Abstract

Facile synthesis of some 1,4-dihydropyridine derivatives via Hantzsch reaction of 5,5-dimethyl-1,3-cyclohexanedione (dimedone), 1,3-diphenyl-2-propen-1-one derivatives and ammonium acetate under solvent-free condition in the presence of silica-supported perchloric acid (HClO4–SiO2) is described. The catalyst is easily prepared, stable, reusable and efficient under the reaction conditions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In recent decades, multicomponent reactions (MCRs) have gained wide applicability in the field of synthetic organic chemistry as they increase the efficiency of the reaction and decrease the number of laboratory operations along with quantities of solvent and chemicals used. These methods also considerably reduce the reaction time and facilitate the yield of products compared with normal multiple-step methods [1]. Therefore, the design of novel MCRs has attracted great attention from research groups working in medicinal chemistry and drug discovery. Some of the examples of MCRs include synthesis of 3,4-dihydropyrimidine derivatives [2] and 1-carbamatoalkyl-2-naphthols [3]. Nevertheless, development and discovery of new MCRs is still in demand.

1,4-Dihydropyridines (DHPs) play a predominant role in medicinal chemistry owing to their significant biological activity [4]. A number of dihydropyridine calcium antagonists have been introduced as potential drugs for treatment of congestive heart failure and angina pectoris [5–7]. The 1,4-DHPs may lead to other beneficial effects such as regression of left-ventricular pressure and vascular hypertrophy, renal protection and antiatherogenic activity [8–10]. Furthermore, the dihydropyridine skeleton is common in anticoagulant, antibacterial and antimycobacterial activities [4, 11]. They also function as neuro-protectants and as anti-platelet treatment of aggregators and are important in Alzheimer’s disease as anti-ischaemic agents [12–15]. They play an important role as antitubercular agents [16, 17]. DHPs are commercially used as calcium channel blockers for treatment of cardiovascular diseases, including hypertension [18].

To model and understand these biological properties and to develop new chemotherapeutic agents based upon the 1,4-DHP motif, considerable effort has been devoted to establish efficient and rapid methods for their synthesis. 1,4-DHPs are generally synthesized using the Hantzsch method [19], which involves cyclocondensation of an aldehyde, a β-ketoester and ammonia either in acetic acid or under reflux in alcohols for long reaction times, typically leading to low yields [20, 21].

In recent years, several new efficient methods have been developed, including the use of FeF3 [22], p-TSA [23], PPA–SiO2 [24], grinding [25], ceric ammonium nitrate [26], PTSA–SDS [27], tris(pentafluorophenyl)borane [28], triphenylphosphine [29], cellulose sulphuric acid [30] and solid-state synthesis [31]. These methods, however, suffer from drawbacks such as unsatisfactory yields, acidic or basic catalysts, extended reaction times, elevated temperatures, tedious work-up, anhydrous organic solvents and use of stoichiometric and/or relatively expensive reagents. Moreover, the main disadvantage of almost all existing methods is that the catalysts are destroyed in the work-up procedure and cannot be recovered or reused. Therefore, the search continues for a better catalyst for synthesis of 1,4-DHPs and polyhydroquinolines in terms of operational simplicity, reusability, economic viability and greater selectivity.

During the course of our studies directed towards the development of practical and environmentally friendly procedures for synthesis of biologically active molecules, such as 3,4-dihydropyrimidin-2(1H)-ones/thiones/imines [32], β-amino ketone compounds [33], amidoalkyl naphthols [34] and 2-amino-4,6-diphenylpyridine-3-carbonitrile derivatives [35] by multicomponent reactions, we developed the applicability of a novel recyclable heterogeneous solid-supported perchloric acid (HClO4–SiO2) for efficient, convenient and facile synthesis of 1,4-DHP derivatives via Hantzsch reaction of dimedone, 1,3-diphenyl-2-propen-1-one derivatives and ammonium acetate under solvent-free condition at 80 °C (Scheme 1). In addition, to the best of our knowledge, there are no reports on the use of solid-supported perchloric acid as a heterogeneous catalyst for this conversion. This fact prompted us to investigate HClO4–SiO2 for synthesis of 1,4-DHP derivatives in a facile and practical manner.

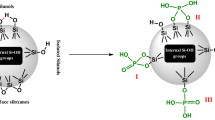

Solid-supported reagents are unique acid catalysts that have become popular over the last two decades. The activity and selectivity of these reagents are dispersed on the surface of a support, and because of this, the effective surface area of the reagent is increased significantly, and hence they are expected to perform more effectively than the individual reagents. Low toxicity, moisture resistance, air tolerance and low prices are other common features that motivate use of solid-supported reagents as attractive alternatives to conventional Lewis acids or metal triflates [36].

