Abstract

Biosynthesis of noble metal nanoparticles is a vast developing area of research. In the present study, silver nanoparticles (Ag-NPs) were synthesized from aqueous silver nitrate through a simple and biosynthetic route using water extract of Curcuma longa (C. longa) tuber powder, which acted simultaneousl as a reductant and stabilizery. The as-prepared samples are characterized using UV–Visible, XRD, TEM, SEM, EDXF, and FT-IR techniques. The formation of Ag-NPs is evidenced by the appearance of the signatory brown color of the solution and UV–vis spectra. Formation of Ag/C. longa was determined by UV–Vis spectroscopy where surface plasmon absorption maxima can be observed at 457–415 nm from the UV–Vis spectrum. The XRD analysis shows that the Ag-NPs are of a face-centered cubic structure. Well-dispersed Ag-NPs with anisotropic and isotropic morphology for 5, 10, and 20 mL of C. longa water extract having a size less than 10 nm are seen in TEM images. The optimum volume extraction to synthesize smallest particle size was 20 mL with mean diameter and standard division 4.90 ± 1.42 nm. FT-IR spectrum indicates the presence of different functional groups in capping the nanoparticles with C. longa. The zeta potential analysis results indicated that the charge of C. longa was negative and increased in Ag/C. longa emulsion with increasing of volumes of extract used (10–20 mL). The most needed outcome of this work will be the development of value-added products from C. longa for biomedical and nanotechnology-based industries.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Green nanotechnology is an area of interest having significant focus in present scenarios with the important objective of facilitating the manufacture of nanotechnology-based products that area eco-friendly and safer for all beings, and with sustainable commercial viability. The “green synthesis” of metal nanoparticles receives greater attention due to their unusual optical, chemical, photo-chemical, and electronic properties [1]. Metal nanoparticles, especially the noble metals, have mainly been studied because of their strong optical absorption in the visible region caused by the collective excitation of the free electron gas [2].

Among noble metal nanoparticles, silver nanoparticles have a wide area of interest as they have a large number of applications such as in non-linear optics, spectrally selective coatings for solar energy absorption, biolabeling, intercalation materials for electrical batteries as optical receptors, as catalyst in chemical reactions, and as antibacterial capacities.

Silver nanoparticles (Ag-NPs) have definite properties. They may perhaps have numerous applications in the fields of dentistry, clothing, catalysis, mirrors, optics, photography, electronics, and food industries [3]. Because of such a broad variety of applications, a wide range of different preparation methods have been developed. However, the developing methods of Ag-NPs preparation must give preference to controlling the size of Ag-NPs. Therefore, nanosilver with small particle size and devoid of aggregation between particles is favored.

There are several ways to reduce Ag+; for instance, use of γ-rays [4], UV irradiation [5], heating and electrochemical reduction [6], application of reducing chemicals, such as hydrazine [7], sodium borohydride [8–10], polyethylene glycerol [11], N,N-dimethylformamide [12], glucose [13], ethylene glycol [14], formaldehyde [15], sodium in liquid ammonia, etc. [16]. However, there is still need for a more economic, commercially viable as well environmentally green synthesis route to synthesize Ag-NPs. The green synthesis of Ag-NPs involves three main steps, which must be evaluated based on green chemistry perspectives, including selection of solvent medium, reducing agent, and nontoxic stabilizers for Ag-NPs [17].

The biosynthesis of nanoparticles, which represents a connection between biotechnology and nanotechnology, has received increasing consideration due to the growing need to develop environmentally friendly technologies for material syntheses. The search for appropriate biomaterials for the biosynthesis of nanoparticles continues through many different synthetic methods [18].

The biosynthetic method using plant extracts has received more attention than chemical and physical methods and even than the use of microbes. The method is suitable for nanoscale metal synthesis due to the absence of any requirement to maintain an aseptic environment [19]. The possibility of using plant materials for the synthesis of nanoscale metals was reported initially by Gardea-Torresdey et al. [20, 21]. Later, the bioreduction of various metals to nanosize materials of various shapes, capable of meeting the requirements of diverse industrial applications, was extensively studied [22]. In continuation, we have demonstrated the prospect of using Vitex Negundo L. leaf and Callicarpa manigayi stem bark methanolic extracts for the synthesis of the Ag-NPs at ambient conditions, without any additive protecting nanoparticles from aggregating, template-shaping nanoparticles or accelerants [23, 24].

