Abstract

Visible-light-driven N-doped TiO2 was prepared by a simple sol–gel process using nitric acid not only as the acid catalyst of the sol–gel reaction but also as the source of nitrogen. The photocatalytic performance of the N-doped TiO2 was investigated by using FTIR spectroscopy to monitor the degradation of trichloroethylene (TCE) during UV and visible irradiation. The photocatalytic degradation of TCE was well-reproduced several times. The activity of Ti–O–N species was supported experimentally. The N-doped TiO2 was found to be responsive to visible light and was stable during repeated runs and maintained the nitrogen species and its activity for at least four months.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Today, photocatalysts are the focus of attention as one type of green technology. Although this technology is expected to be available to effectively utilize light energy, a typical photocatalyst material, TiO2, can utilize only UV light of wavelength shorter than approximately 380 nm. Sunlight is an enormously energetic light source in which the amount of UV light is no more than 3–5% whereas that of visible light is much higher. Photocatalysts, therefore, require visible-light activity.

Various types of visible-light-driven photocatalysts have been developed throughout the world. Chemical doping into TiO2 is one of the effective methods of obtaining visible light activity by forming a narrow band gap or impurity state between its conduction and valence bands. Ohno et al. prepared C4+ and S4+-co doped TiO2 having a rutile phase by calcining rutile TiO2 mixed with (NH2)2CS [1]. These catalysts had an absorption band edge at 700 nm and high activity in the photocatalytic oxidation of some organic compounds [1]. Anpo and Takeuchi [2] prepared a second-generation TiO2 by an advanced metal ion-implantation method.

N-doping has also been widely investigated because its availability [3–13]. N-doped TiO2 photocatalysts are usually prepared by treating TiO2 with NH3, for example, heating TiO2 in an NH3 gas atmosphere [5, 7, 10, 13]. Li et al. [8] prepared N-containing TiO2 powders with a porous surface by the spray pyrolysis of NH4F and TiCl4. Sato et al. [9] prepared a visible-light-sensitive TiO2 photocatalyst by wet-method N-doping, that is, hydrolysis of titanium tetraisopropoxide or TiCl4 with an aqueous NH3 solution. A sol–gel method is also available for obtaining uniform TiO2 nano-sized crystalline particles. Not only TiO2, but also N-doped TiO2 can be prepared by use of a sol–gel precursor solution containing different nitrogen compounds, for example (NH2)2CO [14].

Although photocatalytic properties are evaluated by degradation of organic compounds such as methylene blue [3–8, 12, 14, 15], identification and quantification of the products have rarely been reported. Essential evaluation of the photocatalyst is achieved by understanding the mechanism of reaction of such organic compounds and the interaction between the compounds and the surface of the photocatalyst at a molecular level.

The objectives of this study were preparation of N-doped TiO2 with visible-light activity and examination of the photocatalytic degradation of trichloroethylene (TCE), a volatile organic compound (VOC), by FTIR spectroscopy. Nitric acid is often used as acid catalyst in the sol–gel process to prepare TiO2 [16, 17]. We used nitric acid not only as an acid catalyst, but also as a source of nitrogen to dope the TiO2 with N [18]. This is an easy procedure for preparation of N-doped TiO2 without using an extra nitrogen source, for example NH3, (NH2)2CO, etc.

TCE has been widely used for cleaning some metals and as a dry cleaning solvent. Because of careless handling, such chemical materials have contaminated air, soil, rivers, and groundwater throughout the world. Because photocatalytic degradation of TCE is very important environmentally and ecologically, the products obtained have been globally investigated and reaction mechanisms have been suggested [16, 19–26]. It is very important to investigate the photocatalytic degradation of TCE and its reaction mechanism to examine the reactivity and stability of the prepared N-doped TiO2 and, furthermore, to acquire detailed information for design of effective photocatalysts.

