Abstract

This work studies the effect of the evacuation mode of the solvent to optimize the catalytic performances of sulfated zirconia doped with nickel prepared by the sol gel method in one step. Aerogel and xerogel catalysts exhibit different textural, structural and catalytic properties at various calcination temperatures. Aerogels, obtained by drying under supercritical conditions of solvent, exhibit a developed specific surface area and stabilize zirconia tetragonal phase before heating and even at high calcination temperature. However, xerogels obtained by ordinary drying in an oven are amorphous and has a low surface area and weak porosity. XPS spectroscopy shows that the nickel in aerogels is more reducible than those in xerogels. Aerogels exhibit higher activity than the xerogels, in the n-hexane isomerization reaction.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Sulfated zirconia (SZ) and other sulfated metal oxides are of interest because of their extremely high acidity and excellent activity for the skeletal isomerization of short alkanes at low temperatures [1, 2]. However, SZ deactivates rapidly during n-alkane isomerization due to several factors such as carbon formation, loss of acidity, removal of sulfur entities or a combination of these, restricting its industrial usage [3, 4]. To improve the lifetime of sulfated zirconia in catalysis, various promoters were introduced. In fact, several authors report that promotion of sulfated zirconia with transition and noble metals improves the catalytic activity, selectivity and stability of this solid [5–8]. The high activity of these promoted metal catalysts is attributed to the dehydrogenation reactivity of the promoters and its ability of producing olefinic intermediates.

It is well known that the catalytic properties of sulfated zirconia depend on a number of factors such as synthesis method [9–12], zirconia crystal phase [13], sulfur species [14, 15], calcination temperature [16], and textural properties [17]. The sol–gel process seems to be an attractive route for the preparation of these oxides using one step. In fact, compared to the conventional methods, the sol–gel method provides the ability to control the structure and composition of the final solid mix at a molecular level [18].

One of the important steps in the sol–gel method is solvent elimination after gelation. This step seems to affect textural, structural, sulfur stability and catalytic properties of catalysts. In the same context, we are interested to prepare catalyst based to sulfated zirconia doped with nickel by the sol–gel route to be used in the n-hexane isomerization because of the hydrogenate-deshydrogenate properties of nickel [19] and the good reactivity in some reactions such as n-alkane isomerization [20]. Also, promoting of SZ by Ni improves the catalytic stability in n-alkane isomerization compared to SZ, which is probably due to preventing the accumulation of carbonaceous deposits on the catalyst [20]. In order to improve the reactivity and the stability of this material the effect of two solvent evacuation methods (ordinary drying and drying under hypercritical condition of the solvent) of the gel is investigated. To our knowledge, this work is the first attempt for preparing nickel sulfated zirconia catalyst using the hypercritical solvent evacuation conditions.

Experimental

Sulfated zirconia doped with nickel was prepared as follow: zirconium (IV) propoxide (ALDRICH, 70 % in propanol) was dissolved in 1-propanol (ACROS 99 %) followed by sulfate group addition from concentrated sulfuric acid (ACROS 96 %) with a molar ratio nS/nZr = 0.5. Nickel acetylacetonate was then added with a molar ratio nNi/nZr = 0.1. Finally, water was slowly added to obtain a gel with a hydrolysis ratio nH2O/nZr = 3. The gel was then divided into two parts to be dried. Xerogel was obtained by overnight drying at 393 K in an oven, whereas aerogel was obtained under supercritical conditions of the solvent in an autoclave (T = 536.6 K, p = 51 bar). The resulting solids were calcined under a flow of oxygen at different temperatures in the range 773–923 K with a heating rate of 3 K/min for 3 h. The catalysts are named as XZSN-T for xerogel and AZSN-T for aerogel, where T is the calcination temperature. All reports listed (nS/nZr, nNi/nZr, nH2O/nZr) are optimized.

Textural characterization was performed by a Micromeritics apparatus type ASAP 2000, derived by a computer type AST. Samples were first degassed for 4 h under vacuum at 473 K. Specific surface areas and pore size distributions were determined by BET and BJH methods respectively.

