Abstract

The effect of adding 2-phenylimidazo[1,2-a]pyridine-3-carbaldehyde derivative named (P2), newly synthesized on the electrochemical behavior of C38 steel in molar hydrochloric acid was investigated by using the weight-loss method, potentiodynamic polarization, and electrochemical impedance spectroscopy (EIS) measurements. EIS results show that the transfer resistance increases with the increase of concentration of P2 and it also had an inhibiting effect on C38 steel corrosion in HCl solutions. Weight-loss essays confirm that the corrosion rate decreases as the P2 concentration increases. The inhibition efficiency for this compound studied increased with the increase in the inhibitor concentrations to attain 91.7 % at the 10−3 M of P2. The potentiodynamic polarization curves indicated that P2 acted as a mixed-type inhibitor in hydrochloric acid.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Acid solutions find more and more applications in industry, the most important of which are acid pickling, industrial acid cleaning, acid descaling, and oil well acidizing. The commonly used acids are hydrochloric acid, sulphuric acid, and nitric acid, etc. Since acids are used for cleaning of oxides and corrosion products from surfaces, not to attack the metal, the addition of inhibitors is still recommended. Among the metals most used, mild steel is widely used in many chemical industries due to its low cost and easy availability for fabrication of reaction vessels, tanks, and pipes. Then, inhibitors are added to aggressive acid solutions. Organic inhibitors (OI) are widely added in a lot of industrial processes and have been investigated by several workers [1–5]. OIs act by adsorption, which is facilitated by nitrogen, sulphur, and oxygen atoms as well as cyclic rings or double bonds [6–8] of donating electrons and electronic structure of the molecules leading to physical adsorption and/or chemisorptions [9–11]. Inhibitors behave as a protective barrier against the attack of the corrosive environment and can provide protection for the metal and so they reduce corrosion rate of the metal.

Some organic compounds have also been used as inhibitors of steel corrosion in 1.0 M HCl solution, such as pyrazoles [12–15], triazoles [16–19], tetrazoles [20–23], imidazole derivatives [24–28], and pyridine [29–31].

In the present paper, an imidazopyridine derivative newly synthesized was tested as corrosion inhibitor for C38 steel in 1.0 M HCl using potentiodynamic polarization methods and electrochemical impedance spectroscopy (EIS) measurements and gravimetric method.

Experimental

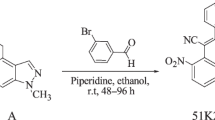

The aggressive solution (1.0 M HCl) was prepared by dilution of analytical-grade 35.4 % HCl with bidistilled water. Prior to all measurements, the C38 steel samples were polished with different emery paper up to 1,200 grade and washed thoroughly with bidistilled water and dried with acetone. The chemical structures of the studied imidazopyridine derivatives are given in Fig. 1. The chemical synthesis procedure is: 10 mol of the precursor imidazo[1,2-a]pyridine is added portions-wise to de N,N-dimethylformamide (DMF) 26 mols (1.9 g) cooled at 0 °C and containing phosphoryl chloride (POCl3) (4 g, 26 mmol). The mixture is then heated at 100 °C for 1 h and neutralized at 0 °C with Na2CO3. The products are extracted with dichloromethane. The organic layer is dried over sodium sulphate and the dichloromethane is removed under reduced pressure. The crude product gel is purified on a silica column and a colorless solid is obtained with 70 % yield.

Gravimetric measurements were carried out in a double-walled glass cell equipped with a thermostat cooling condenser. The solution volume was 50 mL. The steel specimens used had a rectangular form (1 × 1 × 0.05 cm2). The immersion time for the weight loss was 6 h at 308 K. Electrochemical experiments were conducted using impedance equipment (Tacussel-Radiometer PGZ 301) and controlled with Tacussel corrosion analysis software model Voltamaster 4.

A three-electrode electrochemical cell was used. The working electrode was C38 steel with the different surfaces area. Before each experiment, the electrode was polished using emery paper until 1,200 grade. After this, the electrode was cleaned ultrasonically with distillate water.

All potentials were given with reference to the saturated calomel electrode (SCE). The counter electrode was platinum. The aggressive medium used here was 1.0 M HCl solution. The organic compound tested was imidazopyridine derivative. Its molecule formula is shown in Fig. 1. The concentration range of this compound was 10−6–10−3 M.

The working electrode was immersed in test solution for 30 min until a steady-state open-circuit potential (Eocp) was obtained. The polarization curve was recorded by polarization from −800 to 500 mV under potentiodynamic conditions corresponding to 1 mV/s (sweep rate) and under air atmosphere.