Experimental

Materials

Tetraisopropyl orthotitanate (TPOT), nitric acid (69–70%), trichloroethylene (TCE), and ethanol of S reagent grade obtained from Wako Pure Chemicals were used without further purification. Dry nitrogen gas and dry air (ca. 79% nitrogen + 21% oxygen) were obtained from Okaya Sanso. Water was deionized and distilled (Yamato WG23). Titanium dioxide (Wako Pure Chemicals Anatase-type and Nippon Aerosil P25) was used without further purification for comparison of some of its chemical properties with those of our samples.

Preparation of the N-doped TiO2 catalyst

The sol–gel system used to prepare the N-doped TiO2 consisted of 6.8 ml TPOT, 40 ml ethanol, and 10 ml nitric acid as catalyst for the sol–gel reaction and a source of nitrogen. TPOT was added drop by drop to a mixture of the other materials in a glove box filled with dry nitrogen gas at ambient temperature. The solution was stirred during the addition, then thoroughly for an additional 15 min, and finally slowly dried in an oven at 35 °C for 30 days. The resulting dry gel was heated at 300 °C for 3 h.

Non-doped TiO2 was also prepared from a solution containing a small amount of nitric acid as catalyst. A solution containing 0.21 ml nitric acid and the other components used for the N-doped TiO2 preparation was dried at 60 °C for 1 day and then heated at 300 °C for 3 h.

The prepared catalysts were stored at room temperature before characterization and examination of their photocatalytic activity.

Characterization of the N-doped TiO2

The prepared N-doped TiO2 was characterized by UV–visible diffuse reflectance spectroscopy (Shimadzu UV3150), XRD analysis using CuKα radiation (Rigaku RINT2000), FTIR spectroscopy (Shimadzu 8300A), SEM (JSM 7000F), and XPS (ULVAC PHI 5600). The prepared non-doped TiO2 and reference anatase-type TiO2 (Wako Anatase) were also characterized in the same way.

Photocatalytic degradation of TCE

N-doped TiO2, non-doped TiO2, or Nippon Aerosil P25 (P25), 2.50 g, was placed in an infrared cell made of Pyrex glass. Two plates of KBr single crystals were used as the infrared windows and were sealed by Teflon O-rings. The TCE gas samples for the degradation experiment were prepared by dilution with dry air using a Permeater (Gastec PD-1B). The gas samples passed through the cell at 200 ml/min for 30 min, and the valves of the cell were then closed. Degradation of the TCE, by near-UV light irradiation from a 4-W black light bulb (Toshiba FL4BLB) and visible light from a 150-W Xenon lamp (Hamamatsu Photonics C2577) with a 420 nm cutoff filter, was carried out in the cell at ambient temperature. The FTIR spectra of the gas phase in the cell were observed as a function of irradiation time. We can assume that the chemical species that existed in the reaction cell are in equilibrium between the gas phase and the catalyst surface. Therefore, the decomposed species on the catalyst surface appear in the FTIR spectra.

Results and discussion

Characterization of the N-doped TiO2

Figure 1 shows the UV–visible diffuse reflectance spectra of the prepared N-doped TiO2, the non-doped TiO2, and the Wako anatase. The ordinate indicates the Kubelka–Munk function approximating the absorbance. The N-doped TiO2 obviously exhibits visible light absorption ranging from 400 to 600 nm whereas the absorption edge of the non-doped TiO2 and the Wako anatase is located at around 380–420 nm [3–5, 10, 13, 14, 18]. Therefore, the prepared N-doped TiO2 probably utilizes visible light more efficiently than the non-doped TiO2. This result indicates that the TiO2 was definitely doped with nitrogen which formed an impurity band above the valence band of the TiO2, because the original absorbance edge of TiO2 is also observed at around 410–420 nm similar to that of the non-doped TiO2. The absorption edge of the non-doped TiO2 is located at longer wavelength than that of the Wako anatase because of oxygen defects resulting from preparation at low temperature (300 °C).