XRD patterns were obtained on an automatic Philips Panalytical diffractometer using CuKα radiation (λ = 1.5412 Ǻ) and nickel monochromator. The reticular distances calculated are compared to those given by the Joint Committee on Powder Diffraction Standards. The lattice parameters were refined by the Rietveld method with General Structure Analysis Software (FullProof). The crystallite size of ZrO2 tetragonal phase was determined from the characteristic peak (2θ = 30) by using the Scherrer equation D = Kλ/β cos θ, where K = 0.9, D represents the crystallite size, λ = 1.5412 Ǻ the wavelength of Cu Kα radiation and β the corrected half width of the diffraction peak.

FTIR spectra of the samples diluted in KBr were recorded with a Perkin Elmer Pragon 1000PC spectrometer over a range of 4,000–400 cm−1 in the transmission mode.

UV–Vis spectra were recorded on a Perkin Elmer spectrophotometer type Instrument lambda 45 coupled to an integration sphere type RSA-PE-20 in the range 200–800 nm with a speed of 960 nm min−1 and an aperture of 4 nm.

The XPS analyses were performed using a Kratos Analytical AXIS UltraDLD spectrometer. A monochromatized aluminum source (Al Kα = 1486.6 eV) was used for excitation. The X-ray beam diameter is around 1 mm. The analyzer was operated in a constant pass energy of 40 eV using an analysis area of approximately 700 μm × 300 μm. Charge compensation was applied to compensate for the charging effect occurring during the analysis. The C 1s (285.0 eV) binding energy (BE) was used as internal reference. The spectrometer BE scale was initially calibrated against the Ag 3d5/2 (368.2 eV) level. The pressure was in the 10−10 Torr range during the experiments. Simulation of the experimental photopeaks was carried out using Casa XPS software. Quantification took into account a non-linear Shirley background subtraction.

The n-hexane isomerization reaction was performed in a U-shaped tubular reactor operating at atmospheric pressure between 423 and 493 K. A sample of 100 mg catalyst was exposed to a stream of n-hexane (20 Torr) diluted in H2 at a flow rate of 30 mL min−1. The catalyst was pretreated in a fixed bed reactor, first under He flow at 673 K for 2 h and then under H2 for 1 h at 493 K. Hydrogen saturated with n-hexane at 273 K was passed over the catalyst during 5 min and results were collected after this contact time. Reaction products were analyzed by online gas chromatography using a flame ionization detector.

Results and discussion

XRD patterns of the dried aerogel and xerogel before and after calcination at different temperatures are given in Fig. 1.

The aerogel obtained just after solvent evacuation before calcination stabilized the ZrO2 tetragonal phase characterized by the diffraction peaks at 30°, 50° and 60° (JCPDS 17-0923), whereas the xerogel dried at 393 K is amorphous. These results imply that the method of solvent evacuation plays an important role in the stability of tetragonal zirconia phase.

After calcination at 773 K, the aerogel exhibits simultaneous peaks typical of the tetragonal phase and the monoclinic one (peaks at 24°, 28° and 31°). This result is in accordance with others done by Pérez et al. [20] interested in the preparation of the same solids but by impregnation of Zr(OH)4. This result is also confirmed by Rietveld refinement (Fig. 2) showing that all diffraction lines are well indexed on the basis of tetragonal and monoclinic phase. However, the xerogel is still amorphous. After calcination at 923 K, aerogels still exhibit the two zirconia phases whereas xerogels develop pure tetragonal zirconia phase when calcined at 923 K. The stabilization of this phase is always related to the effect of addition of sulfate groups to zirconia [21, 22]. According to the literature, the increase of the calcination temperature of unpromoted sulfated zirconia normally leads to a transition of tetragonal ZrO2 to the monoclinic phase by the loss of sulfur [23]. However, in the present case, this transition is practically absent even at the highest temperature. This result implies that the presence of nickel stabilizes the metastable tetragonal phase of ZrO2 and prevents the transition tetragonal-monoclinic ZrO2 phase at a higher temperature in spite of the sulfate group loss by heating. This result is confirmed by Stefanic et al. [24]. In fact, in our previous work [25] we have shown that the tetragonal phase is well developed in the nickel promoted zirconia sample without sulfate groups. Furthermore, according to R.C. Garvie, the nickel delays the sintering process of small crystals, which leads to the transition of the tetragonal phase to the monoclinic one [26].

Moreover, no crystalline phase relative to any nickel oxide was detected, which is probably due to the low content of nickel.

