Abstract

In this paper, acidic hydrolysis (0–5 vol%) was performed on Chlorella vulgaris biomass using a range of temperature (100–130 °C) and reaction time (0–60 min) with high biomass load (10%—100 g L−1), in order to characterize the kinetic of biomass solubilization, hydrolysis of sugars, proteins and ash release, and to verify the main divergences and similarities in relation to lignocellulosic biomass. More than 90% of the sugars present in the biomass was hydrolyzed and later satisfactorily fermented by S. cerevisiae. The inclusion of acid concentration in the kinetic model for biomass solubilization and sugar hydrolysis led to a modified Michaelis–Menten equation able to simulate efficiently the acidic extraction/hydrolysis data of all experimental runs. Main divergences in relation to lignocellulosics were related to higher reaction order and lower activation energy, reveling better susceptibility of microalgal biomass to acidic treatment. The proposed process is promising and can be easily scaled up at industrial level.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Biomass is a highly promising fossil substitute raw material for future biofuel application owing to several reasons: abundant feedstock availability and possibility to be produced in almost all regions of the world, avoiding competition with food crops [1]. However, its chemical structure (lignocellulose) is complex and change significantly depending on the type. For this reason, several methods of pretreatment are applied to exploit it, for example, alkaline for coconut husk fiber [2], acidic for citric waste [3], hydrothermal for sugarcane straw [4] or biological for wood [5], becoming more complex and severe as a function of the polymeric structure recalcitrance.

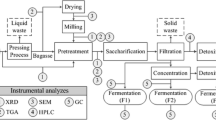

A potential bio-refinery scheme, claiming an environmental gain thanks to carbon cycle and the use of renewables, aims at a controlled depolymerization of biomass which includes the following steps: (1) fractionation of biomass into biopolymers: cellulose, hemicellulose, starch and lignin; (2) depolymerization of the biopolymers and (3) transformation of the monomers into value-added products [1].

More recently, microalgae have been developed and proposed as a potential source of biomass, especially for biofuels applications, initially more devoted to biodiesel (lipid fraction) [6], but then focused also on ethanol [7], methane [8], hydrogen [9] and buthanol [10]. Microalgae have a number of advantages in comparison to higher plants (i.e. lignocellulosic biomass), such as higher growth rates and less recalcitrance due to the absence of lignin and lower amount of cellulose and hemicellulose, being starch (microalgae) or glycogen (cyanobacteria) the main reserve-polysaccharides which are easily hydrolysable by acids [11, 12].

Kinetic studies using acidic pretreatment of lignocellulosic materials are reported in the literature, but for biomass solubilization only [1, 13,14,15,16,17]. For lignocellulosic materials, the acidic treatment is effective as pretreatment to remove hemicellulose and de-structure its three-dimensional arrangement, then helping the enzymatic hydrolysis of cellulose [7, 18]. Thinking of microalgae and cyanobacteria [19, 20], the potential to obtain a higher sugar hydrolysis rate by acidic hydrolysis is increased, but so far most studies on microalgal biomass were focused to determine the best condition of hydrolysis, i.e., to find the optimized value of temperature, time of reaction, acidic concentration and biomass load [7, 21,22,23]. This method is faster but at the same time, it is not efficient to evaluate the nature of biomass hydrolysis and/or degradation processes. Kinetic and thermodynamic information is necessary to be used efficiently in the models to correctly perform process simulation and plant design. In any case, the nature of microalgal biomass is completely different from lignocellulosic biomass and the models traditionally used cannot be suitable for microalgae, so that a model of acidic sugars hydrolysis based on microalgal biomass as substrate has not been developed yet.

In addition, mass balance calculations of nutrients needed, mainly nitrogen and phosphorous, influence the global process economics, because they represent the largest costs in cultivating algae for fuels. The recycling and life cycle assessment (LCA) of these nutrients are a must [24,25,26]. Acidic hydrolysis as a non-specific process promotes not only the release of sugars but also of the other substances present in the biomass (such proteins and ash), and this additional fraction can be useful in the liquor during yeast/bacteria fermentation and needs to be quantified for an accurate investigation to close the loop of nutrients in the process.

In this paper, the range of temperature (100–130 °C) and reaction time (0–60 min) using high biomass load (10%—100 g L−1) were investigated in order to characterize the kinetic of biomass solubilization, hydrolysis of sugars, proteins and ash solubilization from Chlorella vulgaris biomass using themochemical hydrolysis with diluted acid (0–5 vol%). Divergences and similarities with lignocellulosic biomass will be highlighted as well.

