Abstract

The objective of the present study was to investigate the physicochemical properties and powder characterization of hempseed milk powders obtained by whole hempseed and cold-pressed whole hempseed paste (de-oiled). Whole hempseed and de-oiled hempseed paste were used to produce plant based milk powder applying spray drying process. The influence of oil content on physicochemical features, emulsion and rheological properties of the powders was examined. Results showed that dry content, total protein, loose density, tapped density, viscosity, foaming capacity and foaming stability of sprayed-powders produced in milk obtained using whole and de-oiled hemp seeds were not statistically different from each other (p > 0.05). By using de-oiled hempseed cake in feed solution preparation, spray dryer process efficiency increased from 31 to 44% without using any carrier agents. Hempseed powder product with improved properties such as apparent density, solubility, hygroscopicity and emulsion stability index was obtained.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Hempseeds are composed of protein (20–25%), lipids (25–35%), 20–30% carbohydrate, 10–15% insoluble fibre, 4–7% ash, depending on the variety [1, 2] and by this way it can be considered as a rich source of oils, proteins [3] and total polyphenols [4]. One of the valuable compounds is hemp seed oil because of containing essential fatty acids (Linoleic acid (LA, C18:2, ω-6 and α-linolenic acid (ALA, C18:3, ω-3) with the recommended value for human nutrition of 3:1 [5]. Hempseed is a good source of nutritious protein thanks to contain of highly digestible amino acids. In addition, the amount of compounds can ensure needing for infants or children as recommended by FAO/WHO [6]. Moreover, typical terpeno-phenolic compounds as prenylated flavonoids, stilbenoid derivatives, lignanammides and flavonoids were found in hempseed cake [4].

Hempseed cake/meal is a by-products obtained after oil extraction from hempseed such as other methods; solvent extraction [7], supercritical CO2 extraction [8] and cold-pressing process [4, 9]. Hempseed cake is a valuable nutritional supplements with fatty acid composition, antioxidant properties and anti-proliferative capacity and it is a kind of food supplement with positive health effects and an interesting by-product utilizable in food [10]. Studies have shown that hempseed cake is not only used in animal nutrition [11], but also added to food formulations such as meat, bread and potato chips [12].

All the mentioned factors make hempseed oil and its by product (hemp seeds cake) important foods in terms of both market and health values. After hempseed oil production, de-oiled hempseed cake can be sold directly or integrated other food matrix for the enrichment of protein percentage. Hempseed milk can be produced both of materials as whole hempseed and de-oiled whole hempseed. Like other milk alternatives made from plant seeds (soybean, almond, etc.), hemp milk has an unstable emulsion system that tends to coalesce and flocculate due to its oil content. This leads to poor quality, shelf life and consumer acceptance. Emulsifier/stabilizers are used or some technological processes (high pressure homogenization, ultrasonic treatments, pulsed electric field processing etc.) are applied in order to reduce these negative effects and to obtain a stable product [13, 14]. Plant based milk substitutes can also be spray-dried [15] or drum-dried [16] to produce a stable powder, which can be reconstituted to the desired product.

In this study, physicochemical properties and characterization of hemp milk powder produced from both whole hempseed and de-oiled hempseed paste was investigated. The purpose of using different materials (whole hempseed and cold-pressed whole hempseed cake) were to seek an answer to the question of whether hempseed milk powder could be obtained without using any carrier agents. In addition, using possibility of de-oiled hempseed cake was examined the feasibility of the production of the instant hempseed powder from waste-by product. It was also aimed to contribute to increase the usage potential in food matrix of hemp seed plant-based milk, which attracts attention in the food industry.

Materials and Methods

The Materials and Methods section is presented as supplementary Online Resource 1.

Results and Discussion

Spray Drying Process and Product Yield

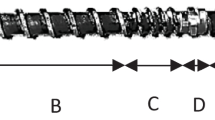

One of the parameters for the spray drying process is inlet temperature [19] and it was selected as 150 °C according to pre-trials for the hempseed milk drying process. Man and Minh [20] also determined 150 °C as the drying inlet temperature of coconut milk with 50% oil content. Powders obtained have shown in Fig. 1.