In this paper, we present an environmentally friendly, ultrafast, one-step, cost-efficient green method for producing Ag/C. longa. The Ag-NPs were prepared using silver nitrate as silver precursor and C. longa tuber powder water extract as reducing agent and stabilizer. Also, the effect of different volumes of C. longa tuber powder water extract was investigated on controling the size of Ag-NPs.

Materials and Methods

Materials

The C. longa tubers were purchased from a local market in Malaysia. AgNO3 (99.98 %) was used as a silver precursor, and was provided by Merck (Frankfurt, Germany). All reagents in this effort were analytical grade and were used as received without further purification. All solutions were freshly prepared using double-distilled water and kept in the dark to avoid any photochemical reactions. All glassware used in experimental procedures were cleaned in a fresh solution of HNO3/HCl (3:1, v/v), washed thoroughly with double distilled water, and dried before use.

Extraction Preparation

The C. longa tubers are shown in Fig. 1a. The C. longa tubers were washed to remove the adhering mud particles and possible impurities. Later, they were dried in sunlight for a week to completely remove the moisture. The tubers were cut into small pieces, powdered in a mixer, and then sieved using a 20-mesh sieve to get a uniform size range. The final sieved powder was used for all further studies (Fig. 1b). For the production of the extract, 0.1 g of C. longa tuber powder was added to a 100-mL Erlenmeyer flask with 20 mL sterile distilled water and then mixed for 4 h in room temperature.

Synthesis of Ag/C. longa emulsion

Briefly, aqueous extract of tubers C. longa (0.25 g) was added to distilled de-ionized water (50 mL) with vigorous stirring for 4 h. Forty milliliters of Ag NO3 (1 × 10−3 M) were then added to 1, 2, 5, 10, and 20 mL of C. longa extract at different five cuvettes and mixed at room temperature (25 °C) for 24 h, respectively. Ag-NPs were gradually obtained during the incubation period. Throughout the reduction process, all solutions were kept at a room temperature in the dark to avoid any photochemical reactions. All solution components were purged with nitrogen gas prior to use. Subsequently, reduction proceeded in the presence of nitrogen to eliminate oxygen. The obtained colloidal suspensions of [Ag (C. longa)] were then centrifuged at 15,000 rpm for 20 min and washed four times to remove silver ion residue. The precipitate nanoparticles were then dried overnight at 30 °C under vacuum overnight to obtain the [Ag (C. longa)].

Characterization methods and instruments

The prepared Ag/C. longa were characterized by ultraviolet–visible spectroscopy (UV–Vis), X-ray diffraction (XRD), transmission electron microscopy (TEM), scanning electron microscopy (SEM), energy dispersive X-ray fluorescence spectrometry (EDXRF), and Fourier transform infrared (FT-IR) spectroscopy. The UV–Vis spectra were recorded over the 300–800 nm range with a UV 1650 PC-Shimadzu B UV–Vis spectrophotometer (Shimadzu. Osaka, Japan). The structures of the Ag-NPs produced were examined by X-ray diffraction (XRD-6000; Shimadzu). The XRD patterns were recorded at a scan speed of 4°/min. TEM observations were carried out on a H-7100 electron microscope (Hitachi, Tokyo, Japan), and the particle size distributions were determined using the UTHSCSA Image Tool v.3.00 program. SEM was performed using a Philips XL-30 instrument (Philips, Eindhoven, Netherlands) to study the morphology of samples. The EDXRF was carried out on a DX-700HS spectrometer (Shimadzu). Meanwhile, the FT-IR spectra were recorded over the range of 400–4,000 cm−1 using a FT-IR Series 100, 1650 Perkin Elmer spectrophotometer (Los Angeles, CA, USA).

Results and discussion

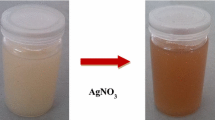

Reduction of Ag+ into Ag-NPs during exposure to water extract of C. longa tuber powder could be followed by the color change. The fresh suspension of C. longa was yellow in color (Fig. 2a). However, after addition of AgNO3 and stirring for 24 h at room temperature, the emulsion turned to light brown, brown, and dark brown, respectively (Fig. 2b–f). The color changes in aqueous solutions are due to the surface plasmon resonance phenomenon. The result obtained in this investigation is found to be interesting because it can serve as a foundation in terms of identification of potential forest plants for synthesizing Ag-NPs.

