Abstract

Brewers’ spent grain (BSG) is the major by-product of the brewing industry, with great potential as a functional ingredient due to its bioactive compounds. Thus, BSG could be suitable for improving the low nutritional quality of wheat-based snacks highly consumed by young people. The objective of this study was to substitute wheat flour with BSG (0, 10, 20, and 30%) for cookies elaboration, and evaluate the dough rheology, phenolic acids, antioxidant capacity, arabinoxylans content and proximate composition of the cookies Protein content and bioactive compounds (ferulic and p-coumaric acids, water unextractable arabinoxylans) of cookies significantly (p < 0.05) increased with the substitution level. In comparison to the wheat-alone cookies, the 20% BSG-containing cookies showed a lower hydrolysis and glycemic index (GI), and less total starch. The low cost, protein-rich BSG with antioxidant capacity improves the nutritional quality of cookies and may confer health benefits beyond basic nutrition.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nowadays, overweight and obesity are a pandemic; children and adolescents have obesogenic dietary patterns based on snacks with low fiber and protein contents, and high in fast digestible starch and glycemic index (GI). The regular consumption of dietary fiber from whole grains and cereal based-products, including arabinoxylans and other non/starch polysaccharides has been associated with a lower risk of chronic diseases [1]. Functional food innovations are being developed by the food industry to prevent nutrition-related diseases, and an effective strategy is the development of baked goods with the addition of different ingredients as fibers [2], pulse flours [3, 4], and flaxseed flours [5].

An interesting ingredient for nutritional enrichment is brewers spent grain (BSG), which consists mainly of proteins, lipids and lignocellulosic material. BSG is the husk-pericarp-seed coat layer of the barley grain which remains as solid residue after the production of wort [6]. BSG has 12–25% cellulose, 12–28% lignin and 20–25% hemicellulose, mostly arabinoxylans (AX). The backbone of AX is composed of β-(1,4)-linked xylose residues, which can be substituted with arabinose residues, those can be esterified with ferulic and p-coumaric acids, two potential antioxidants that can protect against DNA oxidation [7]. Also, they have anti-carcinogenic activity and anti-inflammatory effects [6,7,8]. Recent studies demonstrated that the consumption of AX can provide a favorable modulation of intestinal microbiota, promoting the production of fecal short-chain fatty acids mainly attributed to butyrate production [9]. Additionally, fiber could influence a low glycemic index response of starch based-foods, by the presence of viscous fiber mainly arabinoxylans, one of the major dietary fiber components in BSG. Thus may slow the gastric emptying rate or the absorption of nutrients [10].

The global beer production is estimated at 1.96 billions hectoliters per year, where BSG is the most abundant residue in the beer manufacture. For every 100 L of produced beer, 20 kg of wet BSG are generated [6]. Thus, the use of BSG as a functional ingredient can be a sustainable way of utilization of this agro-industrial waste, providing economic opportunities and waste reduction. Previously, cookies with BSG addition were prepared [11,12,13] with emphasis in dietary fiber but the phenolic acids profile, antioxidant capacity and glycemic index were not addressed. Therefore, the aim of this study was to evaluate the wheat flour’s replacement with BSG for cookies preparation, and to assess phenolic acids profiles, antioxidant capacity, AX content and estimated GI.

Materials and Methods

Materials

Soft wheat flour and fresh BSG were from local milling and brewing industries (Sonora, Mexico). Sodium bicarbonate, shortening, salt, sugar, and dextrose were from a local market. Methanol and acetonitrile HPLC grade were from J. T. Baker (Phillipsburg, NJ). O-phosphoric acid was from Merck (KGaA Darmstadt, Germany), DPPH (2,2-diphenyl-1-picrylhydrazyl) and ABTS (2,2′-azino-bis (3-ethylbenzothiazoline-6-sulphonic acid) radicals, and phenolic acids from Sigma Aldrich (San Luis, MO, USA).

BSG Drying

Fresh BSG was dried in an electric convection oven (Enviro-Pak, Micropak Series MP500, Clackamas, OR, USA) at 45 °C during 10 h and ground in a mill (Model 200, Pulvex, S. A. de C.V., Mexico) with a 0.4 mm mesh, and stored in plastic bags at 10 °C.