The process of preparation of the N-doped TiO2 was observed by FTIR spectroscopy. Figure 2 shows the FTIR spectra of the dried gel containing a large amount of NO3 − (before heat treatment) and the N-doped TiO2 (after heat treatment) compared with that of the Wako anatase. The spectrum of the dried gel mainly has five bands originating from the OH-stretching of Ti–OH and adsorbed water (3,500–2,800 cm−1), OH-bending of adsorbed water (1,630 cm−1), NO-stretching of NO3 − (1,385 cm−1), a tetrahedral TiO-stretching band (840 cm−1) [27], and an octahedral TiO-stretching band (560 cm−1) [27–30]. After the heat treatment, the bands arising from Ti–OH, adsorbed water, and NO3 − drastically decreased in their intensities and almost disappeared. In addition to these results, the relative intensity of the tetrahedral TiO band decreased and that of the octahedral TiO band increased. The spectral shape of the prepared N-doped TiO2 became similar to that of the Wako anatase. These results indicate that the TiOH groups are further polymerized and the resulting water molecules were evaporated by heating. These results also indicate that visible absorption does not originate from the Ti complex with organic compounds because the organic compounds are hardly observed even in the FTIR spectrum of the dried gel before heating.

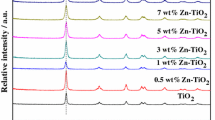

The X-ray powder diffraction pattern of the N-doped TiO2 is compared with that of the Wako anatase in Fig. 3. The clear diffraction peaks appeared at 25.1, 37.9, 48.2, 53.8, and 54.9° in the pattern of the N-doped TiO2. These peaks coincided with the typical pattern of the anatase-type TiO2, indicating that the gel was crystallized by heating and formed the anatase-type TiO2 structure in which a small amount of oxygen was probably replaced with nitrogen. Using the width of the diffraction peak at 25.1°, the particle size of the N-doped TiO2 was estimated by use of Sherrer’s equation, D = 0.9λ/β·cosθ, to be ca 7.9 nm. The slow drying and heating at a relatively low temperature led to moderate particle growth and small particles.

Figure 4 shows the XPS spectra relating to the binding energy of the N 1s electron at around 400 eV for the non-doped and the N-doped TiO2s [11, 31]. A weak peak in the spectrum of the non-doped TiO2 was observed at approximately 402 eV, assigned to the nitrogen molecules adsorbed on the TiO2. In the N-doped TiO2, in addition to this band, a relatively strong peak was observed at 399 eV. The strong 399-eV band is assigned to the O–N bond in the structure of Ti–O–N even though the IR spectrum of the N-doped TiO2 does not show an explicit NO-stretching band (Fig. 2). This result indicates that a small amount of nitrogen oxide species except NO3 − exist in the system [9, 10, 18]. The result from XPS analysis supports the doping of TiO2 by N by use of our procedure. There was, however, no obvious 396 eV band assigned to the Ti–N bond produced by replacement of oxygen in the TiO2 lattice with nitrogen [5, 7, 10, 18]. Because of the small amount of nitrogen species, the spectral peak and shape due to Ti or O for the N–TiO2 was scarcely different from those of the non-doped TiO2.

The SEM images, although not shown here, revealed the N-doped TiO2 is porous and consists of nonuniformly-sized rough particles, which are agglomerates of 20–50 nm-sized spherical particles. The size of the crystalline particles must be much smaller than the apparent size considering the result from XRD analysis, from which the particle size was estimated to be ca 7.9 nm.

