Abstract

Microbiologically influenced corrosion is a serious type of corrosion as approximately 20% of the total economic losses. Sulfate reducing bacteria and Iron oxidizing bacteria are one of the typical representatives of the anaerobic and aerobic bacteria, which are ubiquitous in natural environments and corrode steel structures. Cathodic polarization has been recognized as an effective method for preventing steels from microbial corrosion. Although cathodic polarization method has been widely studied, the specific properties of cathodic current that influences the bacterial removal and inactivation remained largely unclear. This review is to show the main effects of Sulfate reducing bacteria and Iron oxidizing bacteria on metal decay as well as the inhibition mechanism of cathodic polarization in the study of bio-corrosion.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Microbiologically influenced corrosion (MIC) can accelerate deterioration of metal alloys in a wide range of industries such as marine engineering infrastructure, recirculated cooling systems, and oil/gas pipelines, etc. (Jogdeo et al. 2017; Little et al. 1992; Liu and Frank Cheng 2017; Sheng et al. 2007). Microorganisms exhibit extreme tolerance to hostile environments such as acidic and alkaline pH, low and higher temperatures as well as pressure gradients. It is estimated that up to 20% or more of corrosion losses can be attributed to MIC (Fatah et al. 2013). The major characteristics of some anaerobic and aerobic microorganisms are illustrated in Table 1. A number of different groups of microbes carrying out metabolisms such as sulfate reduction (Li et al. 2001), methane production (Boopathy and Daniels 1991), and Fe(III) reduction (Duan et al. 2008) have been implicated in MIC, and these processes can enhance metal dissolution and produce cathodic conditions that cause surface pitting which leads to more rapid corrosion. While the physiological attributes of different microorganism community are generally understood, less is known about the process of MIC. One of the explanations for the difficulty in reaching an adequate understanding of MIC was the lack of an appropriate transfer of knowledge among different areas, including microbiology, metallurgy, electrochemistry, and chemical engineering. Unraveling the complex interaction between microorganisms, the metal surface they inhabit, the metabolite they produce, and how they affect the corrosion process are all important in MIC research.

Microorganisms associated with corrosion damage are anaerobic and aerobic bacteria. Sulfate reducing bacteria (SRB) and Iron oxidizing bacteria (IOB) are one of the typical representatives of the anaerobic and aerobic bacteria, which are ubiquitous in natural environments and corrode steel structures (Ashassi-Sorkhabi et al. 2012; Sand and Gehrke 2003). SRB are commonly considered the main culprits of MIC because there is the wide availability of sulfate (\({\text{SO}}_{4}^{2 - }\)) in environment (e.g., anoxic seawater) (Abbas et al. 2013; Moon et al. 2007). Anaerobic SRB may tolerate exposure to oxygen (O2) for a considerable time until they adhere to the surface of substrate (Zhang et al. 2015). SRB use \({\text{SO}}_{4}^{2 - }\) as the electron acceptor and reduce it to S2− ions or hydrogen sulfide (H2S) (Li et al. 2001). MIC caused by the aerobic bacteria has also been adequately studied (McBeth et al. 2011; Scotto et al. 1985; Yuan and Pehkonen 2007). IOB are another major type of corrosive bacteria, causing serious corrosion damages (Maeda et al. 1999; Wang et al. 2014). IOB oxidize ferrous ions (Fe2+) to ferric ions (Fe3+) with oxygen (O2) as the terminal electron acceptor for energy generation in their metabolism (McBeth et al. 2011; McBeth and Emerson 2016). Under biocatalysis by IOB, the oxidation rate of Fe2+ is much faster than the abiotic chemical oxidation reaction (Liu et al. 2016a). Thus, IOB accelerate the dissolution and localized corrosion of steels. IOB can deposit ferric hydroxide (Fe(OH)3) on the steel surface which can lead to crevice attack and can also provide a suitable environment for the anaerobic bacteria in the region beneath the tubercle to accelerate corrosion. The most aggressive MIC occurs with natural populations containing several bacterial species rather than a single species (Liu et al. 2014; Sung et al. 2011). For example, the interaction between SRB and IOB could together accelerate the pitting corrosion process of steel (Xu et al. 2008). Due to the consumption of O2 by aerobic IOB, the region within biofilm becomes anaerobic easily and anaerobic SRB can proliferate in the locally anaerobic conditions beneath biofilm to accelerate and facilitate corrosion.

MIC is mainly caused by the formation of biofilm (Flemming 2002; Sheng et al. 2007; Videla and Herrera 2005; Wang et al. 2004). Once established on the substratum surface, biofilms are often difficult to control and are almost impossible to eliminate with conventional microbiological control strategies with antimicrobial agents and disinfectants (Costerton et al. 2003). For this reason, it is generally recognized that one of the most effective strategies to control biofilms formation is to prevent adhesion of bacteria at initial steps (Bos et al. 1999). Cathodic polarization (CP) is an effective and commonly used method to prevent metallic facilities from corrosion by applying impressed current to a metallic structure and allowing only the cathodic oxygen reduction reaction to occur. The CP method used for controlling bacterial adhesion is considered to be environmental friendly because it uses electrons as the nontoxic reaction mediator. This method can be widely used in aqueous systems especially useful in marine environments or certain soils where the medium conductivity is high enough to obtain a uniform current distribution over the metal surface for protection. Some investigations suggest that CP can inhibit MIC (Edyvean et al. 1992; Liu and Cheng 2017; van der Borden et al. 2004). However, there is still much controversy with respect to the possible inhibitory mechanisms of CP on MIC (Istanbullu et al. 2012; Liu and Cheng 2017; Pérez et al. 2009).

This review describes the current understanding of MIC mechanisms caused by SRB and IOB, the process of biofilm formation and the role of the bacterial biofilm in both corrosion and mitigation response, and finally the inhibitory effects of CP on MIC.

2 The corrosion mechanisms of typical microorganisms

2.1 The formation process of biofilm and its effect on steel corrosion

Abiotic corrosion can be divided into physical, chemical and electrochemical corrosion. MIC is defined by no single characteristic. It is a complex biogeochemical process initiated and/or exacerbated by the presence and activity of bacteria and their associated biofilms (Castaneda and Benetton 2008; Stadler et al. 2010). Thus, MIC is considered bio-corrosion, and the terms “microbes” and “bacteria” are used interchangeably. Bacteria in the environment exist in the planktonic state, which tends to attach to material surfaces and form a biofilm layer, which consists of a community of bacteria, water, extracellular polymeric substances (EPS), corrosion products, etc. (Alabbas et al. 2013). The initial event of bacterial attachment is important since it lays the foundation for the formation of heterogeneous biofilms. Many surface characteristics such as free energy, charge and roughness can modulate bacterial adhesion (Rosenberger and Kraume 2002). Both reversible and irreversible attachment are possible. Figure 1 shows a schematic process of biofilm development (Chitra et al. 2014): (1) initial attachment of planktonic cells to the metal surface, (2) irreversible attachment of bacterial cells through formation of EPS, (3) formation of a biofilm layer, (4) maturation of a steady-state biofilm layer, (5) detachment of bacterial cells from the biofilm outer surface.

Stages of biofilm development (Chitra et al. 2014)

In some instances, a compact microbial biofilm can act as a diffusion barrier for reactants such as oxygen, aggressive anions and cations (Chongdar et al. 2005; Grooters et al. 2007; Little and Ray 2002). But, the dynamic development of biofilm may also increase corrosion. Biofilm mediate interactions between metal surfaces and the liquid environment, leading to major modifications of the metal–solution interface by drastically changing the composition and concentration of chemical species, pH, and oxygen levels, etc. (Little et al. 1992; Vastra et al. 2016). As a consequence of these changes, the electrochemical behavior of the metal can be modified initiating and enhancing MIC.