Recently, HClO4–SiO2 has emerged as a powerful catalyst in various organic transformations, including Hantzsch condensation [37] and electrophilic substitution of indole with various aldehydes and ketones [38]. It is also reported that HClO4–SiO2 can act as a catalyst for various syntheses, including synthesis of amidoalkyl naphthols [39], xanthene derivatives [40], poly-substituted quinolines [41] and homoallylic amines [42].

Results and discussion

We have developed an efficient synthesis of 1,4-DHP derivatives from reaction of dimedone, 1,3-diphenyl-2-propen-1-one derivatives and ammonium acetate promoted by a catalytic amount of HClO4–SiO2 under solvent-free conditions at 80 °C. Herein, we report our results.

Effect of catalyst

In an initial endeavour, 1 mmol each of dimedone (1), 1,3-diphenyl-2-propen-1-one (2) and ammonium acetate were stirred at 80 °C under solvent-free condition without catalyst. After 6 h, only 60 % of the expected product 4a was obtained after work-up and recrystallization of the crude product from ethanol (Table 1, entry 1). To improve the yield and optimize the reaction conditions, the same reaction was carried out in the presence of a catalytic amount of 0.4 mol% of HClO4–SiO2 under similar conditions. Surprisingly, a significant improvement was observed and the yield of 4a was dramatically increased to 70 % after stirring; the mixture was stirred for only 5 h (entry 2). With this optimistic result in hand, we further investigated the best reaction conditions using different amounts of HClO4–SiO2.

Increasing the quantity of the catalyst to 0.6, 0.8 and 1 mol% gave the corresponding product in 80, 87 and 96 % yields in 4, 3 and 2.5 h, respectively. Use of just 1 mol% was sufficient to drive the reaction forward; larger amounts of the catalyst did not improve the results. Although the use of 1.4 mol% of HClO4–SiO2 permitted the reaction time to be decreased to 2 h, the yield unexpectedly decreased to 85 % (entry 4). A possible explanation for the low product yield is that the starting material or the product may have been destroyed during the reaction when an excess amount (1.4 mol%) of HClO4–SiO2 was used in the exothermic reaction and that 1 mol% HClO4–SiO2 was sufficient to catalyze the reaction effectively.

Effect of solvent

The solvent played an important role in the synthesis of 1,4-DHP derivatives. Various reaction media were screened (ethanol, methanol, t-BuOH, acetonitrile, THF and 1,4-dioxane) using the model reaction (Table 2, entries 1–6). It was found that the best results were obtained with 1 mol% of HClO4–SiO2 under solvent-free condition (Table 2, entry 7). The reaction was completed within 2.5 h, and the expected product was obtained in 96 % yield.

Optimization of temperature

We also examined the effect of temperature. The reaction was studied at various temperatures from 50 to 100 °C. When increasing the temperature, the product yield increased up to 80 °C. After 80 °C, increasing temperature leads to decrease in yields; For example the reaction of dimedone (1), 1,3-diphenyl-2-propen-1-one (2a) and ammonium acetate at 100 °C under solvent-free condition gave the corresponding product (Table 3, entry 6) in 84 % yield, while decreasing the temperature to 80–85 °C led to the product in 96 % yield. At higher temperature the starting material or the product may have been destroyed during the reaction. Therefore, our optimized condition is 1 mol% of HClO4–SiO2 under solvent-free condition at 80 °C.

Reusability of the catalyst

The reusability of the catalyst is one of the most important benefits and makes it useful for commercial applications. Thus, the recovery and reusability of HClO4–SiO2 was investigated. The reusability of the catalyst was checked by separating the HClO4–SiO2 from the reaction mixture by simple filtration, washing with CH2Cl2, and drying in a vacuum oven at 60 °C for 5 h prior to reuse in subsequent reactions. The recovered catalyst could be reused at least three additional times in subsequent reactions without significant loss in product yield (Fig. 1) (Table 4).

