Abstract

The complete procedure for the production of inulin powder from Jerusalem artichoke tubers (JAT) was investigated. The procedure consists of isolation of inulin from JAT, elimination of color from the inulin extract and solidification. Washed tubers were first sliced, dried in a 60 °C oven for 10 h and then milled and sieved into a powder. Inulin was isolated from the JAT powder by hot water extraction using an accelerated solvent extractor (ASE). The effects of temperature and time for the extraction were investigated. The highest extraction efficiency was obtained at the extraction temperature of 80 °C for 20 min. The color of the extract was eliminated using ion exchange process with diethylaminoethyl cellulose as the sorbent. The inulin powder was subsequently obtained by freeze drying. Inulin content and inulin profiles were monitored to evaluate the efficiencies of the complete procedure. The inulin content was indirectly determined by spectrophotometry from free and total fructose measurements using potassium iodide. The inulin profile was monitored using high performance anion exchange chromatography equipped with integrated pulse amperometric detection (HPAEC−PAD). The proposed method provided the inulin production yield of 92.5 %. The present procedure is fast, simple and effective for production of inulin powder from JAT. In addition, infrared spectra and some physico−chemical properties of the obtained inulin powder were determined and compared with the standard inulin.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Inulin is one group of fructans or fructooligosaccharides which are linear polymers of D−fructose joined by β (2→1) linkages and terminated with a single D−glucose which is linked to D−fructose by an α (1→2) linkage [1–3]. The chain length of D−fructose, known as degree of polymerization (DP), varies from 2−60 [4–6]. The DP of inulin depends on various parameters including specific varieties of plants, harvest time, storage time after harvesting and the production procedure for isolating inulin [6–8]. Inulin has a number of interesting properties that can be applied in various fields. Inulin is a functional food “ingredient” since it can be used as a prebiotic agent [9], can stimulate health−promoting gut microflora [10, 11] and may reduce the risk of cancer [9, 12]. Pharmaceutical and cosmetics applications of inulin have been described [13, 14]. For energy production, inulin is an appropriate source for production of ethanol through fermentation [15, 16].

Inulin is found mainly in the tubers and roots of many plants, such as Chicory artichoke (Cynara scolymnus L.), viper’s grass (Scorzonera hispanica L.), Jerusalem artichoke (Helianthus tuberosus L.), globe artichoke (Cynara cardunculus var. scolymus) [17], Yacon (Smallanthus sonchifolius) [18] and dahlia tubers (Dahlia Pinata Cav.) [9, 19]. Inulin is mostly commercialized as a powder, known as Beneo HP [5] and Raftilin®ST or Fibruline [9, 10]. So far, the major crop used for industrial production of inulin is chicory [2, 20]. However, the Jerusalem artichoke tuber has a large amount of inulin, ca. 14–19 % [2, 5, 21], so it should be a valuable source for inulin production. However, the production of inulin from Jerusalem artichoke tuber has not progressed significantly because it has an undesirable flavor, significant color and limited harvest time [22].