In the initial stages of biofilm growth, the distribution of cells and EPS is likely to be heterogeneous, which may result in the areas of the metal substratum being covered by biofilm and adjacent area being exposed to the surrounding environment. The metabolic activity of cells within the biofilm will lead to low oxygen concentrations, and so form an oxygen concentration cell between those regions under the biofilm (anode), and the uncolonized areas exposed to maximal oxygen concentration (cathode) enhancing corrosion (Hamilton 2003). Castaneda and Benetton (2008) investigated that SRB-biofilm heterogeneities caused local gradient differences and increased the bio-catalytic active sites where corrosion processes take place, increased the corrosion rate. Moreover, some studies have proposed that EPS isolated from biofilm have a nonnegligible effect on the corrosion process. Beech and Sunner (2004) proposed that metal ions bound by EPS accelerated the ionization of the metal by chelation, resulting in metal dissolution. Dong et al. (2011) found that excessive EPS stimulated anodic dissolution of carbon steel because Fe2+ from metal dissolution were bound by the polysaccharides in the EPS.

Central to the phenomenon of MIC is the formation of biofilm on the metal surface. The morphology of the biofilm has a significant influence on the corrosion effect, either in a detrimental or beneficial way. Usually, the formation of biofilm is known as the initial stage of MIC.

2.2 Anaerobic bacteria: SRB

SRB is a typical example of anaerobic MIC (Lee et al. 1995). Some researchers do insist that SRB are worthy of studying so much and regard their unique importance in MIC as “Myths of MIC” (Javaherdashti 1999). The corrosion mechanism of metal in the presence of SRB is a complicated biogeochemical process. Various mechanisms are proposed for the corrosion occurrence of SRB.

-

(1)

The cathodic depolarization theory

“Cathodic depolarization theory” (CDT) was the first proposed mechanism for MIC in 1934 by Von Wolzogen Kuhr and Van der Vlugt (1934). According to the classical theory, SRB consume cathodic hydrogen through consuming an enzyme called “hydrogenase” for the reduction of \({\text{SO}}_{4}^{2 - }\) as given below:

Figure 2 schematically summarizes the cathodic depolarization theory of SRB activity. The basic idea of the CDT was that the removal of hydrogen from the cathodic area on the iron surface by the hydrogenases of the bacteria, coupled to the reduction of \({\text{SO}}_{4}^{2 - }\). The resulting corrosion products would thus be FeS and Fe(OH)2. SRB, by using the adsorbed hydrogen in the \({\text{SO}}_{4}^{2 - }\) reduction, catalyze the recombination of the adsorbed atomic hydrogen into hydrogen gas (H2), and increase the rate of cathodic reaction. Thus, the corrosion reaction would be indirectly accelerated by depolarization of the cathodic reaction.

Schematic of the cathodic depolarization theory of SRB activity (Javaherdashti 1999)

Although CDT could explain MIC by SRB on the basis of electrochemistry, it suffers from much controversy in the subsequent decades (Tiller and Booth 1962). The idea that microbial H2 scavenging would accelerate corrosion, proposed by CDT, is very hard to accept. Costello (1974) demonstrated that H2S from \({\text{SO}}_{4}^{2 - }\) reduction was a cathodic active compound; Hence, much of the electrochemical evidence for the “CDT” became disputable. On the basis of CDT, the ratio of corroded Fe2+ to FeS should be 4:1. However, in fact, the ratio varies from 0.9:1 to 1:1 (Javaherdashti 2011). In addition, the CDT was the lack of information on the role of sulfides that are themselves cathodic to iron and thus cause anodic dissolution (Xu et al. 2012). The complexity of biological environments involved with SRB activity makes it very difficult to assess any microbiological effect by means of electrochemical methods, because the physical and chemical parameters at the metal interface are continuously varying due to microbial metabolism. Drawbacks like these have prepared the ground for “new theories”.

-

(2)

MIC by microbes that secrete corrosive metabolites

SRB catalytic activity can promote the corrosion rate via the formation of aggressive corrosive metabolite H2S (Abbas et al. 2013; Jia et al. 2018). This acid attack metals such as Fe0 extracellularly by removing electrons from Fe0 without bio-catalysis. Therefore, acid corrosion can occur without a biofilm in conventional chemical corrosion. In fact, Romero et al. (2005) reported that the bacteria in the SRB biofilm can reach 108 cfu/cm2 to produce enough corrosive H2S. The introduction of H2S reduces the local pH in the biofilm due to H2S dissolution, thereby causing serious local corrosion. But in the whole process, the biofilm slows down the leak of H2S due to its diffusion barrier action.

FeS is considered the main corrosion product when steels are exposed to SRB environments (Fatah et al. 2013; Sheng et al. 2007). The physicochemical properties of the FeS film can affect steel dissolution, which depends on the ferrous ion/sulfide anions ratio, the presence of SRB and how the biofilm has covered the metal surface. However, in bacteria containing media, the sulfide films are usually unstable (Castaneda and Benetton 2008). They are disrupted by bacteria metabolic actions (Abbas et al. 2013). Therefore, the integrity of the protective film will be then degraded and leads to active corrosion cells between the FeS film (cathode) and the nearby metal substrate (anode) accelerating the corrosion rate significantly (Hamilton 2003).

-

(3)

Extracellular electron transfer

Advances in microbiology, electrochemistry and surface analysis techniques have revealed the existence of biochemical pathway associated with MIC. “Extracellular electron transfer” (EET) theory offers better understanding for the study of metal–microbe interactions. Organic carbon molecules (e.g. lactate and acetate) can diffuse into the cytoplasm inside SRB cells to be oxidized. They donate electrons in the oxidation process for \({\text{SO}}_{4}^{2 - }\) reduction. Fe0 in an iron (or steel) matrix is insoluble and thus Fe0 cannot enter the cytoplasm. In MIC caused by SRB, Fe0 oxidation occurs extracellularly while \({\text{SO}}_{4}^{2 - }\) reduction occurs intracellularly with enzyme catalysis. This means the extracellular electrons released by Fe0 oxidation must be transported across the cell wall into the SRB cytoplasm (Li et al. 2015). This kind of EET is achieved by electrogenic biofilm (Venzlaff et al. 2013; Yu et al. 2013). There are two primary categories for the mechanisms of EET. One is the direct electron transfer (DET) using cell-membrane bound redox proteins such as c-type cytochrome, conductive nanowires (pili) (Mehanna et al. 2009; Reguera et al. 2005; Sherar et al. 2011) and the other mediated electron transfer (MET) using electron carriers such as hydrogen or electron transfer mediators such as riboflavin and flavin adenine dinucleotide (FAD) (Jia et al. 2017a, b; Zhang et al. 2015). Figure 3 shows a schematic diagram for the mechanism of MIC by SRB due to cross-cell wall electron transfer involving DET and MET (Li et al. 2015). Based on EET mechanism for MIC, Xu et al. (Xu and Gu 2014) showed that starved SRB biofilm is more corrosive against carbon steel because they utilize extracellular electrons released by Fe0 oxidation as an electron donor when there is a lack of organic carbon in the culture medium. Zhang et al. (2015) investigated that electron transfer is a bottleneck in this type of MIC by SRB because adding an electron mediator to the culture medium to enhance electron transfer accelerated corrosion.