Synthesis of 7,7-dimethyl-5-oxo-2,4-diphenyl-1,4,5,6,7,8-hexahydroquinoline derivatives

Under the optimized set of reaction conditions, we conducted the same reactions using dimedone (1), a variety of different substituted 1,3-diphenyl-2-propen-1-ones (2a–l) and ammonium acetate 3 in the presence of 1 mol% of HClO4–SiO2 under similar conditions (Scheme 1). As expected, satisfactory results were observed, and the results are summarized in Table 5. It is shown that in general a wide range of chalcones could react with dimedone and ammonium acetate smoothly to give 4a–l in good to excellent yields (Table 5, entries 1–12). It is also notable that the electronic property of the aromatic ring of chalcones has some effects on the rate of the condensation process. Generally speaking, shorter reaction time was needed for substrates bearing electron-withdrawing groups on the aromatic rings (Table 5, entries 2–4, 6 and 7). On the other hand, substrates bearing electron-donating groups can afford the corresponding products with almost equally satisfactory yields. A slightly longer reaction period was necessary to complete the reaction (Table 5, entries 5, 8 and 9). A possible mechanism for the formation of title compounds 4a–l is shown in Scheme 2.

Experimental

Apparatus and analysis

Chemicals were purchased from Merck, Fluka and Aldrich Chemical Companies. All yields refer to isolated products unless otherwise stated. 1H nuclear magnetic resonance (NMR) (500 MHz) and 13C NMR (125 MHz) spectra were obtained using a Bruker DRX-500 Avance at ambient temperature with tetramethylsilane (TMS) as internal standard. Fourier-transform infrared (FT-IR) spectra were obtained from KBr discs on a Shimadzu spectrometer. Mass spectra were determined on a Varion-Saturn 2000 GC/MS instrument. Elemental analysis was carried out by means of a PerkinElmer 2400 CHN elemental analyzer flowchart.

Preparation of silica-supported perchloric acid (HClO4–SiO2)

HClO4 (1.8 g, 12.5 mmol, as 70 % aq. solution) was added to a suspension of SiO2 (230–400 mesh, 23.7 g) in Et2O (70.0 mL). The mixture was concentrated, and the residue was heated at 100 °C for 72 h under vacuum to furnish HClO4–SiO2 (0.5 mmol/g) as a free-flowing powder (50 mg = 0.025 mmol of HClO4) [43].

General procedure for the synthesis of 7,7-dimethyl-5-oxo-2,4-diphenyl-1,4,5,6,7,8-hexahydroquinoline derivatives

A mixture of dimedone (1 mmol), 1,3-diphenyl-2-propen-1-one derivatives (1 mmol), ammonium acetate (1 mmol) and HClO4–SiO2 (1 mol%) was stirred at 80 °C for the appropriate time, as shown in Table 5. After completion of the reaction [thin-layer chromatography (TLC) monitoring], the reaction mixture was cooled to ambient temperature, CH2Cl2 was added and the HClO4–SiO2 was filtered off. The filtrate was concentrated to dryness, and the crude solid product was crystallized from EtOH to afford the pure ethyl 7,7-dimethyl-5-oxo-2,4-diphenyl-1,4,5,6,7,8-hexahydroquinoline derivatives (Table 5).

Spectral data for the synthesized compounds

7,7-Dimethyl-5-oxo-2,4-diphenyl-1,4,5,6,7,8-hexahydroquinoline (4a)

IR (KBr, cm−1): 3,290, 3,022, 2,981, 1,668, 1,626, 1,594, 1,488, 1,444, 778, 765, 690; 1H NMR (500 MHz, DMSO-d 6) δ: 0.92 (s, 3H, CH3), 1.04 (s, 3H, CH3), 2.24–2.35 (m, 4H, 2 × CH2), 5.25 (d, J = 6.6 Hz, 1H), 5.94 (d, J = 6.6 Hz, 1H), 6.57 (s, 1H, NH), 7.42 (d, J = 8.0 Hz, 2H, ArH), 7.32–7.46 (m, 3H, ArH), 7.56–7.78 (m, 5H) ppm; 13C NMR (125 MHz, DMSO-d 6) δ: 14.0, 18.0, 38.4, 59.9, 101.9, 105.7, 123.8, 126.4, 127.4, 128.4, 128.7, 129.8, 134.5, 140.6, 143.9, 147.4, 170.9 ppm; MS (ESI): m/z 330 (M+H)+. Anal. Calcd. for C23H23NO (%): C, 83.89; H, 6.99; N, 4.25. Found: C, 83.80; H, 6.91; N, 4.19.

