Abstract

Deep removal of dibenzothiophene from model diesel under mild conditions (323 K) by oxidation with H2O2 was studied, using Na2WO4·2H2O in a halogen-free ionic liquid. The removal of DBT could reach 99.4% and the sulfur content would be reduced from initial 500 to 3 μg/g, which can meet the standards of ultra-deep desulfurization. The model diesel after oxidation could be easily separated by simple decantation, demonstrated an effective and simple separation method. This catalytic system can be recycled five times without significant change on desulfurization results. The mechanism of the catalytic oxidation process was also proposed, a new ionic liquid-peroxytungstate complex was generated as the active species for supplying the active oxygen for desulfurization reaction.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Deep desulfurization of transport fuels has become an environmentally urgent subject worldwide because sulfur compounds existing in fuel will lead to air pollution and acid rain [1]. Nowadays, conventional hydrodesulfurization (HDS) has been demonstrated effective; however, the most refractory sulfur-containing molecules abundant in diesel, such as dibenzothiophene (DBT) and their alkyl derivatives, are extremely difficult to remove. To achieve deep-desulfurization levels from 500 to 15 or 1 μg/g, the existing HDS technology brings about a lot of problems including severe operating conditions, shorter lifetime of catalyst and higher hydrogen consumption, which finally leads to high operating cost. In addition, fuels obtained by deep HDS will suffer from a loss in some properties such as octane numbers and lubricity, etc.

As a novel alternative deep desulfurization process, oxidative desulfurization (ODS) without hydrogen consumption under mild condition has been aroused great interest in many research groups [2]. Usually, ODS process involves the following two steps: first, the refractory sulfur-containing molecules in fuel are oxidized to their corresponding sulfoxide and sulfones; second, the sulfones obtained are removed by extraction. Now various catalytic oxidation systems for deep desulfurization have been investigated, such as H2O2–carboxylic acid [3, 4], H2O2–heteropolyacid [5], H2O2–Ti-containing molecular sieve [6], H2O2–polytungstates [7], superoxides [8] and so on. However, the extractants are usually volatile organic compounds (VOCs), which are flammable, leading to further environmental and safety concerns.

RTILs have been wildly used as environmentally benign alternative solvents for separations, chemical synthesis, electrochemistry and catalysis. Generally, they are nonvolatile, non-explosive, recyclable, easy to handle and thermally robust. The work on deep desulfurization by ionic liquids was well summarized in the review by Kulkarni and Afonso [9]. The extractions of fuels using RTILs to remove sulfur compounds have been reported widely. The efficiencies of sulfur removal, however, are rather low and usually with the range of 10–30%.

Oxidative desulfurization from fuels in IL was developed to be effective [10–17]. H2O2 was usually chosen as oxidant because the process would not lead to environmental pollution and only water is the by-product. Gao et al. have carried out chemical oxidation and extraction processes for desulfurization in the ionic liquid [HMIm] BF4, the removal of DBT from model diesel can reach 60–93% [10]. Zhao et al. applied coordinated IL (C4H9)4NBr·2C6H11NO in the ODS process for the removal of thiophene with acetic acid as catalyst [11]. Lo et al. reported a one-pot desulfurization of light oils by chemical oxidation and solvent extraction in the catalytic system ([BMIM]+ [PF6]− or [BMIM]+ [BF4]−/H2O2/acetic acid) [12]. Li et al. carried out oxidative desulfurization of model diesel in the catalytic system of ionic liquids, 30% H2O2, combined with the catalysts decatungstates [13], phosphotungstic acid [14], V2O5 [15], peroxophosphomolybdate [16], and peroxotungsten and peroxomolybdenum complexes [17]. All the above ionic liquids used contain halogen atoms, and especially BF4 − or PF6 − easily yields white fumes of HF or hydrate precipitates, so there is still much room for the development of more environmental friendly oxidative process.

The efficiency of the extraction increases if the S-species are previously oxidized to the corresponding sulfoxides and sulfones as these species have a much higher distribution coefficient compared to the non-oxidized derivatives. Most recently, Seeberger and Jess have reported the extraction of previously oxidized S-compounds from diesel oil by 1-ethyl-3-methylimidazolium diethylphosphate [EMIM][DEP] and the subsequent IL regeneration by water addition, and subsequent multi-stage evaporation could be an interesting option for deep desulfurization [18]. Here, a halogen-free IL is used to extract the pre-oxidized sulfur compounds from oil, while in our studies, the sulfur compounds are completely oxidized in the ionic liquid, and partial extracted by the ionic liquid used.