Furthermore, the crystallite size determined from X-ray diffraction data (Table 1) showed that all crystalline nickel sulfated zirconia catalysts were of nano-crystalline nature with crystallite size in the range of 16–18 nm.

Textural characterization was evaluated by means of nitrogen adsorption–desorption isotherms at 77 K.

Nitrogen adsorption–desorption isotherms for aerogels calcined at different temperatures are of type IV, characteristic of mesoporous materials according to IUPAC classification [27] with H1 hysteresis loops (Fig. 3). This result implies that those solids are mesoporous with tubular and cylindrical pores. Whereas the isotherms of xerogel catalysts appear as a superposition of type II and type IV isotherms characteristic, respectively, of macroporous and mesoporous materials (Fig. 3) with H3 hysteresis loops, which correspond to broad pores resulting from texture in layers [27].

Specific surface areas of aerogel and xerogel promoted ZrO2–SO4 2− are reported in Table 2.

Furthermore, as it appears in Table 2, the introduction of metal to sulfated zirconia exerts an important effect on the specific surface area. It can be seen that pure unpromoted aerogel AZS calcined at 773 K shows the highest area (120 m2/g) in comparison with promoted aerogel sulfated zirconia AZSN(101 m2/g). In fact, according to Tzompantzi et al. [28], the insertion of Ni in the zirconia network causes important modifications in the textural properties. Catalyst drying under supercritical conditions confer on solids developed texture. As a counterpart, xerogels exhibit low surface area and weak porosity. This difference between aerogel and xerogel may be due to the difference between their solvent evacuation mode. Indeed, when the solvent is removed by simple evaporation in an oven, the liquid–vapor interface within the gel is formed due to surface tension, which acts on the pores and causes their shrinkage. However, under supercritical conditions, the liquid–vapor interface disappears and therefore no capillary pressure develops during drying.

After heating these catalysts at high temperatures, the surface area of aerogels decreases at 873 K and remains practically constant at 923 K. This result suggests that the aerogel lost a part of sulfur during calcination [29]. According to previous work done in our laboratory by I. Mejri [22] dealing with sulfated zirconia, the loss of the sulfur is the most cause of this phenomena. This idea could be also justified by a previous work of C. Morterra [29]. The presence of sulfur could also preserve the surface area after calcination which could explain the same surface areas obtained at 873 and 923 K [30]. Indeed, S. R. Vaudagna [31] also confirmed that the presence of sulfate in Pt/SO4 2−−ZrO2 maintains the specific surface area after heating. However, xerogels exhibit surface areas that increase at higher calcination temperature. This result is probably due to the creation of new pores after a pronounced departure of residual organic groups at higher calcination temperature.

A comparison between our results and others already described in the literature shows the beneficial effect of the simultaneous use of the sol–gel method and hypercritical solvent evacuation conditions. For example, Pérez et al. [20] have prepared the same catalyst but by the classical two-step method: first, precipitation of (ZrOH)4 support, then sulfation. However, these materials exhibit low surface areas (66–4 m2/g).

Furthermore, it appears in Table 2 that the average pore diameter and the surface area of used aerogel and xerogel catalyst calcined at 773 K decreases after reaction. This result is due to the coke deposition at the surface of the catalytic during reaction. This result is confirmed latter on by IR spectroscopy (Fig. 5).

FTIR spectra of the aerogel and xerogel calcined at different temperature are given in Fig. 4.

Aerogel catalysts exhibit a wide peak centered at 3,355 cm−1 attributed to the vibration of hydroxyl group [32, 33] and a fine peak located at 1,615 cm−1 characteristic of non-dissociated water molecules (δHOH) [33]. Indeed, we note a multiplicity of bands in the region 1,000–1,400 cm−1, characteristic of sulfate groups with peaks at 1,244, 1,118 and 1,086 cm−1, characteristic of inorganic chelating bidentate sulfate, which are assigned to asymmetric and symmetric stretching frequencies of S–O and  bonds [34]. The partially ionic nature of the

bonds [34]. The partially ionic nature of the  bond is responsible for the Brønsted acid sites in sulfated zirconia samples [35].

bond is responsible for the Brønsted acid sites in sulfated zirconia samples [35].