7,7-Dimethyl-5-oxo-2-(4-nitrophenyl)-4-phenyl-1,4,5,6,7,8-hexahydroquinoline (4b)

IR (KBr, cm−1): 3,278, 3,076, 2,972, 2,888, 1,655, 1,590, 1,556, 1,494, 1,398, 1,344, 843, 759, 695; 1H NMR (500 MHz, DMSO-d 6) δ: 0.96 (s, 3H, CH3), 1.08 (s, 3H, CH3), 2.22–2.36 (m, 4H, 2 × CH2), 5.73 (d, J = 6.8 Hz, 1H), 6.69 (d, J = 6.8 Hz, 1H), 6.79 (s, 1H, NH), 7.42 (d, J = 8.4 Hz, 2H, ArH), 7.78 (d, J = 8.4 Hz, 2H, ArH), 7.28–7.36 (m, 5H, ArH) ppm; 13C NMR (125 MHz, DMSO-d 6) δ: 14.1, 18.4, 22.4, 35.6, 60.6, 104.0, 106.2, 120.7, 123.4, 126.9, 128.1, 130.2, 130.6, 134.8, 141.2, 143.7, 146.5, 170.1 ppm; MS (ESI): m/z 375 (M+H)+. Anal. Calcd. for C23H22N2O3 (%): C, 73.79; H, 5.88; N, 7.48. Found: C, 73.75; H, 5.90; N, 7.50.

7,7-Dimethyl-5-oxo-2-(4-chlorophenyl)-4-phenyl-1,4,5,6,7,8-hexahydroquinoline (4c)

IR (KBr, cm−1): 3,244, 3,028, 2,984, 1,628, 1,588, 1,500, 834, 766, 696; 1H NMR (500 MHz, DMSO-d 6) δ: 0.98 (s, 3H, CH3), 1.09 (s, 3H, CH3), 2.31–2.44 (m, 4H, 2 × CH2), 5.70 (d, J = 6.6 Hz, 1H), 6.64 (d, J = 6.6 Hz, 1H), 6.89 (s, 1H, NH), 7.38 (d, J = 8.4 Hz, 2H, ArH), 7.66 (d, J = 8.4 Hz, 2H, ArH), 7.52–7.66 (m, 5H, ArH) ppm; 13C NMR (125 MHz, DMSO-d 6) δ: 14.2, 18.2, 35.5, 60.6, 104.3, 106.3, 120.6, 123.5, 127.4, 128.2, 129.7, 130.2, 134.90, 141.3, 143.4, 146.8, 169.6 ppm; MS (ESI): m/z 364.45 (M+H)+. Anal. Calcd. for C23H22ClNO (%): C, 75.94; H, 6.05; N, 3.85. Found: C, 75.90; H, 6.04; N, 3.82.

7,7-Dimethyl-5-oxo-2-(4-bromophenyl)-4-phenyl-1,4,5,6,7,8-hexahydroquinoline (4d)

IR (KBr, cm−1): 3,242, 3,038, 2,974, 1,666, 1,602, 1,506, 1,496, 832, 778, 692; 1H NMR (500 MHz, DMSO-d 6) δ: 0.92 (s, 3H, CH3), 1.04 (s, 3H, CH3), 2.24–2.32 (m, 4H, 2 × CH2), 6.76 (d, J = 6.4 Hz, 1H), 7.10 (d, J = 6.4 Hz, 1H), 7.29 (s, 1H, NH), 7.44 (d, J = 8.4 Hz, 2H, ArH), 7.70 (d, J = 8.4 Hz, 2H, ArH), 7.48–7.62 (m, 5H, ArH) ppm; 13C NMR (125 MHz, DMSO-d 6) δ: 14.5, 19.1, 36.1, 62.4, 100.3, 106.9, 122.3, 124.4, 127.4, 130.2, 130.9, 132.2, 133.5, 140.4, 141.4, 143.4, 169.9 ppm; MS (ESI): m/z 408.9 (M+H)+. Anal. Calcd. for C23H22BrNO (%): C, 67.66; H, 5.40; N, 3.43. Found: C, 67.66; H, 5.39; N, 3.40.

