Abstract

Au/SiO2 catalysts were prepared by self-assembly technique and characterized by EDS, XRD, XPS, AAS and N2 adsorption/desorption. They were found to be very efficient catalysts for the selective oxidation of cyclohexane with air in the absence of any solvent or promoter. The influences of Au loading, reaction temperature, reaction pressure and reaction time on the catalytic activity were explored in detail. Under suitable reaction conditions, the conversion of cyclohexane and total selectivity of cyclohexanone and cyclohexanol were up to ~10 and ~92%, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

For a long time, gold was considered to be a poor catalyst due to its electronic configuration of noble metal, which is usually accompanied by very low activity [1]. However, the study of catalysis by gold has attracted increasing interest since Haruta et al. [2] reported that CO oxidation could be achieved at room temperature over gold catalysts when very small gold nanoparticles were dispersed on suitable oxide supports. So far, the catalytic activity of gold has been recognized for a variety of reactions, such as epoxidation of propylene, NO x reduction, the water–gas shift, selective hydrogenation of acetylene, and reactions involving halogens [3–5].

Oxidation of cyclohexane is one of the most important commercial reactions among the liquid phase oxidation of alkanes, owing to the large demand for its oxidized products, cyclohexanone and cyclohexanol. They are important raw materials for the production of adipic acid and caprolactam finally used in the manufacture of nylon-6 and nylon-66 polymers [6, 7]. Furthermore, they are also very useful as stabilizers, homogenizers, solvents and in the synthesis of various pharmaceuticals, insecticides, and herbicides [8, 9]. Traditional oxidants consist of NaClO, H2O2, PhIO and alkyl hydroperoxides, but the use of molecular oxygen, which is the most inexpensive, abundant and readily available oxidant, provides a better option for replacing oxygen donors because of its economic and environmental virtues. Unfortunately, the technology with which cyclohexane is oxidized by molecular oxygen to produce cyclohexanone and cyclohexanol has not been improved very well up to now, especially not with the use of air. In recent years, supported gold catalysts, including Au/MCM-41, Au/SBA-15, Au/ZSM-5 and Au/Al2O3, have shown high activity in performing the selective cyclohexane oxidation using molecular oxygen [10–15], though their performance still needs to be improved.

Many approaches have been developed to prepare supported gold catalysts, such as impregnation [16], coprecipitation [17], precipitation-deposition [18], ion exchange [19], microemulsion [20] and so on [21–23]. The former three are the most commonly used methods. However, various parameters, for example the Au precursor, the nature of the support, the reaction conditions, particularly the preparation method and the size of gold particles, have already been considered as crucial factors influencing the structure and catalytic activity of gold containing systems [24–28]. From this point of view, developing a new preparation method of supported gold catalyst to better activate the reaction between molecular oxygen and cyclohexane continues to be of far-reaching significance.

The present work is aimed at preparing active Au/SiO2 catalysts by using gold nanoparticles and nanosilica supports functionalized with sulfhydryl groups. Compared with known preparation methods, this self-assembly technique shows outstanding advantages in controlling the size, loading and dispersion of the Au active component. In addition, this catalyst exhibits a relatively high activity for cyclohexane oxidation using air, without any addition of solvent, initiator, reductant or co-catalyst.

Experimental

Catalyst preparation

All the reagents with A.R. grade were directly used in the preparation of catalysts and the oxidation of cyclohexane without further purification. SiO2 supports with a particle size of ~70 nm were synthesized according to the literature method [29]. Spherical gold colloidal nanoparticles with an average diameter of about 6 nm were prepared following a published procedure [30].

Seven mg nanosilica was stirred in the mixed solution of 100 mL toluene and 5 mL 3-mercaptopropyltrimethoxysilane (MPTMS). The slurry was refluxed for 24 h to get thiol-terminated nanosilica. After that, the as-prepared powder was collected and rinsed with copious amounts of toluene and methanol. Note that it is very important to remove the excess of MPTMS from the modified silica to prevent gold particle aggregation during the next step. According to the Au loading, 0.1 g thiol-terminated nanosilica was added in some amount of the gold colloidal suspension with stirring overnight. Then, the solid was filtered, washed with distilled water until free from Cl− against AgNO3 solution, dried under vacuum at 50 °C for 8 h, and finally calcined in air at 500 °C for 2 h.

Characterization techniques

The elemental analysis of samples were measured by a scanning electron microscope (SEM, Hitachi S-570) equipped with X-ray energy dispersive spectrometer (EDS). The phase compositions of the obtained samples were examined by X-ray diffraction (XRD) patterns on a Bruker D8 Advance diffractometer with Cu Kα radiation. X-ray photoelectron spectroscopy (XPS) measurement was performed in a VG Scientific ESCALAB Mark instrument. The C(1s) level was used as an internal reference at 284.6 eV. The amounts of Au loaded on SiO2 were analyzed by atomic absorption spectroscopy (AAS, Varian 240FS). N2 adsorption/desorption isotherms were obtained at −196 °C on an Omnisorp 100CX instrument, and pore size distributions were determined from desorption branch of the isotherms with the Barrett–Joyner–Halenda (BJH) method.