Dough Physical Test

Dough rheological properties of wheat flour (control) and the blends 90:10, 80:20, and 70:30 (wheat flour: BSG) were evaluated with the Brabender Farinograph (Brabender Farino/Resistograph, Model FA/R-2, C.W. Brabender Instruments Inc., South Hackensack, NJ, USA) according to the AACC method 54–21 [14]. The dough development time (min), stability (min), mixing tolerance index (BU), and water absorption (%) were recorded.

Preparation

Cookies were formulated with wheat alone (control) or the wheat-BSG blends, sugar (27.7%), sodium bicarbonate (0.6%), shortening (13.7%), dextrose (7.15%), salt (0.5%), and water (3.4%). All ingredients except flours were placed in a kneader (KitchenAid Classic, Michigan, U.S.A), mixed at low velocity for 3 min; dextrose and water were added and mixed for 2 min and then the wheat flour or blends were added and mixed 2 extra min. The doughs were molded (thickness = 0.5 cm; diameter = 6 cm) and baked in an electric oven (National MFG. CO., NE, USA) at 205 °C during 10 min.

Cookie Evaluation

Proximate Composition

Moisture (method 44–15.02), protein (method 46–13.01), ash (method 08–01.01), and fat contents (method 30–25.01) were quantified in flour, blends and cookies [14].

Color and Texture Measurements

Color parameter of cookies were performed with a Minolta colorimeter (Model Cr-400, Minolta Co., LTD., Japan) on the basis of CIE L*, a*, b* color system. Cookies hardness was measured with a texturometer (Model TA-XT2, Stable Micro System, Godalming, Surrey, UK) with a knife blade (thickness = 0.3 cm). Cookies placed in an adjustable three-point bend assembly were traversed using a test speed of 1 mm/s. The threshold force and distance used were 1g and 1mm, respectively. The maximum force was the cookie hardness.

Antioxidant Capacity

The measurement of the DPPH scavenging capacity was according to Brand-Williams et al. [15] and modified by Malunga and Beta [16]. Defatted cookies (10 mg) were mixed with 12 mL DPPH (8 mg/100 mL 60% aqueous methanol) reagent and incubated for 30 min. Absorbance was read at 515 nm after centrifuge (10,000 x g, 2 min at room temperature). The antioxidant capacity was calculated as the % discoloration [1-(Asample-Ablank)/(Acontrol-Ablank)]*100, and data reported as Trolox (6-hydroxy-2,5,7,8-tetramethylchoman-2-carboxylic acid) equivalent. Trolox concentration of 0, 0.625, 1.25, 2.5, 5, and 10 μM trolox were used to generate the calibration curve. The ABTS+ scavenging capacity was determined according to [16]. Absorbance was read at 734 nm and data reported as trolox equivalent as described in DPPH assay.

Phenolic Acid Content

Phenolic acids extraction was done according to Guo and Beta [17]. Fifty mg of defatted cookies with ethyl ether were mixed with 1 mL iced cold 4 M sodium hydroxide in amber tubes, flashed with nitrogen for 15–30 s, sealed and incubated at 4 °C overnight. The sample was acidified to pH 1.8 with hydrochloric acid, vortexed and centrifuged (Eppendorf 5417 C) at 10,621 x g for 10 min. The supernatant was transferred to new tubes, and 500 μL acidified water (pH 1.8) were added to the residue, vortexed, centrifuged at 10,621 g for 10 min. Fat/lipids were removed from the supernatant by adding 500 μL hexane, vortexed and the supernatant was throw away. Phenolic acids were extracted twice with 1 mL of ethyl acetate. The extracts into glass test tubes were dried with nitrogen (39 °C, 10 min). Reconstitution with 300 μL of 50% methanol/water, and filtration through a 0.2 μm filter was done previously to analysis by HPLC (Alliance 2695, Waters, Milford, MA, USA) equipped with a photodiode array detector (Waters 2996) and a 5 μm RP C18 column (250 × 4.6 mm) (Shim-pack HRC-ODS, Shimadzu, Tokyo, Japan).

