Abstract

In this research, nanofibrous copper (0) was utilized as an efficient nanostructured catalyst in Azide-Alkyne Cycloaddition reaction, reduction of nitrobenzenes to anilines and reduction of aromatic aldehydes to benzyl alcohols. Nanofibrous copper was prepared via dealloying of Cu–Zn powder and was characterized by SEM, TEM, XRD, BET and EDS analyses. This catalyst produced very good results including high product yield, short reaction time and recyclability.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent decades, preparation of porous materials has been a very interesting research field [1]. Apart from zeolites which have natural counterparts [2], metal–organic frameworks [3], porous silicas such as SBA-15 [4] and MCM-41 [5], and covalent organic frameworks [6] have been the subjects of extensive research. A wide variety of methods have been developed for preparing porous metals, including the template method, magnetron sputtering, electrodeposition, and the dealloying process [7]. Porous metals have been used in electrochemical sensors, electrochemical energy systems [8], as well as for electrochemical catalysis and surface-enhanced Raman scattering (SERS) [9].

Dealloying is a very reliable method for preparing porous metals such as gold, in which Ag-Au alloys immersed in nitric acid are dealloyed under free corrosion conditions [10]. The sequential elemental dealloying approach has also been used for the fabrication of porous metal oxides, whose sensors have been exploited for electronic listening [11]. Copper dealloying has also been applied with binary alloys like Mn–Cu [12],Cu–Zr [13], Mg-Cu [14], Al-Cu [15], Ti-Cu [16], and also ternary alloys such as Al-Cu-Mg [17], Ti–Cu–Ag [18] to prepare porous copper. The porosity is dependent on such conditions as potentiostatic dealloying and free corrosion.

N-substituted 1,2,3-triazoles have been prepared through click synthesis in the presence of a Cu (I) catalyst [19]. In addition, a microwave-assisted click chemistry synthesis of 1,4-disubstituted 1,2,3-triazoles via a copper (I)-catalyzed three-component reaction [20] as well as, a synthesis of 1,4-disubstituted 1,2,3-triazoles from in situ generated azides [21], as well as a regioselective synthesis of 1,4,5‐trisubstituted 1,2,3‐triazoles via copper‐catalyzed azide–alkyne cycloaddition has been reported [22]. Furthermore, multicomponent click synthesis of 1,2,3-triazoles from epoxides has been demonstrated to be catalyzed by copper nanoparticles on activated carbon [23]. Selective catalytic reduction of nitro compounds into their amine counterparts is of great value in organic synthesis [24]. The reduction of (i) p-nitrophenol and (ii) hexacyanoferrate (III) by borohydride ions is used as catalytic model reactions for evaluating the catalytic activity of nanocatalysts. It is worth noting that, no reaction should take place in the absence of nanoparticles [25]. Several catalysts have been utilized for this transformation including Raney nickel [26], molybdenum hexacarbonyl and DBU under microwave irradiation [27], carbon monoxide and water in the presence of the PdCl2/Fe/I2 system [28], surface modification of TiO2 nanoparticles [29], zeolite‐supported copper nanoparticles with 2‐propanol as a sustainable reducing agent [30], graphene-ZnO–Au nanocomposites [31], magnetic core–shell nanocatalyst [32], palladium supported on magnetic nanoparticles modified with carbon quantum dots [33], COF-Supported Co/Co(OH)2 nanoparticles [34], hydrazine-Fe3O4 [35], Fe3O4@sepiolite-Pd2+ [36], and supported gold nanoparticles [37]. Furthermore, the reduction of carbonyl compounds to the corresponding alcohols is considered an important transformation in the synthesis of biologically active compounds [38], with several catalysts such as Ni nanoparticles [39], zeolite supported Cu nanoparticles [40], Raney Ni–Al alloy and Al powder [41] and ball milling with NaBH4 [42] having been proposed for this purpose. Given the importance of these transformations in organic synthesis, there is a need for easier, simpler and more efficient methods that overcome the disadvantages. Considering the great versatility of porous and nano-sized copper[43], we decided to utilize the synergic effect of its high surface area and its splendid activity in the catalysis of organic reactions including azide-alkyne cycloaddition reaction, reduction of nitrobenzenes to anilines, and reduction of aromatic aldehydes to benzyl alcohols [44].

