adsorbed chitosanase fractions from the DEAE-Sepharose CL-6B column) was then chromatographed on a Macro-prep DEAE column (12.6 mm × 40 mm) that had been equilibrated with 50 mM sodium phosphate buffer (pH 7). The chitosanase was eluted using a linear 0–1 M NaCl gradient in the same buffer. The fractions containing chitosanase activity were pooled and concentrated using ammonium sulphate precipitation. The pooled enzyme solution fractions were used as a purified preparation.

Protein determination

The protein content was determined using the Bradford method with a Bio-Rad dye reagent concentrate and bovine serum albumin as the standard. After column chromatography, the protein concentration was estimated by measuring the absorbance at 280 nm [6].

Determination of molecular mass

The molecular mass of the purified chitosanase was determined using sodium dodecyl sulfate-polyacrylamide gel electrophoresis (SDS-PAGE) with 12.5 % acrylamide and 2.67 % methylene bis acrylamide in a 0.375 M Tris–HCl buffer (pH 8.8) with 0.1 % (w/v) SDS. Before electrophoresis, proteins were exposed overnight to 10 mM phosphate buffer (pH 7) containing β-mercaptoethanol. The electrode buffer was 25 mM Tris, 192 mM glycine, and 0.1 % (w/v) SDS (pH 8.3). After electrophoresis, the gels were stained with Coomassie Brilliant Blue R-250 in a methanol–acetic acid–water (5:1:5, v/v) solution and decoloured in 7 % acetic acid [6].

Effect of pH and temperature on enzyme activities

The optimum pHs of TKU031 chitosanase were studied by assaying the samples at different pH values. The pH stability of TKU031 chitosanase was determined by measuring the residual activity at pH 7 as described above after the sample had been dialysed against a 50 mM buffer solution of various pH values 3–11 in seamless cellulose tubing (Sankyo). The buffer systems used were glycine·HCl (50 mM, pH 3), acetate (50 mM, pH 4–5), phosphate (50 mM, pH 6–8) and Na2CO3–NaHCO3 (50 mM, pH 9–11). To determine the optimum temperatures for TKU031 chitosanase, the activity values of the samples were measured at various temperatures (25–90 °C). The thermal stability of TKU031 chitosanase was studied by incubating the samples at various temperatures for 60 min. The residual activity was measured as described above.

Results and discussion

Isolation and identification of a chitosanase-producing strain

From the soil samples, five strains with chitosanase activity were isolated, and one of these strains had high chitosanase activity (data not shown). The TKU031 strain produced the highest chitosanase activity and was selected for further study. The potent TKU031 strain was selected to optimise processes and nutritional parameters.

Strain TKU031 is a Gram-positive and endospore-forming Bacillus, with catalase but without oxidase, which grows in both aerobic and anaerobic environments. According to the results of 16S rDNA partial nucleotide sequence (approximately 1.5 kbp) analysis, strain TKU031 is most similar to Bacillus sp. According to the API identification, strain TKU031 was closest to B. cereus with 97 % similarity. Therefore, the isolate was identified as B. cereus.

Production of chitosanase

Chitosanases have been extensively applied in industry and biotechnology [1, 4]. It is important for larger-scale chitosanase production. The production of chitosanase by strain TKU031 was investigated during 5 days of cultivation in the production medium. The 100 mL of basal medium (0.1 % K2HPO4 and 0.05 % MgSO4·7H2O, pH 7) containing 1 % SPP was the most suitable for the production of chitosanase by strain TKU031 at 37 °C. Exponential growth was observed for 2 days, and the stationary phase was reached after 3 days. The highest chitosanase activity of B. cereus TKU031 was detected in the culture on the second day of bacterial growth (data not shown).