Our group synthesized several acidic ILs and applied them in Beckmann rearrangement, alkylation, esterification, polymerization reactions and so on [19–27]. Recently, the effect of different cations or anions on extractive desulfurization has been investigated, finally find the IL [(CH2)4SO3Hmim] [Tos] has the best extraction capacity toward S-compounds in diesel. Using this ionic liquid, the sulfur content of real hydrotreated diesel can be reduced from 438 to 45 μg/g after extracting five times [23]. With our continuous research in ILs, in this article, a combination of ODS and extraction in the system of ([(CH2)4SO3Hmim] [Tos])/Na2WO4·2H2O/H2O2) was developed, which has been found to be an efficient method for the oxidative desulfurization of model diesel. The ionic liquid used is halogen-free in order to avoid the potential safety and environmental problem. The DFT method was also used to study the structure of ionic liquid in order to find the effective Brønsted acid site for reaction. Finally a possible catalytic oxidation mechanism of DBTs in ionic liquid media was proposed.

Experimental

Materials and reagents

All solvents and chemicals in the experiments were commercially available and used without further purification unless otherwise stated. N-methylimidazole and 1,4-butane sultone were purchased from Aldrich.

Synthesis of the room temperature ionic liquid and its structure

The structure of the ionic liquid ([(CH2)4SO3Hmim] [Tos]) is shown in Fig. 1. The ionic liquid was synthesized similarly to the procedures reported previously [19]. In this methodology, 1-methylimidazole (15.8 mL, 0.2 mol) and 1,4-butane sultone (22 mL, 0.2 mol) were charged into a 100-mL round-bottom flask. Then, the mixtures were stirred at 313 K for 10 h. The white solid zwitterion was washed repeatedly with ether (80 × 5 mL) to remove non-ionic residues and dried in vacuum. Then, a stoichiometric amount of p-toluenesulfonic acid hydrate was added slowly and the mixture stirred for 8 h at 353 K, and the ionic liquid was finally obtained.

Oxidative desulfurization of model diesel

Model diesel was prepared by dissolving DBT in n-tetradecane, and the sulfur concentration was 500 μg/g. In a typical run, the ionic liquid (2.5 mmol), Na2WO4·2H2O (0.021 g) and H2O2 (30 wt%, 0.7 mL) were added to the 50 mL flask equipped with a magnetic stirring bar and a reflux condenser, then the mixture was vigorously stirred for 15 min at room temperature. Model diesel (sulfur content: 500 μg/g, 3 mL) was then added and refluxed under vigorous stirring at 323 K for 180 min. After the reaction, the ionic liquid phase can be separated from the reaction mixture with a separating funnel. Samples of upper oil phase (model diesel) were taken every twenty minutes, and the sulfur content was analyzed by gas chromatography coupled with an atomic emission detector (GC-AED).

Oxidation of aromatics

Taking toluene as a model aromatic compound, the oxidation reaction is carried out to analyze the effect of aromatics on sulfur removal. In a typical run, the ionic liquid (2.5 mmol/1 g), Na2WO4·2H2O (0.021 g) and H2O2 (30 wt%, 1 mL) were mixed in a 50 mL flask and stirred vigorously at room temperature. After 15 min, 6 mL toluene is dissolved in 50 mL tetradecane first, and added to the flask, reacting for 6 h at different temperatures. The toluene content in the upper phase was analyzed by chromatography.

Recovery/regeneration of catalytic system

The ionic liquid phase was separated using a separating funnel and extracted three times with equal volume of 1,4-butyrolactone to remove the sulfones produced, and dried under vacuum at 373 K for 2 h in order to remove the oxidant and water. Fresh H2O2 and model diesel then were added to the flask for the next run.