Results and discussion

In the first step, nanofibrous copper (0) was prepared via controlled etching of Cu–Zn alloy by NaOH solution. The etching creates porous sites in the metal texture, accessible by the reactants, and increases the surface area; thus, increasing the reaction rate by providing a greater catalyst- reactant interface. Terminal atoms of interfaces in heterogeneous catalysts have been demonstrated to have higher energy, resulting in a stronger interaction between the catalyst surface and reactant molecules [45]. To verify the structure of the nanocatalyst, several characterization techniques were used including SEM, TEM, XRD, BET and EDS analyses. The SEM images of the nanofibrous copper and the Cu–Zn alloy were recorded to allow a comparison of the surface structure of the metal to be made (Fig. 1). The Cu metal has a very smooth and solid texture before etching. After dealloying of Cu–Zn alloy, the Cu nanofibrous framework stays and the Zn is etched. Accordingly, the porous structure is formed, which is apparent in SEM images. Comparing the Cu–Zn alloy and nanostructured Cu, the difference in the surface texture can be easily detected. It can be seen that nanostructured Cu has a porous structure resembling that of a woven fabric, and can provide ample space for the starting materials to accumulate. The porous nature of the copper catalyst was also examined through transmission electron microscopy (TEM). As can be vividly seen in the TEM image, the metal particles are very transparent, indicating their porous nature (Fig. 2).

The BET test was also conducted to evaluate the gas adsorption capacity of the porous catalyst (Fig. 3). According to the BET analysis, the surface area was calculated to be 8.9 m2/g. It can be concluded from the BET and SEM analyses that the copper texture changed into a fibrous structure form, which can prove more beneficial in providing a greater surface area than solid metal as the catalyst in the chemical reactions.

In the next step, the XRD pattern of the nanoprous copper was recorded (Fig. 4). According to the Debye‐Scherrer equation, the crystallite size was calculated to be 98.7 nm for the peak at 2θ = 43.4°.

It should also be pointed out that the dealloyed content was considerable according to the EDS analysis (Fig. 5). Before dealloying the Cu–Zn alloy had 92.3% of Zn content compared to 8.8%. after dealloying.

After the characterization of the nanofibrous copper, it was decided to utilize this catalyst in the one-pot preparation of 1,2,3-triazole derivatives via azide-alkyne cycloaddition reaction. The reaction was conducted with a mixture of phenyl acetylene (1 mmol), sodium azide (1 mmol), epoxide/alkyl chloride (1 mmol), nano-porous copper (0.05 g) and distilled water (5 mL) under reflux conditions (Scheme 1). The reaction was found to be completed after 6 h, and the corresponding product namely 2-phenyl-2-(4-phenyl-1H-1,2,3-triazol-1-yl) ethan-1-ol was isolated.

Delighted with this result, we decided to prepare the similar products using the same method. As a result, a series of the 1,2,3-triazole derivatives were prepared (Table 1). According to the results, it was found out that the sole product in the ring opening of the epoxides, is the product which was prepared by the nucleophilic attack to the less hindered position of the epoxide ring except for styrene oxide.

After the satisfactory results obtained from the synthesis of 1,2,3-triazole derivatives, we tried to broaden the scope of catalytic activity of the catalyst; thus the reduction reactions were selected as model reactions. In reduction reactions, metal catalysts are utilized to enhance the reaction rate. Metals facilitate the electron and hydrogen transfer on their surface. Given the greater surface area provided by the nanofibrous Cu, it was considered a logical choice for selection as a good catalyst in this reaction. Accordingly, the reduction of nitrobenzenes to anilines was chosen as a benchmark. As a model reaction, nitrobenzene (1 mmol), sodium borohydride (2 mmol), nano-porous copper (0.01 g) and ethanol (5 mL) were heated at reflux conditions. Surprisingly, after 30 min, the reaction was complete and aniline was obtained. It should be noted that the reaction produced negligible yields after 2 h in the absence of the catalyst. Afterwards, a series of nitrobenzenes were converted into their corresponding aniline derivatives (Table 2).

In a similar vein, nanofibrous Cu was used to prepare benzyl alcohols from aromatic aldehyde derivatives (Table 3). Easy post-reaction recovery separation and catalyst reusability are among the great advantages of heterogeneous catalysts. In this regard, after completion of nitrobenzene reduction reaction, the catalyst was removed by simple filtration, washed with ethanol (5 mL) and then reused seven times without significant loss of activity (Fig. 6).