In our previous study, we found that a small synthetic boron-containing molecule could enhance the growth of a chitosanase-producing strain in SPP-containing medium [12]. To investigate whether the common boric compounds could also enhance the growth of other Bacillus spp. chitosanase-producing strains, boric acid and sodium tetraborate were added in the medium for testing as inhibitors or activators of TKU031 growth and TKU031 chitosanase. The growth of B. cereus TKU031 and TKU031 chitosanase production were carried out at 37 °C for 3 days in 100 mL of culture medium (0.1 % K2HPO4, 0.05 % MgSO4·7H2O, and 1 % SPP, pH 7) containing additional boric compounds of 0.05–0.2 % (w/v) boric acid or sodium tetraborate, respectively. The results showed that 0.05–0.2 % (w/v) boric acid inhibited B. cereus TKU031 growth by the second day, but by the third day, 0.05 and 0.1 % (w/v) boric acid had no significant effect on B. cereus TKU031 growth (Fig. 1a). However, 0.05 % (w/v) boric acid enhanced TKU031 chitosanase production by the second day (Fig. 1b). The results of sodium tetraborate were similar to the results of boric acid (Fig. 1c, d). When the strain was cultured for 2 days, boric acid enhanced TKU031 chitosanase production most obviously (195 %), followed by sodium tetraborate for 3 days (177 %).

Effects of the boric compounds on the growth of B. cereus TKU031 (a, c) and chitosanase production (b, d). a, c Effects of boric acid (a) and sodium tetraborate (c) on the growth of B. cereus TKU031. Strain TKU031 was cultured in an SPP-containing medium without (white bars) or with (black bars) 0.05 % (w/v), (dark gray bars) 0.1 % (w/v), (light gray bars) 0.2 % (w/v) boric acid or sodium tetraborate. b, d Effects of boric acid (b) and sodium tetraborate (d) on the chitosanase production from B. cereus TKU031. Strain TKU031 was cultured in an SPP-containing medium without (filled circles) or with (open circles) 0.05 % (w/v), (filled down-pointing triangles) 0.1 % (w/v), (open up-pointing triangles) 0.2 % (w/v) boric acid or sodium tetraborate

To investigate the role which the boric compounds played in the strain and chitosanase production. B. cereus TKU031 was incubated for 2 days without the boric compounds in the medium. The culture supernatant of B. cereus TKU031 was assayed the enzyme activity of chitosanase as the control sample. The boric compounds of 0.05–0.1 % (w/v) boric acid or sodium tetraborate were added, respectively, and the boric compounds interacted with TKU031 chitosanase for 5 min prior to substrate addition. The boric acid exhibited a slight inhibition (97 %) in TKU031 chitosanase activity at 0.05 % (w/v), while the pre-treatment-elicited inhibition (at the same concentration) with sodium tetraborate was 86 %. The results proved that the enhancement of TKU031chitosanase activity was related to the utilisation of the boric compounds by B. cereus TKU031.

The maximum activity of TKU031 chitosanase appeared on the second day of incubation with 0.05 % (w/v) boric acid in the medium. Thus, incubating in 100 mL of 1 % (w/v) SPP and 0.05 % (w/v) boric acid containing media (pH 7) at 37 °C for 2 days was a better condition for the production of TKU031 chitosanase (0.039 U/mL) by strain TKU031.

Purification of chitosanase

The purification of B. cereus TKU031 chitosanase from the culture supernatant was described under “Materials and methods”. A chitosanase was purified from B. cereus TKU031 cultures using a series of purification procedures presented in Table 1. Strain TKU031 secreted two chitosanases. One was washed from the DEAE-Sepharose CL-6B column with the same buffer and the other was eluted in the column. The two chitosanases could be completely separated in the DEAE-Sepharose CL-6B column. The eluted fraction was responsible for most of the chitosanase activity and was pooled for further purification on the Macro-prep DEAE column. After the two chromatography steps, TKU031 chitosanase was purified. As shown in Table 1, the purification steps were combined to give an overall purification of approximately 407.3-fold for chitosanase. The overall activity yield of chitosanase was 4 % with specific chitosanase activities of 2.444 U/mg. The final amount of chitosanase obtained was 0.9 mg. The molecular mass of the purified chitosanase was confirmed to be approximately 43 kDa by SDS-PAGE (Fig. 2). The molecular mass of the TKU031 chitosanase (43 kDa) was similar to the masses of chitosanases from other Bacillus species/strains, such as B. subtilis IMR-NK1 (41 kDa) [14], B. cereus S1 (45 kDa) [8], Bacillus sp. KCTC0377BP (45 kDa) [15], Bacillus sp. 739 (46 kDa) [16], and Bacillus sp. P16 (45 kDa) [17]. The molecular mass of the TKU031 chitosanase was markedly different from the masses of chitosanase from other Bacillus species/strains, such as Bacillus sp. MET1299 (52 kDa) [18], B. subtilis GM9804 (27 kDa) [19], B. subtilis KH-1 (28 kDa) [20], and Bacillus sp. DAU101 (27 kDa) [21].