Oil content showed a significant effect on the product yield (p < 0.05). While product yield was 31.34% in HSMP, it was 44.15% in D-HSMP. The reasons for this the low product yield could be the oil content and the use of no carrier/wall material. As stated in other studies [20] in which products had high oil content were tried to be sprayed at high inlet temperature level, high oil content caused adhesions in the cyclone and product loss by passing to liquid form. Particles with high particle size retain more oil in their bodies [19]. When D-HSMP and HSMP samples were compared, because of containing less oil on their (D-HSMP) outer surfaces, the adhesion to the cyclone was slightly reduced and the product yield was increased compared to the HSMP.

Proximate Analysis

Dry matter content, total ash, protein and oil content of the spray dried samples were summarized in Table 1. Dry matter and protein contents of powder samples were not statistically different from each other (p > 0.05) while oil and ash contents show difference (p < 0.05). The moisture content of powder samples was around 7% and the value is above the 3–4% limit value that powder foods should have [21], but it is in the moisture range (91–98%) determined in powders obtained from oilseed meal at other study [22]. The oil content of the HSMP was determined as 35%, which is in line with the literature [23, 24]. In addition, Kiralan, Gül [25] reported that the oil content of twenty one different hempseed samples from Turkey ranged from 29.6 to 36.5%. The oil ratio in D-HSMP produced from the hempseed cake obtained cold-press process was determined as 10.49%. Supporting this result, House, Neufeld [26] reported that the remaining seed cake or meal containing approximately 10% residual oil. It depends on the cold press process yield and extraction capability but the process can ensure reducing three times of oil content of the seed. Protein content of HMSP and D-HSMP determined as 34% and 31%, respectively (p > 0.05). The remaining seed meal has a high protein content of 35%, which is why it is commercially offered as a source of vegetable protein in the form of hemp protein powder, hemp flour and in shake drinks [26]. Latif and Anwar [9] reported that enzyme-assisted extraction had no noticeable effects on the amounts of protein in hemp seeds. While the total ash content was 7.85% in the HSMP, it was 11.8% in the D-HSMP (p < 0.05). The increasing of ash percentage can be caused removing oil from the seed and total compound percentage.

Physical Characterization of Powder

The water activity values of the powder samples were statistically different from each other (p < 0.05) (Table 1). Accordingly, it can be concluded that the oil content creates a barrier to moisture transfer [17]. As the water activity of the powder samples varies between 0.3 (D-HSMP) and 0.5 (HSMP), it can be defined as a microbially safe product. It is recommended that the water activity value, in which microbial growth can not occur, should be lower than 0.6 [22]. There is no statistical difference between the loose and tapped bulk densities of HSMP and D-HSMP powder samples (p > 0.05) (Table 1). Apparent density of D-HSMP was higher than HSMP (p < 0.05). D-HSMP, which contains less oil content with lower density, was naturally more dense. As can be seen in Table 1 the oil content caused a statistically significant difference on the flowability property of powders. Carr index and Hausher ratio values were calculated in order to evaluate the flow properties of the powders. Both powder samples showed high cohesion properties (> 1.4). As noted in some study high cohesive behaviour has resulted in poor flowability [27]. Carr index values also supported the high cohesive behaviour. When the flowability property was classified considering the Carr index, sample HSMP could be classified as “fair” with the value of 31.91 ± 2.18, and sample D-HSMP represented “bad” flowability performance with the value of 38.29 ± 2.13. The poor flowability of powders could be explained by high levels of oil which obstructed to flow as in accordance with some study [21]. The porosity value of the D-HSMP samples obtained from the de-oiled hempseed cake milk was found to be higher (p < 0.05), having the highest mean particle size (p < 0.05). Particle enlargement can cause porosity [18]. SEM image also supported this result. Especially in the Fig. 2d, porous structures are observed on the particles surface. Furthermore when the water holding capacity was examined, it was concluded that this porous structure also affected the hygroscopicity value. Because, higher hygroscopicity was determined in the D-HSMP sample, which had high porosity (Table 1). Large particles leading to large porous structure could be facilitated the water penetration from the structure. In addition, as in HSMP sample, high oil content also created a barrier to water transfer, resulting in less hygroscopicity (3.86%). Statistically significant differences in the color parameters (L*, a*, b*) of powders were observed (p < 0.05) (Table 1). The changes in L* value are similar to the study [28] that reported de-oiling had significant effects on the color of hempseed cake samples. In that study, higher L* value, lower a* and b* values were obtained in the oil-removed hempseed cake compared to the hempseed cake. Similarly, in the present study, the yellowness (b value) of HSMP was higher than in the D-HSMP (Figs. 2 and 3). This is a result of the more oil containing being more yellow because of more yellowish color of hempseed oil [9]. The red–green (a*) color parameter of D-HSMP was in the negative region with the value of -1.22 ± 0.04, more toward green, while that of HSMP moved to positive region with the value of 2.43 ± 0.02, more toward red. Solubility is one of the most reliable criterion to evaluation of the behavior [22]. The oil content made a statistical difference on the solubility of the samples (p < 0.05) (Table 1). D-HSMP had almost twice as much solubility property as HSMP. This means that it is possible to obtain a food ingredient with increased solubility in food matrix from the de-oiled cake obtained by removing the oil from an oilseed. According to thermograms, glass transition values of the samples were found as 48.84 ºC with 61.47 J/kg and 42.07 ºC with 102.1 J/kg for HSMP and D-HSMP, respectively (Fig. 4).