To assess the stability of the catalyst [47], The conversion versus the reaction time was plotted for the nitrobenzene reduction reaction in the presence of the catalyst. It was obvious that the deactivation of the catalyst occurs in the following runs due to the change in the apparent rate constant in the consecutive experimental runs (Fig. 7).

Assessment of the stability of the catalyst as an indication of the progress of deactivation (e.g. the graph was drawn by the comparison of UV–visible absorption spectra for the reduction of 4-nitrophenol to 4-aminophenol. the disappearance of the absorbance of the reactant at λmax = 400 nm was used as the benchmark)

To demonstrate the superiority of the catalytic performance of nanofibrous copper over the reported catalysts, the reduction of nitrobenzene to aniline was regarded as a representative example (Table 4). While in the majority of cases (except for entry 4), comparative yields of the desired product were obtained following the nanofibrous copper-catalyzed procedure, the reported procedures required long reaction time periods (entry 1), or high catalyst loading (entries 1–4). These results clearly demonstrate that nanofibrous copper is an equally or more efficient catalyst for this reaction.

Experimental

General

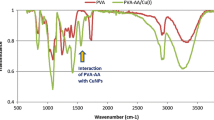

All commercially available chemicals were purchased from Sigma-Aldrich (USA) and Merck (Germany) companies and used without further purification. Products were characterized by their physical constant and comparison with authentic samples. Reaction monitoring was accomplished by TLC on silica gel polygram SILG/UV 254 plates. The IR spectra were recorded on a BOMEM MB-Series 1998 FT-IR spectrophotometer using KBr pellets for the samples and the catalyst in the range of 4000–400 cm−1. 1H and 13C NMR spectra were recorded in DMSO-d6 on a Bruker 250 MHz spectrometer using TMS as the internal standard. Thermal stability of the supported catalyst was examined by BÄHR, SPA 503 Thermo-gravimetric Analyzer (TGA) at heating rate of 10 °C min−1 over the temperature range of 40–950 °C. TEM images were recorded by Zeiss-EM10C-100 kV. SEM images were recorded by ZEISS-FESEM-Sigma VP. XRD analysis was recorded by Panalytical X’ Pert Pro. BET analysis was performed by Quantachrome.

General procedure for the preparation of nanofibrous Copper

In a 250 mL round-bottom flask, 0.5 g of Cu–Zn alloy was mixed with 0.5 g NaOH and 100 mL of distilled water at room temperature for 24 h. Afterwards, the mixture was filtered and washed with distilled water for several times. The nanofibrous copper precipitate was dried at 60 °C for 24 h.

Typical procedure for the preparation of 1,2,3-triazole derivatives

A mixture of phenyl acetylene (1 mmol), sodium azide (1 mmol), epoxide/alkyl chloride (1 mmol), nano-porous copper (0.05 g, 80 mol%) and distilled water (5 mL) was heated at reflux conditions. Completion of the reaction was indicated by TLC [acetone/n-hexane (3:10)], following which the catalyst was filtered, and the product was extracted using ethyl acetate. The organic layer was concentrated, and the product was obtained by evaporating the solvent in a rotary evaporator. Further product purifications can be done via recrystallization in an ethanol–water mixture or in the case of oily substances via column chromatography.

Typical procedure for the reduction of nitrobenzenes to anilines

A mixture of nitrobenzene derivative (1 mmol), sodium borohydride (2 mmol), nano-porous copper (0.01 g, 15 mol%) and ethanol (5 mL) was heated at reflux conditions. After completion of the reaction, as indicated by TLC [EtOAc/n-hexane (1:4) or GC, the catalyst was filtered and the product was obtained after evaporation of ethanol. Further product purifications can be done via recrystallization in an ethanol–water mixture or in the case of oily substances via column chromatography.

Typical procedure for the reduction of aromatic aldehydes into benzyl alcohols

A mixture of aromatic aldehyde (1 mmol), sodium borohydride (2 mmol), nano-porous copper (0.01 g, 15 mol%) and ethanol (5 mL) was heated at reflux conditions. Completion of the reaction was monitored by TLC [ethyl acetate/n-hexane (1:4)] or GC, following which the catalyst was filtered, and the product was obtained after evaporation of ethanol. Further product purifications can be done via recrystallization in an ethanol–water mixture or in the case of oily substances via column chromatography.