Ten μL were injected and the flow rate was 0.6 mL/min with a gradient of A (0.1% acetic acid in water) and B (0.1% acetic acid in methanol) according to Guo and Beta [17]. Phenolic acid monomers were detected by using retention times of their standards at 280 nm. Standard curves (gallic, protocatechuic, p-hydrobenzoic, caffeic, vanillic, syringic, ferulic, p-coumaric, and sinapic acids) were prepared for quantitation.

Arabinoxylans Content

The arabinoxylans (AX) content was determined according to Malunga and Beta [16]. The alditol acetates (1.0 μL) were injected into an Agilent 6890 N gas chromatograph (Agilent Technologies, Santa Clara, CA, USA) equipped with a flame ionization detector by using an autosampler (Agilent Technologies 7863 series). A Supelco 2380 column (30 m × 320 μm × 0.2 μm) (Sigma-Aldrich) and helium gas at a flow rate of 0.9 mL/min were used for separation. Injection, column, and detector temperatures were 275, 275, and 250 °C, respectively, and a run time of 40 min. Monosaccharides were identified by using retention times of their standards and quantified by using the response factor of the internal standard (D-allose). AX content was calculated from: (% arabinose + % xylose) × 0.88.

Sensory Evaluation

An untrained panel of students and employees (n = 88; 46 males and 42 females) aged between 19 and 60 years participated in the sensory evaluation. Overall acceptability was measured using a 15 cm structured hedonic scale (15: Extremely like, 7.5: Neither like nor dislike, 0: Extremely dislike). Cookies baked one day before analysis were served at room temperature under normal illumination [18].

Starch Fractions and Glycemic Index

The digestible (DS), resistant (RS), and total starch (TS) contents were evaluated for the higher acceptability cookies and the control, using the Resistant Starch Assay kit (Megazyme International, Wicklow, Ireland), according to AACC [14]. The GI in vitro was determined according to the 32–40.01 method [14] and Goñi et al. [19], with some modifications. One hundred mg of each sample was suspended in 4 mL of sodium maleate buffer (100 mM, pH 6), containing pancreatic alpha-amylase (30 U/mL) and amyloglucosidase (3 U/mL), and incubated at 37 °C. Aliquots were taken every 30 min for 180 min and reaction ended with ethanol 99% (1:1, v/v). After centrifugation (1500 x g, 10 min) pellets were washed twice with ethanol 50% (v/v). The supernatants were diluted to 100 mL and D-glucose content was quantified with the GOPOD reagent (Megazyme International, Wicklow, Ireland). The hydrolysis index (HI) was the ratio between the areas under curve of the sample and the reference (white bread). The GI was estimated using the eq. GI = 39.71 + 0.549 (HI) from Goñi et al. [19].

Statistical Analysis

Differences were determined by one-way analysis of variance. Tukey-Kramer test for the multiple comparisons of means were carried out at p < 0.05, using the NCSS statistical software version 2007.

Results and Discussion

Table 1 shows the proximate composition of BSG flour, control and BSG-containing cookies. The protein content was 24.13 ± 0.38%, similar to that of other study [20]. BSG increased (p < 0.05) the protein content in the supplemented cookies according to the proportion of BSG added. The addition of 30% of BSG causes a greater improvement in the protein content of cookies. Similarly, the ash content increased with the added BSG level, while the fat content remained comparable (p > 0.05) to that of the control cookies. In a previous study, Kissell and Prentice [21] produced BSG-containing cookies with 55% more protein, 220% more fiber, and 90% more lysine than control cookies made with soft red wheat, and were within the organoleptic limitations for taste and texture.