Experimental

Microalgal biomass and biochemical characterization

Chlorella vulgaris biomass powder was produced by Neoalgae® (Micro seaweed products B-52501749). The characterization included the determination of moisture (method 934.01), ash (method 942.05), protein (method 2001.11), lipid content (method 2003.05), carbohydrates and monomers (HPLC) [27].

Acidic hydrolysis and analytical procedures

Acidic hydrolysis was performed with 10% of solids load (microalgal biomass), in autoclave (Autoclave vapour-lineeco VWR), using temperatures between 100 and 130 °C (P ~ 1 atm), and changing the concentration of catalyst (H2SO4—98% Sigma®) (0, 1, 3 and 5 vol%) and the reaction time (0–60 min) in order to validate the kinetic model proposed and posteriorly discussed.

The mass yield (MY) of the process was evaluated on a dry weight basis after the thermochemical treatment by gravimetry using cellulose acetate filters of 0.45 μm (Whatman®) at 105 °C and 2 h. Filters were pre-dried for 10 min at 105 °C in order to remove any moisture. The relation between solubilized biomass and mass yield is given by:

The amount of total extracted sugars (TS) was determined by Anthrone method [28] and reducing sugars (monomers, RS) using the DNS method [3, 29].

The % of sugars extracted/hydrolyzed was calculated by:

Here the carbohydrate content is given as a relative value between 0 and 0.6 (generally the maximum of carbohydrate accumulation in microalgae and cyanobacteria is 0.6 = 60% of carbohydrate content, in dry weight basis) [7, 30, 31].

Kinetic model

Reaction

The reaction of acidic biomass solubilization is commonly represented by:

The assumption is that H+ participates in the biomass solubilization and sugars hydrolysis as a catalyst, but interactions as reagent should be considered as well. In fact, some speculation about the effect of [H+] only a catalyst was made, explained that it is possible of its neutralization for the biomass due the several biochemical fractions, mainly minerals [17].

Mass yield

An nth order kinetics for biomass solubilization and an mth order for acid hydrolysis were used, resulting in an n + m overall reaction order. The acid concentration term was incorporated in the Arrhenius equation giving a modified equation:

Here Pol indicates biomass concentration, and where:

Here n and m are the orders of reactions to Pol and H+, respectively.

The integration of Eq. 4 yields:

Consequently:

From Eq. 7, at constant Temperature (T) and Pol biomass concentration it is possible to find the k values a corresponding to the [H+] value applied. Then, using Eq. 5, since the values of T (K), R (J/(mol K)) and k (min−1 (g/L)−m) are known, the values of m and E a (kJ/mol) can be found.

Total sugar concentration (extracted/hydrolyzed sugars)

The Michaelis–Menten model was applied to describe the total sugars extracted from the biomass, since sugars concentration in liquid-phase depends on the substrate concentration (biomass and acid concentration):

The following composite constant is used here:

When the substrate concentration is high, the equation becomes zeroth order [32]. In our work, it is proposed to express the [S] term by Eq. 9.1, including the proton as a reactant and the orders of reaction. K M ((g/L)n+m) is the constant of half-saturation and k is the reaction rate constant (min−1). Parameter estimation was performed by non-linear regression validated by the least squares method [33].

Thus, the final equation that can be obtained integrating Eq. 8 is:

Here t is the reaction time.

Additionally, selectivity (S) is defined as:

Here Y represents the yield of the reaction and X the conversion of biomass (Pol). The final reaction time studied in this work, 60 min was considered as the reference time.

Protein and ash solubilization

The extents of solubilized protein and ash were calculated by:

Ethanolic fermentation

Fermentation was performed with S. cerevisiae (Cameo S.p.A.®) using the broth from acidic hydrolysis after adjustment the pH to 5.5 at 30 °C for 48 h. Reducing sugars were measured by DNS method and cellular growth by dry weight (described in the Acidic hydrolysis and analytical procedures section). Ethanol was determined by gas chromatography (Shimadzu GC-14A) injecting 5 μL of centrifugated at 5000 rpm per 10 min (Labnet, Spectrofuge 7 M, bought from Sigma–Aldrich, Milan, Italy) in Eppendorf™), with a Poropak QS packed column (80/100 mesh, 1.7 m length). The carrier gas was helium with a flow rate of 20 mL/min. The injector, column oven and the detector temperatures were 150, 150 and 170 °C. The composition was computed from the GC peak areas according to a calibration curve.

