Abstract

The effect of iodide ions on the corrosion inhibition of mild steel in 1 M sulfuric acid in the presence of poly(acrylamide-co-4-vinylpyridine) copolymer abbreviated by (AM-4VP-9) was studied by weight loss measurements and electrochemical techniques (impedance spectroscopy and polarisation curves) at 18 °C. The results obtained showed that the inhibition efficiency increased with increasing copolymer concentration. It was also found that the inhibition efficiency increased with the addition of potassium iodide (KI) to the copolymer. A synergistic effect was observed between the AM-4VP-9 copolymer and KI. On the other hand, it was found that the inhibiting effect of the system (AM-4VP-9 + KI) increased with increasing immersion time. Polarisation curves indicate that (AM-4VP-9) copolymer act as mixed inhibitors. EIS measurements show an increase of the transfer resistance with the inhibitor concentration.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Acid solutions are widely used in many service environments such as pickling, cleaning, descaling, and oil well acidising. In order to reduce the corrosion of the metal, inhibitors are usually used in these processes. Most of the well-known acid inhibitors are organic compounds containing nitrogen, sulfur and oxygen [1–8]. The adsorption of these molecules depends mainly on some physico-chemical properties of the inhibitor, such as the functional groups, steric factors, aromaticity, electron density at the donor atoms and p-orbital character of donating electrons [8–10], and the electronic structure of the molecules [11].

For polymer inhibitors, polymer amines have been found to be efficient corrosion inhibitors for iron in acidic solutions because of the presence of abundance of π-electrons and unshared electrons pairs on nitrogen atoms, which can interact with the empty d-orbital of iron [12]. Polyacrylamide [13, 14], polyacrylic acid [15], poly(4-vinylpyridine) [16], poly(4-vinylpyridine isopentyl bromide) [17], and poly(4-vinylpyridine poly-3-oxide ethylene) [18] have been reported as efficient corrosion inhibitors for iron in acidic media.

Some authors have reported synergistic inhibition between halide ions and some compounds including polymers. Earlier studies have shown that halide ions synergistically increased the corrosion inhibition efficiency of polyethylene glycol, polyvinylalcohol, polyacrylamide, polyvinylpyrrolidone, and poly(4-vinylpyridine) for mild steel in acidic media [13, 19–23]. Baojiao et al. [24] have reported the effect of quaternised poly(acrylamide-co-4-vinylpyridine) [poly(AM-co-4VP)] on the corrosion inhibition when the 4-vinylpyridine was introduced into the copolymer. The influence of halide ions on the corrosion inhibition of metals by poly(AM-co-4VP) copolymer has not been investigated.

We have, in this work, synthesised a new copolymer AM-4VP-9 in order to quantify its inhibition efficiency and to evaluate the synergistic effect with I− ions. The gravimetric and electrochemical measurements were made using mild steel immersed in molar sulphuric acid with and without the addition of the copolymer poly(acrylamide-co-4-vinylpyridine) (AM-4VP-9) in the presence and absence of iodide ions.

Experimental

Synthesis and characterise of AM-4VP-9 copolymer

The acryl amide compound was provided by Merck. 4VP (Aldrich, 98 %) was dried over calcium hydride overnight and fractionally distilled under reduced pressure (68–69 °C at 15 mmHg), having discarded the first and last 10 % of the monomer. Ammonium persulfate (Aldrich) was used as initiator without further purification.

AM-4VP-9 copolymer was obtained with a yield 88 % and prepared by radical polymerisation of acrylamide (AM) and 4-vinylpyridine (4VP) in aqueous solution, with ammonium persulfate (APS) as initiating agent. The copolymer was repeatedly precipitated in ethanol. The product was then dried under vacuum at room temperature to constant weight and stored in a desiccator. The molecular structure of newly synthesised copolymer AM-4VP-9 is shown in Fig. 1. It was also purified via several cycles of solubilisation/precipitation in the following couple of solvent/non-solvent (water/ethanol). The product obtained is a pure powder.

The AM-4VP-9 copolymer was characterised by proton nuclear magnetic resonance (1H NMR) spectra with a DMX-500 (Bruker, Germany) and the solvents were D2O/DCl. The 1H NMR spectra of AM-4VP-9 copolymer is shown in Fig. 2 with the following spectral data:

-

1.23–1.59 ppm with a maximum at 1.46 ppm (–CH2–) of the linear chains of the copolymer [25, 26]

-

1.88–2.19 ppm with a maximum at 2.04 ppm (–CH–) of the linear chains of the copolymer [25, 26]

-

4.41–4.72 ppm (solvent protons)

-

6.8 ppm (H atom at ortho position of N of 4VP).