Inulin is isolated from plants using extraction based methods. An important physico−chemical property of pure inulin is that it is almost insoluble in cold water, but highly soluble in hot water [20]. Therefore, one of the most common methods for isolation of inulin from plants is hot water extraction. Conventionally, inulin is extracted from Chicory roots by hot water at 70−80 °C in continuous counter current extractors with an extracting time of 1.5−2 h [23]. The technology of inulin extraction from Chicory root is similar to the saccharose extraction from sugar beets [23]. The extraction of inulin from Jerusalem artichoke is similar to the other plants. The conventional procedure is hot water extraction at various temperatures and times such as extraction at 80 °C with mild shaking for 3 h [24], at 80 °C for 1.5 h [25] and 80 °C for 1 h [26]. Recently, ultrasound−assisted extraction has been introduced as a powerful tool for extraction of inulin from various plant tissues. It applies high−frequency and high−intensity sound waves to interact with materials [2, 19]. Ultrasound disrupts plant cell walls thereby facilitating the release of extractable compounds and enhancing mass transport of solvent from the continuous phase into plant cells [13]. The ultrasound assisted extraction of inulin from JAT was reported using extraction temperature at 76.65 °C for 20 min [2]. Nevertheless, it is considered unsuitable for inulin extraction on the large scale. An alternative method for isolation of inulin is the precipitation of inulin by alcohol. This method is efficient and widely used in laboratory. However, it was uneconomical and unsuitable on an industrial scale [2]. More recently, various strategies have been employed to obtain high extraction efficiency for inulin isolation such as pulsed electric fields (PEF) [27] and three−stage homogenate extraction (TSHE) [26]. Another strategy using high pressure for extraction, known as pressurized liquid extraction (PLE) or accelerated solvent extraction (ASE) has been successfully applied for the isolation of interest compounds from various plants such as peperine from pepper and bioactive molecules from Hypericum perforatum L. [28–30]. ASE allows efficient performance, rapid extraction at high temperature and high pressure, minimizing solvent consumption and sample manipulation. To our knowledge, there are no reports of using ASE for the extraction of inulin from plants.

The present study is aimed at investigating the production procedure of inulin powder from Jerusalem artichoke tuber. Besides, high efficiency, rapid and cost effective, the minimizing of inulin degradation during the production is considered. Inulin was extracted from Jerusalem artichoke powder by ASE using water as the extraction solvent. The extract was then subjected to a chromatographic process for elimination of color. Inulin powder was obtained after freeze drying. Inulin content and inulin profile were monitored for all processes. Instrumental analyses of inulin powder by IR and SEM are also reported.

Materials and Methods

Chemicals and Reagents

All chemicals and reagents were of analytical reagent grade. These included sodium hydroxide, potassium iodide, sodium periodate and sodium acetate (Carlo Erba, Rodano, Italy); methanol (Lab-Scan, Bangkok, Thailand); silica gel (0.06 mm for chromatography, Carlo Erba, Val de Reuil, France); diethylaminoethyl cellulose (Sigma, Singapore); barium acetate (Carlo Erba, Val de Reuil, France); citric acid; concentrated hydrochloric acid, and concentrated sulfuric acid (Carlo Erba, Val de Reuil, France), anhydrous D-(−)-fructose and D-(+)-glucose (Univar, New South Wales, Australia). Standards fructooligosaccharide (1-kestose (n = 3) and nystose (n = 4)) were obtained from Fluka. Standard inulin from chicory was purchased from Sigma. All aqueous solutions were prepared using deionized water from RiOsTM Type I Simplicity 185 (Millipore, USA) with the resistivity of 18.2 MΩ.cm.

Intrumentations

The spectrophotometric experiments were carried out on an Agilent 8453 UV−Vis spectrophotometer (Germany). Chromatographic separations were performed on a Dionex DX−500 Ion Chromatographic system (Sunnyvale, USA), consisting of a GP40 gradient pump and an ED 40 electrochemical detector equipped with a thin−layer type amperometric cell. The cell contained a 1.0−mm diameter gold working electrode and a platinum counter electrode in integrated pulse amperometric detection mode (PAD). The separations were performed on a CarboPac PA 1 column set comprised of a guard column (50 × 4 mm i.d.) and analytical column (250 × 4 mm i.d.). The injection volume was 25 μL. Data acquisition and data analysis were under the control of the PeakNet 6.0 Dionex software. The accelerated solvent extractor model ASE−200 (Dionex, USA) with a 22 mL extraction cell and a 30 mL collection cell, was used for the extraction of inulin from Jerusalem artichoke tuber powder. An Isotemp oven (Fisher Scientific, UK) was used for the drying of Jerusalem artichoke tubers. The freeze dryer model ScanSpeed MaxiVac (Scientific, Germany) was employed for preparation of inulin powder. PerkinElmer, Spectrum One (USA), Fourier transform infrared spectroscopy (FT−IR) was used for IR spectra. Microphotographs were obtained using Scanning electron microscopy (Hitachi, S−3000N, Akishima, Tokyo, Japan).