Conversion factors are calculated by:

Here Δ is referred to the difference between time 0 and the end of fermentation, sugars indicate reducing sugars and X is the yeast concentration (g L−1).

Process and fermentation yield were calculated by:

Here 0.5111 is the glucose-ethanol conversion factor according to the stoichiometry of Gay-Lussac.

Results and discussion

The combined use of temperature, acid concentration and time was applied in order to evaluate the susceptibility of microalgal biomass to promote solubilization and, in particular, sugars extraction and hydrolysis, in order to propose a suitable model to simulate efficiently the process. Protein and ash extraction in the liquid phase were taken with account, as acid as a catalyst is not specific. Lastly, ethanolic fermentation was carried out to validate the fermentability of the hydrolyzed matter with S. cerevisiae, and a mass balance of industrial process flowsheet was proposed.

Biomass characterization

The biochemical composition of Chlorella vulgaris is presented in Table 1. The biomass used has a relatively high content of proteins and ash, together with carbohydrate. It is important to remember that microalgae display a biochemical plasticity able to change their composition according to the nutritional and environmental factors. Specifically, for Chlorella vulgaris, nitrogen availability, residence time and light intensity allow to accumulate more or less carbohydrate in the biomass [30].

Carbohydrates in microalgae are present as cell wall components (generally cellulose and soluble hemicellulose) and plastids (mainly in the form of starch) [19]. Glucose was found predominant monosaccharide in the biomass and accounts for more than 70% of total sugars, together with xylose (10.65%), arabinose (10.91%) and rhamnose (5.73%). These results to sugars composition in Chlorella are in according with literature data.

Xylose and arabinose are pentoses which cannot be fermented by Saccharomyces, the most widely used industrial microorganism, and this deserves to be considered as they represent more than 20% of total sugars in Chlorella vulgaris. Genetic improvement is needed in order to increase the ethanol tolerance and ability of yeast and bacteria species to ferment pentose [34]. In addition, some genders, as Pichia, Candida and Kluyveromyces are able to ferment pentose and hexose naturally but at lower rates in comparison to Saccharomyces [35]. However, this point was not addressed here because S. cerevisiae was used.

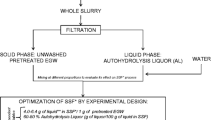

Biomass solubilization

As shown in Fig. 1, the range of temperature (110–130 °C) and acid concentration applied were efficient in the solubilization of microalgal biomass, reaching best values (around 20–25%) with 5% of acid and 60 min of reaction time. However, 120 °C and 3% of acid was considered the best option in terms of solubilization/acid ratio used. It is noteworthy that the zero point was considered when the temperature reached 110, 120 or 130 °C, i.e., the initial heating time was not included. Clearly, this had an effect in the experiments, as at zero point the initial biomass and sugar concentration are not 100% and 0, respectively (Fig. 1, but also Figs. 2 and 3 later on), but the effect is the same for all experimental runs and does not affect the kinetic model. Note that, even though most of published papers use less than 50 g L−1 of biomass [12, 23, 39], a biomass concentration of 100 g L−1 was chosen to obtain a suitable sugars concentration with respect to a real process, even though higher biomass concentration increases the viscosity and can disturb the saccharification yield [10, 22, 38].

According to Table 2, a high reaction order in comparison with lignocellulose solubilization was found: Average values were n = 3.6307 ± 0.1818 and m = 1.4161 ± 0.0649. The activation energy of the process was E a = 41.1919 ± 0.0982 kJ/mol. These values are much lower than cellulose/lignocellulosic biomass under acidic hydrolysis (n and m are first-order and E a range between 100 and 190 kJ/mol). Therefore, microalgal biomass has higher susceptibility to acidic hydrolysis, and the currently proposed process looks promising for application as a single step one to obtain fermentable sugars from microalgal biomass, i.e., using less energy. In the case of lignocellulosic biomass, the acidic treatment is used as pretreatment to remove the hemicellulose fraction and help enzyme accessibility to cellulose fraction (de-structuration of lignocellulose) [1], but additional cost due to the need of specific enzymes is one of the main bottlenecks to cellulosic ethanol consolidation.

The inclusion of the acid concentration in the kinetic of biomass de-structuration during a thermochemical hydrolysis is important and was already proposed [1, 13]. The solubilization of lignocellulosic biomass is usually considered as first order with respect to biomass and acid concentration [13, 15]. This concept was also used in the case of microalgae [39, 40], but the same assumption was not verified in this work (n and m, Table 2), showing the importance of new development for an accurately scientific evaluation and application to process simulation and plant design.