Emulsion Properties of Powders

Proteins in the emulsion act as emulsifying agents [29]. The protein content in both powder samples is not statistically different, but since the proteins in the D-HSMP could not be adequately encapsulated by the oil, it may have been structurally denatured at the temperature and thus D-HSMP powder had a lower emulsion activity index than that of HSMP. In this study, HSMP with smaller particle size had lower emulsion stability index than that of D-HSMP (Table 1). Similar to this study Cao, Shi [30] reported that emulsion stability decreases with decreasing particle size attributing to insufficient hydrophobic/hydrophilic balance for the stabilization. Additionally, the higher hygroscopic property of D-HSMP can be shown as the reason for the higher determination of emulsion stability. Removing oil did not show any statistically significant difference on foam capacity and stability (p > 0.05).

Rheological Properties of Powders

The steady and dynamic properties of the reconstituted powders (1%) were carried out to examine the behavior of the powders in the food matrix. Flow curves (Fig. 5) of D-HSMP and HSMP showed that the relationship between the shear stress-shear rate were linear. This behaviour is classified as Newtonian flow type. Apparent viscosity (ƞ at shear rate 50 s− 1, ƞ50) of D-HSMP was 0.841 ± 0.14 mPa, while that of HSMP was 0.76 ± 0.04 mPa and there was no statistical differences in viscosity values (p = 0.396) (Table 1). The flow behaviour index (n) values of reconstituted D-HSMP (n = 1.034) and HSMP (n = 1.044) were close to 1 because of exhibiting Newtonian fluid characteristics as can be seen in Fig. 5. In Newtonian behaviour apparent viscosity of the sample is constant with increase in shear rate. This means that when powder samples are added to the food matrix at 1% concentration, no increase or decrease in viscosity will occur within a certain shear rate range (0-200 s− 1). When it was examined the dynamic rheological properties, Fig. 6 shows the storage (Gʹ) and loss (Gʺ) modulus as a function of frequency (Hz). The Gʹ values of the samples were higher than the Gʺ values over the whole frequency range. This indicates an elastic structure of both samples rather than a viscous structure.

Conclusion

In this study the potential to produce plant-based milk powder from a whole and de-oiled hemp seed without any carrier agent using spray dryer was investigated. According to results, using milk from de-oiled hemp cake significantly increased the spray dryer process efficiency. Furthermore apparent viscosity, porosity, particle size, hygroscopicity, solubility and emulsion stability index were significantly increased with de-oiled. However the flowability properties of the powder were adversely affected by the oil removal. The rheological properties did not change significantly and 1% solutions of both powder samples showed Newtonian flow behavior. The results can be guide for the further research for the vegetable based milk powder possibilities based on their whole seeds and their cold press cake. In addition, it can be utilized from physicochemical properties and characterization of hempseed milk powder instead of whey protein and milk powder for vegan based products.

