Abstract

The aim of this work was to evaluate copper-chelating, iron-chelating and anticariogenic activity of peptides obtained by enzymatic hydrolysis of P. columbina protein concentrate and to study the effects of chelating peptides on iron bio-accessibility. Two hydrolyzates were obtained from P. columbina protein concentrate (PC) using two hydrolysis systems: alkaline protease (A) and alkaline protease + Flavourzyme (AF). FPLC gel filtration profile of PC shows a peak having molecular weight (MW) higher than 7000 Da (proteins). A and AF hydrolyzates had peptides with medium and low MW (1013 and 270 Da), respectively. Additionally, AF presented free amino acids with MW around 82 Da and higher content of His and Ser. Peptides from AF showed the highest chelating properties measured as copper-chelating activity (the lowest β-carotene oxidation rate: R o ; 0.7 min−1), iron-chelating activity (33 %), and phosphorous and Ca2+ release inhibition (87 and 81 %, respectively). These properties could indicate antioxidant properties, promotion of iron absorption and anticariogenic activity, respectively. In fact, hydrolyzates promoted iron dialyzability (≈16 %), values being higher than that found for P. columbina seaweed. Chelating peptides from both hydrolyzates can maintain the iron in a soluble and bio-accessible form after gastrointestinal digestion.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Bioactive peptides range in size from 2 to 20 amino acid residues and are encrypted within the sequence of the parent protein and only become active when released [1]. Depending on the amino acid sequence, marine algae-derived bioactive peptides may be involved in various biological functions, including antioxidant, antihypertensive, and immunomodulatory effects [2].

Metals are capable of producing reactive oxygen species (ROS) causing damage to biomolecules, and are involved in a variety of pathologic situations (e.g., mutation, carcinogenesis, degenerative and cardiovascular diseases, inflammation, aging) [3]. In addition, ROS have a negative impact in flavor, texture, nutritive value, as well as shelf life of food products and, under extreme conditions, produce toxins. Chelating peptides may prevent this pro-oxidant effect by metal ion chelation, acting as antioxidant [4]. On the other hand, low iron bioavailability food represents a nutritional problem for different sectors of the population such as children, the elderly, and women in the first world [5]. Food fortification with the addition of minerals in the form of iron salts has been proposed to reduce these deficiencies [6]. However, this has some limitations such as low salt solubility, oxidative reactions and modification of the flavor and color of the fortified food. Moreover, bioavailable iron compounds are the most reactive with food matrix, restricting their use to certain foods and decreasing shelf life. In order to increase iron bio-accessibility, enhancers could be used [7]. In this regards, chelating peptides may be an alternative to increase mineral bioavailability. Besides, the positive effect of chelating serin-phosphopeptides derived from milk proteins, on the absorption of calcium has been reported [8]. Furthermore, early studies demonstrated that serin-phosphopeptides were effective anticariogenic compounds due to their chelating ability [9].

Recently, Cian et al. [10] used the same hydrolysis systems to obtain bioactive peptides from P. columbina protein fraction. In that work, the authors found that hydrolyzates had copper chelating peptides with good antioxidant activity. However, no research about other chelating properties of peptides, such as preventing dental caries formation and promoting iron bio-accessibility during in vitro gastrointestinal digestion were studied. Therefore, the aim of this work was to evaluate the copper-chelating, iron-chelating and anticariogenic activity of peptides obtained by enzymatic hydrolysis of P. columbina protein concentrate and to study the effects of chelating peptides on iron bio-accessibility.

Materials and Methods

Reagents were obtained from Sigma Chemical Co. (St. Louis, MO, USA). The alkaline protease (EC 3.4.21.62) was provided by Danisco S.A. (Arroyito, Córdoba, República Argentina) and Flavourzyme (EC 3.4.11.1) was obtained from Sigma Chemical Co. (USA).

Raw materials were hand-picked in Punta Maqueda (Comodoro Rivadavia, Argentina). One kilogram of different specimens of P. columbina was processed according to Cian et al. [11].

Protein concentrate (PC) was prepared dispersing 50 g/kg in distilled water for 2 h and filtered through a filter of 0.297 mm. The filtrated was then centrifuged at 3000×g for 30 min at 4 °C and the supernatant was concentrated using Buchii RII rotary evaporator at low pressure and 30 °C, during 15 min. The protein concentrate (PC) having 1.4 g protein/100 g was frozen until it was used as substrate for enzymatic hydrolysis.