Kinetic constant (k—(min−1) (g/L)−m) values strongly increased as a function of temperature and acid concentration, being improved by 2–3 orders of magnitude with respect to the control condition (no acid addition). A similar effect of temperature is described in several works related to both lignocellulosic and microalgal biomass [1, 12, 13, 22, 23], but so far has not been included at kinetic level, especially for microalgae.

Extracted sugars (total sugars) and reducing sugars (monomers)

The extraction (total sugars) and hydrolysis (reducing sugars) were validated in the same ranges of temperature (110, 120 and 130 °C), acid concentration (0, 1, 3 and 5%) and reaction time (0–60 min) and are displayed in Fig. 2 and Clearly, at lower temperature (110 °C), the amount of total sugars is higher than the reducing sugars measured (Figs. 2a and 3a). In this case, it means that the sugars were separated from the biomass matrix but not efficiently converted to monomers. When the temperature increased (120 and 130 °C), total and reducing sugars values become closer to each other, thus extraction and hydrolysis can be considered as concomitant processes (extraction and hydrolysis) (Figs. 2b, 2c, 3b and 3c).

At 120 °C, more than 90% of reducing sugars were obtained when 3% of sulfuric acid and 30 min of reaction time were used. This was considered as the best condition in the range of the experiments performed. In fact, according to literature 90% of biomass was hydrolyzed when 50 g L−1 of Tribonema sp. was submitted at 121 °C and 3% of sulfuric acid for 30 min [10]. Ashokkumar et al. [23] hydrolyzed 20 g L−1 of Scenedesmus bijugatus biomass at 130 °C and 2% of acid, and obtained around 85% of saccharification. Dunaliella tertiolecta LB999 (50 g L−1) at 121 °C and 3.73% of sulfuric acid for 15 min provided a hydrolysis yield of 44.31%, but here time was probably limiting [41]. Scenedesmus obliquus (50 g L−1, 120 °C and 5% of sulfuric acid for 30 min) provided >90% of saccharification yield [22]. Chlorella vulgaris JSC-6 (120 g L−1, 121 °C and 4–6% of sulfuric acid for 20 min) [38], Scenedesmus obliquus CNW-N (10–40 g L−1, 121 °C and 1.5–2% of sulfuric acid for 20 min) [12] and Chlamydomonas reinhardtii (50 g L−1, 120 °C, 3% of sulfuric acid for 30 min) [39] reached a saccharification yield between 90 and 100%. All these optimized conditions from the literature agree with the experimental results obtained in our work, so that the presently developed model for Chlorella vulgaris could be assumed to be suitable for most of industrial microalgal species considered in the literature. In addition, no significant degradation processes were verified in the variables range used.

From Table 3, we note that most of extracted sugars was solubilized with higher acid concentrations (3 and 5%), but the kinetic constant did not increase as a function of temperature (see 120 and 130 °C with respect to 110 °C), probably due the reduced sugars content on the biomass, because >90% of sugars were already extracted (Fig. 2). As an example, with 5% of acid, k reduced from 1.612 to 1.391 and 1.378 at 110, 120 and 130 °C. On the other hand, kinetic constants for reducing sugars increased as a function of temperature and acid concentration in all experiments inside the range studied and more than 90% of hydrolysis was reached (Table 3; Fig. 3).

According to the assumption [S] = [Pol]n[H+]m, K M can also be expressed including [H+] in its expression, and a value of the half-saturation mass yield (Pol KM ) can be calculated by:

Interestingly, it was found that the value of Pol KM is practically independent of acid concentration, with an average of 42.02 ± 1.75 g/L (Table 3), thus the assumption made in the modified equation is reasonable. In this value of mass yield, around 80% of sugars were saccharified what justify the significantly reduction of the hydrolysis constant (k), which to the model is half of the maximum (k max ).

Furthermore, it is interesting to discuss selectivity values, as this variable allows us to evaluate the selection of best hydrolysis condition because it evaluates both the substrate (Pol) conversion and the product yield (Hydrolyzed Sugars). By looking at Fig. 4, it is perceived that the selectivity increased as a function of acid concentration and temperature with 3% and 120 °C, where more than 90% of saccharification yield was obtained, confirming the best condition mentioned before.