Data Availability

Data is available upon request.

References

Callaway JC (2004) Hempseed as a nutritional resource: an overview. Euphytica 140:65–72

Leonard W, Zhang P, Ying D, Fang Z (2020) Hempseed in food industry: nutritional value, health benefits, and industrial applications. Compr Rev Food Sci Food Saf 19(1):282–308. https://doi.org/10.1111/1541-4337.12517

Fike J (2017) Industrial Hemp: renewed Opportunities for an ancient crop. Crit Rev Plant Sci 35(5–6):406–424. https://doi.org/10.1080/07352689.2016.1257842

Liang J, Zago E, Nandasiri R, Khattab R, Eskin NAM, Eck P et al (2018) Effect of Solvent, Preheating temperature and time on the Ultrasonic extraction of Phenolic Compounds from Cold-Pressed hempseed cake. J Am Oil Chem Soc 95(10):1319–1327. https://doi.org/10.1002/aocs.12108

Chen T, He J, Zhang J, Zhang H, Qian P, Hao J et al (2010) Analytical characterization of Hempseed (seed of Cannabis sativa L.) oil from eight regions in. China J Diet Suppl 7(2):117–129. https://doi.org/10.3109/19390211003781669

Malomo SA, He R, Aluko RE (2014) Structural and functional properties of hemp seed protein products. J Food Sci 79(8):C1512–C1521. https://doi.org/10.1111/1750-3841.12537

Kostić MD, Joković NM, Stamenković OS, Rajković KM, Milić PS, Veljković VB (2013) Optimization of hempseed oil extraction by n-hexane. Ind Crops Pro 48:133–143. https://doi.org/10.1016/j.indcrop.2013.04.028

Da Porto C, Voinovich D, Decorti D, Natolino A (2012) Response surface optimization of hemp seed (Cannabis sativa L.) oil yield and oxidation stability by supercritical carbon dioxide extraction. J Supercrit Fluids 68:45–51. https://doi.org/10.1016/j.supflu.2012.04.008

Latif S, Anwar F (2009) Physicochemical studies of hemp (Cannabis sativa) seed oil using enzyme-assisted cold‐pressing. EJLST 111(10):1042–1048. https://doi.org/10.1002/ejlt.200900008

Difonzo G, de Gennaro G, Pasqualone A, Caponio F (2021) Potential use of plant-based by-products and waste to improve the quality of gluten-free foods. J Sci Food Agric. https://doi.org/10.1002/jsfa.11702

Klir Ž, Novoselec J, Antunović Z (2019) An overview on the use of hemp (Cannabis sativa L.) in animal nutrition. Poljoprivreda 25(2):52–61. https://doi.org/10.18047/poljo.25.2.8

Feng X, Sun G, Fang Z (2022) Effect of Hempseed Cake (Cannabis sativa L.) Incorporation on the Physicochemical and Antioxidant Properties of Reconstructed Potato Chips. Foods 11(2). https://doi.org/10.3390/foods11020211

Wang Q, Jiang J, Xiong YL (2018) High pressure homogenization combined with pH shift treatment: a process to produce physically and oxidatively stable hemp milk. Food Res Int 106:487–494. https://doi.org/10.1016/j.foodres.2018.01.021

Paul AA, Kumar S, Kumar V, Sharma R (2020) Milk Analog: Plant based alternatives to conventional milk, production, potential and health concerns. Crit Rev Food Sci Nutr 60(18):3005–3023. https://doi.org/10.1080/10408398.2019.1674243

Saha D, Nanda SK, Yadav DN (2019) Optimization of spray drying process parameters for production of groundnut milk powder. Powder Technol 355:417–424. https://doi.org/10.1016/j.powtec.2019.07.066

Aidoo H, Sakyi-Dawson E, Tano-Debrah K, Saalia FK (2010) Development and characterization of dehydrated peanut–cowpea milk powder for use as a dairy milk substitute in chocolate manufacture. Food Res Int 43(1):79–85. https://doi.org/10.1016/j.foodres.2009.08.018