Sample Preparation

Jerusalem artichoke tubers were washed with tap water to eliminate soil and then were longitudinally sliced to obtain approximately 2−mm thick pieces. The tubers were dried at 60 °C for 10 h in an oven, milled and sieved through an 850−μm sieve. The powdered tubers were kept for short periods of time at an ambient atmosphere in desiccators, until extraction.

Procedure

Extraction of Inulin from Jerusalem Artichoke Powder by ASE

Accurate weight (2 g) of JA powder along with silica gel (3.6 g) was placed into an extraction cell. The powders were then automatically extracted with water (as the extraction solvent) for 20 min at 80 °C and 1500 psi, controlled by the ASE time program. All experiments were conducted in triplicate.

Elimination of Color of the Inulin Extract

The extract was passed through a glass column (15 cm × 1 cm ID) packed with 15 g of diethylaminoethyl cellulose (DEAE−cellulose) at a flow rate 2 mL min−1, water was used as the eluent.

Determination of Inulin Content by Spectrophotometry

Determination of Free Fructose Content (Ff )

The extract (150 μL) was pipetted into 10 mL volumetric flask containing 20 mmol L−1 citrate buffer 6 (5 mL) and diluted to 10 mL with water. After 5 min, 100 mmol L−1 potassium iodide (150 μL) was added, and mixture was left for an additional 5 min. The absorbance was subsequently measured at 350 nm using a UV−Vis spectrophotometer. The concentration of free fructose was deduced from a calibration curve of standard fructose solutions.

Determination of Total Fructose Content (Ftot)

The extract (0.50 mL) was acidified with 0.2 mol L−1 HCl, in a final volume of 25 mL, and subjected to acid hydrolysis at 97 ± 2 °C for 45 min. The solution was then adjusted to pH 7 with NaOH before dilution with water to 25 mL. A 150 μL portion of the neutral hydrolysate was analyzed spectrophotometrically by the same procedure as described previously for free fructose (Ff).

The inulin content was evaluated using the following equation [5]:

where I is the content of inulin, F tot is total fructose content, Ff is free fructose, k is 0.995, it is a correction factor for the glucose part of inulin and water loss during hydrolysis [5, 31].

Determination of Inulin Profile

The profile of inulin was analyzed by High Performance Anion Exchange Chromatography equipped with an Integrated Pulsed Amperometric Detector. The inulin extracts were diluted to appropriate concentrations with water and filtered through a 0.45 μm membrane filter before injection. The separation conditions were 150 mmol L−1 NaOH as eluent A, 150 mmol L−1 NaOH spiked with 500 mmol L−1 sodium acetate as eluent B, a flow rate of 1.0 mL min−1. The elution gradient was 0−15 min with 100 % eluent A, 15−45 min with linear gradient from 0 to 60 % eluent B, 45−90 min with linear gradient from 60 to 90 % eluent B, 90−110 min with linear gradient from 90 to 100 % eluent B, and 110−120 min with linear gradient from 100 to 0 eluent B. The electrical potential and time period (waveform) for the detector were programmed as follows: E1, +0.1 V (vs. Ag/AgCl) for 400 ms; E2, −2 V for 20 ms; E3, +0.6 V for 10 ms; E4, −0.1 V for 60 ms [6]. Standards inulin including 1-kestose (DP = 3) and nystose (DP = 4) were used for the identification of peaks.

Results and Discussion

Extraction of Inulin by ASE

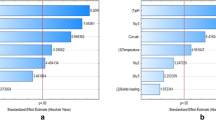

In this study, inulin was extracted using water and was performed at high temperature under high pressure by using an accelerated solvent extractor. The extractions were investigated at temperatures 70−100 °C and extraction times in the range of 10−30 min, while the pressure was kept constant at 1500 psi.