Photocatalytic degradation of TCE

The photocatalytic degradation reactions of TCE on UV or visible irradiation were investigated using the prepared N-doped TiO2. Three typical characteristic IR bands of TCE at 944 cm−1 (C–Cl stretching), 849 cm−1 (C–Cl stretching), and 783 cm−1 (C–H bending) rapidly decreased on UV irradiation. In addition to these, CO (2,231–2,066 cm−1), CO2 (2,398–2,280 cm−1), COCl2 (856 cm−1), HCl (3,037–2,723 cm−1), and dichloroacetyl chloride (DCAC) (800 and 741 cm−1) were mainly produced during the reaction [10, 13, 16, 21, 22, 26]. The degradation of TCE was confirmed by these IR measurements. The time course of the relative amounts of TCE and each product were estimated by analyzing their FTIR spectra. Figure 5 shows the time course, versus irradiation time, of the IR absorbance at 944 cm−1 for TCE, at 2,172 cm−1 for CO, at 2,358 cm−1 for CO2, at 1,832 cm−1 for COCl2, at 2,944 cm−1 for HCl, and at 741 cm−1 for DCAC. The absorbance of TCE, which was initially 0.043, progressively decreased with UV irradiation and almost became zero after irradiation for 3 min. The absorbance of CO, CO2, COCl2, and HCl gradually increased as that of TCE decreased and became 0.009, 0.049, 0.057, and 0.014, respectively, after irradiation for 5 min. However, the intermediate product, DCAC, which also initially increased with UV irradiation, quickly disappeared within the 4-min UV irradiation. This behavior of DCAC indicates that some TCE molecules were converted into COCl2 via DCAC, similar to previous photocatalytic degradation of TCE using TiO2 [16]. Therefore, the prepared N-doped TiO2 works as a highly active photocatalyst during UV irradiation.

The visible-light activity of the N-doped TiO2 was also examined by FTIR measurement as a function of irradiation time. Based on the changes in the absorbance of each species, TCE was degraded and CO, CO2, HCl, and COCl2 were generated during the visible irradiation, similar to UV irradiation. However, no DCAC was found in this case, similar to results reported in a previous paper [10]. The absorbance at 944 cm−1 for TCE, at 2,172 cm−1 for CO, at 2,358 cm−1 for CO2, at 1,832 cm−1 for COCl2, and at 2,944 cm−1 for HCl were plotted versus irradiation time (Fig. 6). The absorbance of TCE progressively decreased with visible irradiation and changed from 0.042 to almost zero after the 40-min irradiation. The absorbance of CO, CO2, COCl2, and HCl gradually increased as that of TCE decreased and the values became 0.0047, 0.053, 0.024, and 0.0026, respectively, after the 40-min irradiation. This result clearly showed that the degradation of TCE was gradually followed by production of CO, CO2, COCl2, and HCl.

The relationship between the decrease in the amount of TCE and the increase in the amount of COCl2 during visible irradiation was found to be somewhat different from that during UV irradiation. The absorbance of COCl2 continuously increased with a decrease in that of DCAC during UV irradiation even after the 2-min irradiation when the TCE almost disappeared. On the other hand, the COCl2 increase corresponded to the TCE decrease during visible irradiation. This phenomenon reflects the fact that COCl2 was directly produced from TCE without producing DCAC during visible irradiation. In addition to this, the relative rate of the rise in CO2 to the decay of TCE during visible irradiation was also faster than that during UV irradiation. This result is supported by the reaction mechanism that the by-products are CO and CO2, respectively, when COCl2 is produced via DCAC and directly from TCE [22]. There are, however, also other reaction processes that produce CO, CO2, and HCl. This is because both CO and CO2 were produced during both UV and visible irradiation, and obviously higher amounts of COCl2 and HCl were produced during UV irradiation than during visible irradiation. The smaller amounts of the chlorine compounds produced during visible irradiation are because of recombination of the Cl radicals [10]. It has been suggested that some chlorine species are strongly adsorbed on the catalyst and form a particular structure during visible irradiation. On the other hand, the DCAC produced during UV irradiation is adsorbed and forms a phosgene-like structure [10, 32] on the catalyst and is then desorbed into the gas phase.