-

7.5–7.8 ppm (H atom at the meta position of N and the ortho position of N+ of 4VP).

-

8.53 ppm (H atom at the meta position of N+ of 4VP) [26, 27].

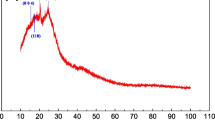

The UV–visible absorption spectra Fig. 3 were recorded with a Shimadzu UV 260 spectrophotometer. The presence of the 4VP in AM-4VP-9 copolymer is confirmed by UV–visible spectrum. The monomer of the 4VP shows an intense absorption at 256 nm which is connected to the π–π* band which is in agreement with the results of Bernard et al. [28]. However, the acrylamide monomer does not show any absorption in this area. From the 1HNMR and UV–visible spectra, we calculated the percentage (%) of 4VP and acrylamide in the copolymer chains. Table 1 gives the values of weight rapport of acrylamide and 4-vinylpyridine monomers in AM-4VP-9 copolymer obtained from the 1H NMR and UV–visible spectra.

The molecular weight was determined by water size exclusion chromatography (GPC) using a set of three columns TSK PWXL obtained from TOSO Haas (length ¼ 30 cm, interior diameter ¼ 7.8 cm) and coupled to an automatic refract-meter or light scattering apparatus, and the molecular weight was also determined by a capillary standard UbBelohde viscometer, with a thermostated bath at 25 ± 0.1 °C. Table 2 gives the results of the AM-4VP-9 copolymer obtained by water size exclusion chromatography (GPC) and by viscosity.

Methods and materials

Prior to each gravimetric or electrochemical experiment, the surface of the specimens was abraded successively with emery paper. The samples were polished finally with emery paper up 1,200 grade. Weight loss was measured on sheets of steel of 2 cm2 apparent surface area. The specimens were then rinsed with acetone and bi-distilled water before being weighed and immersed in 50 ml of the corrosive medium. A clean weighed mild steel sample was completely immersed at an inclined position in the vessel for 4 h of immersion in 1 M H2SO4, with and without the addition of inhibitor at different concentrations.

A solution of 1 M H2SO4 was prepared from an analytical reagent grade 98 % H2SO4 and bi-distilled water and was used as corrosion media. The chemical composition of mild steel is given in Table 3.

Electrochemical measurements were carried out in a conventional three-electrode electrolysis cylindrical Pyrex glass cell. The working electrode had the form of a disc cut from iron sheet. The exposed area to the corrosive solution was 1 cm2. A saturated calomel electrode (SCE) and a platinum electrode were used, respectively, as a reference and auxiliary electrodes. All potentials are given in the SCE scale. The cell was thermostated at 291 ± 1 K.

The current–voltage curves are recorded with a potentiostat (Amel 549) using a linear sweep generator (Amel 567) at a scan rate of 1 V/min. Before recording the cathodic curves, the iron electrode was polarised at 800 mV for 10 min. For anodic curves, the potential of the electrode was swept from its open circuit value after 30 min free corrosion. The test solution was de-aerated for 30 min in the cell with pure nitrogen. Gas bubbling was maintained throughout the experiments.

Electrochemical impedance spectroscopy (EIS) was carried out with a voltalab PGZ 100 electrochemical system at E corr after immersion in solution. After determination of the steady-state current at a given potential, sine wave voltage (10 mV) peak to peak, at frequencies between 100 kHz and 10 mHz, was superimposed on the rest potential. Computer programs automatically controls the measurements performed at rest potentials after 30 min of exposure. EIS diagrams are given in the Nyquist representation.

Results and discussion

Weight loss measurements

Concentration effect of AM-4VP-9 copolymer

The effect of addition of AM-4VP-9 copolymer tested at different concentrations on the corrosion of steel in H2SO4 solution was studied by weight loss at 18 °C after 4 h of immersion. Inhibition efficiency (E w %) is calculated as follows Eq. (1):

W corr and W° corr are the corrosion rates of steel in the presence and absence of the organic compounds, respectively.