In addition, we noted bands at 1,380 cm−1 attributed to the vibration of νS=O or the asymmetric stretching mode of O=S=O [36] and at 1,445 cm−1, characteristic of a covalently bonded S=O group, which displays Lewis acid sites in sulfated zirconia samples [34]. Moreover, we note the presence of peaks at 437, 585 and 982 cm−1, characteristic of ZrO2 [37].

Calcination at high temperature (923 K) does not seem to affect the environment of sulfate groups. This result is in agreement with those obtained by X-ray diffraction, which shows that no tetragonal-monoclinic phase transition has occurred in the investigated calcination temperature range, which indicates the persistence of sulfate groups. Furthermore, the transition of the tetragonal phase to the monoclinic one is known to be related to the loss of sulfur by catalysts [22]. However, for xerogel catalysts, many IR bands of sulfate groups disappear. Therefore, the disappearance of some bands (1,380, 1,244 and 1,118 cm−1) for the xerogel shows the effect of solvent evacuation method on the sulfur stability of the catalyst. In fact, this result suggests that sulfate species are more stable in aerogel catalysts.

Furthermore, the bands at 2,846 and 2,943 cm−1 correspond to organic residue [33], which decreases in intensity at high calcination temperature. This result is probably the cause of creation of new pores.

FTIR spectra, displayed in Fig. 5, of used aerogel and xerogel catalysts show an increase intensity bands of organic residue located at 2,846 and 2,943 cm−1 confirming the deposit of coke on the surface of the catalyst during the reaction.

UV–Vis spectra, represented in Fig. 6, of aerogel catalysts show the presence of a band at 210 nm attributed to the charge transfer O2− → Zr4+ with a high coordination number of tetragonal zirconia (probably 8) [38] and a band around 325 nm attributed to the charge transfer O2− → Ni2+ [39] and/or to the charge transfer in ZrO2 in a weak state of coordination [38]. We note also a band at 386 nm which can be attributed to the d–d transition of octahedral Ni2+ [41, 42]. Moreover, we note the appearance of a new band at 420 nm at higher calcination temperature (923 K), characteristic of the d–d transition of octahedral Ni2+ [43] and disappearance of the band at 386 nm. However, we note that the shift of the band due to the charge transfer O2− → Ni2+ (from 325 to 345 nm) for the xerogel calcined at 773 K (Table 3). A band at 386 nm attributed to the d–d transition of Ni2+octahedral is also shifted to 392 nm. We note the presence of a broad band around 600 nm, at higher calcination temperature, which is characteristic of the d–d transition of Ni2+ tetrahedral [41, 42]. In fact, compared to the aerogels, the shift of some bands and the disappearance or appearance of others, in the xerogels, is probably due to the alteration of the environment and symmetry of nickel by the migration of Ni ions from octahedral to tetrahedral coordination.

Therefore, this result suggests the important effect of the evacuation mode of solvent in the symmetry of metal in the catalyst. According to Shibiao et al. [43], octahedral Ni2+ ions are easier to reduce to the metallic state than tetrahedral Ni2+ ions. It seems that drying catalysts under supercritical conditions confers an easier reducibility of nickel.

Quantitative XPS results of aerogel and xerogel catalysts calcined at 773 K are presented in Table 4.

The Zr 3d5/2 photopeak is centered at a BE of 182.9 eV. It can be assigned to Zr(IV) oxidation state in ZrO2 oxide form [16, 44]. The S 2p3/2 photopeak presents a BE value of 169.1 eV, characteristic of sulfate species [44]. For aerogel catalysts, the Ni 2p doublet could be decomposed into two species centered at 853.8 eV characteristic of Ni2+ in NiO oxide form [45, 46] and at 856.6 eV assigned to Ni2+ in NiSO4 sulfate form [47]. Indeed, the shift in the BE to higher value and the well not resolved satellite peaks (named as S peak in Fig. 7) associated with the Ni 2p3/2 and Ni 2p1/2 may be attributed to the formation of nickel sulfate [48]. The O 1s photopeak was asymmetrical and could be decomposed into two species, the major one with BE of 530.5 eV assigned to O2− in ZrO2 or NiO and the second minor one with BE of 532.2 eV [44] due to oxygen belonging to sulfate species (Fig. 7). However, for xerogel catalysts, the component of Ni 2p assigned to nickel sulfate is shifted to higher BE to 857.3 eV (ΔE = + 0.7 eV), suggesting a strong interaction between Ni2+ and SO4 2−. This result implies that Ni in xerogels is less reducible than those in aerogels. Furthermore, the component assigned to oxygen related to sulfates becomes the major species to the detriment of the species related to O2− in ZrO2 or NiO.