Protein hydrolyzates (A and AF) were obtained using 800 mL batch thermostatic reactor. The reaction pH was continuously measured using pH-meter IQ Scientific Instruments, and adjusted by adding base (NaOH, 2 mol/L) or acid (HCl, 2 mol/L) with a burette. Substrate concentration was 1.4/100 g dispersion. Working conditions for the enzymes were: temperature 55 °C, pH 9.5, enzyme⁄substrate (E⁄S) ratio 0.4/100 g for alkaline protease and temperature 55 °C, pH 7.0, enzyme⁄substrate (E⁄S) ratio 5/100 g for Flavourzyme.

PC hydrolyzates were prepared using the following systems: Simple hydrolysis system: Hydrolyzate A (hydrolysis with alkaline protease during 2 h) and sequential hydrolysis system: Hydrolyzate AF (hydrolysis with alkaline protease 2 h + hydrolysis with Flavourzyme during 4 h; total reaction time, 6 h). Once the hydrolysis was finished, the enzymes were inactivated by thermal treatment following the manufacturer guidelines and the hydrolyzates were centrifuged at 2000×g for 15 min at 4 °C. The supernatant obtained was lyophilized.

Free amino groups were measured using o-phthaldialdehyde, according to Nielsen et al. [12] and expressed as mEq L-Serine/100 g solids. The degree of hydrolysis (DH) was calculated as:

Where: h tot is the total number of peptide bonds in the protein substrate (8.6 mEq/g protein); h is the number of peptide bonds cleaved during hydrolysis, and h 0 is the content of free amino groups of substrate. h tot was calculated taking into account the amino acid profile of protein concentrate.

Characterization of PE and PE Hydrolyzates

Chemical composition was determined using the AOAC procedures [13]. Proteins were determined by the Kjeldahl method (N × 6.25).

Fast protein liquid chromatography (FPLC) was carried out in an AKTA Prime system equipped with a Superdex peptide column (GE Life Sciences, Piscataway, NJ, USA). Injection volume was 100 μL (5.8 mg protein/mL) and elution was carried out using 0.75 mol/L ammonium bicarbonate at 1 mL/min. Elution was monitored at 214 nm and molecular mass was estimated using molecular weight (MW) standards from Pharmacia: blue dextran (2,000,000 Da), cytochrome C (12,500 Da), aprotinin (6512 Da), bacitracin (1450 Da), cytidine (246 Da) and glycine (75 Da).

Amino acid analysis was made according to Alaiz et al. [14]. Samples (15 mg), containing 3–5 mg of protein were hydrolyzed with 1.5 mL of 6 mol/L HCl. The solutions were sealed in tubes under nitrogen and incubated in an oven at 110 °C for 24 h. Amino acids were determined after derivatization with diethyl ethoxymethylenemalonate by high-performance liquid chromatography (HPLC), using D,L-α-aminobutyric acid as internal standard. The HPLC system consisted of a Model Agilent 1100 Series with a VWD detector (Santa Clara, CA, USA) equipped with a 300 × 3.9 mm i.d. reversed-phase column (Novapack C18, 4 m; Waters). A binary gradient was used for elution with a flow of 0.9 mL/min. The solvents used were (A) sodium acetate (25 mmol/L) containing sodium azide (0.02 g/100 mL) pH 6.0 and (B) acetonitrile. Elution was as follows: time 0.0–3.0 min, linear gradient from A/B (91/9) to A/B (86/14); 3.0–13.0 min, elution with A/B (86/14); 13.0–30.0 min, linear gradient from A/B (86/14) to A/B (69/31); 30.0–35.0 min, elution with A/B (69/31). Eluted amino acids are detected at 280 nm. The column was maintained at 18 °C. Tryptophan was determined by HPLC-RP chromatography after basic hydrolysis according to Yust et al. [15].