Schematic illustration for the mechanism of MIC by SRB due to cross-cell wall electron transfer involving direct electron transfer (DET) and mediated electron transfer (MET) (Li et al. 2015)

-

(4)

Biocatalytic cathodic sulfate reduction theory

Gu et al. (2009) proposed a new MIC theory called “biocatalytic cathodic sulfate reduction theory” (BCSR) based on bioenergetics. When there is a lack of food source (e.g. lactate) due to diffusional limitation, the sessile cells under an SRB biofilm will switch to elemental iron as an alternate electron donor for the reduction of \({\text{SO}}_{4}^{2 - }\) to harvest energy for metabolic activities. The following equations can be used to explain SRB corrosion in BCSR (Li et al. 2015):

The cell potential for the redox reaction coupling Reactions (8) and (9) is ΔEo′ = +230 mV versus the standard hydrogen electrode (SHE) [calculated from – 217 mV to (– 447 mV)] under the conditions of 25 °C, pH 7, 1 M concentration for solutes and 1 bar partial pressure for gases. This positive cell potential corresponds to a Gibbs free energy change of reaction ΔGo′ = −178 kJ/mol \({\text{SO}}_{4}^{2 - }\) based on the following equation, in which n is the number of electrons for \({\text{SO}}_{4}^{2 - }\) reduction (n = 8) and F is the Faraday constant (F = 96,485 C/mol):

The negative ΔGo′ suggests an exergonic reaction that it is highly favorable thermodynamically and that corrosion of steels can occur spontaneously.

When lactate is used as the organic carbon source, the following oxidation reaction occurs in the cytoplasm (Xu and Gu 2014):

In fact, Fe0 is slightly more energetic than lactate because the ΔEo′ value for Fe2+/Fe0 (− 447 mV) is slightly more negative than that for CO2 + acetate/lactate (− 430 mV). The equilibrium potentials above are used to calculate the thermodynamic driving force of MIC. However, favorable driving force does not mean that corrosion will occur if kinetics is retarded. \({\text{SO}}_{4}^{2 - }\) reduction has a high activation energy. It will proceed in the SRB cytoplasm via the adenosine phosphosulfate (APS) pathway catalyzed by multiple enzymes. Thus, Gu et al. (2009) proposed the BCSR theory by treating Fe0 oxidation as the anodic reaction and biocatalytic \({\text{SO}}_{4}^{2 - }\) reduction as the cathodic reaction. The word “cathodic” is used in BCSR merely to suggests that it is a reduction reaction in the corrosion mechanism, thus providing energy for SRB metabolic activities such as active transport, signal amplification and organic synthesis (Xu and Gu 2014). There is actually no physical cathode at the site where \({\text{SO}}_{4}^{2 - }\) reduction occurs because it happens in the SRB cytoplasm.

Put simply, there is not a single mechanism to explain all of the SRB-related corrosion on different materials. The mechanisms are quite complex involving several bio-and physico-chemical parameters. Apart from the chemistry changing of the metal–solution interface and/or the metabolites in corrosion, the investigation of electrogenic biofilm of bacteria is still very useful in MIC. The new trends in research should focus on bio-electrochemical phenomena at the metal surface.

2.3 Aerobic bacteria: IOB

IOB are bacteria that can harness energy from the oxidation of Fe(II) to Fe(III) for growth, which are ubiquitous in various environments such as marine environment (Moradi et al. 2011) and oil field (Liu et al. 2016b). Fe(II) can function as an electron donor and O2 can function as a terminal electron acceptor under aerobic conditions in the presence of IOB (Emerson and Moyer 1997). Under biocatalysis by IOB, the oxidation rate of Fe(II) to Fe(III) seem to be much faster than that of abiotic chemical oxidation. Thus, IOB accelerate the dissolution of metal and the development of localized corrosion (Liu et al. 2016a). Compared to potential inorganic energy sources for IOB, the oxidation of Fe(II) to Fe(III) yields the lowest Gibbs free energy (ΔG0 = −29 kJ mol−1, Fe2+ + 0.25O2 + H+ → Fe3+ +0.5H2O) for cellular metabolism. Furthermore, if the Fe(III) is precipitated as an iron oxide-hydroxide [Fe2+ + 0.25O2 + 2.5H2O → Fe(OH)3 + 2H+], the energetic yield is estimated to be double (Emerson et al. 2010).

IOB can promote oxidation of Fe(II) and induce different types of steel corrosion, especially localized corrosion (Moradi et al. 2011; Starosvetsky et al. 2008). The main corrosion products induced by IOB are iron oxides such as FeOOH, Fe2O3 and Fe3O4, the main reaction process is shown in reaction (12)–(18) (Jin et al. 2015):

Anodic reaction:

Cathodic reaction:

Wang et al. (Wang et al. 2014) have put forward “crevice corrosion induced by iron oxide” for aerobic IOB-induced MIC mechanisms. Figure 4 is the mechanism schematic of the crevice corrosion initiated by the Fe(OH)3 layer under aerobic conditions. Under aerobic conditions, the carbon steel surface beneath the iron oxide layer could form small anodic sites to transfer electrons from Fe0 to oxygen at cathodic sites to form hydroxyl, which could continuously oxidize Fe0 to Fe2+ as energy source for cells and form iron oxide precipitation and lower the local pH. At the anodic site, Fe0 oxidization continued, ultimately forming a pit on the carbon steel surface.

Schematic of the crevice corrosion initiated by the Fe(OH)3 layer under aerobic conditions (Wang et al. 2014)

The corrosion process induced by IOB is also owing to the presence of biofilm formed on surfaces of metallic materials. The development of a biofilm is facilitated by the production of EPS which play a key role in MIC. In addition to promoting the growth of sessile bacteria, EPS can also to bind metal ions considerably modifying the redox reaction pathways in the biofilm/metal interface (as shown in Fig. 5a), such as direct electron transfer from a metal surface (Beech and Sunner 2004). Some electroactive EPS-bound metal ions in a biofilm can act as electron “shuttles” to transport electrons to the terminal electron acceptor O2 (as shown in Fig. 5b), which accelerates corrosion. Nevertheless, EPS at later incubation stages can act as an oxygen barrier and thereby inhibit corrosion (Jin and Guan 2014). Liu et al. (2017) studied the effect of EPS on the corrosion behavior and mechanism of carbon steel, and found that 240 mg L−1 of 7 day-old EPS secreted by IOB could inhibit corrosion due to the formation of a compact adsorbed EPS film.

Schematic of corrosion reactions involving EPS-bound metal ions in oxygenated biofilm: a Fe3+ is bound by EPS and the Fe3+–EPS complex is deposited on the metal surface, b In the presence of oxygen, acting as terminal electron acceptor, Fe2+ in EPS is reoxidised to Fe3+ (Beech and Sunner 2004)

The corrosion mechanism of IOB is much less comprehensively understood than the corrosion mechanism of SRB. It remains to be further strengthened, using the advanced molecular biology technology and microelectrode technology, revealed from the microcosmic IOB corrosion process so as to provide theoretical support for better corrosion prevention.