In order to compare their UV and visible light activities, the photocatalytic degradation was also carried out using the non-doped TiO2 and P25 in the same way as using the N-doped TiO2. Figure 7 shows the absorbance decay of TCE in these experiments on photocatalytic degradation using N-doped TiO2, non-doped TiO2, and P25 during UV or visible irradiation. Although TCE was quickly degraded during UV irradiation with all the catalysts, it was not readily degraded during visible irradiation with the non-doped TiO2 and P25. All three catalysts were highly active during UV irradiation whereas the non-doped TiO2 and P25 were almost inactive during visible irradiation. These results indicated that the N-doping by our method clearly enhanced the visible light activity of the original TiO2 catalyst for TCE degradation.

The duration of the photocatalytic activity of the N-doped TiO2 during the UV and visible irradiation was investigated by repeated use of the catalyst. Degradation of TCE was observed during cycling of UV and visible light irradiation for 2 and 30 min, respectively. The TCE in the cell was replaced with a fresh sample every cycle. TCE was hardly degraded for 60 min in the dark. TCE was almost degraded within 2 min by UV irradiation over four times and in 30 min by visible irradiation over three times. The N-doped TiO2 was activated by both UV and visible light and its photocatalytic activity was stable during our experiments.

In this study the prepared N-doped TiO2 did not contain a Ti–N bond but did contain an O–N bond in the structure of Ti–O–N . The change in photocatalytic activity of the N-doped TiO2 was observed in order to examine the durability of this nitrogen species. Figure 8 shows the time course of the relative absorbance of TCE during photocatalytic degradation of TCE by visible irradiation using the N-doped TiO2 as prepared and after storage for 22, 59, and 121 days after preparation. TCE was almost degraded within 30–40 min by every sample of catalyst. The N-doped TiO2 was found to retain the nitrogen species and its activity for at least four months.

Conclusions

In this study, the N-doped TiO2 of the visible-light-driven photocatalyst was prepared by a simple sol–gel process using nitric acid not only as an acid catalyst for the sol–gel reaction but also as a nitrogen source. The XPS spectra of the N-doped TiO2 relating to the binding energy of the N 1s electron indicated a strong 399-eV band which can be assigned to the O–N bond in the Ti–O–N structure.

The photocatalytic performance of the N-doped TiO2 was investigated by monitoring the degradation of TCE during UV and visible irradiation. TCE was rapidly degraded during both UV and visible irradiation, and CO, CO2, COCl2, and HCl were generated as products. DCAC as an intermediate product was found only on UV irradiation and not during visible irradiation. The amount of COCl2 continuously increased during UV irradiation even after the TCE almost disappeared whereas during visible irradiation the increase in COCl2 corresponded to the TCE decrease. This phenomenon reflects the fact that COCl2 was directly produced from TCE, and DCAC was not generated during visible irradiation. During irradiation with visible light the N-doped TiO2 remarkably degraded the TCE. The photocatalytic degradation using the N-doped TiO2 was reproducible in three or four continuous experiments. The N-doped TiO2 prepared by our simple sol–gel method was found to have high potential for visible light activity and was stable during repeated runs. The nitrogen species and its activity remained for at least four months.

References

T. Ohno, T. Tsubota, M. Toyofuku, R. Inaba, Catal. Lett. 98, 255 (2004)

M. Anpo, M. Takeuchi, Int. J. Photoenergy 3, 89 (2001)

S. Sato, Chem. Phys. Lett. 123, 126 (1986)

T. Ihara, M. Miyoshi, Y. Iriyama, O. Matsumoto, S. Sugihara, Appl. Catal. B: Environ. 42, 403 (2003)

R. Asahi, T. Morikawa, T. Ohwaki, K. Aoki, Y. Taga, Science 293, 269 (2001)

Y. Cong, L. Xiao, J. Zhang, F. Chen, M. Anpo, Res. Chem. Intermed. 32, 717 (2006)

S. Yang, L. Gao, J. Am. Ceram. Soc. 87, 1803 (2004)

D. Li, H. Haneda, S. Hishita, N. Ohashi, Res. Chem. Intermed. 331, 31 (2005)

S. Sato, R. Nakamura, S. Abe, Appl. Catal. A 131, 284 (2005)

S.K. Joung, T. Amemiya, M. Murabayashi, K. Itoh, Chem. Eur. J. 12, 5526 (2006)