Cyclohexane oxidation with air

All cyclohexane oxidations were carried out according to the following procedures: 0.01 g Au/SiO2 and 4 mL cyclohexane were put into a 100 mL autoclave reactor. Then the mixture was stirred and heated to the reaction temperature after having been sealed up. Once the temperature had equilibrated, air was pumped into the system continuously and the pressure was kept at a certain value. After the reaction, the autoclave was cooled to room temperature and slowly depressurized. Product samples were identified and quantified immediately by gas chromatography (GC) with the internal standard method using chlorobenzene as the standard substance [31]. Blank cyclohexane oxidation reactions without catalyst and over pure SiO2 supports were also carried out. To study the reuse of the as-prepared Au/SiO2 catalyst, the most recently used catalyst was separated from the reaction mixture, washed with alcohol, dried at ambient temperature, and then put into the next catalytic cyclohexane oxidation.

Results and discussion

Catalyst characterization

EDS study

Fig. 1 shows the EDS spectrums of original SiO2 supports (a), MPTMS functionalized SiO2 supports (b), MPTMS/SiO2-supported Au compound (c), and Au/SiO2 catalyst after calcination at 500 °C (d). It is obvious that sulfur element in sample b originates from MPTMS. Even though Au nanoparticles have been assembled on the MPTMS functionalized SiO2 supports, the sulfur element is still present. The high temperature curing process basically removes the sulfur element, and pure Au/SiO2 catalyst is finally obtained. Digital photographs of MPTMS functionalized SiO2 supports (a) and MPTMS/SiO2-supported Au compound (b) are given in Fig. 2. It can be seen that MPTMS/SiO2 is light gray before reacting, but its color becomes deep red after immobilizing Au nanoparticles. On the basis of the above data, we can conclude that in our system, Au nanoparticles are really immobilized on the surface of thiol-functionalized silica through the strong Au–S bonds. Their existence has been confirmed by many previous works, where the bonding of thiols to gold surfaces was exploited [32–36]. The procedure for preparing Au/SiO2 catalyst is shown in Scheme 1.

XRD characterization

Fig. 3 shows the XRD patterns of the Au/SiO2 catalysts prepared with different Au loadings. When the Au loading is below or equal to 4%, the XRD pattern only exhibits a diffraction in 15–30° in 2θ, which corresponds to the amorphous SiO2. A possible reason is that gold particles with smaller size uniformly disperse on the supports, leading to the highly dispersed Au diffraction peak. However, when the Au loading is raised to 5%, the XRD pattern shows two wider diffraction peaks of gold. At this time, the Au particle size is about 6.3 nm estimated by the Scherrer formula.

This result indicates that Au nanocrystals are highly dispersed on the SiO2 supports without any significant agglomeration or sintering to bigger particles. Therefore, this kind of Au/SiO2 catalyst should be beneficial for cyclohexane oxidation according to the previous literatures, which reported that gold can be catalytically active on inactive supports only when it is at a highly dispersed state [37], and only the methods that able to produce small gold particles on oxide supports can lead to performing catalysts [24, 38].

XPS measurement

XPS spectra of Au/SiO2 were performed and shown in Fig. 4. The peaks of Au4f 7/2 and Au4f 5/2 on Au/SiO2 are centered at 83.5 and 87.2 eV, respectively, which is associated with metallic gold species [39].

AAS analysis

Au loading (wt%) determined by AAS and calculated Au loading rate are listed in Table 1. As observed in Table 1, using the self-assembly preparation method can make Au nanoparicles support on the SiO2 supports effectively, obtaining a high Au loading rate.

Textural properties

Fig. 5 depicts the N2 adsorption/desorption isotherms and the corresponding pore size distributions of SiO2 and 5% Au/SiO2. As shown, pure SiO2 and 5% Au/SiO2 exhibit similar N2 adsorption/desorption isotherms of type H1 following the IUPAC classification [40]. The narrow hysteresis loops and almost parallel adsorption–desorption branches indicate that pores of the samples are both cylinder-shaped. After gold nanoparticles were loaded, the pore diameter peak value of SiO2 reduces from 42.13 nm to 38.04 nm; the pore volume also decreases from the original 0.070 cm3 g−1 to 0.023 cm3 g−1; the specific surface area drops sharply to 23.58 m2 g−1 from 36.04 m2 g−1. That is to say, loading gold in this way resulted in dramatic decrease of specific surface area and pore volume. The decrease of pore diameter can be accounted for by the dispersion of gold nanoparticles within the channels of SiO2 [13].