The extraction efficiency is expressed as percent of extracted inulin in the extract per dried weight of powdered tuber. As seen in Fig. 1, extraction at 70 °C gave the lowest inulin content for all the studied extraction times. The highest extraction efficiency was obtained at the extraction temperature of 80 °C for 20 min. The decrease in extracted inulin content at longer extractions times was possibly due to the acid−heat sensitivity of the fructose molecule [5].

The inulin profiles under various extraction conditions were also investigated as a typical profile, shown in Fig. 2. The chromatograms show the distribution of DPs, each peak represents each DP. Considering as intervals of DP values as follow: 3−10, 11−20, 21−30, and 31−40. It can be seen that DPs 3–20 provided highest contents. Table 1 summarizes the effect of extraction temperatures for the extraction time of 20 min on the mean (n = 2) of relative peak areas of each interval. It is clearly seen that the major DPs at all the studied temperatures are DP 3−10 and DP 11−20, totaling ca. 60−70 %. The separate amounts of DP3−10 and DP11−20 were in the same range of 30−39 % relative area for the extraction at the 80 °C with the average peak area of 37.77 and 37.81 % for DP3−10 and DP11−20, respectively. It can be concluded that the major DPs (DPs 3–20) obtained at 80 °C are higher than those from 70 to 100 °C. Therefore, the inulin profiles reveal the results which are in good agreement with the results in term of the extraction efficiency mentioned previously, i.e., the optimum extraction condition was 80 °C for 20 min.

The primary advantage of using ASE to extract inulin from JAT powder is the rapid extraction time used (20 min), much shorter than the extraction time by the conventional method (1−1.5 h) [6, 24]. The use of water as the extraction solvent is economical and it is environmentally more desirable since it does not use organic solvents. In addition, the extracts obtained from ASE were clear, without the need for filtration or centrifugation.

Elimination of Color from Inulin Extract

The obtained inulin extract has a dark brown color. Various methods have been used for the elimination of inulin extract color. For example, chemicals such as lead acetate [32], lime and carbon dioxide [33], dialysis process [9], activated carbon [20] and ion exchange resin [9, 34] were reported. In this study, chemical treatment and ion exchange were studied for elimination of the color in the extract. Visual observation as well as the absorption spectra was used to evaluate the effectiveness of the decolorization process. It was found that ion exchange process using anion exchange resin, DEAE−cellulose, is the most effective strategy color in inulin extract. The visual observation (data not shown) is in good agreement with the absorption spectrum (supplementary data) which shows significant reduction in absorbance at all visible wavelengths. In addition, inulin contents and profiles obtained after color elimination by DEAE-cellulose were not significantly different from those before the elimination process.

Preparation of Inulin Powder

In this study, freeze drying was used for solidification of inulin from the inulin extract. Freeze drying was chosen because it is performed at low temperature, thus the degradation of inulin can be minimized. The obtained inulin powder is white (Fig. 3a) and displays a texture similar to the Chicory inulin standard (Fig. 3b).

Some physico-chemical properties of the produced inulin powder were also studied and the results are compared to the standard inulin from Chicory. The infrared spectra are shown in Fig. 4, revealing the similarity of the peaks with the previous works [20, 35]. SEM images of the obtained inulin powder and chicory (Fig. 5a and b), show similar microphotographs of amorphous spherical shapes with some agglomerates.

Conclusion

This is the first report that demonstrates the systematical study for the preparation of inulin powder from Jerusalem artichoke tubers. Inulin was firstly isolated from tuber powder of Jerusalem artichoke using accelerated solvent extraction. The color of the inulin extract was eliminated using DEAE resin. Freeze drying was subsequently used for solidification of the inulin extract. The inulin content and inulin profiles were used to evaluate the efficiency of the procedure. The proposed method is efficient, rapid and is accomplished at a low cost. Under the optimum conditions, the inulin production yield calculated based on the obtained inulin powder and the powdered tuber used was 92.5 %.