Calculation methods

All calculations were performed by applying the generalized gradient-corrected density functional theory using the DMol3 module in Materials Studio package of Accelrys. BLYP exchange correlation function, double-numeric quality basis set with polarization functions (DNP) were both employed and all electrons are included throughout the calculations. A thermal smearing of 0.005 Hartree was used to improve the computational performance. All SCF tolerances were set to fine, i.e., the tolerance of energy, gradient and displacement were converged to 1.0e-5 Ha, 0.002 Ha/Å and 0.005 Å, respectively.

In the cation of this ionic liquid, there are four H atoms ionizable as proton donors. The deprotonation energy for each H atom is calculated using the following Eq. 1:

EDP is the deprotonation energy; Ecation is the total energy of cation with the charge of +1; Ecation-H is the total energy of cation when removing one ionizable H atom. Larger deprotonation energy will leads to weaker acidity of the Brønsted acid site.

Results and discussion

Effect of aromatics

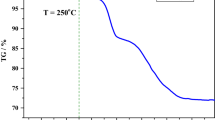

Aromatic compounds are another kind of important components existing in the diesel, so experiments were carried out to investigate whether the aromatics would be involved in this oxidation reaction. Taking toluene as model compound, the conversions of toluene oxidation at different temperatures are shown in Fig. 2. The conversion of toluene becomes larger when increasing the reaction temperature; while the reaction temperature is below 323 K, toluene will not be involved in the oxidation reaction, even if excess H2O2 is added. So a conclusion could be obtained that under lower temperature (T ≤ 323 K), the catalytic system has no catalytic oxidative activity to toluene, so the reaction temperature should be less than 323 K for better selectivity.

Optimization of reaction conditions

Effect of reaction temperature

Given the assumption that the reactions follow pseudo-first order reaction kinetics, the relationship between lnC and reaction time (t) follows Eq. 2.

As clearly evidenced from the plot of Fig. 3, the data obtained at each temperature were approximately on a straight line, indicating that the kinetics of the reaction of dibenzothiophene can be well approximated with a pseudo-first order rate law under the adopted reaction conditions. The slope of the lnC–t plot under each temperature are −k (k is the pseudo-first order rate constant) according to Eq. 2. An increase in the reaction temperature from 298 to 323 K has led to a remarkable increase in the reaction rate constant, indicating higher temperature is favorable for desulfurization. Taking the consideration on the effect of aromatics, higher temperature will finally lead to the oxidation of the aromatics, so the preferred temperature is 323 K.

Fig. 4 shows the Arrhenius plots of toluene and DBT in the considered temperature range, where the rate constants are evaluated by the lnC–time plot of Fig. 3. The calculated activation energy of DBT (15.14 kJ/mol) was much lower than that of toluene (119.6 kJ/mol). This agrees well with their behaviors under different reaction temperature, i.e., toluene cannot be involved in the oxidation reaction until the temperature reach 333 K, however, the oxidation of DBT can start at room temperature.

Effect of ionic liquid amount

The influence of the amount of the ionic liquid on the desulfurization rate is illustrated in Fig. 5. With increasing the amount of ionic liquid, the reaction rate constant increases, which further lead to the increase of reaction rate. This phenomenon may be caused by the fact that the increase of the amount of the ionic liquid may lead to better extraction of DBT from diesel to the ionic liquid phase, and more DBT are involved in the catalytic oxidation reaction, so the extraction capability of the ionic liquid is also important. Good desulfurization rate can be obtained when the ionic liquid amount reaches 2.5, and to keep increasing the ionic liquid amount would not change the sulfur removal rate significantly, so the preferred ionic liquid amount is 2.5 mmol.

Effect of H2O2 amount

The effect of the oxidant amount was studied, and the results are shown in Fig. 6. The desulfurization performance becomes better with increasing the H2O2 amount. After the amount of H2O2 reaches 0.7 mL, only a little improvement in desulfurization efficiency could be obtained if continually increasing the amount of the oxidant.

From all the above experiments, the optimum reaction conditions can be obtained as follows: 2.5 mmol ionic liquid, 0.021 g Na2WO4·2H2O, 3 mL model diesel (500 μg/g S), 0.7 mL H2O2 and 323 K. Under these conditions, the sulfur content can be reduced to 3 μg/g after 180 min, which can meet the requirements of the ultra-deep desulfurization. The removal of dibenzothiophene (DBT) from model diesel under mild condition (323 K) could reach 99.4%.