Table 4 gives the values of inhibition efficiency obtained from the weight loss measurements for different concentrations of copolymer in 1 M H2SO4. The results show that the inhibition efficiency increases with increasing inhibitor concentrations. The inhibition by AM-4VP-9 copolymer can be explained in terms of adsorption on the metal surface. The adsorption of the AM-4VP-9 molecules could occur due to the formation of links between the d-orbital of iron atoms, involving the displacement of water molecules from the metal surface, and the lone electron pairs.

It is shown that the compounds, having a higher electron density load around the heteroatom’s specially nitrogen atoms, exhibit protective properties which depend upon their ability to reduce the corrosion rate. Effectively, the heterocyclic-containing nitrogen in the polymer structure and electronegative functional groups, π electrons and the conjugated double bands have been proved to perform as inhibitors of the corrosion [8, 9, 11, 21, 22]. The compound can be absorbed by the interaction between the lone pair of electrons of the nitrogen and oxygen atoms and the metal surface. The optimum concentration required to achieve an efficiency of 60.20 % is found to be 100 mg l−1.

Synergic effect

Table 5 lists the results of the inhibition efficiency for the corrosion of mild steel in 1 M H2SO4 in the presence of 10 and 10−1 mg l−1 AM-4VP-9 copolymer with different concentrations of KI (synergic effect) obtained from weight loss measurements at 18 °C after 4 h immersion. The results obtained in Table 5 are represented in Fig. 4.

An increase in inhibition efficiencies can be clearly shown from the results according to the concentration of the KI. This result indicates the synergetic effect between AM-4VP-9 and KI. The maximum of synergy is observed for a precise concentration of KI for each case. Any later increase in the concentration of KI is accompanied by a reduction in the value of the inhibition efficiency. These results are in agreement with the literature [14, 20].

For the high concentration of AM-4VP-9 (C P = 10 mg/l), we observe two fields of variations. The first is an increase in the synergy effect which reaches a maximum (E (%) = 88.60 %) for a weak concentration of the KI (0.008 %). Beyond this value, by increasing the KI concentration, the value of the inhibition efficiency decreases. For the low concentration of AM-4VP-9 (C P = 10−1 mg/l), we observe an increase in the synergy effect according to the KI concentration and the value of the inhibition efficiency attains the maximal value 86.23 % at 0.012 % of KI concentration. After this value, we observe a slight decrease in this synergy effect, which reached 82.50 % for a concentration of KI (0.020 %).

Effect of immersion time

The results obtained of the inhibition efficiency for the corrosion of mild steel in 1 M H2SO4 with 10−1 and 10 mg l−1 of AM-4VP-9 copolymer in the presence of 0.008 % KI obtained from weight loss measurements at 18 °C after different times of immersion are shown in Table 6. The results show that there is an increase in the Inhibition efficiency with an increasing time of immersion which is in agreement with the literature [19].

Polarisation measurements

Concentration effect of AM-4VP-9 copolymer

Current–potential characteristics resulting from cathodic and anodic polarisation curves of steel in 1 M H2SO4 in the presence of the AM-4VP-9 copolymer at various concentrations are evaluated. The cathodic and anodic plots of AM-4VP-9 copolymer are shown in Fig. 5. Table 7 sets out the electrochemical parameters and inhibition efficiencies (E I ) determined by Eq. (2):

I corr and I°corr are the corrosion current density values with and without the inhibitor, respectively, determined by extrapolation of cathodic Tafel lines to the corrosion potential.

The polarisation resistance (R p) and corresponding efficiency inhibition values of mild steel in 1 M H2SO4 in the absence and presence of different concentrations of the inhibitor are also given in Table 7. In this case, the inhibition efficiency (E R %) is calculated by Eq. (3):

where R p and R p′ are the polarisation resistance with and without the inhibitor, respectively.

Table 7 also gives the corresponding electrochemical parameter values of corrosion potentials E corr, corrosion current I corr, cathodic Tafel slope b c, b a and inhibition efficiencies E% for different concentrations of compounds derived from the potentiodynamic polarisation curves.

The increase in AM-4VP-9 copolymer concentrations causes a decrease in the corrosion rate, that is, shifts both the anodic and cathodic curves to lower values of current densities. This implies that the hydrogen evolution reactions are inhibited. This may be ascribed to adsorption of the copolymer over the corroding surface [14, 19, 29].