Furthermore, the difference in reducibility of nickel in the two kinds of catalysts is probably due to its reduction easier in nickel oxide than in nickel sulfate. It should be noted that xerogels are rich in NiSO4, whereas nickel in aerogels is present in high quantity as an oxide NiO. This result is in agreement with those obtained by UV–Vis indicating that Ni in xerogels is less reducible than those in aerogels.

Moreover, as it appears in Table 4, the amount of carbon present at the surface of aerogel catalyst increases after the isomerization reaction. This result confirms the formation of coke on the surface of the catalyst during the n-hexane reaction.

The catalytic stability of the promoted nickel sulfated zirconia and the unpromoted one was evaluated at 443 K for 175 min. Undoped sulfated zirconia is active during 30 min (Fig. 8). However, its activity decreases and becomes very weak. On the other hand, the catalytic activity of sulfated zirconia doped with nickel is characterized, after a transition period of 50 min, by stabilization in time. This stability can be maintained approximately for 90 min of time on stream.

The catalytic properties of promoted nickel sulfated zirconia and the unpromoted one are tested in the n-hexane isomerization between 443 and 493 K. The corresponding results (Figs. 9, 10) show that the introduction of nickel in the bulk of sulfated zirconia improves the catalytic properties of the catalysts in all the reaction temperature range studied in particular at 443 K, which seems to be the optimal reaction temperature. This result is in good agreement with the literature data which indicates that metal, due to its hydrogenate-dehydrogenate properties [49], improves the catalytic performances of sulfated zirconia. Indeed, several works showed that the addition of transition metals and their oxides such as manganese, or iron to sulfated zirconia increases its catalytic activity and selectivity with a better stability [50]. Pérez et al. showed that the incorporation of 1 wt% of nickel strongly enhances the activity of sulfated zirconia. According to these authors, the dehydrogenating properties of NiO are not the main factor responsible for the different catalytic behavior between the unpromoted and Ni-promoted sulfated zirconia. The increase of the Lewis acid site density ZrO–SO4 2− in the presence of Ni suggests that Ni could increase the strength of the acid–base pair of sulfate zirconia, hence increasing its dehydrogenating properties.

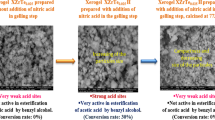

The catalytic properties of aerogels and xerogels calcined at different temperatures are tested in the n-hexane isomerization between 443 and 493 K. The corresponding results (Table 5) show that the evacuation mode of the solvent has an impact on the catalytic properties of the catalyst. These catalysts produce several isomers (Table 6) the 2,2-dimethylbutane (22DMB), the 2-methylpentane (2MP) and the 3-methylpentane (3MP) in the investigated reaction temperature range. The aerogel calcined at 773 K is active in the whole reaction temperature range. This result can be related to the development of the tetragonal ZrO2 phase at high calcination temperature and thus to the stabilization of sulfate groups on an adequate environment. However, the xerogel calcined at the same temperature is inactive. The inactivity of the xerogel could be explained by its amorphous state. Although monoclinic [51], cubic [52] and amorphous sulfated zirconia [53] are able to catalyze isomerization, the tetragonal phase is usually considered the active phase and it necessary to obtain activity of sulfated zirconia in n-alkane isomerization [54]. After heating at high calcination temperature, the catalytic activity of aerogels decreases. This activity decrease can be explained by the blockage of some pores by organic groups traduced by the decrease of the surface area at high temperature.

The xerogels calcined at 873 and 923 K are inactive in all studied reaction temperature range. This result is probably due to the by the loss of sulfate groups acting as active site for n-alkane isomerization [36]. This could be confirmed from FTIR spectra, it does not show any band at 1,380 cm−1 associated to the active sulfate group. In addition, this inactivity is to be also related to the low surface area and the weak porosity in the xerogel and therefore the access of reactant molecules to active sites becomes difficult.