Catalytic cyclohexane oxidation over Au/SiO2

Blank tests were performed in the absence of catalyst and presence of pure SiO2 supports, under the conditions of reaction temperature 150 °C, 3.0 MPa air and reaction time 4 h. However, almost no cyclohexane conversion can be monitored after these reactions, which are similar to the experimental results reported by Lü et al. and Reddy et al. [10, 41].

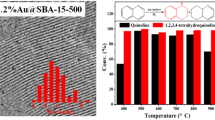

Effect of Au loading

We used the Au/SiO2 catalysts with different gold content to study the effect of Au loading on the aerobic oxidation of cyclohexane. The experimental results are presented in Fig. 6. With increasing Au loading, the conversion of cyclohexane increased, while the total selectivity of cyclohexanone and cyclohexanol slightly decreased. The reason may be that when the Au loading is lower, there are fewer active sites on the Au/SiO2 catalyst, but enhancing the gold content can cause much more active sites disperse evenly on the SiO2 supports. Finally, 1% Au/SiO2 was chosen to test other catalytic properties of Au/SiO2 catalysts, owing to the biggest ratio of cyclohexanone to cyclohexanol (4.27) at this moment.

Effect of reaction temperature

Fig. 7 shows the influence of reaction temperature. When the reaction temperature increased from 130 to 190 °C, the conversion of cyclohexane sharply increased. In contrast, the total selectivity of cyclohexanone and cyclohexanol and the ratio of cyclohexanone to cyclohexanol decreased with reaction temperature. 12.5% of cyclohexane conversion and 60.0% of cyclohexanone and cyclohexanol selectivity were obtained at 190 °C. It is evident that the higher reaction temperature is unbeneficial to get the target products of catalytic cyclohexane oxidation, due to the decomposition and deep oxidation of cyclohexane at higher temperature. Considering all factors synthetically, 150 °C was chosen as the best reaction temperature.

Effect of reaction pressure

At the optimum temperature, the effect of reaction pressure on cyclohexane oxidation was explored. As shown in Fig. 8, with an increase in the air pressure, the conversion of cyclohexane increased, while the total selectivity of cyclohexanone and cyclohexanol decreased. Only the ratio of cyclohexanone to cyclohexanol had little change. This is because the oxygen concentration is promoted by high pressure, which is advantageous for forward reaction. Based on the data, 3.0 MPa was defined as the optimum pressure of the reaction when all other factors were fixed.

Effect of reaction time

Fig. 9 illustrates the effect of reaction time over Au/SiO2. It can be seen that the conversion of cyclohexane and the ratio of cyclohexanone to cyclohexanol smoothly increased with time, while the total selectivity of cyclohexanone and cyclohexanol was downtrend. Obviously, the longer reaction time is unfavorable for the selective production of cyclohexanone and cyclohexanol because of more by-products. At the optimum reaction time (4 h), the Au/SiO2 catalyst showed 10.1% cyclohexane conversion, and 91.9% selectivity for cyclohexanone and cyclohexanol.

Recycling studies

Recycling tests with repeated use of 1% Au/SiO2 in four consecutive reactions were carried out under the typical reaction conditions. It can be seen from Fig. 10 that with every run, the total selectivity and the ratio of cyclohexanone to cyclohexanol changed slightly, but the conversion of cyclohexane gradually dropped from 10.1 to 7.53%. The decrease in activity probably related to the unavoidable loss of Au active component and surface carbon depositions on the catalyst. The change of Au content in four consecutive reactions (Table 2) partially confirms our conjecture. As can be seen, the loss of Au was relatively great after Au/SiO2 was used for the first time, whereas Au content was still above 0.9% even after repeated use for 4 times.

Conclusions

Gold nanoparticles supported on nanosilica were prepared by a novel self-assembly technique. Experimental results indicate that this catalyst is effective for the oxidation of cyclohexane with air. 1% Au/SiO2 yielded a maximum of 10.1% of cyclohexane conversion, 91.9% of selectivity for cyclohexanone and cyclohexanol under the suitable conditions of reaction temperature 150 °C, 3.0 MPa air, reaction time 4 h.