The electrochemical parameters obtained from the polarisation curves also indicate that corrosion current density decreases markedly in the presence of AM-4VP-9 compared to the blank solution, and also decreases with increasing concentration of the inhibitor. It is clearly observed that the presence of AM-4VP-9 copolymer does not shift E corr remarkably; the values remain almost unchanged.

The parallel Tafel curves obtained indicate that the hydrogen evolution reaction is activation controlled, and the addition of AM-4VP-9 copolymer does not modify the mechanism of this process. Being weakly basic, the compounds, rapidly protonated in acid solutions, exist in their cationic form. Due to electrostatic attraction, the inhibitors are strongly adsorbed onto the electron-rich areas blocking the cathodic sites. This is in agreement with the increase of the cathodic over potential and shift of the steady corrosion potential to less noble directions in the presence of inhibitors.

The anodic curves, with and without AM-4VP-9 inhibitor, show that the inhibition mode depended upon the electrode potential. In the case where the corrosion inhibition depends on the potential of the electrode, the observed phenomena are generally described as corrosion inhibition of the interface associated with the formation of a protective layer of adsorbed inhibition species at the electrode surface [14–17]. We conclude that the AM-4VP-9 has an effect on the cathodic and anodic behaviour of steel and that the compound acts as a mixed inhibitor.

From polarisation resistance measurements (Table 7), we remark that R p increases with increasing of AM-4VP-9 inhibitor concentration. E% increases with the increase of inhibitor concentration to attain 56 % at 100 mg l−1. We may conclude that the inhibition efficiencies of AM-4VP-9 obtained by electrochemical, polarisation resistance and weight loss methods are in good agreement.

Effect of iodide ion concentration

Halide ions are known to improve the adsorption of some organic cations as inhibitors on the corroding metal surface, enhancing its inhibition efficiency considerably. This phenomenon, which has been ascribed to the synergistic effect, is often most pronounced with iodide ions. Experiments were undertaken in the present study to assess the effect of addition of iodide ions on the corrosion inhibition performance of the AM-4VP-9 copolymer for mild steel in 1 M H2SO4. The potentiodynamic polarisation curves for the mild steel in 1 M H2SO4 at different concentrations of KI at 18 °C are similar to their homologue in the absence of KI. So we note that the addition of the iodide ions shifts the E corr to positive values and reduces both the anodic iron dissolution and cathodic hydrogen evolution reactions. The i corr were reduced in the presence of the iodide ions compared to their absence. The values of i corr depend on iodide concentration. Similar observations have been reported in the literature [14, 20, 30].

The addition of iodide ions to AM-4VP-9 produces pronounced effects on the anodic and cathodic currents compared to those obtained in the presence of just AM-4VP-9, but in the cathodic current it was more significant than that of the anodic current. The electrochemical parameters obtained from the polarisation curves are listed in Table 8. The results indicate that the corrosion current density is reduced from 1,650 μA cm−2 in the free acid solution to 757 μA cm−2 in the presence of AM-4VP-9 copolymer. These values were further reduced to 157 μA cm−2 after the introduction of different concentrations of KI.

It is clearly seen that the combination of AM-4VP-9 and KI considerably decreased the corrosion current densities compared to the free acid and AM-4VP-9 solutions leading to higher inhibition efficiency. This is a clear indication of synergistic effect between the copolymer AM-4VP9 and KI.

Impedance measurements

Concentration effect of AM-4VP-9 copolymer

The inhibitive performances of organic inhibitors are widely discussed on the basis of EIS characteristics [13]. The EIS technique has been used to evaluate the efficiency of some organic substances as inhibitors for corrosion of mild steel in acids and others [1–3, 13]. The corrosion behaviour of steel, in the absence and presence of AM-4VP-9 in the presence of KI, was also investigated by electrochemical impedance spectroscopy (EIS) at 308 K after 30 min of immersion. And the corrosion behaviour of mild steel in acidic solution in the presence and absence of AM-4VP-9 was also investigated by electrochemical impedance spectroscopy (EIS) at 291 K after 30 min of immersion (Fig. 6). The charge-transfer resistance (R t) values are calculated from the difference in impedance at lower and higher frequencies. The charge transfer-resistance values (R t) were calculated from the difference in impedance at low and high frequencies [1–3, 13]. The double layer capacitance (C dl) was obtained at the frequency f m at which the imaginary component of the impedance is maximal (Z i, max) by Eq. (4):

The inhibition efficiency obtained from the charge transfer-resistance was determined by Eq. (5):

where R t and R t′ are, respectively, the transfer-resistances values without and with addition of inhibitor.