2.4 MIC in the mixed culture of SRB and IOB

Bacteria are major colonizers on a substrate surface in almost all environments (An et al. 2010; Ilhan-Sungur and Çotuk 2010; Quan et al. 2010). Thus, the majority of MIC studies have investigated the effects of pure or mixed culture bacteria on corrosion behavior of a variety of metals and alloys such as iron, copper, aluminum (Agwa et al. 2017; Guan et al. 2017; Huttunen-Saarivirta et al. 2017). The main categories of bacteria typically linked to corrosion in terrestrial and aquatic habitats are SRB (Jia et al. 2018), Sulfur oxidizing bacteria (Xin et al. 2009), IOB (Emerson and Moyer 1997), Iron reducing bacteria (Herrera and Videla 2009), Nitrate reducing bacteria (Jia et al. 2017a, b), and Acid producing bacteria (Xu et al. 2016). These bacteria can coexist and adhere in biofilm, forming complex consortia on corroding metallic surfaces (Beech and Sunner 2004). For example, anaerobic SRB and aerobic IOB are sometimes found together in the biofilm (Liu et al. 2015). In an aerobic environment, IOB oxidize ferrous ions (Fe2+) to ferric ions (Fe3+), where the electrons released are used as energy sources for growth. Subsequently, these ferric ions (Fe3+) precipitates as iron hydroxide complexes, which can cause a blockage by the formation of tubercles in the pipeline. With the mixed culture system, anaerobic SRB may propagate rapidly and attack metals in the locally anaerobic conditions beneath the iron-rich tubercles in the presence of IOB. The interaction between SRB and IOB accelerated the corrosion process of metal specimens (Xu et al. 2007). Xu et al. (2008) investigated the localized corrosion behavior of 316L stainless steel in the presence of anaerobic SRB and aerobic IOB. They found that the synergies between the metal surface, abiotic corrosion products, bacterial cells and their metabolic products increased the corrosion rate and accelerated pitting propagation. Rao et al. (2000) suggested that aerobic iron bacteria and SRB induced corrosion of carbon steel in the cooling water system, and beneath the tubercles, SRB induced significant pitting corrosion. Eun-Hae Sung et al. (2011) assessed the effects of microbial growth on metal corrosion. With the mixed culture system, the number of SRB in the presence of IOB, was 66 times higher than that of the sole SRB culture, which was attributed to the potential synergetic effects. It increased the degrees of corrosion by factors of 2–7 compared with that of the single IOB and SRB cultures. Meanwhile, in the mixed culture, black sulfide formed by SRB was observed beneath the tubercles formed by IOB. SRB can also exists in aerobic conditions (Beech and Sunner 2004). Liu et al. (2015) investigated corrosion behavior of carbon steel in the presence of SRB and IOB with 4.2 mg/L dissolved O2. The results showed that the synergistic effect of SRB and IOB played a key role for the pitting corrosion of carbon steel. They illustrated the pitting corrosion schematic of carbon steel in the presence of SRB and IOB (Fig. 6a). In the first step, planktonic cells attach on the coupon surface (Fig. 6a). Then, a large amount of metabolites were produced, accompanying with the formation of biofilm. In the third step, a steady-state biofilm layer was formed with a local anaerobic environment which will promote the growth of SRB (Fig. 6c). On the one hand, in the presence of SRB and IOB, IOB could oxides Fe2+ to Fe3+, and S2− produced by SRB could react with Fe2+, which would promote the formation of pitting corrosion. On the other hand, SRB switched to elemental Fe to obtain sulfate-reduced electrons due to local shortage of organic carbon underneath biofilm.

The formation propagation mechanism of pitting corrosion in the mixture of SRB and IOB: a initial period, b formation of biofilm, and c formation and propagation of pitting corrosion (Liu et al. 2015)

The importance of microbial synergy has recently been reconfirmed in studies of steel corrosion. The corrosion rate obtained with the combination of SRB and IOB is considerably higher than those measured in pure cultures. The research on synergistic corrosion caused by anaerobic and aerobic bacteria can help to reveal the MIC mechanism under operating conditions and provide theoretical support for MIC control.

3 The influence of cathodic polarization on MIC

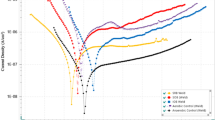

Cathodic Polarization (CP) has been recognized for a long time as a reliable, effective and economic method to prevent corrosion of pipelines, marine structures, tanks (Gurrappa 2005). It is a proven technique which is able to arrest ongoing corrosion and induce and sustain steel passivity (Christodoulou et al. 2010). According to the National Association of Corrosion Engineers (NACE) standard RP-0169, the criteria of CP is applying an impressed current or potential to induce negative steel polarization, in other words to drive the steel potentials more cathodically than − 770 mV versus saturated calomel electrode (SCE), where corrosion process is thermodynamically impossible to occur (Pourbaix 1996). Under these conditions the steel will be immune to corrosion. The influence of CP on bacterial activity is important in modifying the economics of protection and the occurrence of corrosion. Edyvean et al. (1992) found that, whether for stainless steel or carbon steel, CP can inhibit the settlement and attachment of aerobic microorganisms to the surface of the electrode. Researchers have controlled the current or potential of metal surface to prevent biofilm growth. Shirtliff et al. (2005) provided a constant flux of 370 μA/cm2 on a stainless-steel electrode surface. The results suggested that current application was unable to reduce biofilm and even increased the number of biofilm bacteria. Similarly, Borden et al. (2004) applied a current between 2.86 and 4.76 μA/cm2 to induce bacterial detachment of growing Staphylococcus epidermidis biofilm from surgical stainless steel. Other researchers have controlled the potential of electrode surfaces to prevent cell growth. For example, Edyvean et al. (1992) poised a stainless steel at negative potentials and observed a decrease in bacterial settlement and attachment. Little and Wagner’s work (Little et al. 1997) also investigated the interaction of CP and the biofilm formation on steels. They confirmed that, when the CP current was intermittent, the corrosion attack due to the microorganisms became more aggressive.

The understanding of the mutual interaction of CP and MIC is vague. Some of the inhibitory mechanisms of CP on MIC has been interpreted in terms of (1) electrophoretic force and electrostatic repulsive force (Hong et al. 2008), (2) The effect of oxygen reduction reaction (Istanbullu et al. 2012; Pérez et al. 2009) and (3) the excessive electrons supplied by CP power source used as the electron donor by bacteria (Liu and Cheng 2017). However, none of these mechanisms is widely accepted because of conflicting results in the literature (Edyvean et al. 1992; Little et al. 1997) and the impossibility of comparing the different electrochemical systems.

3.1 Electrostatic repulsive force and electrophoretic force

On an electrically conductive surface over which current or potential is applied, adhesion of the bacterial cells may be influenced by electrostatic force and electrophoretic force. Wilson et al. (2001) stated that, bacterial surfaces appear to be negatively charged by virtue of ionized phosphoryl and carboxylate substituents on outer cell envelope surfaces under normal conditions. A cathodic polarized surface is a negatively charged region and would therefore repel approaching negatively charged bacterial cell during the process of attachment (Heckels et al. 1976).

Under these scenarios, there are overwhelming studies on the mutual effect of CP and microbial activity. de Saravia et al. (1997) studied the influence of mixed anaerobic bacterial biofilm on cathodically protected 304L stainless steel. The results showed that there was a decrease in the number of attached cells when CP was applied in the initial stages of biofilm formation, which may be influenced by electrostatic forces. And this decrease was greater at more negative potentials. But, CP did not have an effect when a stationary biofilm was formed. Busscher and Weerkamp (1987) has reported that the adhesion of bacteria to the solid surface would be influenced by electrostatic repulsion. Busalmen and de Sanchez (2001) have contrasted the adhesion of Pseudomonas fluorescens to nonpolarized and negatively polarized thin films of gold. When imposed a strong negative charge to the metal surface (− 0.5 and − 0.2 V vs. Ag/AgCl), bacterial adhesion was strongly inhibited. There was a repulsive electrostatic interaction with the negatively charged bacterial cells that depended on the electrical potentials of the surfaces. Hong et al. (2008) clarified the specific role of electric currents (cathodic and anodic) in order to develop the optimal strategy for controlling bacterial adhesion. They applied a 15 μA/cm2 cathodic current and found that the applied current promoted 80% detachment of bacteria from the electrode surface, 20% of bacteria still remained on the electrode surface despite the presence of electrostatic and electrophoretic repulsive forces. In contrast, when an anodic current was applied, the bacteria that remained on the surface became inactive with time, although bacterial detachment was not significant. Poortinga et al. (2001) found that the electrophoretic force and electrostatic repulsion resulting from a impressed cathode current stimulated desorption of adhering bacteria.