References

Modler HW (1994) Bifidogenic factors-sources, metabolism and applications. Int Dairy J 4:383–407

Lingyun W, Jianhua W, Xiaodong Z, Da T, Yalin Y, Chenggang C, Tianhua F, Fan Z (2007) Studies on the extracting technical conditions of inulin from Jerusalem artichoke tubers. J Food Eng 79:1087–1093

Panchev I, Naiden D, Kovacheva D, Slavov A (2011) Physicochemical characteristics of inulins obtained from Jerusalem artichoke (Helianthus tuberosus L.). Eur Food Res Technol 233:889–896

Prosky L, Hoebregs H (1999) Method of determine food inulin and oligofructose. J Nutr 129:1418s–1423s

Saengkanuk A, Nuchadomrong S, Jogloy S, Patanothai A, Srijaranai S (2011) A simplified spectrometric method for the determination of inulin in Jerusalem artichoke (Helianthus tuberosus L.) tubers. Eur Food Res Technol 233:609–616

Saengthongpinit W, Sajjaanantakul T (2005) Influence of harvest time and storage temperature on characteristics of inulin from Jerusalem artichoke (Helianthus tuberosus L.) tubers. Postharvest Biol Technol 37:93–100

Leroy G, Grongnet JF, Mabeau S, Corre DL, Baty Julien C (2010) Changes in inulin and soluble sugar concentration in artichokes (Cynara scolymus L.) during storage. J Sci Food Agric 90:1203–1209

Vulsteke G, Calus A (1990) Influence of variety, date of harvest and storage time on factors connected with the crystallisation on canned scorzonera (Scorzonera hispanica). Plant Foods Hum Nutr 40:149–166

López − Molina D, Navarro − Martínez MD, Melgarejo FR, Hiner ANP, Chazarra S, Rodríguez − López JN (2005) Molecular properties and prebiotic effect of inulin obtained from artichoke (Cynara scolymus L.). Phytochemistry 66:1476–1484

Takeuchi J, Nagashima T (2011) Preparation of dried chips from Jerusalem artichoke (Helianthus tuberosus) tubers and analysis of their function properties. Food Chem 126:922–926

Roberford MB (2005) Introducing inulin-type fructans. Br J Nutr 93:S13–S25

Kiss A, Forgo P (2011) Investigations on inulin-type oligosaccharides with regard to HPLC analysis and prospective food applicability. Monatsh Chem 142:547–553

Vinatoru M (2001) An overview of the ultrasonically assisted extraction of bioactive principles from herbs. Ultrason Sonochem 8:303–313

Mussatto SI, Mancilha IM (2007) Non-digestible oligosaccharide: a review. Carbohydr Polym 68:587–597

Matías J, González J, Royana L, Barrena RA (2011) Analysis of sugar by liquid chromatography-mass spectrometry in Jerusalem artichoke tubers for bioethanol production optimization. Biomass Bioenerg 3:2006–2012

Zhao CH, Chi Z, Zhang F, Guo FJ, Li M, Song WB, Chi Z−M (2011) Direct conversion of inulin and extract of tubers of Jerusalem artichoke into single cell oil by co-cultures of Rhodorula mucilaginosa TJY15a and immobilized inulinase-producing yeast cells. Bioresour Technol 102:6128–6133

Pandino G, Lombardo S, Mauromicale G (2011) Chemical and morphological characteristics of new clones and commercial varieties of globe artichoke (Cynara cardunculus var. scolymus). Plant Foods Hum Nutr 66:291–297

Delgado GT, Tamashiro WM, Maróstica Junior MR, Pastore GM (2013) Yacon (Smallanthus sonchifolius): a functional food. Plant Foods Hum Nutr 68:222–228

Milani E, Koocheki A, Golimovahhed QA (2011) Extraction of inulin from Burdock root (Arctium lappa) using high intensity ultrasound. Int J Food Sci Technol 46:1699–1704

Abou − Arab AA, Talaat HA, Abu − Salem FM (2011) Physico−chemical properties of inulin produced from Jerusalem artichoke tubers on bench and pilot plant scale. Aust J Basic Appl Sci 5:1297–1309