L. Wicikowski, B. Kusz, L. Murawski, K. Szaniawska, B. Susla, Vacuum 54, 221 (1999)

J.L. Gole, J.D. Stout, J. Phys. Chem. A 108, 1230 (2004)

R. Nakamura, T. Tanaka, Y. Nakato, J. Phys. Chem. B 108, 10617 (2004)

A.R. Gandhe, S.P. Naik, J.B. Fernandes, Microporous Mesoporous Mater. 87, 103 (2005)

X. Yan, T. Ohno, K. Nishijima, R. Abe, B. Ohtani, Chem. Phys. Lett. 429, 606 (2006)

K. Oki, S. Tsuchida, H. Nishikiori, N. Tanaka, T. Fujii, Int. J. Photoenergy 5, 11 (2003)

K. Oki, S. Yamada, S. Tsuchida, H. Nishikiori, N. Tanaka, T. Fujii, Res. Chem. Intermed. 29, 827 (2003)

C.X. Dong, A.P. Xian, E.H. Ham, J.K. Shang, J. Mater. Sci. 41, 6168 (2006)

M.R. Nimlos, W.A. Jacoby, D.M. Blake, T.A. Milne, Environ. Sci. Technol. 27, 732 (1993)

S.J. Hwang, C. Petucci, D. Raftery, J. Am. Chem. Soc. 120, 4388 (1998)

P.B. Amama, K. Itoh, M. Murabayashi, J. Mol. Catal. A: Chem. 176, 165 (2001)

J.S. Kim, K. Itoh, M. Murabayashi, B.A. Kim, Chemosphere 38, 2969 (1999)

K.H. Wang, H.H. Tsai, Y.H. Hsieh, Appl. Catal. B: Environ. 17, 313 (1998)

K.H. Wang, H.H. Tsai, Y.H. Hsieh, Chemosphere 36, 2763 (1998)

S. Yamazaki-Nishida, S. Cervera-March, K.J. Nagano, M.A. Anderson, K. Hori, J. Phys. Chem. 99, 15814 (1995)

M. Kang, J.H. Lee, S.H. Lee, C.H. Chung, K.J. Yoon, K. Ogino, S. Miyata, S.J. Choung, J. Mol. Catal. A: Chem. 193, 273 (2003)

P. Tarte, in Physics of Non-Crystalline Solids, ed. by J.A. Prins, (North Holland, Amsterdam, 1965), p. 549

M.L. Galzada, L. Delolmo, J. Non-Cryst. Solids 121, 413 (1990)

S.B. Amor, G. Baud, J.P. Besse, M. Jacquet, Mater. Sci. Eng. B47, 110 (1997)

L. Castañeda, J.C. Alonso, A. Ortiz, E. Andrade, J.M. Saniger, J.G. Bañuelos, Mater. Chem. Phys. 77, 938 (2002)

T. Ihara, M. Miyoshi, M. Ando, S. Sugihara, Y. Iriyama, J. Master. Sci. 36, 4201 (2001)

S.K. Joung, T. Amemiya, M. Murabayashi, K. Itoh, J. Photochem. Photobiol. A: Chem. 184, 273 (2006)

Acknowledgments

The authors thank Ms A. Momozawa of this university for her experimental assistance during the first stage of this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yokosuka, Y., Oki, K., Nishikiori, H. et al. Photocatalytic degradation of trichloroethylene using N-doped TiO2 prepared by a simple sol–gel process. Res Chem Intermed 35, 43–53 (2009). https://doi.org/10.1007/s11164-008-0019-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-008-0019-z