Dough’s Physical Properties

There were significant changes in dough rheological properties among the samples (Table 2). The development time, that is the time to reach the appropriate dough consistency (500 BU), as well as the dough stability, increased with the BSG substitution level. The most important farinographic parameters for the food industry are development time, stability, mixing tolerance index, and water absorption. Desirable properties of flours are high stability and water absorption, not too long development time, and low mixing tolerance index. The development time (28.42 min) required for the 70:30 mix could be unacceptable for this industry, since that would represent higher energy cost. Starch, protein, lipids, and pentosans contribute significantly to the interactions during dough formation and development [22]. Water absorption of the wheat flour and/or their blends with BSG depends on their constituents. Besides protein content, starch damage and pentosans influence the water absorption. Differences in water absorption may be related to the chemical composition of the interacting constituents in the flour or blends.

The dough prepared with the 80:20 mix was the strongest. The protein of the BSG could promote the disulfide bonds forming relatively strong crosslinks within and between polypeptide chains and also stabilize other less energetic bonds such as hydrogen bonds and hydrophobic interactions [22]. The interpolypeptide disulfide bonds can be mobilized through the disulfide interchange reaction [23]. It seems that the interactions that occurred in the 70:30 mix did not contribute to dough strength, contrarily the resistance to mixing declined, therefore the mixing tolerance index increased. The 80:20 mix showed the highest water absorption (64.7%), an intermediate development time (23.75 min), high stability (32.85 min), and lower mixing tolerance index (7.5 BU); therefore, it is a good choice to prepare a protein enriched cookies with an increased AX content.

Cookies’ Physical Characteristics

BSG contributes to particular physical characteristics when used as additive in foods. In cookies, it tends to increase their width and thickness [24]. In this study, the supplemented cookies increased (p < 0.05) their thickness with the BSG level, but contradictory to other studies, width was reduced. This suggests an interaction between gluten and BSG proteins, increasing the dough’s elasticity, and carrying to a spring back in the cookie [25]. Color is another important parameter (Table 2), especially in “L” value (luminosity) that showed a reduction (p < 0.05); this is attributed to the brownish color of BSG. Generally, panelists give low values to darker cookies, reducing its overall acceptability [24]. Textural properties are especially important in cookies since it determines its acceptability. In this study, the addition of BSG increased cookie thickness (Table 2). The 70:30 mix gave brittle cookies (p < 0.05) than the 80:20 mix cookies because the former tended to break, being 30% the supplement limit. A significant increase in cookies hardness for 90:10 and 80:20 mixes was found. However, a decrease (p < 0.05) in the hardness of 70:30 cookies compared to 90:10 and 80:20 was observed, this difference could be due to that the 70:30 cookie became more brittle and required less force for rupture.

Cookies’ Antioxidant Capacity

Table 3 shows the antioxidant capacity of cookies by DPPH and ABTS scavenging assays. The free radical scavenging activity of control cookies was 6.7 and 100.4 μM TE/g, when using DPPH and ABTS, respectively. Antioxidant capacity of the cookies increased (p < 0.05) with BSG addition level, comparable to cookies added with different levels of barley [26]. The degree of change in antioxidant capacity was higher when using DPPH instead of the ABTS assay, probably due to differences in free radical scavenging mechanism. DPPH scavenging assay involves electron transfer whereas ABTS involves hydrogen atom transfer in addition to electron transfer. Phenolic acids are major contributors to the antioxidant capacity of cereals [27]. Consequently, bound phenolic acids are liberated prior to testing of the antioxidant capacity of cereals [28]. Recently, Malunga et al. [29] demonstrated that bound phenolic acids do exhibit antioxidant capacity. In this study, whole cookies flour was used directly to estimate their antioxidant capacity. Thus, the increase in antioxidant capacity of cookies following addition of BSG might be attributed to BSG’s insoluble-bound phenolic compounds. As far as we know, there is no report on antioxidant capacity of BSG supplemented cookies and/or its relation with its phenolic composition.