Ethanolic fermentation

Fermentation of the hydrolyzed Chlorella biomass was carried out using S. cerevisiae, leading to the results presented in Fig. 5. Here, it can be seen that the fermentation was fast and reached a sugars consumption of 75% in 24 h. If we consider pentose-excluding sugars (hexoses) only, the reduction was 94.2%, indicating a good performance. The ethanol to sugar factor was 0.307, when the maximum stoichiometric value is 0.5111 (Gay-Lussac stoichiometry), but this is normal because a lower yeast inoculum concentration was used, and part of the carbohydrates are metabolized to cellular multiplication. Similar values are reported by other authors [2, 41, 42]. On the other hand, when a high inoculum concentration (10% m v−1) is used, this yield is increased to values about 95% of sugars consumption, and more than 80% of ethanol yield can be achieved [43], whereas our work, it was 60.6% (Table 4).

Literature values of ethanol/biomass yields are 0.163 gethanol/gbiomass (Arthrospira platensis—chemical hydrolysis) [42], 0.140 gethanol/gbiomass (Dunaliella tertiolecta—chemeoenzimatic) [41] and 0.214–0.233 gethanol/gbiomass (Chlorella vulgaris FSP-E—enzymatic and chemical hydrolysis, respectively) [12]. In this work, a value of 0.150 gethanol/gbiomass was achieved, using low yeast inoculum concentration <0.1 g L−1 of yeast and considering a biomass with 50% of carbohydrates). The stoichiometrically maximum value considering a biomass with 50% of carbohydrates is 0.26.

Nutrient recovery and industrial process development

Acidic hydrolysis, as aforementioned, is a non-specific process and all biomass components are attached and can be dissolved. A special attention was paid to the protein content accounting for most of N fraction in the biomass and ash (mineral content, in particular P content), because N and P salts are the main nutrient requirements for microalgae cultivation (apart of carbon which comes from CO2), and consequently, they are crucial in determining cultivation costs.

The repetition of the experiments (with a 1 L—scale reactor) at 120 °C with 3% of acid (in quadruplicate) showed the same mass and saccharification yield reported before, confirming the reproducibility of the process (Fig. 6a). In view of ethanol production within a biorefinery approach, the acidic thermochemical process proved to be efficient in the solubilization of protein and ash fractions too: as shown in Fig. 6b, the liquid phase obtained in the best conditions (120 °C, 3% of acid and 30 min) contained around 80% of the ash and 70% of the proteins present in the initial biomass.

Nutrient recovery is a ‘hot topic’ in order to recycle the maximum of these nutrients in the process of microalgae cultivation so that to minimize the consumption of these nutrients [44,45,46,47,48,49]. This possibility was checked with respect to algae cultivation in several standard mediums, which are recipes providing an optimized mixture of nutrients to support their growth [45]. In our currently proposed process, most of solubilized nutrients go to the fermentation, thus helping the yeast growth. After that, ethanol is distilled, yeast are centrifuged and recirculated, and the effluent remaining (stillage/vinasse) has the major concentration of nitrogen and phosphorous, among other nutrients. Therefore the recycling or recovery of this effluent is mandatory. In addition, the solid waste from hydrolysis process account for around 30% in mass of the initial biomass and its components can be recovered too. To this scope, the most efficient processes to recover the nutrients and increase energy efficiency are hydrothermal liquefaction (HTL), flash hydrolysis and anaerobic digestion.

For instance, HTL with Arthrospira platensis at 190–210 °C for 2–4 h was able to recover 78–90% of nitrogen present in biomass [50]. The main disadvantage of HTL is its high-energy duty, caused by the rather high temperature and pressure operating conditions. Scenedesmus obliquus was grown in the hydrolysate obtained by flash hydrolysis obtained from the same specie for flash hydrolysis at 280 °C and 9 s of residence time with a protein recovery of 65% in the liquid phase [46]. This species obtained better performance in batch cultivation than in the standard medium for autotrophic growth, thanks to the combination of heterotrophy (mixotrophy). In continuous cultivation mode, the productivities ranged between 0.62 and 0.72 g/(L day), showing satisfactory performances [26]. When anaerobic digestion is used for nutrient recycling, it is necessary to discuss about liquid phase (biofertilizer), because several non-gasifiable nutrients in the operation conditions, such as N and P, remain in mineral conditions in the final effluent, known as digestate, especially as ammonium and phosphate salts [47, 48]. Anaerobic digestion provides a liquid biofertilizer that can be also used for the cultivation of microorganisms (nutrient recycling) with an increase in sustainability and autonomy of the process; and is already integrated in an ethanol biorefinery [47]. For instance, Chlorella vulgaris was cultivated in sugarcane stillage anaerobically biodigested with the consumption of a great amounts of N and P of the effluent [49].