The EIS measurements were carried out using a transfer function analyzer (Analytical Radiometer PGZ 301), with a small amplitude AC signal (10 mV rms), over a frequency domain from 100 kHz to 100 MHz at 308 K and an air atmosphere. The polarization resistance, R p, is obtained from the diameter of the semicircle in Nyquist representation.

Results and discussion

Electrochemical impedance spectroscopic studies

The corrosion behavior of C38 steel, in acidic solution containing different concentration of imidazopyridine compound, was investigated by the EIS at 308 K after 30 min of immersion. The obtained results are presented in Fig. 2. The impedance parameters calculated are given in Table 1. The diagrams are composed of one capacitive loop. The charge-transfer resistance values (R ct) were calculated from the difference in real impedance at lower and higher frequencies as suggested by Tsuru et al. [32]. To obtain the double-layer capacitance (C dl), the frequency at which the imaginary component of the impedance is maximum (−Z max) is found and C dl values were obtained from the Eq. (1):

In this case, the inhibition efficiency is calculated using charge-transfer resistance from Eq. (2):

where R ct(inh) and R ct are the charge-transfer resistance in the presence and absence of different products, respectively.

Results obtained show that R ct increases and C dl tends to decrease with increasing of inhibitor concentration.

A decrease in the C dl values, which can result from a decrease in the local dielectric constant and/or an increase in the thickness of the electrical double layer, suggests that the inhibitor acted by adsorption at the metal solution/interface [33].

Polarization curves

The polarization curves of C38 steel in 1.0 M HCl obtained with and without various concentrations of used inhibitor is shown in Fig. 3. Electrochemical parameters such as corrosion current density (I corr), corrosion potential (E corr), Tafel slope constants calculated from Tafel plots (−βc) and the inhibition efficiency (E I %) were determined by Tafel extrapolation method and are given in Table 2. E I % was calculated using Eq. (3):

where I corr and I corr(inh) are the corrosion current density values without and with inhibitor, respectively.

It is seen that the addition of various concentrations of inhibitor affects the polarization curves and consequently decreases I corr significantly, due to increase in the blocked fraction of electrode surface by adsorption. Cathodic curves gave rise to parallel Tafel lines, indicating that the hydrogen evolution is activation controlled and the reduction mechanism is not affected by the presence of inhibitor. These results demonstrated that the hydrogen evolution reaction was inhibited and that the inhibition efficiency increased with inhibitor concentrations. The maximum quantity of the inhibitor reported in Table 1 corresponds to the optimum concentration of the inhibitor. The presence of inhibitor does not cause any significant shift in the E corr value. This implies that the inhibitor, P2, acts as a mixed-type inhibitor, affecting both anodic and cathodic reactions [34]. According to Riggs and coworkers [35], if the displacement in corrosion potential is more than ±85 mV/SCE with respect to the corrosion potential of the blank, the inhibitor can be considered as a cathodic or anodic type, but the maximum displacement in the present case is less than 20 mV/SCE, which indicates that P2 is a mixed-type inhibitor. According to Cao [36], if the shift in E corr is negligible, the inhibition is most probably caused by a geometric blocking effect of the adsorbed inhibitive species on the surface of corroding metal.

Gravimetric measurements

The effect of addition of P2 at different concentrations on C38 steel corrosion in 1.0 M HCl solution was studied by weight-loss measurement after 6 h of immersion. Table 3 shows the values deduced of W corr and the inhibition efficiency (E w %) determined by the following equation:

where W corr and \( W^\circ_{\text{corr}} \) are the corrosion rates of C38 steel in the presence and absence of each inhibitor, respectively.

Table 3 clearly indicates a decrease in the corrosion rate in the presence of all concentrations of this compound. This effect is hugely marked at higher concentration of inhibitor. The presence of P2 gave a high inhibiting. This is probably due to the presence of oxygen and nitrogen atom according to Every and Riggs [37]; the organic compound containing the nitrogen and oxygen has better inhibition efficiency, in acidic media.