Diagrams obtained from these investigations for mild steel in 1 M H2SO4 in the presence of various concentrations of AM-4VP-9 alone are shown in Fig. 6. The fact that impedance diagrams have a semicircular appearance shows that the corrosion of steel is controlled by a charge transfer process and that the presence of an inhibitor does not alter the mechanism of dissolution of mild steel in H2SO4.

Table 9 gives the values of the charge transfer resistance R t, double layer capacitance C dl and inhibition efficiency obtained from the above plots. It can be seen that the presence of AM-4VP-9 enhances the values of R t and reduces the C dl values. We remark that the increase of R t and decrease of double-layer capacitance (C dl) and the efficiency increases when the concentration of AM-4VP-9 increases. In fact, the presence of AM-4VP-9 copolymer enhances the value of R t in acidic solution. Values of double layer capacitance are also brought down to the maximum extent in the presence of AM-4VP-9 and the decrease in the values of C dl follows the order similar to that obtained for I corr in this study.

The decrease in C dl may be due to the adsorption of the copolymer to form an adherent film on the metal surface and suggests that the coverage of the metal surface with this film decreases the double layer thickness [14, 19].

Effect of iodide ion

The Nyquist plots for the mild steel in 1 M H2SO4 at different concentrations of KI at 18 °C are similar to their homologue in absence of KI. So we note that the addition of the iodide ions further enhances R t values and reduces C dl values. This can be attributed to the enhanced adsorption of the copolymer in the presence of KI because of the synergistic effect of iodide ions.

The impedance parameters derived from these investigations are mentioned in Table 10. As we notice, the results indicate that the charge transfer-resistance values increased from 22 Ω cm2 in the free acid solution to 45 Ω cm2 in the presence of 10 mg l−1 AM-4VP-9 copolymer. These values increased further to 190 Ω cm2 on the introduction of 10 mg l−1 of AM-4VP-9 concentration in the presence 0.012 % of KI. These results indicate a good synergetic effect between AM-4VP9 and KI.

Time effect

The addition of KI further enhances R t values. This can be attributed to the enhanced adsorption of AM-4VP-9 in the presence of KI because of the synergistic effect of the iodide ions. Nyquist plots for mild steel in 1 MH2SO4 in the presence of 10 mg/l of AM-4VP-9 in combination with 0.008 % KI for different immersion times are shown in Fig. 7.

Typical impedance spectra obtained in the presence of 10 mg/l AM-4VP-9 + 0.008 % KI are shown in Fig. 7. The Nyquist plots were recorded after different immersion periods and each spectrum is characterised by a single full semi-circle. The calculated values of R t (Ω cm2) for mild steel immersed in the inhibited H2SO4 solution at different exposure times and corresponding inhibition efficiency (\( E_{{R_{\text{t}} }} \% \)) are set out in Table 11.

It is seen from Fig. 7 that the impedance diagrams do show semi-circles. It is found that the R t values for steel in 1 M H2SO4 with the combined inhibitor (AM-4VP-9 + KI) increase with immersion time. The obtained impedance diagrams have an almost semi-circular appearance, indicating that a charge transfer process mainly controls the corrosion of mild steel. In fact, the presence of 10 mg/l AM-4VP-9 + 0.008 % KI compound enhances the value of R t in acidic solution. The change in R t values and, consequently, of the inhibition efficiency may be due to the gradual replacement of water molecules by the iodide ions and by the adsorption of AM-4VP-9 molecules on the metal surface, decreasing the extent of dissolution [3, 19]. Some authors attributed this phenomenon to the film formed by the protective molecule inhibitors being thicker when the immersion time increases [31].

The change in R t values and, consequently, of inhibition efficiency may be due to the gradual replacement of water molecules by the iodide ions and by the adsorption of AM-4VP9 molecules on the metal surface, decreasing the extent of dissolution [3] and the results may be due to the adsorption of this compound on the metal surface leading to the formation of film from acidic solution.