2-Phenyl-2-(4-phenyl-1H-1,2,3-triazol-1-yl)ethanol (Table 1, Entry 1): Pale yellow solid; 1HNMR(400 MHz, CDCl3) δ 8.22 (s, 1H;NCH = C), 7.31–7.78 (m, 10 H; ArH), 4.71–4.84, 4.21–4.34 (2 m, 2H; CH2), 3.72 (dd, 3JH,H = 8.7 Hz, 3 J = 4.7 Hz, 1H; CHCH2), 3.36 (wide peak 1H, OH); 13C NMR (100 MHz, CDCl3) δ 147.8 (NCCH), 138.1, 131.9, 129.9, 129.8, 129.5, 128.9, 128.2, 126.4, 121.6 (NCCH), 67.6 (CHCH2), 64.7 (CH2); IR (neat, cm−1) ν 699, 765, 1050, 1073, 1124, 1275, 1379, 1456, 1497, 2939, 3032, 3087, 3123, 3478.

Conclusion

Nanofibrous copper was prepared using a simple and straightforward method that involved the dealloying of Cu–Zn alloy in an alkaline solution. This nanoporous catalyst proved useful in azide-alkyne cycloaddition reactions, reduction of nitrobenzenes to anilines, and reduction of aromatic aldehydes to benzyl alcohols. Given the satisfactory results obtained from these reactions, it can serve as an alternative nanostructured catalyst for similar organic reactions as well as functional group transformations. This catalyst showed very good results including high product yield, short reaction time and recyclability.

References

Slater AG, Cooper AI (2015) Porous materials Function-led design of new porous materials. Science 348:e8075

Gottardi G, Galli E 2012 Natural zeolites (Vol. 18). Springer Science, Business Media.

Liu Y, O’Keeffe M, Treacy MM, Yaghi OM (2018) The geometry of periodic knots, polycatenanes and weaving from a chemical perspective: a library for reticular chemistry. Chem Soc Rev 47:4642

Zhao D, Feng J, Huo Q, Melosh N, Fredrickson GH, Chmelka BF, Stucky GD (1998) Triblock copolymer syntheses of mesoporous silica with periodic 50 to 300 angstrom pores. Science 279:548

Zhao XS, Lu GQ, Millar GJ (1996) Advances in mesoporous molecular sieve MCM-41. Ind Eng Chem Res 35:2075

Cote AP, Benin AI, Ockwig NW, O’Keeffe M, Matzger AJ, Yaghi OM (2005) Porous, crystalline, covalent organic frameworks. Science 310:1166

Abbas A, Abbas S, Wang X (2016) Nanoporous copper: fabrication techniques and advanced electrochemical applications. Corros Rev 34:249

Zhang J, Li CM (2012) Nanoporous metals: fabrication strategies and advanced electrochemical applications in catalysis, sensing and energy systems. Chem Soc Rev 41:7016

Chen LY, Yu JS, Fujita T, Chen MW (2009) Nanoporous copper with tunable nanoporosity for SERS applications. Adv Func Mater 19:1221

Erlebacher J, Aziz MJ, Karma A, Dimitrov N, Sieradzki K (2001) Evolution of nanoporosity in dealloying. Nature 410:450

Solanki V, Krupanidhi SB, Nanda KK (2017) Sequential elemental dealloying approach for the fabrication of porous metal oxides and chemiresistive sensors thereof for electronic listening. ACS Appl Mater Interfaces 9:41428

Hayes JR, Hodge AM, Biener J, Hamza AV, Sieradzki K (2006) Monolithic nanoporous copper by dealloying Mn–Cu. J Mater Res 21:2611

Lu HB, Li Y, Wang FH (2007) Synthesis of porous copper from nanocrystalline two-phase Cu–Zr film by dealloying. Scripta Mater 56:165

Zhao C, Qi Z, Wang X, Zhang Z (2009) Fabrication and characterization of monolithic nanoporous copper through chemical dealloying of Mg–Cu alloys. Corros Sci 51:2120

Liu WB, Zhang SC, Li N, Zheng JW, Xing YL (2011) A facile one-pot route to fabricate nanoporous copper with controlled hierarchical pore size distributions through chemical dealloying of Al–Cu alloy in an alkaline solution. Microporous Mesoporous Mater 138:1