The produced sulfones and water were existed in the ionic liquid phase and the treated model diesel could be separated by simple decantation, which provided an effective and simple separation method for this ODS process. This catalytic system combines oxidation and extraction procedure into one step, demonstrated to be efficient and effective.

Recycling of catalytic system

The recycling capability of the catalytic system (including ionic liquid and Na2WO4) was also investigated. The catalytic ODS system after simple treatment can be recycled by only adding fresh model diesel and H2O2, and no significant change on catalytic activity could be found after five recycles, and sulfur removal could keep over 99% (see Table 1). During the reaction, all the DBT molecules are oxidized to the corresponding sulfone, and finally only a trace amount of sulfone remained in the model diesel phase. The slight decrease of sulfur removal after five cycles might be ascribed to the mechanical loss during the separation of product. Now the catalytic oxidative desulfurization of commercial diesel is being carried out in our group.

DFT study of the acidity of ionic liquid

Since an acidic environment is essential for an oxidation reaction involving H2O2 as an oxidant [28], and the acidity in this reaction media was derived from the ionic liquid, so the acidity of the reaction media would directly depend upon the acidity of the ionic liquid. In this study, there are four hydrogen atoms in the cation that are ionizable as proton donors. In order to find the possible effective acid sites for the reaction, density functional theory (DFT) method was used to calculate their deprotonation energy. For convenience, the labeling of different H atoms is shown in Fig. 1.

The deprotonation energy calculated for the four different acidic acid sites (H1, H2, H3 and H4) are 269.3, 288.8, 287.2 and 273.4 kcal/mol. Smaller deprotonation energy leads to stronger acidity of the Brønsted acid site, so we can conclude that the acidity of the four active hydrogen atoms decreased as follows: H1 > H4 > H3 > H2. The strength of the acidity depends on their chemical environments, and can be explained by the inductive effect of electron-withdrawing group on acidity. Inductive effects operate through bonds by successive bond polarizations. As such, they diminish rapidly with distance so that very little effect results if an inductive effect must be transferred through more than four bonds. That means the sulfo group (–SO3) is too far to affect their acidities of H1, H2 and H3; and the electron-withdrawing group (3-methyl imidazole-1-yl) will not affect the acidity of H4. The strongest acidity of H1 is caused by the strong inductive effect of the two N atoms in the imidazole ring. The H4 atom is slightly weaker in acidity because of the weaker inductive effect of the electron-withdrawing group, i.e. sulfo group (–SO3). As for H2 and H3, they have similar chemical environments, only one adjacent N atom will affect their acidities strongly, and the effect of the other N atom in the imidazole ring is reduced owing to the distance between them, so the acidities of H2 and H3 are weak and similar. Generally, the more acidic site tends to be easily involved in the reaction, so H1 is the major protonic acid site, and H4 in the –SO3H group, slightly weak in acidity, is also another possible site to be involved in the reaction.

Possible catalytic oxidation mechanism

During the reaction, visible color change could be seen when H2O2 was mixed with the acidic ionic liquids and Na2WO4, indicating some kind of reaction happened among them. Meanwhile, a homogeneous catalytic system could be obtained because no precipitate was found after centrifugation at very high speed. The catalyst (Na2WO4) reacted with H2O2 to form peroxotungstate, which can be easily decomposed even at 25 °C [29], so it is difficult to form homogeneous phase at the absence of ionic liquid. Therefore, we propose that ionic liquid can coordinate to tungsten, and this coordination stabilized the catalytic system. On the basis of the above results and previous reports, the possible concept model of the ODS process may be depicted as shown in Fig. 7. The ionic liquid is immiscible with diesel, and has been demonstrated to be a good extractant for deep desulfurization in our previous study [23], so the sulfur compounds can be partially extracted into the ionic liquid phase. When H2O2 was added, the tungstate accepted the active oxygen from the oxidant H2O2 to form a new peroxytungstate species, which has stronger coordinating capability, so we are inclined to believe that peroxytungstate anion could interact with IL, and form a new kind of peroxytungstate-ionic liquid complex, which makes the resultant catalyst system well mixed and possess the capability of carrying active oxygen species to oxidize the extracted S-compounds to sulfones, then more S-compounds are continually extracted into ionic liquid phase, and the cycle repeated until all the DBT is oxidized completely, finally only trace amounts of sulfones remains in the oil phase.