Baysan U, Zungur Bastıoglu A, Coskun NO, Konuk Takma D, Ulkeryıldız Balcık E, Sahin-Nadeem H et al (2021) The effect of coating material combination and encapsulation method on propolis powder properties. Powder Technol 384:332–341. https://doi.org/10.1016/j.powtec.2021.02.018

Atalar I, Yazici F (2018) Effect of different binders on reconstitution behaviors and physical, structural, and morphological properties of fluidized bed agglomerated yoghurt powder. Dry Technol 37(13):1656–1664. https://doi.org/10.1080/07373937.2018.1529038

Samsu ZA, Mohamad Zahir AZ (2020) Production of oil palm milk powder by spray drying technique. Mater Today:Proc 31:306–312. https://doi.org/10.1016/j.matpr.2020.06.015

Man LVV, Minh VV (2009) Optimization of Technoogological Parameters in the spray drying of coconut milk powder with high Fat Content.Sci Technol Develop12(4)

Zungur Bastioglu A, Tomruk D, Koc M, Ertekin FK (2016) Spray dried melon seed milk powder: physical, rheological and sensory properties. J Food Sci Technol 53(5):2396–2404. https://doi.org/10.1007/s13197-016-2214-z

Drozlowska E, Lopusiewicz L, Mezynska M, Bartkowiak A (2020) Valorization of Flaxseed Oil cake residual from Cold-Press Oil production as a material for Preparation of Spray-Dried functional powders for Food Applications as Emulsion Stabilizers. Biomol 10(1). https://doi.org/10.3390/biom10010153

Liang J, Appukuttan Aachary A, Thiyam-Holländer U (2015) Hemp seed oil: minor components and oil quality. Lipid Technol 27(10):231–233. https://doi.org/10.1002/lite.201500050

Tura M, Mandrioli M, Valli E, Rubino RC, Parentela D, Gallina Toschi T (2022) Changes in the composition of a cold-pressed hemp seed oil during three months of storage. J Food Comp Anal 106:104270. https://doi.org/10.1016/j.jfca.2021.104270

Kiralan M, Gul V, Kara SM (2010) Fatty acid composition of hempseed oils from different locations in Turkey. Span J Agr Res 8(2):385–390

House JD, Neufeld J, Leson G (2010) Evaluating the quality of protein from hemp seed (Cannabis sativa L.) products through the use of the protein digestibility-corrected amino acid score method. J Agric Food Chem 58(22):11801–11807. https://doi.org/10.1021/jf102636b

Ermis E, Karasu EN (2020) Spray drying of de-oiled sunflower protein extracts: functional Properties and characterization of the powder. Gida / the Journal of Food 39–49. https://doi.org/10.15237/gida.GD19096

Teh SS, Bekhit AED, Carne A, Birch J (2013) Effect of the defatting process, acid and alkali extraction on the physicochemical and functional properties of hemp, flax and canola seed cake protein isolates. J Food Meas Charact 8(2):92–104. https://doi.org/10.1007/s11694-013-9168-x

Abdullah Z, Taip FS, Mustapa Kamal SM, Abdul Rahman RZ (2021) The effect of drying temperature and sodium caseinate concentration on the functional and physical properties of spray-dried coconut milk. J Food Sci Technol 58(8):3174–3182. https://doi.org/10.1007/s13197-020-04820-9

Cao W, Shi L, Hao G, Chen J, Weng W (2021) Effect of molecular weight on the emulsion properties of microfluidized gelatin hydrolysates. Food Hydrocoll 111:106267. https://doi.org/10.1016/j.foodhyd.2020.106267

Acknowledgements

The authors thank to Ondokuz Mayis University Hemp Research Institute for providing hemp seeds.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

M.M.: Methodology, Investigation, Formal analysis, Writing – original draft; Z.T.: Formal analysis; M.K.: Formal analysis; A.B.: Writing – review & editing; F.Y.: Supervision.

Corresponding author

Ethics declarations

Ethics Statement

Not applicable.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Conflict of Interest

There are no conflicts of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mortas, M., Besir, A., Tok, Z. et al. Physicochemical Properties and Characterization of a New Product: Spray Dried Hempseed Milk. Plant Foods Hum Nutr 78, 358–365 (2023). https://doi.org/10.1007/s11130-023-01053-x

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11130-023-01053-x