7,7-Dimethyl-5-oxo-2-(4-methylphenyl)-4-phenyl-1,4,5,6,7,8-hexahydroquinoline (4e)

IR (KBr, cm−1): 3,248, 3,030, 2,996, 2,980, 1,640, 1,624, 1,592, 1,490, 831, 770, 696; 1H NMR (500 MHz, DMSO-d 6) δ: 0.92 (s, 3H, CH3), 1.02 (s, 3H, CH3), 2.27–2.31 (m, 4H, 2 × CH2), 2.26 (s, 3H, CH3), 5.42 (d, J = 6.4 Hz, 1H), 6.23 (d, J = 6.4 Hz, 1H), 6.65 (s, 1H, NH), 7.32 (d, J = 8.4 Hz, 2H, ArH), 7.58 (d, J = 8.4 Hz, 2H, ArH), 7.44–7.56 (m, 5H, ArH) ppm; 13C NMR (125 MHz, DMSO-d 6) δ: 14.2, 18.0, 37.9, 61.2, 103.4, 105.8, 122.8, 124.7, 128.5, 130.3, 131.4, 141.4, 142.5, 143.9, 147.5, 148.1, 169.8 ppm; MS (ESI): m/z 344 (M+H)+. Anal. Calcd. for C24H25NO (%): C, 83.96; H, 7.29; N, 4.08. Found: C, 83.97; H, 7.22; N, 4.04.

7,7-Dimethyl-5-oxo-2-phenyl-4-(4-chlorophenyl)-1,4,5,6,7,8-hexahydroquinoline (4f)

IR (KBr, cm−1): 3,244, 3,032, 2,986, 1,666, 1,606, 1,584, 1,500, 1,456, 834, 776; 1H NMR (500 MHz, DMSO-d 6) δ: 0.96 (s, 3H, CH3), 1.04 (s, 3H, CH3), 2.30–2.42 (m, 4H, 2 × CH2), 5.62 (d, J = 6.8 Hz, 1H), 6.32 (d, J = 6.8 Hz, 1H), 7.25 (s, 1H, NH), 7.33 (d, J = 8.0 Hz, 2H, ArH), 7.53 (d, J = 8.0 Hz, 2H, ArH), 7.55–7.77 (m, 5H, ArH) ppm; 13C NMR (125 MHz, DMSO-d 6) δ: 14.1, 20.4, 33.9, 61.3, 104.4, 105.8, 122.8, 123.4, 124.9, 127.7, 132.5, 133.3, 134.4, 136.2, 140.1, 141.5, 143.5, 149.6, 168.7 ppm; MS (ESI): m/z 364.45 (M+H)+. Anal. Calcd. for C23H22ClNO (%): C, 75.94; H, 6.05; N, 3.85. Found: C, 75.90; H, 6.02; N, 3.82.

7,7-Dimethyl-5-oxo-2-phenyl-4-(4-nitrophenyl)-1,4,5,6,7,8-hexahydroquinoline (4g)

IR (KBr, cm−1): 3,344, 3,040, 2,952, 2,862, 1,654, 1,588, 1,478, 832, 752, 696; 1H NMR (500 MHz, DMSO-d 6) δ: 0.98 (s, 3H, CH3), 1.06 (s, 3H, CH3), 2.33–2.42 (m, 4H, 2 × CH2), 6.04 (d, J = 6.4 Hz, 1H), 6.54 (d, J = 6.4 Hz, 1H), 6.88 (s, 1H, NH), 7.36 (d, J = 8.0 Hz, 2H, ArH), 7.60 (d, J = 8.0 Hz, 2H, ArH), 7.50–7.62 (m, 5H, ArH) ppm; 13C NMR (125 MHz, DMSO-d 6) δ: 14.4, 17.9, 36.3, 55.6, 62.3, 98.5, 106.4, 113.6, 126.4, 127.2, 128.5, 130.4, 134.5, 139.6, 140.4, 141.7, 155.6, 169.8 ppm; MS (ESI): m/z 375 (M+H)+. Anal. Calcd. for C23H22N2O3 (%): C, 73.79; H, 5.88; N, 7.49. Found: C, 73.74; H, 5.85; N, 7.47.

7,7-Dimethyl-5-oxo-2-phenyl-4-(4-methoxyphenyl)-1,4,5,6,7,8-hexahydroquinoline (4h)

IR (KBr, cm−1): 3,222, 3,034, 2,952, 2,860, 2,828, 1,660, 1,584, 1,444, 840, 759, 696; 1H NMR (500 MHz, DMSO-d 6) δ: 0.94 (s, 3H, CH3), 1.04 (s, 3H, CH3), 2.19–2.31 (m, 4H, 2 × CH2), 3.78 (s, 3H, OCH3), 5.80 (d, J = 7.0 Hz, 1H), 6.64 (d, J = 7.0 Hz, 1H), 7.15 (s, 1H, NH), 7.36 (d, J = 8.4 Hz, 2H, ArH), 7.64 (d, J = 8.4 Hz, 2H, ArH), 7.46–7.72 (m, 5H, ArH) ppm; 13C NMR (125 MHz, DMSO-d 6) δ: 14.1, 21.1, 32.4, 60.5, 100.3, 105.4, 119.4, 122.4, 126.4, 129.4, 130.6, 133.3, 135.6, 140.4, 143.7, 144.4, 145.8, 148.5, 169.5 ppm; MS (ESI): m/z 360 (M+H)+. Anal. Calcd. for C24H25NO2 (%): C, 80.22; H, 6.98; N, 3.90. Found: C, 80.20; H, 7.00; N, 3.88.