Cookies’ Phenolic Acids and Arabinoxylans Content

The phenolic acid content of cookies is presented in Table 3, where of the 9 phenolic acids screened, only p-coumaric acid and trans-ferulic acid were detected in the BSG-containing cookies (A1). BSG contains ferulic and p-coumaric acids in high concentrations [8]. In this study, BSG inclusion to cookies significantly increased (p < 0.05) the concentration of phenolic acid compared with the control. Ferulic acid (Table 3) was predominant in all cookies and varied from 419 (control) to ~3000 μg/g (30% BSG inclusion). A 10% BSG addition to cookies resulted in a three-fold increase of ferulic acid respect to control cookies. A further 1.5-fold increase in ferulic acid concentration was observed for every additional 10% BSG inclusion. The control cookies were absent of p-coumaric acid while increased from 200 to 700 μg/g according to the level of BSG addition to the cookies (A1).

Phenolic compounds of barley are mainly bound to arabinoxylans [28]; therefore, we present the arabinoxylans content following BSG inclusion (Table 4). The concentration of water extractable arabinoxylans (WEAX) did not change with BSG inclusion suggesting that BSG and wheat flour had similar WEAX content. However, the concentration of water un-extractable arabinoxylans (WUAX) increased (p < 0.05) with BSG inclusion. Like with phenolic acids, the concentration of WUAX increased by ~1.7 times with 10% increase BSG inclusion level. The degree of substitution (arabinose to xylose ratio) for WUAX decreased with addition of BSG (from 0.99 to 0.5) which suggests that degree of substitution of BSG arabinoxylans is much lower than that of wheat flour.

As it is well known the phenolic acids content and antioxidant capacity are related [7, 8, 30]. The antioxidant capacity of the cookies was highly correlated to its phenolic acid and arabinoxylans content (R = 0.95) [26]. Ferulic acid bound to arabinoxylans, as in wheat and barley, induces antioxidant capacity [29]. Thus, the association of arabinoxylans content, phenolic acid content, and antioxidant capacity of cookies could be due to feruloylated arabinoxylans. As shown above, the antioxidant capacity of BSG supplemented cookies was higher (p˂0.05) than control. The bound phenolic acids may help to scavenge oxygen reactive species and prevent propagation of lipid hydroperoxide into gastrointestinal tract [29]. In addition, ferulic acid can indirectly mediate a prebiotic modulation in gut microbiota [31]. The addition of BSG to cookies could represent important health benefit.

Cookies’ Sensory Evaluation

The results of the sensory assessment of cookies produced from wheat-BSG flour blends are shown in Fig. 1. The overall acceptability of the 90:10 and 80:20 mix cookies were 10.1 and 9.7 points in the structured hedonic scale, respectively, statistically similar (p > 0.05) to the 9.9 points of control cookies, and rated as acceptable. However, the 70:30 mix cookie was considered unacceptable (mean score of 6.8 points), because flavor and texture, possibly because the higher BSG substitution increased the bitter taste and brittle texture. Ikuomola et al. [32] found a similar result in the taste score of cookies with increased malted barley bran, attributed to the astringent taste of bitter substances as tannins.

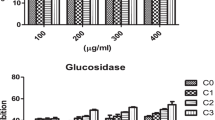

Cookies’ Starch Fractions and Glycemic Index

Table 5 presents the starch fractions, HI and GI of control and the 80:20 mix cookies, with the highest values for white bread. In comparison with the control cookie, the 80:20 mix cookie had less digestible and more resistant starch. These BSG-containing cookies presented the lowest total starch, HI (shown in A2), and GI. The GI of the control cookie of this study was 81.2, similar to the value reported by Reyes-Pérez et al. [33] for the same type of cookies. In our study, the estimated GI of the 20% BSG-containing cookies was 74.8. Reyes-Pérez et al. [33] found a GI of 68.5 for cookies with 30% addition of wheat bran. In addition to different substitution levels, the fibrous materials between the two studies are from different sources, and they were subjected to different processes, which may affect their dietary fiber content and particle size distribution. Components of fiber as cellulose, hemicellulose, and lignin, can affect the digestion of starches [34]. Contact between the substrate and the digestive enzyme decreases as the size of the fiber component increases, affecting the enzyme access due to steric hindrance [35]. Such factors contribute to different GI values of these fiber-enriched cookies.