Chelating Properties

Copper-chelating activity by assay of β -carotene oxidation (CCA) was determined by the assay of β-carotene oxidation according to Megías et al. [16]. The assay mixture was 200 μL of 10 g/L β-carotene, 10 μL of 50 μmol/L CuSO4, and 200 μL samples. The concentration of samples was 13 g/L of protein. The degradation of β-carotene was monitored by recording the decrease in absorbance at 470 nm. Absorbance was measured at 0, 30, 60, 90, 120, 150 and 180 min. A positive control (200 μL β-carotene + 10 μL CuSO4) and a negative control (200 μL β-carotene + 10 μL buffer phosphate) were run. To determine the inhibition rate (Ro), the results of β-carotene degradation at 470 nm vs. time were fitted with the following exponential decay equation:

Where: y is absorbance at 470 nm, t is time, y o and A are the regression parameters, and R o is the oxidation rate. R o measures the speed which β-carotene is oxidized, and indirectly the copper chelating capacity. Determinations were carried out in triplicate.

Iron-chelating activity (ICA) was determined by mixing 50 μL of sample with 50 μL of 8 mg/L iron solution and incubating 30 min at room temperature. The assay mixture was adjusted to 300 μL with 150 mmol/L pH 4.5 acetate buffer, containing 0.03 mmol/L of ascorbic acid. A 200 μmol/L solution of ferrozine was prepared and 50 μL were added to assay mixture. The absorbance at 560 nm was measured at 5 min after ferrozine addition. The concentration of samples was 13 g/L of protein. A negative control with 50 μL of 8 mg/L iron solution + 250 μL acetate buffer + 50 μL of ferrozine was run. Determinations were carried out in triplicate and the iron-chelating activity was calculated as:

Anticariogenic activity was determined mixing 20 mg of hydroxyapatite with 10 mL of 0.1 mol/L pH 7.0 Tris buffer, during 5 min. Then, 4 mL of sample (8.8 g/L protein) were added to assay mixture and stirred during 20 min. Subsequently, 10 mL of 0.4 mol/L pH 4.2 acetate buffer was added, mixed for another 20 min, and centrifuged at 4500×g for 5 min at 24 °C. A positive control with 20 mg hydroxyapatite + 14 mL Tris buffer + 10 mL acetate buffer, and a control sample with 10 mL Tris buffer + 4 mL sample + 10 mL acetate buffer were run. The calcium and phosphorous content from supernatant were determined according to Itoh and Ueno [17] and AOAC [13] procedures, respectively. Determinations were carried out in triplicate and the anticariogenic activity was calculated as inhibition of Ca2+ and P release [18]:

Where: CS is the Ca2+ or P content of sample system, CCS is the Ca2+ or P content of control sample, and CC(+) is the Ca2+ or P content of positive control.

Effect of A and AF Chelating Peptides on Iron Bio-accessibility

The iron bio-accessibility was assayed using the method developed by Miller et al. [19] modified by Drago et al. [20]. This method measures mineral dialyzability under controlled pH conditions after a digestion simulating physiological process (pepsin and pancreatin), using a dialysis membrane (cut off 6–8 kDa). Two model systems using FeSO4 were prepared containing 25 mL of 16 mg Fe/L + 4.8 g protein /L of A hydrolyzate and 25 mL of 16 mg Fe/L + 4.8 g protein/L of AF hydrolyzate. The dispersions were mixed and shaken overnight at 4 °C. The test was performed twice by triplicate and the iron dialyzability was calculated as the amount of iron dialysate expressed as a percentage of total iron content in the sample:

Where: FeD (%) is the percentage of iron dialysated, mg ID is mg of iron dialysated, and mg IS is mg of iron of the sample. Dialyzability was used as an indicator of potential iron bio-accessibility. Total mineral content of sample was measured by atomic absorption spectroscopy after dry mineralization. Ash was removed with 20 % HCl (v/v). An atomic absorption spectrometer (atomic absorption spectrophotometer analyst 300 Perkin-Elmer, Norwalk, CT, USA) was used.

Statistical Analysis

All results were expressed as mean ± SD. The data were considered by one-way analysis of variance, using the software Statgraphics Plus 3.0. The statistical differences between samples were determined using the LSD (least significant difference) test. The significance was established at P < 0.05.