Effect of temperature

Temperature can affect the steel corrosion in the acidic media in the presence and absence of inhibitor. To determine the action energy of the corrosion process, gravimetric measurements were taken at various temperatures (291–323 K) in the absence and presence of 10 mg/l of AM-4VP-9 copolymer alone and with 0.008 % KI at 2 h of immersion. The corresponding results are given in Table 12. The inhibition efficiency (E%) and degree of surface coverage (Θ) of the inhibitor in the presence and absence of KI were calculated using Eqs. (1) and (6) [31, 32].

where W and W′ are the corrosion rate of steel due to the dissolution in 1 M H2SO4 in the absence and the presence of definite concentrations of inhibitor, respectively. Θ is the degree of surface coverage of the inhibitor.

From these results, we can deduce that the corrosion rate increases in the blank with the rise of temperature, but in the presence of the copolymer and copolymer with KI, the dissolution of mild steel is widely retarded. The values of inhibition efficiency obtained from the weight loss at various temperatures show that the inhibition efficiency increases with increasing temperature indicating that higher temperature favours the adsorption of copolymer and copolymer with KI on the dissolution of steel at the surface. The corrosion process and protectiveness of an inhibitor are significantly dependent on the temperature.

Figure 8 shows Arrhenius plots for mild steel corrosion rates for blank, inhibitor and inhibitor + KI solution. Straight lines are obtained for the supporting electrolyte and all compounds. The values of the slopes of these straight lines permit the calculation of the Arrhenius activation energy using Eq. (7).

T is the absolute temperature. A is a constant and R is universal gas constant.

Table 13 gives the values of E a obtained. The calculations show that E a decreases in the presence of inhibitor. The decrease in E a in inhibited solutions and the previously considered influence of temperature on the protective effect support the assumption for chemisorptions of AM-4VP-9 and (AM-4VP-9 + KI) on the metal surface [33, 34]. Szauer et al. [35, 36] state that the lower activation energy value of the process in the presence of the inhibitor compared to that in its absence can be attributed to its chemisorptions, while the opposite is the case with physical adsorption.

Adsorption isotherm

Basic information on the interaction between the inhibitor and the mild steel can be provided by the adsorption isotherm. The adsorption of the organic compounds can be described by two main types of interaction: physical adsorption and chemisorptions. These are influenced by the chemical structure of the inhibitor, the type of the electrolyte and the charge and nature of the metal. The surface coverage Θ of the metal surface by the adsorbed inhibitor was calculated using Eq. (6):

The θ values for different inhibitor concentrations at different temperatures were tested by fitting to various isotherms. By far the best fit was obtained with the Langmuir isotherm. According to this isotherm, Θ is related to concentration inhibitor C via

where K designates the adsorption equilibrium constant.

This equation is the ideal equation that should be applied to the ideal case of the physical and chemical adsorption on a smooth surface with no interaction between adsorbed molecules.

It was found that a plot of C/Θ versus C gives straight lines, showing that the adsorption of AM-4VP-9 alone and in combination with KI from H2SO4 1 M on the mild steel surface obeys the Langmuir adsorption isotherm (Fig. 9).

Conclusions

-

AM-4VP-9 inhibits the corrosion of mild steel in H2SO4 and affects both anodic and cathodic Tafel slopes.

-

Synergistic effects between AM-4VP-9 copolymer and KI have been observed. The addition of KI significantly enhances the inhibition efficiency of the copolymer. The adsorption of AM-4VP-9 copolymer is stabilised by the presence of iodide ions in the solutions.

-

The inhibition efficiency of (AM-4VP-9 + KI) improves with increasing immersion time.

-

The chemisorptions of AM-4VP-9 are stabilised by the presence of iodide ions in the solutions.

-

The adsorption of AM-4VP-9 and (AM-4VP-9 + KI) on the metal surface from 1 M H2SO4 obeys the Langmuir adsorption isotherm.