Conclusions

The BSG is suitable to obtain protein enriched cookies with a higher AX content. The ferulic and p-coumaric acids, as well as the antioxidant capacity increased with the BSG substitution in the cookie formulation. Besides, the 20% of BSG substitution reduced the glycemic index compared to the control cookie. The 80:20 mix of wheat flour and BSG can be used to prepare value-added acceptable cookies.

Abbreviations

- ABTS:

-

2,2′-azino-bis (3-ethylbenzothiazoline-6-sulphonic acid)

- AX:

-

Arabinoxylans

- BSG:

-

Brewers´ Spent Grain

- BU:

-

Brabender Units

- DS:

-

Digestible Starch

- DPPH:

-

2,2′-diphenyl-1-picrylhydrazyl

- GI:

-

Glycemic Index

- HI:

-

Hydrolysis Index

- RS:

-

Resistant Starch

- TS:

-

Total Starch

- WEAX:

-

Water Extractable Arabinoxylans

- WUAX:

-

Water Unextractable Arabinoxylans

References

Reis SF, Gullón B et al (2014) Evaluation of the prebiotic potential of arabinoxylans from brewer’s spent grain. Appl Microbiol Biotechnol 98(22):9365–9373

Bilgiçli N, İbanogˇlu Ş, Herken EN (2007) Effect of dietary fibre addition on the selected nutritional properties of cookies. J Food Eng 78:86–89

Zucco F, Borsuk Y, Arntfield SD (2011) Physical and nutritional evaluation of wheat cookies supplemented with pulse flours of different particle sizes. LWT-Food Sci Technol 44:2070–2076

Yousaf AA, Ahmed A et al (2013) Nutritional and functional evaluation of wheat flour cookies supplemented with gram flour. Int J Food Sci Nutr 64:63–68

Ganorkar PM, Jain RK (2014) Effect of flaxseed incorporation on physical, sensorial, textural and chemical attributes of cookies. Food Res Int 21:1515–1521

Mussatto SI, Dragone G, Roberto IC (2006) Brewers’ spent grain: generation, characteristics and potential applications. J Cereal Sci 43:1–14

McCarthy AL, O’Callaghan CY et al (2012) Phenolic extracts of brewers’ spent grain (BSG) as functional ingredients-assessment of their DNA protective effect against oxidant-induced DNA single strand breaks in U937 cells. Food Chem 134:641–646

McCarthy AL, O’Callaghan C et al (2013) Brewers’ spent grain; bioactivity of phenolic component, its role in animal nutrition and potential for incorporation in functional foods: a review. Proc Nutr Soc 72:117–125

Ingerslev AK, Theil PK et al (2014) Resistant starch and arabinoxylan augment SCFA absorption, but affect postprandial glucose and insulin responses differently. Br J Nutr 111:1564–1576

Øverby NC, Sonestedt E et al (2013) Dietary fiber and the glycemic index: a background paper for the nordic nutrition recommendations 2012. Food Nutr Res 57(1):20709

Öztürk S, Özboy Ö, Cavidoglu I, Köksel H (2002) Effects of brewer’s spent grain on the quality and dietary fibre content of cookies. J I Brewing 108:23–27

Petrović JS, Pajin BS et al (2017) Quality properties of cookies supplemented with fresh brewer's spent grain. Food and Feed Research 44(1):57–63

Okpala LC, Ofoedu PI (2018) Quality characteristics of cookies produced from sweet potato and wheat flour blend fortified with brewer’s spent grain flour. Curr Res Nutr Food Sci 6(1)

AACC International (2000) Approved Methods of the American Association of Cereal Chemists, 10th Ed. St. Paul, The Association

Brand-Williams W, Cuvelier ME, Berset C (1995) Use of a free radical method to evaluate antioxidant activity. LWT-Food Sci Technol 28:25–30

Malunga LN, Beta T (2015) Antioxidant capacity of water-extractable arabinoxylan from commercial barley, wheat, and wheat fractions. Cereal Chem 92(1):29–36

Guo W, Beta T (2013) Phenolic acid composition and antioxidant potential of insoluble and soluble dietary fibre extracts derived from select whole-grain cereals. Food Res Int 51:518–525