Adsorption isotherms are usually used to describe the adsorption process. The most frequently used isotherms include: Langmuir, Frumkin, Temkin Flory–Huggins, Dhar–Flory–Huggins, Bockris–Swinkels. Adsorption of the organic molecules occurs as the interaction energy between molecule and metal surface is higher than that between the H2O molecule and the metal surface. The simple mechanistic picture of the adsorption process was proposed by Langmuir. Langmuir isotherm assumes that:

-

The metal surface contains a fixed number of adsorption sites and each site holds one adsorbate;

-

\( \Updelta G^\circ_{\text{ads}} \) is the same for all sites and it is independent of the surface coverage, θ = E %/100;

-

The adsorbates do not interact with one another, i.e., there is no effect of lateral interaction of the adsorbates on \( \Updelta G^\circ_{\text{ads}} \) [38, 39].

The Langmuir adsorption isotherm given a relatively simple mathematical expression of C, the concentration of inhibitor, K, the adsorptive equilibrium constant and θ, may be written in the following rearranged form:

The adsorptive equilibrium constant leads to determinate the standard adsorption free energy (\( \Updelta G^\circ_{\text{ads}} \)) using:

Figure 4 presents the relationship between C/θ and C. The curve obtained yields a straight line with slope almost equals unity (1.08). The strong correlation factor R² = 0.9998 suggests that the adsorption of P2 on metal surface obeys well the Langmuir adsorption isotherm. The reciprocal of intercept of the straight lines C/θ-axis is K = 93843.84 L/mol. The standard free energy of adsorption (\( \Updelta G^\circ_{\text{ads}} \)) value deduced is −39.61 kJ/mol. Generally, values of \( \Updelta G^\circ_{\text{ads}} \) up to −20 kJ/mol are consistent with electrostatic interactions between the charged molecules and the metal (physisorption) while those around −40 kJ/mol or higher are associated with chemisorptions as a result of sharing or transfer of electrons from organic molecules to the metal surface to form a coordinate type of bond (chemisorptions) [40, 41].

The negative value of \( \Updelta G^\circ_{\text{ads}} \) indicate the stability of the adsorbed layer on the steel surface and spontaneity of the adsorption process and also chemical and physical adsorption can occur together, but any adsorbed layers beyond the first must be physically adsorbed.

Conclusions

On the basis of these results, the following conclusions may be drawn:

-

P2 inhibits the corrosion of C38 steel in 1.0 M HCl. The inhibition efficiency depends on the molecular structure.

-

Impedance method indicates that imidazopyridine derivative adsorbs on C38 steel surface with increasing charge-transfer resistance and decreasing the double-layer capacitance.

-

The inhibition efficiency increases with increasing inhibitor concentrations to attain a maximum value of 91.7 % for inhibitor P2 at 10−3 M.

-

Polarization study shows that imidazopyridine act as a mixed-type inhibitor.

-

P2 adsorbs on the steel surface according to the Langmuir isotherm.

References

F.B. Ravari, A. Dadgarinezhad, I. Shekhshoaei, J. Chil. Chem. Soc. 55, 328 (2010)

F. Bentiss, M. Lagrenee, M. Traisnel, B. Mernari, H. El Attari, J. Appl. Electrochem. 29, 1073 (1999)

M. Dahmani, A. Et-Touhami, S.S. Al-Deyab, B. Hammouti, A. Bouyanzer, Int. J. Electrochem. Sci. 5, 1060 (2010)

P. Kutej, J. Vosta, J. Pancir, J. Macak, N. Hackerman, J. Electrochem. Soc. 142, 829 (1995)

J.M. Bastidas, J.L. Polo, E. Cano, J. Electrochem. Soc. 30, 1173 (2000)

B. Hammouti, A. Zarrouk, S.S. Al-Deyab, I. Warad, Orient. J. Chem. 27, 23 (2011)

A. Fouda, H. Mahfouz, J. Chil. Chem. Soc. 54, 408 (2009)

I. Elouali, B. Hammouti, A. Aouniti, Y. Ramli, M. Azougagh, E.M. Essassi, M. Bouachrine, J. Mater. Environ. Sci. 1, 1 (2009)

M.A. Quraishi, D. Jamal, Corrosion 56, 156 (2000)

M. Benabdellah, A. Yahyi, A. Dafali, A. Aouniti, B. Hammouti, A. Ettouhami, Arab. J. Chem. 4, 343 (2011)

M. Elayyachy, B. Hammouti, A. El Idrissi, A. Aouniti, Port. Electrochim. Acta. 29, 57 (2011)

K. Tebbji, A. Aouniti, A. Attayibat, B. Hammouti, H. Oudda, M. Benkaddour, S. Radi, A. Nahle, Indian J. Chem. Technol. 18, 244 (2011)

K. Tebbji, H. Oudda, B. Hammouti, M. Benkaddour, S.S. Al-Deyab, A. Aouniti, S. Radi, A. Ramdani, Res. Chem. Intermed. 37, 985 (2011)