Economic and energetic analysis will confirm the real applicability of this technology because even with these promising numbers, cultivation costs of microalgae are still high in comparison with other crops [7]. Some points that need to be developed to increase the process feasibility are: solid fraction recycling, yeast recycling, stillage utilization, pentose fermentation and lipid fraction destination.

Conclusion

In this work, it was shown that the acidic treatment of microalgal biomass is effective to solubilize biomass and hydrolyze the biomass sugars (by more than 90% present in Chlorella vulgaris). A model of nth order for biomass solubilization and a modified Michaelis–Menten equation were able to simulate efficiently the experimental hydrolysis data, acid concentration with mth order kinetics is included in this model, and showing an activation energy lower than for lignocellulosic biomass. After the thermochemical process, most of the proteins and ash present in the biomass are released in the liquid-phase and can be used in the ethanolic fermentation step. It was also shown that S. cerevisiae fermented satisfactorily most of the sugars. The simplicity and efficiency of the process make this arrangement promising and a block flow diagram of an industrial process was eventually proposed.

Change history

04 October 2017

An erratum to this article has been published.

18 May 2020

In this paper, acidic hydrolysis (0���5��vol%) was performed on Chlorella vulgaris biomass using a range of temperature (100���130����C) and reaction time (0���60��min) with high biomass load (10%���100��g��L���1), in order to characterize the kinetic of biomass solubilization, hydrolysis of sugars, proteins and ash release, and to verify the main divergences and similarities in relation to lignocellulosic biomass. More than 90% of the sugars present in the biomass was hydrolyzed and later satisfactorily fermented by S. cerevisiae. The inclusion of acid concentration in the kinetic model for biomass solubilization and sugar hydrolysis led to a modified Michaelis���Menten equation able to simulate efficiently the acidic extraction/hydrolysis data of all experimental runs. Main divergences in relation to lignocellulosics were related to higher reaction order and lower activation energy, reveling better susceptibility of microalgal biomass to acidic treatment. The proposed process is promising and can be easily scaled up at industrial level.

References

Negahdar L, Delidovich I, Palkovits R (2016) Aqueous-phase hydrolysis of cellulose and hemicellulose over molecular acidic catalysis: insights into the kinetics and reaction mechanism. Appl Catal B 184:285–298

Cabral MMS, Abud AKS, Silva CEF, Almedia RMRG (2016) Bioethanol from coconut husk fiber. Cienc Rural 46(10):1872–1877

Silva CEF, Gois GNSB, Silva LMO, Almeida RMRG, Abud AKS (2015) Citric waste saccharification under different chemical treatments. Acta Scientiarum Technol 37(4):387–395

Rocha MSRS, Pratto B, Junior RS, Almeida RMRG, Cruz AJG (2017) A kinetic model for hydrothermal pretreatment of sugarcane straw. Biores Technol 228:176–185

Song L, Yu H, Ma F, Zhang X (2013) Biological pretreatment under non-sterile conditions for enzymatic hydrolysis of corn stover. BioResources 8(3):3802–3816

Tercero EAR, Domenicali G, Bertucco A (2014) Autotrophic production of biodiesel from microalgae: an updated process and economic analysis. Energy 76:807–815

Silva CEF, Bertucco A (2016) Bioethanol from microalgae and cyanobacteria: a review and technological outlook. Process Biochem 51:1833–1842

Ding L, Cheng J, Xia A, Jacob A, Voelklein M, Murphy JD (2016) Co-generation of biohydrogen and biomethane through two-stage batch co-fermentation of macro- micro-algal biomass. Biores Technol 218:224–231

Kumar G, Sivagurunathan P, Thi NBD, Zhen G, Kobayashi T, Kim S, Xu K (2016) Evaluation of different pretreatments on organic matter solubilization and hydrogen fermentation of mixed microalgae consortia. Int J Hydrog Energy 41:21628–21640

Wang Y, Guo W, Lo Y, Chang J, Ren N (2014) Charactherization and kinetics of bio-butanol production with Clostridium acetobutylicum ATCC 824 using mixed sugar medium simulating microalgae-based carbohydrates. Biochem Eng J 91:220–230

Chisti Y (2007) Biodiesel from microalgae. Biotechnol Adv 25:294–306

Ho S, Huang S, Chen C, Hasunuma T, Kondo A, Cheng J (2013) Bioethanol production using carbohydrate-rich microalgae biomass as feedstock. Biores Technol 135:191–198

Saeman JF (1945) Kinetics of wood saccharification: hydrolysis of cellulose and decomposition of sugars in dilute acid at higher temperature. Ind Eng Chem 37:43–52