References

A. El Sayed, J. Appl. Electrochem. 27, 193 (1997)

M. Ajmal, A.S. Mideen, M.A. Quraishi, Corros. Sci. 36, 79 (1994)

F. Bentiss, M. Traisnel, M. Lagrenee, Corros. Sci. 42, 127 (2000)

X.L. Cheng, H.Y. Ma, S.H. Chen, R. Yu, X. Chen, Z.M. Yao, Corros. Sci. 41, 321 (1999)

M. Ajmal, J. Rawat, M.A. Quraishi, Br. Corros. J. 34, 220 (1999)

S. Kertit, B. Hammouti, Appl. Surf. Sci. 93, 59 (1996)

S.A. Abd El-Maksound, Int. J. Electrochem. Sci. 3, 528 (2008)

A. Chetouani, B. Hammouti, A.T. Benhadda, M. Daoudi, Appl. Surf. Sci. 249, 375 (2005)

K.F. Khaled, Electrochim. Acta 48, 2493 (2003)

M. Lebrini, M. Lagrenée, M. Vezin, L. Gengembre, F. Bentiss, Corros. Sci. 47, 485 (2005)

F. Bentiss, M. Lagrenée, M. Traisnel, J.C. Hornez, Corros. Sci. 41, 789 (1999)

C. Jeyaprabha, S. Sathiyanarayanan, G. Venkatachari, Appl. Surf. Sci. 253, 432 (2007)

S.A. Umoren, E.E. Ebenso, Mater. Chem. Phys. 106, 387 (2007)

S.A. Umoren, Y. Lia, F.H. Wang, Corros. Sci. 52, 1777 (2010)

S.A. Umoren, Y. Lia, F.H. Wang, Corros. Sci. 52, 2422 (2010)

Y. Abed, B. Hammouti, F. Touhami, A. Aouniti, S. Kertit, A. Mansri, K. Elkacemi, Bull. Electrochem. 17, 105 (2001)

A. Chetouani, K. Medjahed, K.E. Benabadji, B. Hammouti, S. Kertit, A. Mansri, Prog. Org. Coat. 46, 312 (2003)

Y. Abed, Z. Arrar, B. Hammouti, F. Touhami, M. Taleb, S. Kertit, A. Mansri, Anticorros. Methods Mater. 48, 304 (2001)

L. Larabi, Y. Harek, M. Traisnel, A. Mansri, J. Appl. Electrochem. 34, 833 (2004)

L. Larabi, Y. Harek, Portgu. Electrochim. Acta. 22, 227 (2004)

S.A. Umoren, O. Ogbobe, E.E. Ebenso, U.J. Ekpe, Pigment Resin Technol. 35, 284 (2006)

S.A. Umoren, U.M. Eduok, E.E. Oguzie, Portgu. Electrochim. Acta 26, 533 (2008)

S.A. Umoren, O. Ogbobe, E.E. Ebenso, Bull. Electrochem. 22, 155 (2006)

G. Baojiao, L. Yuexian, J. Hongfang, J. Polym. Int. 52, 1468 (2003)

B. Grassl, G. Clisson, A. Khoukh, L. Billon, Eur. Polym. J. 44, 50 (2008)

Z. Gui, J. Qian, Q. An, H. Xu, Q. Zhao, Eur Polym. J. 45, 1403 (2009)

K. Benmansour, K. Medjahed, L. Tennouga, A. Mansri, Eur. Polym. J. 39, 1443 (2003)

Y. Bernard, D. Coleman, R.M. Fuoss, J. Am. Chem. Soc. 77, 5472 (1955)

G. Mu, X. Li, Q. Qu, J. Zhou, Corros. Sci. 48, 445 (2006)

C. Jeyaprabha, S. Sathiyanarayanan, S. Muralidharan, G. Venkatachari, J. Braz. Chem. Soc. 17, 61 (2006)

S.R. Lodha, Pharm. Rev. 6, 1 (2008)

A. Zarrouk, B. Hammouti, H. Zarrok, I. Warad, M. Bouachrine, Der Pharma Chem. 2, 263 (2011)

F.S. de Souza, A. Spinelli, Corros. Sci. 51, 642 (2009)

C. Selles, O. Benali, B. Tabti, L. Larabi, Y. Harek, J. Mater. Environ. Sci. 3, 2028 (2012)

T. Szauer, A. Brandt, Electrochim. Acta 26, 1209 (1981)

Z. A. Foroulis, in Proceedings of the 6th European Symposium on Corrosion Inhibitors, Ferrara, 1985, p. 48

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mansri, A., Bouras, B., Hammouti, B. et al. Synergistic effect of AM-4VP-9 copolymer and iodide ion on corrosion inhibition of mild steel in 1 M H2SO4 . Res Chem Intermed 39, 1753–1770 (2013). https://doi.org/10.1007/s11164-012-0710-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-012-0710-y