R. Salghi, L. Bazzi, B. Hammouti, E. Zine, S. Kertit, S. El Issami, E. Ait Eddi, Bull. Electrochem. 17, 429 (2001)

M. Elouafi, B. Hammouti, H. Oudda, S. Kertit, R. Touzani, A. Ramdani, Anti-Corros. Methods Mater. 49, 199 (2002)

S. El Issami, L. Bazzi, A. Benlhachemi, R. Salghi, B. Hammouti, S. Kertit, Pigment Resin Tech. 36, 161 (2007)

F. Bentiss, M. Traisnel, H. Vezin, M. Lagrenee, Corros. Sci. 45, 371 (2003)

K. Bekkouch, A. Aouniti, B. Hammouti, S. Kertit, J. Chim. Phys. 96, 838 (1999)

M.A. Quraishi, R. Sardar, Corrosion 58, 748 (2002)

S. Kertit, B. Hammouti, Appl. Surf. Sci. 93, 59 (1996)

K.F. Khaled, N.S. Abdelshafi, A. El-Maghraby, N. Al-Mobarak, J. Mater. Environ. Sci. 2, 166 (2011)

S. Kertit, H. Essouffi, B. Hammouti, M. Benkaddour, J. Chim. Phys. 95, 2072 (1998)

E.-S.M. Sherif, Mater. Chem. Phys. 129, 961 (2011)

A. Dafali, B. Hammouti, A. Aouniti, R. Mokhlisse, S. Kertit, K. Elkacemi, Ann. Chim. Sci. Mater. 25, 437 (2000)

M. Mousavi, M. Mohammadalizadeh, A. Khosravan, Corros. Sci. 53, 3086 (2011)

A. Dafali, B. Hammouti, S. Kertit, J. Electrochem. Soc. India 50, 62 (2001)

M. Benabdellah, A. Ousslim, B. Hammouti, A. Elidrissi, A. Aouniti, A. Dafali, K. Bekkouch, M. Benkaddour, J. Appl. Electrochem. 37, 819 (2007)

M. Abdallah, H.E. Megahed, M. Sobhi, Monatshefte fur Chem. 141, 1287 (2010)

O. Krim, A. Elidrissi, B. Hammouti, A. Ouslim, M. Benkaddour, Chem. Eng. Commun. 196, 1536 (2009)

K. Bouhrira, F. Ouahiba, D. Zerouali, B. Hammouti, M. Zertoubi, N. Benchat, E-J Chem 7, S35 (2010)

A. Chetouani, B. Hammouti, K. Medjahed, A. Mansri, Der Pharma Chem. 3, 307 (2011)

T. Tsuru, S. Haruyama, B. Gijutsu, J. Jpn. Soc. Corros. Eng. 27, 573 (1978)

E. McCafferty, N. Hackerman, J. Electrochem. Soc. 119, 146 (1972)

D. Jayaperumal, Mater. Chem. Phys. 119, 478 (2010)

O.L. Riggs Jr, in Corrosion Inhibitors, ed. by C.C. Nathan (The National Association of Corrosion Engineers (NACE), Houston, 1973), pp. 2–27

C. Cao, Corros. Sci. 38, 2073 (1996)

R.L. Every, O.L. Riggs, Mat. Prot. 3, 46 (1964)

A. Chetouani, B. Hammouti, A. Aouniti, N. Benchat, T. Benhadda, Prog. Org. Coat. 45, 373 (2002)

L.L. Shreir, R.A. Jarman, G.T. Burstein, Corrosion (vols 1 & 2), 8th edn. (Butterworth and Heinmann, Oxford, 2000), p.2587. ISBN O 7506 1077

M. Bouklah, N. Benchat, A. Aouniti, B. Hammouti, M. Benkaddour, M. Lagrenée, H. Vezin, F. Bentiss, Prog. Org. Coat. 51, 118 (2004)

M. Dahmani, S.S. Al-Deyab, A. Et-Touhami, B. Hammouti, A. Bouyanzer, R. Salghi, A. Elmajdoubi, Int. J. Electrochem. Sci. 7, 2513 (2012)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghazoui, A., Saddik, R., Hammouti, B. et al. Inhibitive effect of imidazopyridine derivative towards corrosion of C38 steel in hydrochloric acid solution. Res Chem Intermed 39, 2369–2377 (2013). https://doi.org/10.1007/s11164-012-0763-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-012-0763-y