Pedrero DL, Pangborn RM (1989) Evaluación sensorial de los alimentos. Métodos analíticos. Editorial Alhambra Mexicana. D.F. México

Goñi I, Garcia-Alonso A, Saura-Calixto F (1997) A starch hydrolysis procedure to estimate glycemic index. Nutr Res 17(3):427–437

Santos M, Jiménez JJ, Bartolomé B et al (2003) Variability of brewer’s spent grain within a brewery. Food Chem 80:17–21

Kissel LT, Prentice N (1979) Protein and fiber enrichment of cookie flour with brewer’s spent grain. Cereal Chem 56(4):261–266

Bushuk, W (1998) Interaction in wheat doughs. In: Interactions: The keys to cereal quality, 1st edn. American Association of Cereal Chemists, Inc., St. Paul, Minnesota, pp 8–16

Goldstein S (1957) Sulfydryl- und disulfidgruppen der Klebereiweisse und ihre beziehung zur backfahigkeit der brotmehle. Mitt. Geb. Lebensmittel Unters Hyg 48:87–93

Ajanaku KO, Dawodu FA et al (2011) Functional and nutritional properties of spent grain enhanced cookies. Am J Food Technol 6(9):763–771

Sharif K, Butt MS, Huma N (2005) Oil extraction from rice industrial waste and its effect on physico-chemical characteristics of cookies. Nutrition Food Science 35(6):416–427

Sharma P, Gujral HS (2014) Cookie making behavior of wheat-barley flour blends and effects on antioxidant properties. LWT-Food Sci Technol 55:301–307

Adom KK, Liu RH (2002) Antioxidant activity of grains. J Agric Food Chem 50:6182–6187

Masisi K, Beta T, Moghadasian MH (2016) Antioxidant properties of diverse cereal grains: a review on in vitro and in vivo studies. Food Chem 196:90–97

Malunga LN, Izydorczyk M, Beta T (2017) Effect of water-extractable arabinoxylans from wheat aleurone and bran on lipid peroxidation and factors influencing their antioxidant capacity. Bioact Carbohydr Diet Fibre 10:20–26

Reis SF, Abu-Ghannam N (2014) Antioxidant capacity, arabinoxylans content and in vitro glycaemic index of cereal-based snacks incorporated with brewer's spent grain. LWT-Food Sci Technol 55(1):269–277

Costabile A, Klinder A, Fava F et al (2007) Whole-grain wheat breakfast cereal has a prebiotic effect on the human gut microbiota: a double-blind, placebo-controlled, crossover study. Br J Nutr 99:110–120

Ikuomola DS, Otutu OL, Oluniran DD (2017) Quality assessment of cookies produced from wheat flour and malted barley (Hordeum vulgare) bran blends. Cogent Food Agric 3(1):1293471

Reyes-Pérez F, Salazar-García MG et al (2013) Estimated glycemic index and dietary fiber content of cookies elaborated with extruded wheat bran. Plant Foods Hum Nutr 68:52–56

Lattimer JM, Haub MD (2010) Effects of dietary fiber and its components on metabolic health. Nutrients 2:1266–1289

Sajilata MG, Singhal RS, Kulkarni PR (2006) Resistant starch–a review. Compr Rev Food Sci Food Saf 5:1–17

Acknowledgements

The authors gratefully acknowledge María Teresa Zúñiga Ramos, Maribel Yael Valencia Tapia, Yésica Martínez Nuñez, as well as Cervecería Cuauhtémoc-Moctezuma, S. A. de C.V., Navojoa, Sonora, México.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no conflict of interest in submission of this manuscript.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic Supplementary Material

ESM 1

(DOCX 60 kb)

Rights and permissions

About this article

Cite this article

Heredia-Sandoval, N.G., Granados-Nevárez, M., Calderón de la Barca, A.M. et al. Phenolic Acids, Antioxidant Capacity, and Estimated Glycemic Index of Cookies Added with Brewer’s Spent Grain. Plant Foods Hum Nutr 75, 41–47 (2020). https://doi.org/10.1007/s11130-019-00783-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11130-019-00783-1