3.2 The effect of oxygen reduction reaction

When applying a CP to a metallic structure, CP increases the hydroxyl ion (OH−) concentration and the partial reduction of oxygen (O2) leads to hydrogen peroxide (H2O2) production. At the same time, the consequent pH increase diminishes the solubility of calcium magnesium at the metal surface favoring the precipitation of a calcareous scale. There is evidence that the electrochemical changes CP produces on the surrounding environment influence the settlement of fouling organisms.

-

(1)

Increased interfacial pH values

Under CP, the electrochemical reactions that occur on the surface of metallic structures are the reduction of O2.

and the reduction of water leading to hydrogen evolution for more negative cathodic potentials.

Recent results have demonstrated that CP inhibited microbiological growth and attachment because of the increased pH values generated in the vicinity of the protected steel surface. Pérez et al. (2009) investigated the influence of cathodic currents on biofouling processes in metal/anticorrosive paint/seawater systems. The results indicated that an increased interfacial pH as a consequence of the cathodic currents cause a marked decline of biofouling attachment. Del Pozo et al. (2009) afforded a potential means to significantly reduce the number of viable bacteria by prolonged exposure of biofilm to electrical current alone, and to call this phenomenon as the “electricidal effect”. The mechanism of the “electricidal effect” could relate to the pH changes.

That is to say, biofilm are able to modify metal–solution interface by drastically changing the physical, chemical and hydrodynamic conditions (de Saravia et al. 1997). But, owing to the buffering capacity of seawater and the microbial activity within the biofilm, the interfacial pH value was lower than the expected theoretical value.

-

(2)

The production of H2O2

According to Eq. (19), oxygen is reduced to OH− through a four-electron pathway on metal surfaces. However, at the same time, the partial reduction of oxygen leads to H2O2 production through a two-electron pathway (Babić and Metikoš-Huković 1993).

The mechanism of the antibacterial activity of electrical current has been suggested to result from the generation of H2O2. Istanbullu et al. (2012) found that H2O2 was produced near 316L SS surfaces when a negative potential was applied. H2O2 produced on a SS surface was able to prevent biofilm growth. Dhar et al. (1982) applied an electrochemical study on the prevention of bacterial attachment and found that the applied biofilm growth was inhibited. They thought that this was due to the production of H2O2. Del Pozo et al. (2009) applied a current between 1.626 × 10−3 and 1.626 × 10−6 μA cm−2 on electrode surface to prevent planktonic bacterial attachment and did not detect H2O2. This is most likely because H2O2 was produced at a low concentration near the electrode surface and could not be detected in the bulk solution.

-

(3)

The formation of calcareous deposits

Both reactions (19) and (20) can generate OH− ions near the surface of metallic structures resulting in the precipitation of calcium carbonates (CaCO3) and magnesium hydroxides (Mg(OH)2) on the cathodically protected surfaces according to the following reactions (Sun et al. 2012):

The importance of calcareous deposits to the effectiveness and efficiency of cathodic protection in submerged ocean situations is generally recognized (Guezennec 1994). These calcareous deposits can act as a physical barrier to general corrosion attack, impede solute diffusion (e.g. oxygen), reduce the current density required to maintain a given potential, and consequently decrease the cost of cathodic protection. It is widely believed that bacterial cells are able to attach to negatively charged surfaces by using divalent cations such as Ca2+ and Mg2+ as a “bridge”. The precipitation of calcium and magnesium ions results in a decrease in their local concentration and thus they would be unavailable to the bacteria (Edyvean et al. 1992). Eashwar et al. (2009) stated that calcareous deposits developed quite rapidly on polarized SS cathodes and lead to a significant reduction of bacterial numbers.

3.3 The excessive electrons supplied by CP

However, some findings were opposite to those listed above. Some studies have found that hydrogen produced by the cathode can encourage growth of hydrogenase-containing bacteria such as SRB (Guezennec 1994). Nekoksa and Gutherman’s work (1991) showed that the CP application enhanced the incubation and growth of microbes, with more bacteria settling on a cathodic protected stainless steel than on unpolarized ones. Similar results were obtained by Olivares et al. (2003), who found that the SRB population on CP-applied (− 850 mV vs. Cu/CuSO4) pipeline steel was twice of the microorganisms on the coupons without CP application. In the latest report, Liu et al. (2017) found that the CP facilitated the bacterial attachment to the steel, and the number of sessile cells on the steel increases as the CP potential becomes more negative. They proposed that if the CP potential is sufficiently negative, the SRB use the electrons from the CP source. The excessive electrons supplied by the CP power source that accumulated on the steel surface are used as the electron donor by SRB in their metabolism. Fe0 would not act as the electron donor, as schematically shown in Fig. 7a. However, when the potential is not sufficient locally due to potential fluctuations caused by the shielding effect of the biofilm, SRB would use electrons from the steel directly initiating pitting corrosion (Fig. 7b).

Schematic diagrams illustrating a SRB use electrons supplied by CP power source, and b sessile SRB use electrons from the steel directly (Liu and Cheng 2017)

Some of reported results of relevant literature on this topic are controversial to each other. Undoubtedly, not enough is known about the relationship between cathodic polarization and microbial attachment. CP has been recognized for a long time as an effective way to prevent MIC. Chen et al. (2015) have reported that the pH in SRB-containing medium was higher than that in the SRB-free medium. And owing to the formed biofilm of bacteria, the cathodic protection potential for carbon steel is more negative under biotic conditions. In SRB-containing aqueous solutions, Esquivel et al. (2015) suggested that the applied CP potential should be shifted to − 950 mV versus Cu/CuSO4 electrode or even more negative values in order to achieve good control on the MIC. But, the negative CP potential would stimulate the cathodic hydrogen generation which would promote the stress corrosion cracking (SCC) susceptibility of the steel (Wu et al. 2015). Therefore, the investigation of appropriate CP potential and the mutual effect between CP and microbial attachment are stronger required.

4 Future perspectives

MIC of steels is a great issue in many industries such as gas/oil pipelines, storage tanks, residual water treatment systems, steel pilings in marine applications, and, more recently, offshore wind farms. MIC is rarely linked to a single mechanism or to a single species of microorganisms. It results from the synergistic effect between microbes, metals, metabolites, and their environment. Despite considerable research efforts into the MIC phenomenon, there is still ongoing dispute with respect to which component, biotic or abiotic, is of greater relevance to MIC process. Advances in microbiology, electrochemistry and surface analysis techniques allow for better understanding the dynamic processes of biological and abiotic reactions in space and time and how these, in turn, affect mechanisms and accelerate rates of electrochemical reactions leading to corrosion. The author believes that a better understanding of the corrosion caused by communities of bacteria is envisioned to ultimately aid in the design of better MIC prevention and mitigation strategies for a variety of steel constructions. Conventional ways to combat MIC are well-known physical and chemical methods such as pigging, applying antimicrobial agents and disinfectants, but, especially from an environmental point of view, it is necessary to find new ways to control microbial deleterious effects through environmentally friendly approaches.