Conclusions

Catalytic oxidative desulfurization from model diesel by Na2WO4·2H2O in acidic ionic liquids [(CH2)4SO3Hmim] [Tos] was carried out with H2O2 as an oxidant under mild conditions (323 K). The removal of dibenzothiophene (DBT) from model diesel could reach 99.4%, and the sulfur content would be reduced from initial 500 to 3 μg/g, which can meet the standards of ultra-deep desulfurization. The produced sulfones and water existed in the ionic liquid phase and the model diesel could be separated by simple decantation, which provided an effective and simple separation method for this ODS process. The catalyst system separated can be easily recycled without significant change on the catalytic activity after recycling five times.

A density functional study on the Brønsted acidity shows that the H1 site in the imidazole ring has the strongest acidity and is the major active site for the reaction, and the H4 site in the –SO3H group is slightly weaker in acidity, and is also possibly involved in the reaction. A mechanism has been proposed for the catalytic oxidation reaction, in which a new kind of peroxytungstate-ionic liquid complex is generated to make the catalytic system homogenous, and is also supposed to be an active species, carrying the active oxygen necessary for the reaction.

References

Babich IV, Moulijn JA (2003) Science and technology of novel processes for deep desulfurization of oil refinery streams: a review. Fuel 82:607–631

Anisimov AV, Tarakanova AV (2009) Oxidative desulfurization of hydrocarbon raw materials. Russ J Gen Chem 52:32–40

Yazu K, Makino M, Ukegawa K (2004) Oxidative desulfurization of diesel oil with hydrogen peroxide in the presence of acid catalyst in diesel oil/acetic acid biphasic system. Chem Lett 33:1306–1307

Filippis PD, Scarsella M (2003) Oxidative desulfurization: oxidation reactivity of sulfur compounds in different organic matrixes. Energy Fuels 17:1452–1455

Lü HY, Gao JB, Jiang ZX, Jing F, Yang YX, Wang G, Li C (2006) Ultra-deep desulfurization of diesel by selective oxidation with [C18H37N(CH3)3]4[H2NaPW10O36] catalyst assembled in emulsion droplets. J Catal 239:369–375

Kong L, Li G, Wang X, Wu B (2006) Oxidative desulfurization of organic sulfur in gasoline over Ag/TS-1. Energy Fuels 20:896–902

Jiang X, Li HM, Zhu WS, He LN, Shu HM, Lu JD (2009) Deep desulfurization of fuels catalyzed by surfactant-type decatungstates using H2O2 as oxidant. Fuel 88:431–436

Chan NY, Lin TY, Yen TF (2008) Superoxides: alternative oxidants for the oxidative desulfurization process. Energy Fuels 22:3326–3328

Kulkarni PS, Afonso CAM (2010) Deep desulfurization of diesel fuel using ionic liquids: current status and future challenges. Green Chem 12:1139–1149

Lu L, Cheng SF, Gao JB, Gao GH, He MY (2007) Deep oxidative desulfurization of fuels catalyzed by ionic liquid in the presence of H2O2. Energy Fuels 21:383–384

Zhao DS, Sun ZM, Li FT, Ran Liu, Shan HD (2008) Oxidative desulfurization of thiophene catalyzed by (C4H9)4NBr 2C6H11NO coordinated ionic liquid. Energy Fuels 22:3065–3069

Lo WH, Yang HY, Wei GT (2003) One-pot desulfurization of light oils by chemical oxidation and solvent extraction with room temperature ionic liquids. Green Chem 5:639–642

Li HM, Jiang X, Zhu WS, Lu JD, Shu HM, Yan YS (2009) Deep Oxidative desulfurization of fuel oils catalyzed by decatungstates in the ionic liquid of [Bmim]PF6. Ind Eng Chem Res 48:9034–9039

Li HM, He LN, Lu JD, Zhu WS, Jiang X, Wang Y, Yan YS (2009) Deep oxidative desulfurization of fuels catalyzed by phosphotungstic acid in ionic liquids at room temperature. Energy Fuels 23:1354–1357