Curcuma longa as an aldehyde can reduce silver ions to Ag-NPs. The possible chemical equations for preparing the Ag-NPs are:

After dispersion of silver ions in the C. longa aqueous solution matrix (Eq. 1), the extract was reacted with the Ag+ (aq) to form the [Ag (C. longa)]+ complex, which reacted with aldehyde groups in the molecular structure of the methanolic extract to form Ag/C. longa due to the reduction of silver ions through the oxidation of aldehyde to carboxylic acid groups (Eq. 2).

UV–Vis spectroscopy analysis

The formation of Ag-NPs was followed by measuring the surface plasmon resonance (SPR) of the C. longa and Ag/C. longa emulsions over the wavelength range from 300 to 800 nm. The preparation of Ag-NPs was studied by UV–Vis spectroscopy, which has proven to be a useful spectroscopic method for the detection of prepared metallic nanoparticles. Figure 3a shows that Ag-NPs started forming when [Ag (C. longa)]+ reacted directly at room temperature. In UV–Vis spectra, the spherical Ag-NPs must display a SPR band at around 400 nm [25, 26]. The shift to the left or right (blue or red shifts) in the λ max of the SPR peaks could be related to obtaining Ag-NPs at various shapes, sizes, or solvent dependencies of formed Ag-NPs. From this research, the SPR band characteristics of Ag-NPs were detected around 415–457 nm (Fig. 3a, b), which strongly suggests that the Ag-NPs were spherical in shape which has been confirmed by the TEM results of this study [26, 27].

The intensity of the SPR peak increased as the volume of C. longa extract increased, which indicated the continued reduction of the silver ions, and the increase of the absorbance indicates that the concentration of Ag-NPs increases (Fig. 3c). There is no characteristic UV–Vis absorption of Ag-NPs in C. longa emulsions. The SPR peak at 457 nm indicates the formation of Ag-NPs in 1 mL C. longa extract. Gradually, with the increase in the volume of C. longa extract from 2 to 5 and 10 mL, the corresponding peak intensities increased, with concomitant blue shifts in wavelength from 455 to 450 and 417 nm, respectively.

Also, with the increase again in the volume of C. longa extract to 20 mL, the matching peak intensities increase once more, with attendant blue shifts in wavelength to 415 nm. Therefore, colloidal Ag-NPs prepared at these absorption bands were assumed to correspond to the Ag-NPs extra fine and homogeneous distribution, with relatively small size (less than 5 nm). Thus, there is a normal case in this situation for the SPR absorption band for the particles, which agreed with the TEM results, whereby blue shifts were observed as the size decreased with the increase of the volume of the C. longa extract to 1, 2, 5, 10, and 20 mL respectively [28, 29]. This phenomenon could be due to the fact that the C. longa extract as stabilizer and reducing agent was able to control the nanoparticles size effectively, which resulted in the very small size.

X-ray diffraction

Figure 4 shows the X-ray diffraction (XRD) patterns of vacuum-dried Ag-NPs synthesized using C. longa. The XRD patterns of Ag/C. longa indicated that the structure of Ag-NPs is face-centered cubic (fcc) [27].

In addition, all the Ag-NPs had a similar diffraction profile, and XRD peaks at 2θ of 38.18°, 44.25°, 64.72°, and 77.40° could be attributed to the 111, 200, 220 and 311 crystallographic planes of the fcc silver crystals, respectively [30]. The XRD pattern thus clearly illustrated that the Ag-NPs formed in this study are crystalline in nature. The main crystalline phase was silver and there were no obvious other phases such as impurities found in the XRD patterns (Ag XRD Ref. No. 01-087-0719).

The average particle size of Ag-NPs can be calculated using the Debye–Scherrer equation (3):

where K is the Scherrer constant with value from 0.9 to 1 (shape factor), λ is the X-ray wavelength (1.5418 Å), β1/2 is the width of the XRD peak at half height, and θ is the Bragg angle. From the Scherrer equation, the average crystallite size of Ag-NPs for samples at 24 h of stirring time are found to be lower than 10 nm in size, which are also in line with the TEM results discussed later [24].