7,7-Dimethyl-5-oxo-2-phenyl-4-(4-methylphenyl)-1,4,5,6,7,8-hexahydroquinoline (4i)

IR (KBr, cm−1): 3,228, 3,044, 2,948, 2,872, 1,662, 1,582, 1,490, 812, 762, 694; 1H NMR (500 MHz, DMSO-d 6) δ: 0.92 (s, 3H, CH3), 1.04 (s, 3H, CH3), 2.31–2.45 (m, 4H, 2 × CH2), 2.24 (s, 3H, CH3), 5.61 (d, J = 7.0 Hz, 1H), 5.84 (d, J = 7.0 Hz, 1H), 6.22 (s, 1H, NH), 7.40 (d, J = 8.4 Hz, 2H, ArH), 7.54 (d, J = 8.4 Hz, 2H, ArH), 7.41–7.63 (m, 5H, ArH) ppm; 13C NMR (125 MHz, DMSO-d 6) δ: 14.4, 20.5, 33.8, 62.4, 104.5, 106.1, 124.7, 128.9, 130.8, 131.9, 132.7, 141.5, 141.9, 142.6, 147.2, 148.5, 168.3 ppm; MS (ESI): m/z 344 (M+H)+. Anal. Calcd. for C24H25NO (%): C, 83.96; H, 7.29; N, 4.08. Found: C, 83.92; H, 7.26; N, 4.06.

7,7-Dimethyl-5-oxo-2-(4-chlorophenyl)-4-(3-nitrophenyl)-1,4,5,6,7,8-hexahydroquinoline (4j)

IR (KBr, cm−1): 3,228, 3,074, 2,966, 1,668, 1,588, 1,534, 1,492, 1,344, 826; 1H NMR (500 MHz, DMSO-d 6) δ: 0.94 (s, 3H, CH3), 1.04 (s, 3H, CH3), 2.23–2.33 (m, 4H, 2 × CH2), 5.74 (d, J = 6.6 Hz, 1H), 6.62 (d, J = 6.6 Hz, 1H), 7.12 (s, 1H, NH), 7.34 (d, J = 8.4 Hz, 2H, ArH), 7.54 (d, J = 8.4 Hz, 2H, ArH), 7.44–7.60 (m, 4H, ArH) ppm; 13C NMR (125 MHz, DMSO-d 6) δ: 14.1, 19.1, 33.3, 61.6, 103.7, 105.6, 124.8, 128.0, 128.8, 131.6, 132.6, 140.9, 141.2, 141.5, 146.3, 147.6, 168.1 ppm; MS (ESI): m/z 409.45 (M+H)+. Anal. Calcd. for C23H21ClN2O3 (%): C, 67.56; H, 5.16; N, 6.82. Found: C, 67.54; H, 5.12; N, 6.79.

7,7-Dimethyl-5-oxo-2-(4-nitrophenyl)-4-(4-chlorophenyl)-1,4,5,6,7,8-hexahydroquinoline (4k)

IR (KBr, cm−1): 3,226, 3,076, 2,964, 1,664, 1,584, 1,534, 1,496, 1,348, 828; 1H NMR (500 MHz, DMSO-d 6) δ: 0.82 (s, 3H, CH3), 1.00 (s, 3H, CH3), 2.18–2.29 (m, 4H, 2 × CH2), 5.64 (d, J = 6.5 Hz, 1H), 5.81 (d, J = 6.5 Hz, 1H), 6.20 (s, 1H, NH), 7.48 (d, J = 8.0 Hz, 2H, ArH), 7.60 (d, J = 8.0 Hz, 2H, ArH), 7.38–7.46 (m, 4H, ArH) ppm; 13C NMR (125 MHz, DMSO-d 6) δ: 13.9, 21.6, 33.6, 63.4, 105.7, 106.6, 123.2, 126.9, 131.5, 131.6, 133.4, 141.5, 141.9, 143.8, 147.6, 148.7, 165.6 ppm; MS (ESI): m/z 409.45 (M+H)+. Anal. Calcd. for C23H21ClN2O3 (%):C, 67.56; H, 5.16; N, 6.82. Found: C, 67.55; H, 5.15; N, 6.83.