5 Conclusion

MIC of steels caused by aerobic and anaerobic bacteria in several industrial environments are discussed: (1) generally, biofilm formation is the initial stage of MIC, and biofilm can also influence the physical and chemical parameters at metal–solution interface, modifying the electrochemical behavior of the metal in a detrimental or beneficial way. (2) Mechanisms of anaerobic SRB and aerobic IOB in MIC are analyzed. Owing to the complexity of the microbe-metal interaction, the underlying mechanism of MIC allows for multi-mechanisms explanation for corrosion damage of steels. (3) The synergistically aggressive roles between SRB and IOB are responsible for severe pitting corrosion of metal specimens. (4) CP has been recognized as an effective way to prevent MIC. When CP is applied, microbial adhesion is affected by the imposed current over relatively extended periods of time. However, there is still confusion and limitations about the interaction between microbial activity and the process of preventing corrosion by CP in published literature. To investigate MIC, a clear understanding of its mechanisms is needed to guide field operators on how to mitigate and inhibit MIC.

References

Abbas FMA, Bhola R, Spear JR, Olson DL, Mishra B (2013) Electrochemical characterization of microbiologically influenced corrosion on linepipe steel exposed to facultative anaerobic desulfovibrio sp. Int J Electrochem Sci 8:859–871

Agwa OK, Iyalla D, Abu GO (2017) Inhibition of bio corrosion of steel coupon by Sulphate reducing bacteria and Iron oxidizing bacteria using Aloe Vera (Aloe barbadensis) extracts. J Appl Sci Environ Manage 21:833–838

Alabbas FM, Williamson C, Bhola SM, Spear JR, Olson DL, Mishra B et al (2013) Influence of sulfate reducing bacterial biofilm on corrosion behavior of low-alloy, high-strength steel (API-5L X80). Int Biodeterior Biodegradation 78:34–42

An CJ, He YL, Huang GH, Yang SC (2010) Degradation of hexahydro-1,3,5-trinitro-1,3, 5-triazine (RDX) by anaerobic mesophilic granular sludge from a UASB reactor. J Chem Technol Biotechnol 85:831–838

Ashassi-Sorkhabi H, Moradi-Haghighi M, Zarrini G, Javaherdashti R (2012) Corrosion behavior of carbon steel in the presence of two novel iron-oxidizing bacteria isolated from sewage treatment plants. Biodegradation 23:69–79

Babić R, Metikoš-Huković M (1993) Oxygen reduction on stainless steel. J Appl Electrochem 23:352–357

Beech IB, Sunner J (2004) Biocorrosion: towards understanding interactions between biofilms and metals. Curr Opin Biotechnol 15:181–186

Boopathy R, Daniels L (1991) Effect of pH on anaerobic mild steel corrosion by methanogenic bacteria. Appl Environ Microbiol 57:2104–2108

Borden AJVD, Mei HCVD, Busscher HJ (2004) Electric-current-induced detachment of staphylococcus epidermidis strains from surgical stainless steel. J Biomed Mater Res B Appl Biomater 68B:160–164

Bos R, Mei HCVD, Busscher HJ (1999) Physico-chemistry of initial microbial adhesion interactions-its mechanisms and methods for study. FEMS Microbiol Rev 23:179–230

Busalmen JP, de Sanchez SR (2001) Adhesion of pseudomonas fluorescens (ATCC 17552) to nonpolarized and polarized thin films of gold. Appl Environ Microbiol 67:3188–3194

Busscher HJ, Weerkamp AH (1987) Specific and non-specific interactions in bacterial adhesion to solid substrata. FEMS Microbiol Lett 46:165–173

Castaneda H, Benetton XD (2008) Srb-biofilm influence in active corrosion sites formed at the steel-electrolyte interface when exposed to artificial seawater conditions. Corros Sci 50:1169–1183

Chen X, Wang G, Gao F, Wang Y, He C (2015) Effects of sulphate-reducing bacteria on crevice corrosion in X70 pipeline steel under disbonded coatings. Corros Sci 101:1–11

Chitra S, Anand B, Vaidiyanathan R, Balasubramanian V (2014) A review on microbial mediated corrosion on mild steel by inactivating the extracellular polysaccharide secreted by aerobic/anaerobic microorganism. Chem Sci Rev Lett 3:56–62

Chongdar S, Gunasekaran G, Kumar P (2005) Corrosion inhibition of mild steel by aerobic biofilm. Electrochim Acta 50:4655–4665

Christodoulou C, Glass G, Webb J, Austin S, Goodier C (2010) Assessing the long term benefits of impressed current cathodic protection. Corros Sci 52:2671–2679

Costello JA (1974) Cathodic depolarization by sulphate-reducing bacteria. South African J Sci 70:202–204

Costerton JW, Lewandowski Z, Caldwell DE, Korber DR, Lappinscott HM (2003) Microbial biofilms. Annu Rev Microbiol 49:711–745

de Saravia SGG, de Mele MFL, Videla HA, Edyvean RGJ (1997) Bacterial biofilms on cathodically protected stainless steel. Biofouling 11:1–17

del Pozo JL, Rouse MS, Mandrekar JN, Steckelberg JM, Patel R (2009) The electricidal effect: reduction of staphylococcus and pseudomonas biofilms by prolonged exposure to low-intensity electrical current. Antimicrob Agents Chemother 53:41–45

Dhar HP, Howell DW, Bockris JOM (1982) The use of in situ electrochemical reduction of oxygen in the diminution of adsorbed bacteria on metals in seawater. J Electrochem Soc 129:2178–2182

Dong ZH, Liu T, Liu HF (2011) Influence of eps isolated from thermophilic sulphate-reducing bacteria on carbon steel corrosion. Biofouling 27:487–495

Duan J, Wu S, Zhang X, Huang G, Du M, Hou B (2008) Corrosion of carbon steel influenced by anaerobic biofilm in natural seawater. Electrochim Acta 54:22–28

Eashwar M, Subramanian G, Palanichamy S, Rajagopal G, Madhu S, Kamaraj P (2009) Cathodic behaviour of stainless steel in coastal indian seawater: calcareous deposits overwhelm biofilms. Biofouling 25:191–201

Edyvean RGJ, Maines AD, Hutchinson CJ, Silk NJ, Evans LV (1992) Interactions between cathodic protection and bacterial settlement on steel in seawater. Int Biodeterior Biodegradation 29:251–271

Emerson D, Moyer C (1997) Isolation and characterization of novel iron-oxidizing bacteria that grow at circumneutral ph. Appl Environ Microbiol 63:4784–4792

Emerson D, Fleming EJ, McBeth JM (2010) Iron-oxidizing bacteria: an environmental and genomic perspective. Annu Rev Microbiol 64:561–583

Esquivel RG, Olivares GZ, Gayosso MJH, Trejo AG (2015) Cathodic protection of XL 52 steel under the influence of sulfate reducing bacteria. Mater Corros 62:61–67

Fatah MC, Ismail MC, Wahjoedi BA (2013) Effects of sulphide ion on corrosion behaviour of X52 steel in simulated solution containing metabolic products species: a study pertaining to microbiologically influenced corrosion (MIC). Corros Eng Sci Technol 48:211–220

Flemming HC (2002) Biofouling in water systems–cases, causes and countermeasures. Appl Microbiol Biotechnol 59:629–640

Grooters M, Harneit K, Wöllbrink M, Sand W, Stadler R, Fürbeth W (2007) Novel steel corrosion protection by microbial extracellular polymeric substances (EPS)–biofilm-induced corrosion inhibition. Adv Mater Res 20–21:375–378

Gu T, Zhao K, Nesic S (2009) A new mechanistic model for mic based on a biocatalytic cathodic sulfate reduction theory. Corrosion

Guan F, Zhai X, Duan J, Zhang J, Li K, Hou B (2017) Influence of sulfate-reducing bacteria on the corrosion behavior of 5052 aluminum alloy. Surf Coat Technol 316:171–179

Guezennec JG (1994) Cathodic protection and microbially induced corrosion. Int Biodeterior Biodegradation 34:275–288