Dan Z, Qin F, Sugawara Y, Muto I, Hara N (2012) Fabrication of nanoporous copper by dealloying amorphous binary Ti–Cu alloys in hydrofluoric acid solutions. Intermetallics 29:14

Aburada T, Fitz-Gerald JM, Scully JR (2011) Synthesis of nanoporous copper by dealloying of Al-Cu-Mg amorphous alloys in acidic solution: The effect of nickel. Corros Sci 53:1627

Dan Z, Qin F, Makino A, Sugawara Y, Muto I, Hara N (2014) Fabrication of nanoporous copper by dealloying of amorphous Ti–Cu–Ag alloys. J Alloy Compd 586:S134

Tornøe CW, Christensen C, Meldal M (2002) Peptidotriazoles on solid phase:[1,2,3]-triazoles by regiospecific copper (I)-catalyzed 1, 3-dipolar cycloadditions of terminal alkynes to azides. J Org Chem 67:3057

Appukkuttan P, Dehaen W, Fokin VV, Van der Eycken E (2004) A microwave-assisted click chemistry synthesis of 1, 4-disubstituted 1, 2, 3-triazoles via a copper (I)-catalyzed three-component reaction. Org Lett 6:4223

Feldman AK, Colasson B, Fokin VV (2004) One-pot synthesis of 1, 4-disubstituted 1, 2, 3-triazoles from in situ generated azides. Org Lett 6:3897

Spiteri C, Moses JE (2010) Copper-catalyzed azide–alkyne cycloaddition: regioselective synthesis of 1, 4, 5-trisubstituted 1, 2, 3-triazoles. Angew Chem Int Ed 49:31

Alonso F, Moglie Y, Radivoy G, Yus M (2011) Multicomponent click synthesis of 1, 2, 3-triazoles from epoxides in water catalyzed by copper nanoparticles on activated carbon. J Org Chem 76:8394

Tafesh AM, Weiguny J (1996) A review of the selective catalytic reduction of aromatic nitro compounds into aromatic amines, isocyanates, carbamates, and ureas using CO. Chem Rev 96:2035

Herves P, Pérez-Lorenzo M, Liz-Marzán LM, Dzubiella J, Lu Y, Ballauff M (2012) Catalysis by metallic nanoparticles in aqueous solution: model reactions. Chem Soc Rev 41:5577

Burge HD, Collins DJ, Davis BH (1980) Intermediates in the Raney nickel catalyzed hydrogenation of nitrobenzene to aniline. Ind Eng Chem Prod Res Dev 19:389

Spencer J, Anjum N, Patel H, Rathnam RP, Verma J (2007) Molybdenum hexacarbonyl and DBU reduction of nitro compounds under microwave irradiation. Synlett 2007:2557

Skupiń J, Zukowska A, Chajewski A (2001) Reduction of nitrobenzene to aniline with carbon monoxide and water in the presence of the PdCl2/Fe/I2 system. React Kinet Catal Lett 72:21

Makarova OV, Rajh T, Thurnauer MC, Martin A, Kemme PA, Cropek D (2000) Surface modification of TiO2 nanoparticles for photochemical reduction of nitrobenzene. Environ Sci Technol 34:4797

Subramanian T, Pitchumani K (2012) Selective reduction of nitroarenes by using zeolite-supported copper nanoparticles with 2-propanol as a sustainable reducing agent. ChemCatChem 4:1917

Roy P, Periasamy AP, Liang CT, Chang HT (2013) Synthesis of graphene-ZnO-Au nanocomposites for efficient photocatalytic reduction of nitrobenzene. Environ Sci Technol 47:6688

Nasab MJ, Kiasat AR (2016) Multifunctional Fe 3 O 4@ n SiO 2@ m SiO 2/Pr-Imi-NH 2· Ag core–shell microspheres as highly efficient catalysts in the aqueous reduction of nitroarenes: improved catalytic activity and facile catalyst recovery. RSC Adv 6:41871

Gholinejad M, Zareh F, Nájera C (2018) Nitro group reduction and Suzuki reaction catalysed by palladium supported on magnetic nanoparticles modified with carbon quantum dots generated from glycerol and urea. Appl Organomet Chem 32:e3984