7,7-Dimethyl-5-oxo-2-(4-chlorophenyl)-4-(4-methylphenyl)-1,4,5,6,7,8-hexahydroquinoline (4 l)

IR (KBr, cm−1): 3,318, 3,040, 2,956, 2,878, 1,666, 1,584, 1,496, 816, 774; 1H NMR (500 MHz, DMSO-d 6) δ: 0.96 (s, 3H, CH3), 1.08 (s, 3H, CH3), 2.27–2.39 (m, 4H, 2 × CH2), 2.22 (s, 3H, CH3), 6.37 (d, J = 7.0 Hz, 1H), 6.98 (d, J = 7.0 Hz, 1H), 7.21 (s, 1H, NH), 7.42 (d, J = 8.0 Hz, 2H, ArH), 7.78 (d, J = 8.0 Hz, 2H, ArH), 7.57–7.71 (m, 4H, ArH) ppm; 13C NMR (125 MHz, DMSO-d 6) δ: 14.1, 18.4, 36.4, 63.3, 99.6, 107.6, 125.8, 127.9, 128.3, 129.3, 130.2, 132.7, 134.5, 139.6, 141.3, 142.0, 170.3 ppm; MS (ESI): m/z 378.45 (M+H)+. Anal. Calcd. for C24H24ClNO (%): C, 76.30; H, 6.36; N, 3.71. Found: C, 76.28; H, 6.40; N, 3.71.

Conclusions

HClO4–SiO2 is an efficient, non-toxic, reusable and solid-supported acid catalyst, prepared and utilized for synthesis of 1,4-DHPs via three-component reaction of dimedone with a wide range of 1,3-diphenyl-2-propen-1-one derivatives and ammonium acetate in solvent-free condition. This modified methodology is superior to existing methodologies for synthesis of 1,4-DHPs.

References

A. Domling, I. Ugi, Angew. Chem. Int. Ed. 39, 3168 (2000)

P. Karthikeyan, S.S.Kumar, A.S. Arunrao, M.P. Narayan, P.R. Bhagat, Res Chem. Intermed. (2012). doi:10.1007/s11164-012-0689-4

Z. Song, X. Sun, L. Liu, Y. Cui, Res. Chem. Intermed. (2012). doi:10.1007/s11164-012-0744-1

K. Sirisha, D. Bikshapathi, G. Achaiah, V.M. Reddy, Eur. J. Med. Chem. 46, 1564 (2011)

C.E. Sunkel, M.F. Fau de Casa-Juana, L. Santos, A.G. Garcia, C.R. Artalijero, M. Villarroya, M.A. Gonzalez-Morales, M.G. Lopez, J. Cillero, S. Alonso, J.P. Priego, J. Med. Chem. 35, 2407 (1992)

D. Vo, W.C. Matowe, M. Ramesh, N. Iqbal, M.W. Wolowyk, S.E. Howlett, E.E. Knaus, J. Med. Chem. 38, 2851 (1995)

S.F. Flaim, R. Zelis, Fed. Proc. 40, 2877 (1981)

T. Godfraind, S.J. Salomone, Cardiovasc. Pharmacol. 30, S1 (1997)

P.A. Van Zwieten, Blood Press. 1, 5 (1998)

W.G. Nayler, J. Clin. Basic Cardiol. 2, 155 (1999)

R.S. Kumar, A. Idhayadhulla, A.J.A. Nasser, J. Selvin, Eur. J. Med. Chem. 46, 804 (2011)

V. Klusa, Drugs Future 20, 135 (1995)

R.G. Bretzel, C.C. Bollen, E. Maeser, K.F. Federlin, Am. J. Kidney Dis. 21, 53 (1993)

R. Boer, V. Gekker, Drugs Future 20, 499 (1995)

R.G. Bretzel, C.C. Bollen, E. Maeser, K.F. Federlin, Am. J. Kidney Dis. 17, 465 (1992)

A.R. Trivedi, D.K. Dodiya, B.H. Dholariya, V.B. Kataria, V.R. Bhuva, V.H. Shah, Bioorg. Med. Chem. Lett. 21, 5181 (2011)

M. Khoshneviszadeh, N. Edraki, K. Javidnia, A. Alborzi, B. Pourabbas, J. Mardaneh, R. Miri Bioorg, Med. Chem. 17, 1579 (2009)