References

Hammer B, Nørskov JK (1995) Nature 376:238–240

Haruta M, Yamada N, Kobayashi T, Iijima S (1989) J Catal 115:301–309

Haruta M (2003) Chem Record 3:75–87

Meyer R, Lemire C, Shaikhutdinov SK, Freund HJ (2004) Gold Bull 37:72–124

Haruta M (2003) Gold Bull 37:27–36

Schuchardt U, Carvalho WA, Spinacé EV (1993) Synlett 10:713–718

Schuchardt U, Cardoso D, Sercheli R, Pereira R, Cruz RS, Guerreiro MC, Mandelli D, Spinace EV, Fires EL (2001) Appl Catal A Gen 211:1–17

Faith WL, Keyes DB, Clark RL (1957) Industrial chemicals, 2nd edn. Wiley, New York

Musser MT (1987) In: Gerhartz W (ed) Encyclocarbons of industrial chemistry. VCH, Weinheim

Lü GM, Ji D, Qian G, Qi YX, Wang XL, Suo JS (2005) Appl Catal A Gen 280:175–180

Zhao R, Ji D, Lü GM, Qian G, Yan L, Wang XL, Suo JS (2004) Chem Commun 7:904–905

Lü GM, Zhao R, Qian G, Qia YX, Wang XL, Suo JS (2004) Catal Lett 97:115–118

Zhu K, Hu JC, Richards R (2005) Catal Lett 100:195–199

Xu YJ, Landon P, Enache D, Carley AF, Roberts MW, Hutchings GJ (2005) Catal Lett 101:175–179

Xu LX, He CH, Zhu MQ, Fang S (2007) Catal Lett 114:202–205

Bamwenda GR, Tsubota S, Nakamura T, Haruta M (1997) Catal Lett 44:83–87

Hodge NA, Kiely CJ, Siddiqui MRH, Hutchings GJ, Pankhurst QA, Wsgner FE, Rajaram RR, Golunski SE (2002) Catal Today 72:133–144

Mallick K, Witcomb MJ, Scurrell MS (2004) J Mol Catal A Chem 215:103–106

Riahi G, Guillemot D, Polisset-Thfoin M, Khodadadi AA, Fraissard J (2002) Catal Today 72:115–121

Chen W, Xiao YH, Zhan YY, Cai GH, Wei KM, Zheng Q (2004) Spectrosc Spectr Anal 24:1096–1098 (in Chinese)

Xu LX, He CH, Zhu MQ, Wu KJ, Lai YL (2008) Catal Commun 9:816–820

Li X, Ma XC, Li ST, Wen SL, Lun N (2004) J Mater Sci Eng 22:48–51 (in Chinese)

Kozlova AP, Kozlov AI, Sugiyama S, Matsui Y, Asakura K, Iwasawa Y (1999) J Catal 181:37–48

Bond GC, Thompson DT (1999) Catal Rev Sci Eng 41:319–388

Hashmi ASK, Hutchings GJ (2006) Angew Chem Int Ed 45:7896–7937

Dobrosz I, Jiratova K, Pitchon V, Rynkowski JM (2005) J Mol Catal A Chem 234:187–197

Park ED, Lee JS (1999) J Catal 186:1–11

Casaletto MP, Longo A, Venezia AM, Martorana A, Prestianni A (2006) Appl Catal A Gen 302:309–316

Xue W, Zhang JC, Wang YJ, Zhao XQ (2005) Acta Pet Sinica 21:37–43 (in Chinese)

Xie J, Wang YJ, Li YT, Zhao XQ, Wei Y (2008) Gold 3–6 (in Chinese)

Huang G, Guo YA, Zhou H, Zhao SK, Liu SY, Wang AP, Wei JF (2007) J Mol Catal A Chem 273:144–148

Doron A, Katz E, Willner I (1995) Langmuir 11:1313–1317

Huang XH, Huang HZ, Wu NZ, Hu RS, Zhu T, Liu ZF (2000) Surf Sci 459:183–190

Liu FK, Hsu YT, Wu CH (2005) J Chromatogr A 1083:205–214

Pan BF, Gao F, Ao LM, Tian HY, He R, Cui DX (2005) Colloids Surf A 259:89–94

Hu RS, Liu ST, Zhu T, Liu ZF (1999) Acta Phys-Chim Sin 15:961–965 (in Chinese)

Schubert MM, Hackenberg S, Veen ACV, Muhler M, Plzak V, Behm RJ (2001) J Catal 197:113–122

Haruta M (2002) CATTECH 6:102–115

Castaño P, Zepeda TA, Pawelec B, Makkee M, Fierro JLG (2009) J Catal 267:30–39

Sing KSW, Everett DH, Haul RAW, Mosenu L, Pierotti RA, Rouquerol J, Siemieniewska T (1985) Pure & Appl Chem 57:603–619

Reddy SS, Raju BD, Padmasri AH, Prakash PKS, Rao KSR (2009) Catal Today 141:61–65

Acknowledgments

This work was financially supported by Doctor Foundation of Hebei University of Engineering, National Natural Science Foundation of China (20636030, 20476022), and Natural Science Foundation of Hebei Province, China (E2009000911).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xie, J., Wang, Y., Li, Y. et al. Self-assembly preparation of Au/SiO2 catalyst and its catalysis for cyclohexane oxidation with air. Reac Kinet Mech Cat 102, 143–154 (2011). https://doi.org/10.1007/s11144-010-0246-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-010-0246-3