Xu D, Zhu WS, Li HM, Zhang JT, Zou F, Shi H, Yan YS (2009) Oxidative desulfurization of fuels catalyzed by V2O5 in ionic liquids at room temperature. Energy Fuels 23:5929–5933

He LN, Li HM, Zhu WS, Guo JX, Jiang X, Lu JD, Yan YS (2008) Deep oxidative desulfurization of fuels using peroxophosphomolybdate catalysts in ionic liquids. Ind Eng Chem Res 47:6890–6895

Zhu WS, Li HM, Jiang X, Yan YS, Lu JD, Xia JX (2007) Oxidative desulfurization of fuels catalyzed by peroxotungsten and peroxomolybdenum complexes in ionic liquids. Energy Fuels 21:2514–2516

Seeberger A, Jess A (2010) Desulfurization of diesel oil by selective oxidation and extraction of sulfur compounds by ionic liquids—a contribution to a competitive process design. Green Chem 12:602–608

Gui JZ, Cong XH, Liu D, Zhang XT, Hu ZD, Sun ZL (2004) Novel brosted acidic ionic liquid as efficient and reusable catalyst system for esterification. Catal Commun 5:473–477

Gui JZ, Liu D, Chen XM, Zhang XT, Song LJ, Sun ZL (2007) Cyclotrimerization of an aliphatic aldehyde catalyzed by acidic ionic liquid. React Kinet Catal Lett 90:35–43

Gui JZ, Liu D, Wang C, Lu F, Lian JC, Jiang H, Sun ZL (2009) One-pot synthesis of 3,4-dihydropyrimidin-2(1H)-ones catalyzed by acidic ionic liquids under solvent-free conditions. Synth Commun 39:3436–3643

Liu D, Gui JZ, Wang C, Lu F, Yang Y, Sun Z (2010) Oxidative aromatization of Hantzsch 1,4-dihydropyridines catalyzed by ferric perchlorate in ionic liquids with air. Synth Commun 40:1004–1008

Liu D, Gui JZ, Song LJ, Zhang XT, Sun ZL (2008) Deep desulfurization of diesel fuel by extraction with task-specific ionic liquids. Petrol Sci Technol 26:973–982

Gui JZ, Liu D, Cong XH, Zhang XT, Jiang H, Hu ZD, Sun ZL (2005) Clean synthesis of adipic acid by direct oxidation of cyclohexene with H2O2 catalyzed by Na2WO4·2H2O and acidic ionic liquid. J Chem Res 5:520–522

Liu D, Gui JZ, Zhu XQ, Song LJ, Sun ZL (2007) Synthesis and characterization of task-specific ionic liquids possessing two brönsted acid sites. Synth Commun 37:759–765

Gui JZ, Deng YQ, Hu ZD, Sun ZL (2004) A novel task-specific ionic liquid for Beckmann rearrangement: a simple and effective way for product separation. Tetrahedron Lett 45:2681–2683

Gui JZ, Ban HY, Cong XH, Zhang XT, Hu ZD, Sun ZL (2004) Selective alkylation of phenol with tert-butyl alcohol catalyzed by Brönsted acidic imidazolium salts. J Mol Catal A 225:27–31

Deng YQ, Ma ZF, Wang K, Chen J (1999) Clean synthesis of adipic acid by direct oxidation of cyclohexene with H2O2 over peroxytungstate—organic complex catalysts. Green Chem 1:275–276

Hida T, Nogusa H (2009) Practical and versatile oxidation of alcohol using novel Na2WO4–H2O2 system under neutral conditions. Tetrahedron 65:270–274

Acknowledgments

We are grateful for the financial supports from the National Natural Science Foundation of China (No. 20706027), the Education Department of China (No. 209031), Liaoning Excellent Talents in University (No. LR201024), Natural Science Foundation of Liaoning Province (No. 20102131) and Foundation of the Education Department of Liaoning Province (No. 2009A430 and 2010243).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, D., Gui, J., Ding, J. et al. Oxidation of dibenzothiophene catalyzed by Na2WO4 in a halogen-free ionic liquid. Reac Kinet Mech Cat 104, 111–123 (2011). https://doi.org/10.1007/s11144-011-0347-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-011-0347-7