A.C. Gaudio, A. Korolkovas, Y. Takahata, J. Pharm. Sci. 83, 1110 (1994)

A. Hantzsch, Liebigs Ann. Chem. 215, 1 (1882)

R. Alajarin, J.J. Vaquero, J.L.N. Garcia, J. Alvarez-Builla, Synlett. 297 (1992)

A. Sausins, G. Duburs, Heterocycles 27, 269 (1988)

R. Surasani, D. Kalita, A.V.D. Rao, K. Yarbagi, K.B. Chandrasekhar, J. Fluor. Chem. 135, 91 (2012)

S. Ko, C.F. Yao, Tetrahedron 62, 7293 (2006)

A. Khojastehnezhad, F. Moeinpour, A. Davoodnia, Chin. Chem. Lett. 22, 807 (2011)

S. Kumar, P. Sharma, K.K. Kapoor, M.S. Hundal, Tetrahedron 64, 536 (2008)

S. Ko, C.F. Yao, Tetrahedron Lett. 62, 7293 (2006)

A. Kumar, R.A. Maurya, Synlett 6, 883 (2008)

S. Chandrasekhar, Y.S. Rao, L. Sreelakshmi, B. Mahipal, C.R. Reddy, Synthesis 11, 1737 (2008)

A. Debache, W. Ghalem, R. Boulcina, A. Belfaitah, S. Rhouati, B. Carboni, Tetrahedron Lett. 50, 5248 (2009)

J. Safari, S.H. Banitaba, S.D. Khalili, J. Mol. Catal. A Chem. 335, 46 (2011)

T.-S. Jin, Y. Yin, L.-B. Liu, T.-S. Li, Arkivoc xiv, 28 (2006)

S.S. Mansoor, S.S. Shafi, S.Z. Ahmed, Arab. J. Chem. (2011). doi:10.1016/j.Arabjc.2011.09.018

S.S. Mansoor, K. Aswin, K. Logaiya, S.P.N. Sudhan, J. Saudi Chem. Soc. (2012). http://dx.doi.org/10.1016/j.jscs.2012.04.008

S.S. Mansoor, K. Aswin, K. Logaiya, S.P.N. Sudhan, J. Saudi Chem. Soc. (2012). http://dx.doi.org/10.1016/j.jscs.2012.06.003

S.S. Mansoor, K. Aswin, K. Logaiya, S.P.N. Sudhan, J. Saudi Chem. Soc. (2012). http://dx.doi.org/10.1016/j.jscs.2012.07.011

S. Rostamizadeh, A.M. Amani, G.H. Mahdavinia, N. Shadjou, Chin. Chem. Lett. 20, 779 (2009)

M. Maheswara, V. Siddaiah, G.L.V. Damu, C.V. Rao, Arkivoc ii, 201 (2006)

T. Vinod Kamble, R. Kailash Kadam, S. Neeta Joshi, B. Dnyanoba Muley, Catal. Commun. 8, 498 (2007)

H.R. Shaterian, H. Yarahmadi, M. Ghashang, Tetrahedron 64, 1263 (2008)

M.A. Bigdeli, M.M. Heravi, G.H. Mahdavinia, J. Mol. Catal. A Chem. 275, 25 (2007)

M. Narasimhulu, T.S. Reddy, K.C. Mahesh, P. Prabhakar, C.B. Rao, Y. Venkateswarlu, J. Mol. Catal. A Chem. 266, 114 (2007)

L. Nagarapu, V. Paparaju, G. Pathuri, S. Kantevari, R.R. Pakkiru, R. Kamalla, J. Mol. Catal. A Chem. 267, 53 (2007)

A. K. Chakraborthi, R. Gulhane, Chem. Commun. 22, 1896 (2003)

Acknowledgments

The authors gratefully acknowledge the University Grants Commission, Government of India, New Delhi for financial support (Major Research Project: F. No. 40-44/2011(SR)). The authors also acknowledge C. Abdul Hakeem College Management, Dr. W. Abdul Hameed, Principal and Dr. M. S. Dastageer, Head of the Research Department of Chemistry for the facilities and support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mansoor, S.S., Aswin, K., Logaiya, K. et al. Silica-supported perchloric acid (HClO4–SiO2): a mild, reusable and highly efficient heterogeneous catalyst for multicomponent synthesis of 1,4-dihydropyridines via unsymmetrical Hantzsch reaction. Res Chem Intermed 40, 357–369 (2014). https://doi.org/10.1007/s11164-012-0968-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-012-0968-0