Overend RP, Chronet E (1987) Fractionation of lignocellulosics by steam-aqueous pretreatments. Phil Trans R Soc Lond A 321:523–536

Chum HL, Johnson DK, Black SK, Overend RP (1990) Pretreatment-catalyst effects and the combined severity parameter. Appl Biochem Biotechnol 24(25):1–14

Belkacemi K, Abatzaglou N, Overend RP, Chornet E (1991) Phenomenological kinetics of complex systems: mechanistic considerations in the solubilization of hemicelluloses following aqueous/steam treatments. Ind Eng Chem Res 3:2416–2425

Jacobsen SE, Wyman CE (2000) Cellulose and hemicellulose hydrolysis models for application to current and novel pretreatment processes. Appl Biochem Biotechnol 84–86:81–96

Mosier N, Wyman C, Dale B, Elander R, Lee YY, Holtzapple M, Landisch M (2005) Features of promising technologies for pretreatment of lignocellulosic biomass. Biores Technol 96(6):673–686

Chen C, Zhao X, Yen H, Ho S, Cheng C, Lee D, Bai F, Chang J (2013) Microalgae-based carbohydrates for biofuel production. Biochem Eng J 78:1–10

Vitova M, Bisova K, Kawano S, Zachleder V (2015) Accumulation of energy reserves in algae: from cell cycles to biotechnological applications. Biotechnol Adv 33:1204–1218

Choi SP, Nguyen MT, Sim SJ (2010) Enzymatic pre-treatment of Chlamydomonas reinhardtii biomass for ethanol production. Biores Technol 101:5330–5336

Miranda JR, Passarinho PC, Gouveia L (2012) Pre-treatment optimization of Scenedesmus obliquus microalga for bioethanol production. Biores Technol 104:343–348

Ashokumar U, Salom Z, Tiwari ON, Chinnasamy S, Mohamed S, Ani FN (2015) An integrated approach for biodiesel and bioethanol production from Scenedesmus bijugatus cultivated in a vertical tubular photobioreactor. Energy Convers Manage 101:778–786

Yang J, Xu M, Zhang X, Hu Q, Sommerfeld M, Chen Y (2011) Life-cycle analysis on biodiesel production from microalgae: water footprint and nutrients balance. Biores Technol 102:159–165

Biller P, Ross AB, Skill SC, Lea-Langton A, Balasundaram B, Hall C, Riley R, Leewellyn CA (2012) Nutrient recycling of aqueous phase for microalgae cultivation from the hydrothermal liquefaction process. Algal Res 1:70–76

Barbera E, Sforza E, Kumar S, Morosinotto T, Bertucco A (2016) Cultivation of Scenedesmus obliquus in liquid hydrolysate from flash hydrolysis for nutrient recycling. Biores Technol 207:59–66

AOAC—Association of Analytical Chemists (2002) Official methods of analysis of the Association of Official Analytical Chemists, 17th ed., Gaithersburg: Ed. William Horwitz,

Trevelyan WE, Harrison JS (1952) Studies on yeast metabolism. 1. Fractionation and microdetermination of cell carbohydrates. Biochem J 50(3):298–303

Miller JG (1959) Use of dinitrosalicyclic acid reagent for determination of reducing sugars. Anal Chem 31(3):426–428

Silva CEF, Sforza E (2016) Carbohydrate productivity in continuous reactor under nitrogen limitation: effect of light and residence time on nutrient uptake in Chlorella vulgaris. Process Biochem 51:2112–2118

Silva CEF, Sforza E, Bertucco A (2017) Effects of pH and carbon source on Synechococcus PCC 7002 cultivation: biomass and carbohydrate production with different strategies for pH control. Appl Biochem Biotechnol 181:682–698

Deichmann U, Schuster S, Mazat J, Comish-Bowden A (2014) Comemorating the 1913 Michaelis-Menten paper Die Kinetik der Invertinwikiring: three perspectives. FEBS J 281:435–463

Markovsky I, Huffel SV (2007) Overview of total least squares methods. Signal Process 87:2283–2302

Jang Y, Park JM, Choi S, Choi YJ, Seung DY, Cho JH, Lee SY (2012) Engineering of microorganisms for the production of biofuels and perspectives based on systems metabolic engineering approaches. Biotechnol Adv 30:989–1000

Kuhad RC, Gupta R, Khasa YP, Singh A, Zhang YHP (2011) Bioethanol production from pentose sugars: current status and future prospects. Renew Sustain Energy Rev 15(9):4950–4962