Results and Discussion

Characterization of A and AF Hydrolyzates

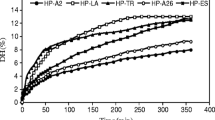

In the present study, PC was hydrolyzed by alkaline protease (A) or sequentially hydrolyzed by alkaline protease + Flavourzyme (AF), resulting in 13.7 and 19.7 % degree hydrolysis (DH) for A and AF, respectively. The higher DH of AF system is attributed to the addition of Flavourzyme enzyme, which is a mixture of endo- and exopeptidases. Both enzymes (endo- and exopeptidases) are able to hydrolyze proteins in a more efficient way than an endoprotease alone [21].

Free amino group content of PC, A and AF was 133.1, 164.1 and 209.0 mEq/100 g of solids, respectively. The relatively high free amino group content of PC may be due to mycosporine-like amino acids (MAAs) naturally presents in red seaweeds [1]. As expected, A and AF had significantly higher (P < 0.05) free amino group content than PC. This increase is due to proteolysis action of alkaline protease or/and Flavourzyme. Also, AF free amino group content was higher than that obtained for A. As mentioned before, Flavourzyme has exopeptidase activity, favoring the rapid release of free amino acids and di- and tri- peptides that contributes to increase free amino group [21].

Table 1 shows amino acid profile of PC and its hydrolyzates. Glu, Asp and Ala were the most abundant amino acids. Similar results were obtained for other red seaweeds such as Palmaria palmata [22]. Alanine was present in high levels in PC, A and AF. Also, AF hydrolyzate had higher content of His and Ser than PC and A. In this sense, the His content was 1.4 times higher for AF than PC. On the other hand, A hydrolyzate had higher content of Val, Met and Cys than PC and AF. FPLC gel filtration profile of A and AF hydrolyzate showed effective protein degradation by enzymatic hydrolysis process of PC components (>7000 Da), generating intermediate and low molecular weights (MW) species in A and AF hydrolyzate, respectively (ESM 1b and c). The peak of 270 Da in AF hydrolyzate profile probably corresponds to small peptides generated by Flavourzyme. This fraction could be formed by di-peptides, considering 120 Da the average MW of amino acids. Also, AF hydrolyzate profile showed a peak of 82 Da which could correspond to free amino acids. These results showed both hydrolyzates presented differences respect to DH, size of the peptides, and amino acid composition.

Chelating Properties

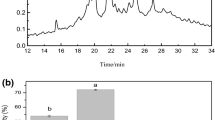

ESM 2a shows the oxidation of β-carotene (measured as decrease in absorbance at 470 nm) vs. time, for negative (without Cu2+) and positive (with Cu2+) controls and samples (PC, A, and AF). For negative control as time reaction increases, absorbance at 470 nm decreases slightly. This is due to autoxidation of β-carotene initiated by light in the presence of oxygen or by peroxides [16]. However, for positive control the absorbance at 470 nm decreases rapidly with the reaction time, indicating the strong oxidation of β-carotene catalyzed by copper.

The oxidation rate (R o ) were 1.8; 1.2 and 0.7 min−1 for PC, A and AF, respectively. As can be seen, AF hydrolyzate showed higher copper-chelating activity (CCA) than A with the lowest R o , indicating that size and amino acid composition of peptides affected this property. Note that R o measures the speed which β-carotene is oxidized. Torres-Fuentes et al. [5] reported that a combination of high His content, around 20–30 %, and small peptide size provide the best chelating activities. In this sense, the His content of AF was higher than that obtained for A and also lower MW components (around 270 Da) were present. Thus, His residues and di-peptides should be involved in the formation of complexes with Cu2+ and thus decreasing β-carotene oxidation.

In agreement with CCA, AF hydrolyzate showed the highest iron-chelating activity (ESM 2b). As happen for CCA, this activity depends on the sequence and size of peptides. In this regard, Guo et al. [23] identified by electrospray ionization tandem mass spectrometry (LC–ESI-MS/MS) one tri-peptide from alaska pollock skin with high iron-chelating activity. The amino acid sequence of this peptide was identified as Ser-Cys-His (345 Da). Also, Wang et al. [24] found that Asn-Cys-Ser peptide from sesame protein hydrolyzates showed the highest Zn2+ and Fe2+ chelating ability, which was even higher than that of reduced glutathione. Therefore, the iron-chelating activity of AF could be due to the lower MW peptides having higher content of His and Ser (Table 1).