Morphology study

The presence of a narrow distribution of Ag-NPs in TEM images are in accordance with the UV–Vis spectral study. TEM images and their corresponding particle size distributions of Ag/C. longa emulsion with the different volume of C. longa extract (5, 10 and 20 mL) are shown in Fig. 5. For the TEM study, a drop of the Ag-NPs solutions synthesized by treating AgNO3 solution with different volumes of C. longa was deposited onto a TEM copper grid. After drying, the grids were imaged using TEM. The TEM images and their size distributions revealed that the mean diameters and standard deviation of Ag-NPs were about 10.46 ± 5.58, 8.18 ± 3.53, and 4.90 ± 1.42 nm for 5, 10, and 20 mL (Fig. 5a–c) of C. longa extract, respectively.

The numbers of Ag-NPs counted for TEM images were around 1,006, 1,041, and 1,065 for 5, 10, and 20 mL for C. longa extract, repectively. These results proved that the diameters of the Ag-NPs synthesized in this method depended on the volumes used of C. longa extract. Also, Fig. 4 show the Ag-NPs surrounded by the C. longa extract. The dark points in these figures represent that the large-scale distribution and size homogeneity of Ag-NPs increases with the increase of volume extract.

Figure 6a–d shows the SEM images and EDXRF spectrum for the C. longa and Ag/C. longa emulsion (10 and 20 mL) after 24 h stirring time. The structure of C. longa extract without Ag-NPs showed a mass with specific form, that is a typical shape of plant extract. As shown in Fig. 6b–c for the synthesis of Ag-NPs in C. longa extract (10 and 20 mL), when the volumes of extract increase the size of nanosilver decreases.

Thus, these results confirm that extract of C. longa can control the shape and size of the Ag NPs. Also, the exterior surfaces of Ag/C. longa become shiny in the spherical-shaped spots, due to the presence of small sized Ag-NPs .

Figure 6d shows the EDXRF spectra for the C. longa; the peaks around 1.7, 2.8, 3.8, and 4.5 keV are related to the binding energies of C. longa. In Fig. 6d, the peaks around 1.3, 3.1, 3.3, and 3.4 keV are related to the silver elements in the C. longa extract [31, 32]. Additionally, the EDXRF spectra for the Ag/C. longa confirmed the presence of Ag-NPs in the C. longa extraction without any impurity peaks. Also, with the increased percentages of Ag-NPs in the C. longa extract (10 and 20 mL), the intensity of the Ag-NP peaks in the EDXRF spectra increased. The EDXRF spectra clearly show that with increases in the volume of C. longa extract (10 and 20 mL) in Ag/C. longa emulsion, the percentage yields increases to 38.58 and 45.53 %, respectively. The results indicate that the synthesized nanoparticles are composed of high purity Ag-NPs.

Zeta potential measurement

As shown in Fig. 7, the Ag-NPs obtained possess a negative zeta potential value. Zeta potential is an essential parameter for characterization of stability in aqueous Ag/C. longa emulsion. A minimum of ±30 mV zeta potential values is required for an indication of stable nano-suspension [27].

The narrow and sharp peaks in the zeta potential analysis indicate uniformity and good distribution of Ag-NPs. The zeta potential for the C. longa extract and Ag/C. longa emulsion were equal to −18.3 ± 4.6, −9.8 ± 3.8, and −4.2 ± 2.5 mV, respectively (Fig. 7a–c). So, these results clearly indicate that the particles are unstable for long time, and the surface charge of the particles increases with the decreases of volume of the C. longa extract from 20 to 10 mL (Fig. 7b, c).