The inactivity of the xerogel XZSN-923 in spite of its crystalline state can be explain by a fast deactivation by coking at the surface of the catalytic during reaction. Furthermore, the easier reducibility of nickel in the aerogel than in xerogel, confirmed by XPS technique and UV–Vis spectroscopy, can explain the difference behavior of the two catalysts (aerogel and xerogel) in terms of their catalytic performances in the isomerization of n-hexane. The aerogels are more active than the xerogels, in the n-hexane isomerization reaction due to the capability of nickel metallic particles formation at low reduction temperatures in the aerogel catalyst. Moreover, it is possible that metal takes part in the n-hexane isomerization reaction by an active site probably ‘‘metal oxy’’ to prevent deposit coke (responsible for a rapid deactivation of the catalysts) and probably the decomposition of active sulfate species. A comparable result is reported by Song et al. [24].

Moreover, the way of preparation of the catalysts and principally the drying under high pressure appears also as an influent factor for the amelioration of the catalytic properties of catalysts. In our laboratory, Raissi et al. [7] have tried Cr–ZrO2–SO4 2− catalysts, prepared by the same preparation conditions. These materials are less active than nickel promoted sulfated zirconia aerogels, in the n-hexane isomerization.

Conclusion

Promotion of sulfated zirconia with nickel improved the catalytic properties and stability of sulfated zirconia in n-hexane isomerization. Moreover, the presence of nickel in sulfated zirconia allows the stabilization of the ZrO2 tetragonal phase and a better retention of sulfate groups at high calcination temperature.

The comparative study of the textural and structural properties of xerogel and aerogel catalysts show that the method of solvent evacuation plays an important role in the stability of sulfur at different calcination temperatures and in the reducibility of nickel. We would like to emphasize that synthesis by sol gel in one step and drying in the hypercritical conditions of solvent confers to the catalysts a developed texture and stabilizes the tetragonal ZrO2 phase at different calcination temperatures. However, the drying of the gels in ordinary conditions destroys its texture and retard the crystallization of the ZrO2 tetragonal phase.

The difference of characteristics of the two kinds of catalysts has an impact on their catalytic properties in the n-hexane isomerization reaction. Furthermore, aerogels exhibit higher activity due to its more developed surface, its easier reducibility of nickel and stability of tetragonal ZrO2 phase which is believed to be an ideal crystalline catalytic active phase.

References

Hong Z, Fogash KB, Dumesic JA (1999) Catal Today 51:269

Adeeva V, Dehaan JW, Janchen J, Lei GD, Schunemann V, Vandeven LJM, Sachtler WMH, Vansanten RA (1995) J Catal 151:364

Subramaniam B, Arunajatesan V, Lyon CJ (1999) Catal Deactiv 126:63

Yang Y, Weng H (2009) J Mol Catal 304:65

Urzhuntsev GA, Ovchinnikova EV, Chumachenko VA, Yashnik SA, Zaikovsky VI, Echevsky GV (2013) Chem Eng J. doi: 10.1016/j.cej.2013.08.092

Belskaya OB, Danilova IG, Kazakov MO, Gulyaeva TI, Kibis LS, Boronin AI, Lavrenov AV, Likholobov VA (2010) Appl Catal A 387:5–12

Raissi S, Younes MK, Ghorbel A, Garin F (2009) J Sol–Gel Sci Technol. doi: 10.1007/s10971-009-2113-0

Blekkan EA, Johnsen KA, Løften T (2005) React Kinet Catal Lett 86(1):149–155

Schmidt F (2001) Appl Catal A 221:15

Ward DA, Ko EIF (1995) J Catal 157:321

Armendariz H, Coq B, Tichit D, Dutartre R, Figueras F (1998) J Catal 173:345

Bianchi CL, Ardizzone S, Cappelletti G (2004) Surf Interface Anal 36:745

Vera CR, Pieck CL, Shimizu K, Parera JM (2002) Appl Catal A 230:137

Platero EE, Mentruit MP, Arean CO, Zecchina A (1996) J Catal 162:268

Barthos R, Lonyi F, Engelhardt J, Valyon J (2000) Top Catal 10:79

Resofski G, Muhler M, Sprenger S, Wild U, Paal Z (2003) Appl Catal A 240:71

Akkari R, Ghorbel A (2002) Stud Surf Sci Catal 143:1045

Ward DA, Ko EI (1995) Ind Eng Chem Res 34:421

Martin GA, Imelik B (1974) Surf Sci 42:157

Pérez M, Armendariz H, Toledo JA, Vazquez A, Navarrete J, Montoya A, Garcia A (1999) J Mol Catal A 149:169