SDS-PAGE analysis of the chitosanase produced by B. cereus TKU031. Lanes M molecular markers (170, 130, 95, 72, 55, 43, 34, 26, 17, and 10 kDa), 1 culture supernatant, 2 crude enzyme, 3 adsorbed chitosanase fractions after DEAE-Sepharose CL-6B chromatography, 4 adsorbed chitosanase fractions after Macro-prep DEAE chromatography

Effects of pH and temperature

The pH activity profiles of TKU031 chitosanase revealed maximum activity at pH 5 (Fig. 3a). The optimum pH 5 for TKU031 chitosanase activity was similar to that of most bacterial chitosanases, which display optimum activities at acidic pH values in a range from 4.5 to 6.5 [9, 10]. The pH stability profiles of TKU031 chitosanase were determined by measurement of the residual activity at pH 7 after incubation at various pH values at 37 °C for 60 min. The TKU031 chitosanase were relatively stable at pH 5–9 retaining more than 95 % of the initial activity (Fig. 3a). The TKU031 chitosanase became more sensitive to pH changes below pH 5 and beyond pH 9. The decrease of activity at lower and higher pH ranges may be due to the instability of the protein, rather than an acid–base catalytic mechanism reported in previous results [10, 22].

The effect of temperature on the activity of TKU031 chitosanase was also studied. The optimum temperature for TKU031 chitosanase was 50 °C (Fig. 3b). To examine the thermal stability of TKU031 chitosanase, the enzyme solution in 50 mM phosphate buffer (pH 7) was allowed to incubate for 60 min at various temperatures, then the residual activity was measured. The TKU031 chitosanase maintained its initial activity from 20 to 40 °C and had 75 % of its activity at 50 °C, but it was completely inactivated at 60 °C (Fig. 3b).

Substrate specificity

For the substrate specificity of TKU031 chitosanase, chitin and chitosan with degrees of deacetylation (DD) ranging from 60 to 98 % were used as substrates, as summarised in Table 2. The TKU031 chitosanase could hydrolyse chitosan, but it exhibited no activity on colloidal chitin, chitin, and carboxylmethyl cellulose (CMC). These results indicate that the physical form of the substrate affects the rate of hydrolysis. In previous reports, most bacterial chitosanases hydrolyse chitosan efficiently and chitin to a lesser extent [10].

Chitosan oligosaccharide preparation and product analysis

The chitosan oligosaccharides were produced from the water-soluble chitosan with TKU031 chitosanase. The course of chitosan sample degradation was conveniently studied by measurement of total and reducing sugar. The results revealed the total sugar and reducing sugar of the sample as a function of reaction time. The chitosan sample total and reducing sugar values produced a similar pattern (Fig. 4). The total and reducing sugar increased and the chitosan sample recovery decreased dramatically in the early reaction stage, which can be attributed to an endo-type degradation process. The TKU031 chitosanase was added to a reaction solution after 5 days, but it did not improve the increase in total and reducing sugar levels. Selective precipitation in 90 % methanol and acetone solutions was performed to obtain low degrees of polymerisation (DP) oligomers as described earlier [5]. Using MALDI-TOF analysis of the 90 % acetone solution precipitation, it appeared that the chitosan oligosaccharides had DP up to 8. The higher DP chitooligomers were precipitated as a light yellow powder in the methanol solution. The low DP oligomer fraction MALDI-TOF–MS (mass spectra) revealed pronounced differences among crude enzyme-generated chitooligomers, as demonstrated for chitosan depolymerisation. The hydrolysates contained chitooligomers (GlcN-oligomers) and several partial N-acetylated forms (Table 3). The TKU031 chitosanase reaction product is a mixture of DP 3–8 hetero-chitooligomers (Table 3). From these results, chitosan hydrolysis by the TKU031 chitosanase combined with a selective methanol precipitation is a quick and simple method to obtain good chitooligosaccharide yields with DPs up to 8 and low molecular weight oligomers.