Lee OK, Oh Y, Lee EY (2015) Bioethanol production from carbohydrate-enriched residual biomass obtained after lipid extraction of Chlorella sp. KR-1. Biores Technol 196:22–27

Hernandez D, Riano B, Coca M, Garcia-Gonzalez MC (2015) Saccharification of carbohydrates in microalgal biomass by physical, chemical and enzymatic pre-treatments as a previous step for bioethanol production. Chem Eng J 262:939–945

Wang Y, Guo W, Cheng C, Ho S, Chang J, Ren N (2016) Enhancing bio-butanol production from biomass of Chlorella vulgaris JSC-6 with sequential alkali pretreatment and acid hydrolysis. Biores Technol 200:557–564

Nguyen MT, Choi SP, Lee J, Lee JH, Sim SJ (2009) Hydrothermal acid pretreatment of Chlamydomonas reinhardtii for ethanol production. J Microbiol Biotechnol 19(2):161–166

Zhou N, Zhang Y, Wu X, Gong X, Wang Q (2011) Hydrolysis of Chlorella biomass for fermentable sugars in the presence of HCl and MgCl2. Biores Technol 102:10158–10161

Lee OK, Kim AL, Seong DH, Lee CG, Jung YT, Lee JW, Lee EY (2013) Chemeo-enzymatic saccharification and bioethanol fermentation of lipid-extracted residual biomass of the microalga, Dunaliella tertiolecta. Biores Technol 132:197–201

Markou G, Angelidaki I, Nerantzis E, Georgakakis D (2013) Bioethanol production by carbohydrate-enriched biomass of Antrospira (Spirulina) platensis. Energies 6:3937–3950

Laurens LML, Nagle N, Davis R, Sweeney N, Van Wychen S, Lowell A, Prenkos PT (2015) Acid-catalyzed algal biomass pretreatment for integrated lipid and carbohydrate-based biofuels production. Green Chem 17:1145–1158

Kumar S, Gupta RB (2008) Hydrolysis of microcrystalline cellulose in subcritical and supercritical water in a continuous flow reactor. Ind Eng Chem Res 47(23):9321–9329

Barreiro DL, Bauer M, Mornung U, Posten C, Kruse A, Prens W (2015) Cultivation of microalgae with recovered nutrientes after hydrothermal liquefaction. Algal Res 9:99–106

Garcia-Moscovo JL, Obeid W, Kumar S, Hatcher PG (2013) Flash hydrolysis of microalgae (Scenedesmus sp.) for protein extraction and production of biofuels intermediates. J Supercrit Fluids 82:183–190

Moraes BS, Zaiat M, Bonomi A (2015) Anaerobic digestion of vinasse from sugarcane ethanol production in Brazil: challenges and perspectives. Renew Sustain Energy Rev 44:888–903

Silva CEF, Abud AKS (2016) Anaerobic biodigestion of sugarcane vinasse under mesophilic conditions using manure as inoculum. Rev Ambient Agua 11(4):763–777

Marques SSI, Nascimento IA, Almeida PF, Chinalia FA (2013) Growth of Chlorella vulgaris on sugarcane vinasse: the effect of anaerobic digestion pretreatment. Appl Biochem Biotechnol 171:1933–1943

Yao C, Wu P, Pan Y, Lu H, Chi L, Meng Y, Cao X, Xue S, Yang X (2016) Evaluation of the integrated hydrothermal carbonization-algal cultivation process for enhanced nitrogen utilization in Arthrospira platensis production. Biores Technol 216:381–390

Acknowledgements

The authors thank CNPq—Brazil (National Research Council of Brazil)—Process number 249182/2013-0, for resources and fellowship. C.E.F. Silva designed and performed the experiments, summarized and discussed the results, wrote the article and approved the final version. A. Bertucco analyzed the results, wrote the article and approved the final version.

Author information

Authors and Affiliations

Corresponding author

Additional information

The original version of this article was revised. The figures caption of Fig. 4, Fig. 5 and Fig. 6 was published incorrectly. The right figure captions is updated in the article.

An erratum to this article is available at https://doi.org/10.1007/s11144-017-1279-7.

Rights and permissions

About this article

Cite this article

de Farias Silva, C.E., Bertucco, A. Dilute acid hydrolysis of microalgal biomass for bioethanol production: an accurate kinetic model of biomass solubilization, sugars hydrolysis and nitrogen/ash balance. Reac Kinet Mech Cat 122, 1095–1114 (2017). https://doi.org/10.1007/s11144-017-1271-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-017-1271-2