Davis BH, Keogh RA, Srinivasan R (1994) Catal Today 20:219

Mejri I, Younes MK, Ghorbel A (2006) J Sol–Gel Sci Technol 40(1):3

Srinivasan R, Taulbee D, Davis BH (1991) Catal Lett 9:1

Stefanic G, Didovic M, Music S (2007) J Mol Struct 435:834

Kamoun N, Younes MK, Ghorbel A, Mamede AS, Rives A (2012) J Porous Mater 19:375

Garvie RC (1985) J Phys Chem 82:218

IUPAC Recommendations (1994) Pure Appl Chem 66:1739

Tzompantzi FJ, Manriquez ME, Padilla JM, Del Angel G, Gomez R, Mantilla A (2008) Catal Today 133–135:154

Morterra C, Cerrato G, Signoretto M (1996) Catal Lett 36:129

Yamagushi T, Tanabe K, Kung YC (1986) Mater Chem Phys 16:67

Vaudagna SR, Comelli RA, Fígoli NS (1996) React Kinet Catal Lett 58(1):111–117

Signoretto M, Pinna F, Strukul G, Chies P (1997) J Catal 167:522

Babou F, Coudurier G, Vedrine JC (1995) J Catal 152:341

Yamaguchi T, Jin T, Tanabe K (1986) J Phys Chem 90:3148

Mishra MK, Tyagi B, Jasra RV (2003) Ind Eng Chem Res 42(23):5727

Bensitel M, Sauer O, Lavelly JC, Morrow BA (1988) Mater Chem Phys 19:147

Chackalackal S, Staffort FE (1966) J Am Chem Soc 88:723

Castellon ER, Lopez AJ, Torres PM (2003) J Solid State Chem 175:159

Barbara SK, Friederike CJ, Robert S (2005) J Catal 68:233

Scheffer B, Heijeinga JJ, Moulijn JA (1987) J Phys Chem 91:4752

Lee KM, Lee WY (2002) Catal Lett 83:6

Kim SY, Goodwin JG, Hammache S, Auroux A, Galloway D (2001) J Catal 201:1

Shibiao R, Jinheng Q, Chunyan W, Bolian X, Yining F, YiChin C (2007) J Catal 28(7):651

Morant C, Sanz JM, Galán L, Soriano L, Rueda F (1989) Surf Sci 218:331

Kim P, Kim Y, Kim H, Song IK, Yi J (2004) J Mol Catal A 219:87

Heracleous E, Lee AF, Wilson K, Lemonidou AA (2005) J Catal 231:159

Wagner CD, Moulder JF, Davis LE, Riggs WM, Muilenburg GE Perking-Elmer corporation, Physical Electronics Division

Siriwardane RV, Poston JA Jr, Fisher EP, Shen MS, Miltz AL (1999) Appl Surf Sci 152:219

Gaspar AB, Dieguez LC (2003) J Catal 220:309. doi:10.1016/S0021-9517(03)00297-5

Hsu CY, Heimbush CR, Armes CT, Gates BC (1992) J Chem Soc Chem Commun 1645

Stichert W, Schüth F (1998) J Catal 174:242

Belido AF, Ivanova AS, Pakhomov NA, Volodin AM (2000) J Mol Catal A 158:409

Jentoft XGFC, Jentoft RE, Girgsdies F, Ressler T (2002) Catal Letter 81:25

Ishida T, Yamaguchi T, Tanabe K (1988) Chem Lett 1869

Song SX, Kydd RA (1998) Catal Lett 51:95

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kamoun, N., Younes, M.K., Ghorbel, A. et al. Effect the solvent evacuation mode on the catalytic properties of nickel-modified sulfated zirconia catalysts: n-hexane isomerization. Reac Kinet Mech Cat 111, 199–213 (2014). https://doi.org/10.1007/s11144-013-0638-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-013-0638-2