FT-IR chemical analysis

The FT-IR spectra were recorded to identify the possible biomolecules responsible for the reduction of the Ag+ ions and capping of the bioreduced Ag-NPs synthesized by the C. longa extract. The C. longa tuber powder extract after complete bioreduction of Ag+ was centrifuged at 15,000 rpm for 20 min to isolate the Ag-NPs from proteins and other compounds present in the solution. Figure 8a shows the FT-IR spectrum of C. longa tuber powder extract that did not contain AgNO3, whereas Fig. 8b, c shows the spectrum of the Ag-NPs that were biosynthesized in 10 and 20 mL of C. longa extract. The spectrum in Fig. 8a show transmission peaks at 3,295, 2,923, 1,638, 1,375, 1,134, 1,004, 851, 514, and 393 cm−1. The transmission peaks for the Ag/C. longa (Fig. 8b) were obtained at 3,321, 2,904, 1,943, 1,633, 1,417, 1,141, 1,004, 865, 694, 510, and 320 cm−1. Similarly, transmission peaks for the Ag/C. longa (Fig. 8c) were obtained at 3,329, 2,920, 1,952, 1,643, 1,420, 1,147, 1,011, 867, 689, 510, and 299 cm−1. Three absorption peaks located around 865, 1,004, and 1,141 and 867, 1,011, and 1,147 cm−1 can be assigned as the absorption peaks of –C–N stretching vibrations of the amine –C–O–C or –C–O groups, respectively (Fig. 8b, c) [24, 33]. The bonds or functional groups such as –C–O–C–, –C–O and –C=C– derived from heterocyclic compounds, e.g., alkaloid or flavones, and the amide (I) bond derived from the proteins which are present in the tuber powder extract are the capping ligands of the nanoparticles [34]. The broad and strong bands at 3,321–2,904 cm−1 and 3,329–2,920 cm−1 were due to bonded hydroxyl (–OH) or amine groups (–NH) and aliphatic C–H of the C. longa tuber powder extract, respectively (Fig. 8b, c). The broad peaks at 1,943, 510, and 302 cm−1 and 1,952, 510, and 299 cm−1 are related to the Ag-NP banding with oxygen from the hydroxyl group of C. longa extract compounds, respectively (Fig. 8b, c).

Conclusions

In summary, we have described a simple and green method of colloidal Ag-NPs synthesis by directly using C. longa tuber powder water extract. Ag-NPs were successfully synthesized under room temperature at different volumes of C. longa extract. The Ag-NPs were characterized by UV–Vis, XRD, TEM, FESEM, EDXRF, zeta potential, and FT-IR spectra. The Ag-NPs were synthesized with an average size of 10.46 ± 5.58, 8.18 ± 3.53, and 4.90 ± 1.42 nm for 5, 10, and 20 mL of aqueous C. longa tuber powder extract, with spherical-shaped structures. Thus, the diameters of the biosynthesis Ag-NPs depended on the volume used of the C. longa extract. Biosynthesis of Ag-NPs using green resources like C. longa is a better alternative to chemical synthesis, since this green synthesis is pollutant-free and eco-friendly. From the results obtained in this effort, one can affirm that C. longa tuber powder can play an important role in the bioreduction and stabilization of silver ions to Ag-NPs.

References

P. Mohanpuria, N.K. Rana, S.K. Yadav, J. Nanopart. Res. 10, 507 (2008)

M.B. Mohamed, V. Volkov, S. Link, M.A.E. Sayed, Chem. Phys. Lett. 317, 517 (2000)

M. Rai, A. Yadav, A. Gade, Biotechnol. Adv. 27, 76 (2009)

K. Shameli, M.B. Ahmad, W.M.Z. Wan Yunus, N.A. Ibrahim, Y. Gharayebi, S. Sedaghat, Int. J. Nanomed. 5, 1067 (2010)

K. Shameli, M.B. Ahmad, W.M.Z. Wan Yunus, A. Rustaiyan, N.A. Ibrahim, M. Zargar, Y. Abdollahi, Int. J. Nanomed. 5, 875 (2010)

Y.H. Zhang, F. Chen, J.H. Zhuang, Y. Tang, D.J. Wang, Y.J. Wang, A.G. Dong, N. Ren, Chem. Commun. 2814 (2002)

K. Szczepanowicz, J. Stefańska, R.P. Socha, Physicochem. Probl. Miner. 45, 85 (2010)

K. Shameli, M.B. Ahmad, M. Zargar, W.M.Z. Wan Yunus, A. Rustaiyan, N.A. Ibrahim, Int. J. Nanomed. 6, 581 (2010)

K. Shameli, M.B. Ahmad, W.M.Z. Wan Yunus, N.A. Ibrahim, Int. J. Nanomed. 5, 743 (2010)

K. Shameli, M.B. Ahmad, M. Zargar, W.M.Z. Wan Yunus, N.A. Ibrahim, Int. J. Nanomed. 6, 331 (2011)

K. Shameli, M.B. Ahmad, S.D. Jazayeri, S. Sedaghat, P. Shabanzadeh, H. Jahangirian, M. Mahdavi, Y. Abdollahi, Int. J. Mol. Sci. 13, 6639 (2012)