Gurrappa I (2005) Cathodic protection of cooling water systems and selection of appropriate materials. J Mater Process Technol 166:256–267

Hamilton WA (2003) Microbially influenced corrosion as a model system for the study of metal microbe interactions: a unifying electron transfer hypothesis. Biofouling 19:65–76

Heckels JE, Blackett B, Everson JS, Ward ME (1976) The influence of surface charge on the attachment of neisseria gonorrhoeae to human cells. J Gen Microbiol 96:359

Herrera LK, Videla HA (2009) Role of iron-reducing bacteria in corrosion and protection of carbon steel. Int Biodeterior Biodegradation 63:891–895

Hong SH, Jeong J, Shim S, Kang H, Kwon S, Ahn KH et al (2008) Effect of electric currents on bacterial detachment and inactivation. Biotechnol Bioeng 100:379–386

Huttunen-Saarivirta E, Rajala P, Bomberg M, Carpén L (2017) Eis study on aerobic corrosion of copper in ground water: influence of micro-organisms. Electrochim Acta 240:163–174

Ilhan-Sungur E, Çotuk A (2010) Microbial corrosion of galvanized steel in a simulated recirculating cooling tower system. Corros Sci 52:161–171

Istanbullu O, Babauta J, Duc Nguyen H, Beyenal H (2012) Electrochemical biofilm control: mechanism of action. Biofouling 28:769–778

Javaherdashti R (1999) A review of some characteristics of mic caused by sulfate-reducing bacteria: past, present and future. Anti-Corrosion Methods Mater 46:173–180

Javaherdashti R (2011) Impact of sulphate-reducing bacteria on the performance of engineering materials. Appl Microbiol Biotechnol 91:1507–1517

Jia R, Yang D, Xu D, Gu T (2017a) Electron transfer mediators accelerated the microbiologically influence corrosion against carbon steel by nitrate reducing pseudomonas aeruginosa biofilm. Bioelectrochemistry 118:38–46

Jia R, Yang D, Xu J, Xu D, Gu T (2017b) Microbiologically influenced corrosion of C1018 carbon steel by nitrate reducing pseudomonas aeruginosa biofilm under organic carbon starvation. Corros Sci 127:1–9

Jia R, Tan JL, Jin P, Blackwood DJ, Xu D, Gu T (2018) Effects of biogenic H2S on the microbiologically influenced corrosion of C1018 carbon steel by sulfate reducing desulfovibrio vulgaris biofilm. Corros Sci 130:1–11

Jin J, Guan Y (2014) The mutual co-regulation of extracellular polymeric substances and iron ions in biocorrosion of cast iron pipes. Bioresour Technol 169:387–394

Jin J, Wu G, Guan Y (2015) Effect of bacterial communities on the formation of cast iron corrosion tubercles in reclaimed water. Water Res 71:207–218

Jogdeo P, Chai R, Shuyang S, Saballus M, Constancias F, Wijesinghe SL et al (2017) Onset of microbial influenced corrosion (MIC) in stainless steel exposed to mixed species biofilms from equatorial seawater. J Electrochem Soc 164:C532–C538

Kuehr VW, Vlugt VD (1934) De grafiteering van gietijzer als electrobiochemich process in anaerobe gronden

Lee W, Lewandowski Z, Nielsen PH, Hamilton WA (1995) Role of sulfate-reducing bacteria in corrosion of mild steel: a review. Biofouling 8:165–194

Li SY, Jeon KS, Kang TY, Kho YT, Kim YG (2001) Microbiologically influenced corrosion of carbon steel exposed to anaerobic soil. Corrosion 57:815–828

Li H, Xu D, Li Y, Feng H, Liu Z, Li X et al (2015) Extracellular electron transfer is a bottleneck in the microbiologically influenced corrosion of C1018 carbon steel by the biofilm of sulfate-reducing bacterium desulfovibrio vulgaris. PLoS ONE 10:e0136183

Little B, Ray R (2002) A perspective on corrosion inhibition by biofilms. Corrosion -Houston Tx- 58:424–428

Little B, Wagner P, Mansfeld F (1992) Microbiologically influenced corrosion of metals and alloys. Electrochim Acta 37:2185–2194

Little BJ, Wagner PA, Hart KR, Ray RI (1997) Spatial relationships between bacteria and localized corrosion. Spatial Relationships Between Bacteria & Localized Corrosion

Liu T, Cheng YF (2017) The influence of cathodic protection potential on the biofilm formation and corrosion behaviour of an x70 steel pipeline in sulfate reducing bacteria media. J Alloy Compd 729:180–188

Liu H, Frank Cheng Y (2017) Mechanism of microbiologically influenced corrosion of X52 pipeline steel in a wet soil containing sulfate-reduced bacteria. Electrochim Acta 253:368–378

Liu H, Zheng B, Xu D, Fu C, Luo Y (2014) Effect of sulfate-reducing bacteria and iron-oxidizing bacteria on the rate of corrosion of an aluminum alloy in a central air-conditioning cooling water system. Ind Eng Chem Res 53:7840–7846

Liu H, Fu C, Gu T, Zhang G, Lv Y, Wang H et al (2015) Corrosion behavior of carbon steel in the presence of sulfate reducing bacteria and iron oxidizing bacteria cultured in oilfield produced water. Corros Sci 100:484–495

Liu H, Gu T, Zhang G, Cheng Y, Wang H, Liu H (2016a) The effect of magneticfield on biomineralization and corrosion behavior of carbon steel induced by iron-oxidizing bacteria. Corros Sci 102:93–102

Liu H, Gu T, Zhang G, Wang W, Dong S, Cheng Y et al (2016b) Corrosion inhibition of carbon steel in CO2-containing oilfield produced water in the presence of iron-oxidizing bacteria and inhibitors. Corros Sci 105:149–160

Liu H, Gu T, Asif M, Zhang G, Liu H (2017) The corrosion behavior and mechanism of carbon steel induced by extracellular polymeric substances of iron-oxidizing bacteria. Corros Sci 114:102–111

Maeda T, Negishi A, Komoto H, Oshima Y, Kamimura K, Sugio T (1999) Isolation of iron-oxidizing bacteria from corroded concretes of sewage treatment plants. J Biosci Bioeng 88:300–305

McBeth JM, Emerson D (2016) In situ microbial community succession on mild steel in estuarine and marine environments: exploring the role of iron-oxidizing bacteria. Front Microbiol 7:767–780

McBeth JM, Little BJ, Ray RI, Farrar KM, Emerson D (2011) Neutrophilic iron-oxidizing “zetaproteobacteria” and mild steel corrosion in nearshore marine environments. Appl Environ Microbiol 77:1405–1412

Mehanna M, Basseguy R, Delia ML, Bergel A (2009) Role of direct microbial electron transfer in corrosion of steels. Electrochem Commun 11:568–571

Moon KM, Cho HR, Lee MH, Shin SK, Koh SC (2007) Electrochemical analysis of the microbiologically influenced corrosion of steels by sulfate-reducing bacteria. Met Mater Int 13:211–216

Moradi M, Duan J, Ashassi-Sorkhabi H, Luan X (2011) De-alloying of 316 stainless steel in the presence of a mixture of metal-oxidizing bacteria. Corros Sci 53:4282–4290

Nekoksa G, Gutherman B (1991) Cathodic protection criteria for controlling microbially influenced corrosion in power plants

Okabe S, Odagiri M, Ito T, Satoh H (2007) Succession of sulfur-oxidizing bacteria in the microbial community on corroding concrete in sewer systems. Appl Environ Microbiol 73:971–980

Olivares G, Mejia G, Caloca G, Lopez I, Dabur F, Ulloa-Ochoa C, et al (2003) Sulfate reducing bacteria influence on the cathodic protection of pipelines that transport hydrocarbons. Corrosion