References

S.L. Wang, T.W. Liang, Y.H. Yen, Carbohydr. Polym. 84, 732 (2011)

H.P. Li, L. Qin, Z.D. Wang, S. Li, Res. Chem. Intermed. 38, 1421 (2012)

A.I. Khalaf, F.M. Helaly, S.M. El-Sawy, Res. Chem. Intermed. (2013). doi:10.1007/s11164-013-1046-y

A. Busilacchi, A. Gigante, M. Mattioli-Belmonte, S. Manzotti, R.A.A. Muzzarelli, Carbohydr. Polym. 98, 665 (2013)

T.W. Liang, Y.J. Chen, Y.H. Yen, S.L. Wang, Process Biochem. 42, 527 (2007)

S.L. Wang, T.Y. Lin, Y.H. Yen, H.F. Liao, Y.J. Chen, Carbohydr. Res. 341, 2507 (2006)

S.L. Wang, H.T. Lin, T.W. Liang, Y.J. Chen, Y.H. Yen, S.P. Guo, Bioresour. Technol. 99, 4386 (2008)

M. Kurakake, S. Yo-u, K. Nakagawa, M. Sugihara, T. Komaki, Curr. Microbiol. 40, 6 (2000)

X.A. Gao, W.T. Ju, W.J. Jung, R.D. Park, Carbohydr. Polym. 72, 513 (2008)

X. Jiang, D. Chen, L. Chen, G. Yang, S. Zou, Carbohydr. Res. 355, 40 (2012)

V.M. Dembitsky, A.A.A. Al Quntar, M. Srebnik, Chem. Rev. 111, 209 (2011)

T.W. Liang, Y.Y. Chen, P.S. Pan, S.L. Wang, Int. J. Biol. Macromol. 63, 8 (2014)

T. Imoto, K. Yagishita, Agric. Biol. Chem. 35, 1154 (1971)

C.L. Chiang, C.T. Chang, H.Y. Sung, Enzym. Microb. Technol. 32, 260 (2003)

Y.J. Choi, E.J. Kim, Z. Piao, Y.C. Yun, Y.C. Shin, Appl. Environ. Microbiol. 70, 4522 (2004)

G.E. Aktuganov, A.V. Shirokov, A.I. Melent’ev, Prikl. Biokhim. Mikrobiol. 39, 536 (2003)

Y.Y. Jo, K.J. Jo, Y.L. Jin, K.Y. Kim, J.H. Shim, Y.W. Kim, R.D. Park, Biosci. Biotechnol. Biochem. 67, 1875 (2003)

P.I. Kim, T.H. Kang, K.J. Chung, I.S. Kim, K.C. Chung, FEMS Microbiol. Lett. 240, 31 (2004)

A. Colomer-Pallas, Y. Pereira, M.F. Petit-Glatron, R. Chambert, Biochem. J. 369, 731 (2003)

C.A. Omumasaba, N. Yoshida, Y. Sekiguchi, K. Kariya, K. Ogawa, J. Gen. Appl. Microbiol. 46, 19 (2000)

Y.S. Lee, J.S. Yoo, S.Y. Chung, Y.C. Lee, Y.S. Cho, Y.L. Choi, Appl. Microbiol. Biotechnol. 73, 113 (2006)

T. Katsumi, M. Lacombe-Harvey, H. Tremblay, R. Brzezinski, T. Fukamizo, Biochem. Biophys. Res. Commun. 338, 1839 (2005)

Acknowledgment

This work was supported in part by a Grant from the National Science Council, Taiwan (NSC 102-2313-B-032-001-MY3, NSC 102-2621-M-032-005 and NSC 102-2811-B-032-001).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wang, CL., Su, JW., Liang, TW. et al. Production, purification and characterisation of a chitosanase from Bacillus cereus . Res Chem Intermed 40, 2237–2248 (2014). https://doi.org/10.1007/s11164-014-1601-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-014-1601-1