I. Pastoriza Santos, L.M. Liz Marzán, Langmuir 15, 948 (1999)

M.B. Ahmad, K. Shameli, W.M.Z. Wan Yunus, N.A. Ibrahim, Aust. J. Basic Appl. Sci. 4, 2158 (2010)

P. Setua, R. Pramanik, S. Sarkar, J. Phys. Chem. B. 114, 7557 (2010)

P. Praus, M. Turicová, M. Klementová, J. Braz. Chem. Soc. 20, 1351 (2009)

L. Sun, Z. Zhang, H. Dang, Mater. Lett. 57, 3874 (2003)

P. Raveendran, J. Fu, S.L. Wallen, J. Am. Chem. Soc. 125, 13940 (2003)

M. Sathishkumar, K. Sneha, S.W. Won, C.W. Cho, S. Kim, Y.S. Yun, Colloid Surf. B 73, 332 (2009)

A. Rai, A. Singh, A. Ahmad, M. Sastry, Langmuir 22, 736 (2006)

J.L. Gardea Torresdey, J.G. Parsons, K. Dokken, J.R. Peralta Videa, H. Troiani, P. Santiago, M. Jose Yacaman, Nano Lett. 2, 397 (2002)

J.L. Gardea Torresdey, E. Gomez, J.R. Peralta Videa, J.G. Parsons, H. Troiani, M. Jose Yacaman, Langmuir 19, 1357 (2003)

S.S. Shankar, A. Rai, B. Ankamwar, A. Singh, A. Ahmad, M. Sastry, Nat. Mater. 3, 482 (2004)

M. Zargar, A.A. Hamid, F.A. Bakar, M.N. Shamsudin, K. Shameli, F. Jahanshiri, F. Farahani, Molecules 16, 6667 (2011)

K. Shameli, M.B. Ahmad, E.A.J. Al-Mulla, N.A. Ibrahim, P. Shabanzadeh, A. Rustaiyan, Y. Abdollahi, S. Bagheri, S. Abdolmohammadi, M.S. Usman, M. Zidan, Molecules 17, 8506 (2012)

K.L. Kelly, E. Coronado, L.L. Zhao, G.C. Schatz, J. Phys. Chem. B. 107, 668 (2003)

A.L. Stepanov, Tech. Phys. 49, 143 (1997)

K. Shameli, M.B. Ahmad, S.D. Jazayeri, P. Shabanzadeh, P. Sangpour, H. Jahangirian, Y. Gharayebi, Chem. Cent. J. 6, 73 (2012)

M.B. Ahmad, J.J. Lim, K. Shameli, N.A. Ibrahim, M.Y. Tay, Molecules 16, 7237 (2011)

M.B. Ahmad, M.Y. Tay, K. Shameli, M.Z. Hussein, J.J. Lim, Int. J. Mol. Sci. 12, 4872 (2011)

M.B. Ahmad, K. Shameli, M. Darroudi, W.M.Z. Wan Yunus, N.A. Ibrahim, Am. J. Appl. Sci. 6, 1909 (2009)

K. Shameli, M.B. Ahmad, M. Zargar, W.M.Z. Wan Yunus, N.A. Ibrahim, P. Shabanzadeh, M.G. Moghaddam, Int. J. Nanomed. 6, 271 (2011)

M.B. Ahmad, J.J. Lim, K. Shameli, N.A. Ibrahim, M.Y. Tay, B.W. Chieng, Chem. Cent. J. 6, 101 (2012)

J. Huang, Q. Li, D. Sun, Y. Lu, Y. Su, X. Yang, H. Wang, Y. Wang, W. Shao, N. He, J. Hong, C. Chen, Nanotechnology 18, 1 (2007)

L. Luo, S. Yu, S. Qian, T. Zhou, J. Am. Chem. Soc. 127, 2822 (2005)

Acknowledgments

The authors thank the University Putra Malaysia (UPM) for its financial support (RUGS, Project No. 9199840). The authors are also grateful to the staff of the Department of Chemistry UPM for their help in this research, and the Institute of Bioscience (IBS/UPM) for technical assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shameli, K., Ahmad, M.B., Shabanzadeh, P. et al. Effect of Curcuma longa tuber powder extract on size of silver nanoparticles prepared by green method. Res Chem Intermed 40, 1313–1325 (2014). https://doi.org/10.1007/s11164-013-1040-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-013-1040-4