As shown in ESM 3, AF hydrolyzate had the highest anticariogenic activity, inhibiting Ca2+ and P release more efficiently than A. His content of AF was higher than that found for A (Table 1) and both were higher than that of PC. The difference on demineralization from hydroxyapatite among samples can be due to a buffer effect of His imidazole group, which pKa is 6.04. Thus, the amount of His and amino acid sequence of peptides generated by proteolysis would be involved in anticariogenic activity. Adamson and Reynolds [25] reported that casein phosphopeptides have a cluster with a sequence of three PO4 2−-Ser and two Glu, which stabilize amorphous calcium phosphate and acts as a buffer in the Ca2+ and P releasing. In this sense, FPLC profile of AF hydrolyzate showed a peak of 82 Da (free amino acids), which could act as a buffer in the Ca2+ and P release.

Iron dialyzability (FeD %) was 15.87 and 16.82 % for A and AF, respectively. These values were higher than that obtained for Cian et al. [26] for P. columbina seaweed (2.63 %) using the same methodology. The high values of iron bio-accessibility can be attributed to iron chelating peptides, which are able to maintain the iron in a soluble and bio-accessible form. As mentioned before, AF peptides had higher copper-chelating activity (CCA), iron-chelating activity (ICA) and anticariogenic activity than A peptides. However, for iron dialyzability no significant difference (P > 0.05) between both hydrolyzates was found, indicating that new peptides generated by gastrointestinal digestion from A and AF hydrolyzates have similar capacity for maintain iron in a soluble and bio-accessible form.

Conclusions

We have demonstrated that chelating peptides of P. columbina hydrolyzate obtained with sequential hydrolysis system (AF) have high copper-chelating activity, iron-chelating activity and Ca2+ and P release inhibition. These properties could indicate antioxidant properties, promotion of iron absorption and anticariogenic activity, respectively. AF presented better chelating properties than A hydrolyzate. Differences between both samples regarding degree of hydrolysis, size of the peptides, and amino acid composition can explain these results. Additionally, A and AF hydrolyzates have peptides that promote iron bio-accessibility under simulated gastrointestinal digestion. Chelating peptides from both hydrolyzates can maintain the iron in a soluble and bio-accessible form after gastrointestinal digestion.

Abbreviations

- PC:

-

Pyropia columbina protein concentrate

- A:

-

Hydrolyzate obtained with alkaline protease during 2 h

- AF:

-

Hydrolyzate obtained with alkaline protease 2 h + Flavourzyme 4 h

References

Harnedy P, Fitzgerald R (2011) Bioactive proteins, peptides and amino acids from macroalgae. J Phycol 47:218–232

Fan X, Bai L, Zhu L, Yang L, Zhang X (2014) Marine algae-derived bioactive peptides for human nutrition and health. J Agric Food Chem 62:9211–9222

Orsini Delgado M, Galleano M, Añón M, Tironi V (2015) Amaranth peptides from simulated gastrointestinal digestion: antioxidant activity against reactive species. Plant Foods Hum Nutr 70:27–34

Cian R, Martínez-Augustin O, Drago S (2012) Bioactive properties of peptides obtained by enzymatic hydrolysis from protein byproducts of Porphyra columbina. Food Res Int 49:364–372

Torres-Fuentes C, Alaiz M, Vioque J (2011) Affinity purification and characterization of chelating peptides from chickpea protein hydrolyzates. Food Chem 129:485–490

Zhu L, Glahn R, Yeung C, Miller D (2006) Iron uptake by caco-2 cells from NaFeEDTA and FeSO4: effects of ascorbic acid, pH, and a Fe(II) chelating agent. J Agric Food Chem 54:7924–7928

Bernardi C, Drago SR, Sánchez H, Freyre (2006) Formulation and sensory evaluation of Prosopis alba (Algarrobo) pulp cookies with increased iron and calcium dialyzabilities. Plant Foods Hum Nutr 61:37–42

Cross K, Huq L, Reynolds E (2007) Casein phosphopeptides in oral health-chemistry and clinical applications. Curr Pharm Des 13:793–800

Aimutis W (2004) Bioactive properties of milk proteins with particular focus on anticariogenesis. J Nutr 134:989–995