Mullangi D, Chakraborty D, Pradeep A, Koshti V, Vinod CP, Panja S, Vaidhyanathan R (2018) Heterogenous Catalysts: highly stable cof-supported Co/Co (OH) 2 nanoparticles heterogeneous catalyst for reduction of nitrile/nitro compounds under mild conditions. Small 14:1870169

Cantillo D, Moghaddam MM, Kappe CO (2013) Hydrazine-mediated reduction of nitro and azide functionalities catalyzed by highly active and reusable magnetic iron oxide nanocrystals. J Org Chem 78:4530

Ghonchepour E, Islami MR, Bananezhad B, Mostafavi H, Tikdari AM (2019) Synthesis of recoverable palladium composite as an efficient catalyst for the reduction of nitroarene compounds and Suzuki cross-coupling reactions using sepiolite clay and magnetic nanoparticles (Fe3O4@ sepiolite-Pd2+). C R Chim 22:84

Zhu H, Ke X, Yang X, Sarina S, Liu H (2010) Reduction of nitroaromatic compounds on supported gold nanoparticles by visible and ultraviolet light. Angew Chem Int Ed 49:9657

Chakraborty S, Bhattacharya P, Dai H, Guan H (2015) Nickel and iron pincer complexes as catalysts for the reduction of carbonyl compounds. Acc Chem Res 48:1995

Kidwai M, Bansal V, Saxena A, Shankar R, Mozumdar S (2006) Ni-nanoparticles: an efficient green catalyst for chemoselective reduction of aldehydes. Tetrahedron Lett 47:4161

Subramanian T, Pitchumani K (2012) Transfer hydrogenation of carbonyl compounds and carbon–carbon multiple bonds by zeolite supported Cu nanoparticles. Catal Sci Technol 2:296

Rayhan U, Do JH, Arimura T, Yamato T (2015) Reduction of carbonyl compounds by Raney Ni–Al alloy and Al powder in the presence of noble metal catalysts in water. C R Chim 18:685

Naimi-Jamal MR, Mokhtari J, Dekamin MG, Kaupp G (2009) Sodium tetraalkoxyborates: intermediates for the quantitative reduction of aldehydes and ketones to alcohols through ball milling with NaBH4. Eur J Org Chem 2009:3567

Sayyahi S, Saghanezhad SJ (2019) Copper-Based Bulk and Nano-Catalysts for the One-Pot Propargylamine Synthesis. Mini-Rev Org Chem 16:361

Tappan BC, Steiner SA III, Luther EP (2010) Nanoporous metal foams. Angew Chem Int Ed 49:4544

Gao W, Hood ZD, Chi M (2017) Interfaces in heterogeneous catalysts: advancing mechanistic understanding through atomic-scale measurements. Acc Chem Res 50:787

Salamatmanesh A, Miraki MK, Yazdani E, Heydari A (2018) Copper (I)–caffeine complex immobilized on silica-coated magnetite nanoparticles: a recyclable and eco-friendly catalyst for click chemistry from organic halides and epoxides. Catal Lett 148:3257

Scott SL (2018) A Matter of life (time) and death. ACS Catal 8:e8597

Dell’Anna MM, Intini S, Romanazzi G, Rizzuti A, Leonelli C, Piccinni F, Mastrorilli P (2014) Polymer supported palladium nanocrystals as efficient and recyclable catalyst for the reduction of nitroarenes to anilines under mild conditions in water. J Mol Catal A: Chem 395:307

Davarpanah J, Kiasat AR (2013) Catalytic application of silver nanoparticles immobilized to rice husk-SiO2-aminopropylsilane composite as recyclable catalyst in the aqueous reduction of nitroarenes. Catal Commun 41:6

Keshipour S, Adak K (2018) Reduction of Nitroaromatics to Amines with Cellulose Supported Bimetallic Pd/Co Nanoparticles. Iran J Chem Chem Eng 37:23

Acknowledgements

The authors gratefully acknowledge the financial support from the Mahshahr Branch, Islamic Azad University, Iran.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Saghanezhad, S.J., Buhamidi, M.M., Ebadi, S. et al. Entangled nanofibrous copper: an efficient and high performance nanostructured catalyst in azide-alkyne cycloaddition reaction and reduction of nitroarenes and aromatic aldehydes. Reac Kinet Mech Cat 133, 897–911 (2021). https://doi.org/10.1007/s11144-021-02011-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-021-02011-x