Pérez M, Gervasi CA, Armas R, Stupak ME, Di Sarli AR (2009) The influence of cathodic currents on biofouling attachment to painted metals. Biofouling 8:27–34

Poortinga AT, Smit J, Mei HCVD, Busscher HJ (2001) Electric field induced desorption of bacteria from a conditioning film covered substratum. Biotechnol Bioeng 76:395–399

Pourbaix M (1996) Atlas of electrochemical equilibria in aqueous solutions. NACE International, Houston

Quan XC, Tang H, Xiong WC, Yang ZF (2010) Bioaugmentation of aerobic sludge granules with a plasmid donor strain for enhanced degradation of 2,4-dichlorophenoxyacetic acid. J Hazard Mater 179:1136–1142

Rao TS, Sairam TN, Viswanathan B, Nair KVK (2000) Carbon steel corrosion by iron oxidising and sulphate reducing bacteria in a freshwater cooling system. Corros Sci 42:1417–1431

Reguera G, Mccarthy KD, Mehta T, Nicoll JS, Tuominen MT, Lovley DR (2005) Extracellular electron transfer via microbial nanowires. Nature 435:1098–1101

Romero MD, Duque Z, RodríGuez L, RincóN OD, PéRez O, Araujo I (2005) A study of microbiologically induced corrosion by sulfate-reducing bacteria on carbon steel using hydrogen permeation. Corrosion 61:68–75

Rosenberger S, Kraume M (2002) Filterability of activated sludge in membrane reactors. Desalination 146:373–379

Sand W, Gehrke T (2003) Microbially influenced corrosion of steel in aqueous environments. Rev Environ Sci Biotechnol 2:169–176

Scotto V, Cintio RD, Marcenaro G (1985) The influence of marine aerobic microbial film on stainless steel corrosion behaviour. Corros Sci 25:185–194

Sheng X, Ting Y-P, Pehkonen SO (2007) The influence of sulphate-reducing bacteria biofilm on the corrosion of stainless steel aisi 316. Corros Sci 49:2159–2176

Sherar BWA, Power IM, Keech PG, Mitlin S, Southam G, Shoesmith DW (2011) Characterizing the effect of carbon steel exposure in sulfide containing solutions to microbially induced corrosion. Corros Sci 53:955–960

Shirtliff ME, Bargmeyer A, Camper AK (2005) Assessment of the ability of the bioelectric effect to eliminate mixed-species biofilms. Appl Environ Microbiol 71:6379

Stadler R, Wei L, Fürbeth W, Grooters M, Kuklinski A (2010) Influence of bacterial exopolymers on cell adhesion of desulfovibrio vulgaris on high alloyed steel: corrosion inhibition by extracellular polymeric substances (EPS). Mater Corros 61:1008–1016

Starosvetsky J, Starosvetsky D, Pokroy B, Hilel T, Armon R (2008) Electrochemical behaviour of stainless steels in media containing iron-oxidizing bacteria (IOB) by corrosion process modeling. Corros Sci 50:540–547

Sun W, Liu G, Wang L, Li Y (2012) A mathematical model for modeling the formation of calcareous deposits on cathodically protected steel in seawater. Electrochim Acta 78:597–608

Sung EH, Han JS, Ahn CM, Seo HJ, Kim CG (2011) Biological metal corrosion in saline systems by sulfur-reducing and iron-oxidizing bacteria. Water Qual Res J Can 46:321–331

Tiller AK, Booth GH (1962) Polarization studies of mild steel in cultures of sulphate-reducing bacteria. Part 3. halophilic organisms. Trans Faraday Soc 56:1689–1696

van der Borden AJ, van der Werf H, van der Mei HC, Busscher HJ (2004) Electric current-induced detachment of staphylococcus epidermidis biofilms from surgical stainless steel. Appl Environ Microbiol 70:6871–6874

Vastra M, Salvin P, Roos C (2016) Mic of carbon steel in amazonian environment: electrochemical, biological and surface analyses. Int Biodeterior Biodegradation 112:98–107

Venzlaff H, Enning D, Srinivasan J, Mayrhofer KJJ, Hassel AW, Widdel F et al (2013) Accelerated cathodic reaction in microbial corrosion of iron due to direct electron uptake by sulfate-reducing bacteria. Corros Sci 66:88–96

Videla HA, Herrera LK (2005) Microbiologically influenced corrosion: looking to the future. Int Microbiol 8:169–180

Wang W, Li X, Wang J, Xu H, Wu J (2004) Influence of biofilms growth on corrosion potential of metals immersed in seawater. Mater Corros 55:30–35

Wang H, Ju LK, Castaneda H, Cheng G, Newby BMZ (2014) Corrosion of carbon steel C1010 in the presence of iron oxidizing bacteria acidithiobacillus ferrooxidans. Corros Sci 89:250–257

Wilson WW, Wade MM, Holman SC, Champlin FR (2001) Status of methods for assessing bacterial cell surface charge properties based on zeta potential measurements. J Microbiol Methods 43:153–164

Wu T, Yan M, Zeng D, Xu J, Sun C, Yu C et al (2015) Stress corrosion cracking of X80 steel in the presence of sulfate-reducing bacteria. J Mater Sci Technol 31:413–422

Xin B, Zhang D, Zhang X, Xia Y, Wu F, Chen S et al (2009) Bioleaching mechanism of Co and Li from spent lithium-ion battery by the mixed culture of acidophilic sulfur-oxidizing and iron-oxidizing bacteria. Bioresour Technol 100:6163–6169

Xu D, Gu T (2014) Carbon source starvation triggered more aggressive corrosion against carbon steel by the desulfovibrio vulgaris biofilm. Int Biodeterior Biodegradation 91:74–81

Xu C, Zhang Y, Cheng G, Zhu W (2007) Localized corrosion behavior of 316L stainless steel in the presence of sulfate-reducing and iron-oxidizing bacteria. Mater Sci Eng A 443:235–241

Xu C, Zhang Y, Cheng G, Zhu W (2008) Pitting corrosion behavior of 316L stainless steel in the media of sulphate-reducing and iron-oxidizing bacteria. Mater Charact 59:245–255

Xu D, Li Y, Gu T (2012) A synergistic d-tyrosine and tetrakis hydroxymethyl phosphonium sulfate biocide combination for the mitigation of an srb biofilm. World J Microbiol Biotechnol 28:3067–3074

Xu D, Li Y, Gu T (2016) Mechanistic modeling of biocorrosion caused by biofilms of sulfate reducing bacteria and acid producing bacteria. Bioelectrochemistry 110:52–58

Yu L, Duan J, Du X, Huang Y, Hou B (2013) Accelerated anaerobic corrosion of electroactive sulfate-reducing bacteria by electrochemical impedance spectroscopy and chronoamperometry. Electrochem Commun 26:101–104

Yuan SJ, Pehkonen SO (2007) Microbiologically influenced corrosion of 304 stainless steel by aerobic pseudomonas ncimb 2021 bacteria: afm and xps study. Colloids Surf B 59:87–99

Zhang P, Xu D, Li Y, Yang K, Gu T (2015) Electron mediators accelerate the microbiologically influenced corrosion of 304 stainless steel by the desulfovibrio vulgaris biofilm. Bioelectrochemistry 101:14–21

Acknowledgements

This study was funded by National Natural Science Foundation of China (No. 41576076).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Lv, M., Du, M. A review: microbiologically influenced corrosion and the effect of cathodic polarization on typical bacteria. Rev Environ Sci Biotechnol 17, 431–446 (2018). https://doi.org/10.1007/s11157-018-9473-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11157-018-9473-2