Cian R, Garzón A, Betancur-Ancona D, Chel-Guerrero L, Drago S (2015) Hydrolyzates from Pyropia columbina seaweed have antiplatelet aggregation, antioxidant and ACE I inhibitory peptides which maintain bioactivity after simulated gastrointestinal digestion. LWT Food Sci Technol 64:881–888. doi:10.1016/j.lwt.2015.06.043

Cian R, Salgado P, Drago S, González R, Mauri A (2014) Development of naturally activated edible films with antioxidant properties prepared from red seaweed Porphyra columbina biopolymers. Food Chem 146:6–14

Nielsen P, Petersen D, Dambmann C (2001) Improved method for determining food protein degree of hydrolysis. J Food Sci 66:642–646

AOAC (1995) Official methods of analysis, 16th edn. Horowitz, Washigton DC

Alaiz M, Navarro J, Giron J, Vioque E (1992) Amino acid analysis by high-performanceliquid chromatography after derivatization with diethylethoxymethylenemalonate. J Chromatogr A 591:181–186

Yust M, Pedroche J, Girón-Calle J, Vioque J, Millán F, Alaiz M (2004) Determination of tryptophan by high-performance liquid chromatography of alkaline hydrolyzates with spectrophotometric detection. Food Chem 85:317–320

Megías C, Pedroche J, Yust M, Girón-Calle J, Alaiz M, Millán F, Vioque J (2008) Production of copper-chelating peptides after hydrolysis of sunflower proteins with pepsin and pancreatin. LWT Food Sci Technol 41:1973–1977. doi:10.1016/j.lwt.2007.11.010

Itoh A, Ueno K (1970) Evaluation of 2-hydroxy-1-(2-hydroxy-4-sulpho-1-naphthylazo)-3-naphthoic acid and hydroxynaphthol blue as metallochromic indicators in the EDTA titration of calcium. Analyst 95:583

Warner E, Kanekanian A, Andrews A (2001) Bioactivity of milk proteins: 1. Anticariogenicity of whey proteins. Int J Dairy Technol 54:151–153

Miller D, Schricker B, Rasmussen R, Van Campen D (1981) An in vitro method for estimation of iron availability from meals. Am J Clin Nutr 34:2248–2256

Drago S, Binaghi M, Valencia M (2005) Effect of gastric digestion pH on iron, zinc and calcium availability from preterm and term starting infant formulas. Food Sci 70:107–112

Chang C, Wu K, Chiang S (2007) Antioxidant properties and protein compositions of porcine haemoglobin hydrolyzates. Food Chem 100:1537–1543

Fleurence J (1999) Seaweed proteins: biochemical, nutritional aspects and potential uses. Trends Food Sci Technol 10:25–28

Guo L, Hou H, Li B, Zhang Z, Wang S, Zhao X (2013) Preparation, isolation and identification of iron-chelating peptides derived from Alaska pollock skin. Process Biochem 48:988–993

Wang C, Li B, Ao J (2012) Separation and identification of zinc-chelating peptides from sesame protein hydrolysate using IMAC-Zn2+ and LC–MS/MS. Food Chem 134:1231–1238

Adamson N, Reynolds E (1995) Characterization of multiply phosphorylated peptides selectively precipitated from a pancreatic casein digest. J Dairy Sci 78:2653–2659

Cian RE, Fajardo MA, Alaiz M, Vioque J, González RJ, Drago S (2014) Chemical composition, nutritional and antioxidant properties of the red edible seaweed Porphyra columbina. Int J Food Sci Nutr 65:299–305

Acknowledgments

The authors are thankful to CAI + D 2011 PI 0292 LI and PRODEP-SEP: Hydrolyzates and Bioactive Peptides network for the financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no conflicts of interest.

Human and Animal Rights

This article does not contain any studies with human or animal subjects.

Rights and permissions

About this article

Cite this article

Cian, R.E., Garzón, A.G., Ancona, D.B. et al. Chelating Properties of Peptides from Red Seaweed Pyropia columbina and Its Effect on Iron Bio-Accessibility. Plant Foods Hum Nutr 71, 96–101 (2016). https://doi.org/10.1007/s11130-016-0533-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11130-016-0533-x