Van Loo J, Coussement P, De Leenmheer L, Hoebregs H, Smits G (1995) On the presence of inulin and oligofructose as natural ingredients in the western diet. Crit Rev Food Sci Nutr 35:525–552

Modler HW, Jones JD, Mazza G (1993) Observation on long-term storage and processing of Jerusalem artichoke tuber (Helianthus tuberosus). Food Chem 48:279–284

Van der Poel PW, Schiweek H, Schwartz T (1998) Sugar technology, beet and cane sugar manufacture, 1st edn. Bartens, Berlin

Baldini M, Danuso F, Turi M, Vannozzi GP (2004) Evaluation of new clones of Jerusalem artichoke (Helianthus tuberosus L.) for inulin and sugar yield from stalks and tubers. Ind Crop Prod 19:25–40

Gaafar AM, Serag El-Din MF, Boudy EA, El-Gazar HH (2010) Extraction conditions of inulin from Jerusalem artichoke tubers and its effects on blood glucose and lipid profile in diabetic rats. J Am Sci 6:36–43

Li H, Zhu H, Qioa J, Du J, Zhang H (2012) Optimization of the main liming process for inulin crude extract from Jerusalem artichoke tubers. Front Chem Sci Eng 6:348–355

Zhu Z, Bals O, Grimi N, Vorobiev E (2012) Pilot scale inulin extraction from chicory roots assisted by pulsed electric fields. Int J Food Sci Technol 47:1361–1368

Anand R, Verma N, Gupta DK, Puri SC, Hadda G, Sharma VK, Qazi GN (2005) Comparison of extraction techniques for extraction of bioactive molecules from Hypericum perforatum L. plant. J Chromatogr Sci 43(10):530–531

Upadhya V, Pai SR, Sharma AK, Hegde HV, Kholkute SD, Joshi RK (2014) Compound specific extraction of camptothecin from Nothapodyte nimoniana and piperine from Piper nigrum using accelerated solvent extractor. J Anal Methods Chem. doi:10.1155/2014/932036

Mey ED, Maere HD, Dewulf L, Paelinck H, Sajewicz M, Fraeye I, Kowalska T (2014) Application of accelerated solvent extraction (ASE) and thin layer chromatography (TLC) to determination of piperine in commercial samples of pepper (Piper nigrum L.). J Liq Chromatogr Relat Technol 37:2980–2988

Steegmans M, Iliaens S, Hoebregs H (2004) Enzymatic, spectrophotometric determination of glucose, fructose, sucrose, and inulin/oligofructose in foods. J AOAC Int 87:1200–1207

Wack M, Blaschek W (2006) Determination of the structure and degree of polymerization of fructans from Echinacea purpurea roots. Carbohydr Res 341:1147–1153

Zhi − fu Z, Hong − ji Z, Jin − jin Y, Chao L, Gui − yan G, Yi − wei Z (2009) Impurity removal from inulin extract of Jerusalem artichoke tubers by carbonation. Food Sci 30:67–71

Krzywonos M, Lapawa A (2012) Decolorisation of sugar beet molasses vinasse by ion exchange. Clean: Soil, Air, Water 40:1408–1414

Grube M, Bekers M, Kaminska E (2002) Infrared spectra of some fructans. Spectroscopy 16:289–296

Acknowledgments

This work was financially supported by the Higher Education Research Promotion and National Research University Project of Thailand, Office of the Higher Education Commission, through the Food and Functional Food Research Cluster of Khon Kaen University (FC 1.1.1. MS) and the center for Innovation in Chemistry (PERCH-CIC). The authors thank Prof. Richard L. Deming (California State University of Fullerton, USA) for assistance with the English.

Conflict of Interest

All authors report no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Srinameb, Bo., Nuchadomrong, S., Jogloy, S. et al. Preparation of Inulin Powder from Jerusalem Artichoke (Helianthus tuberosus L.) Tuber. Plant Foods Hum Nutr 70, 221–226 (2015). https://doi.org/10.1007/s11130-015-0480-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11130-015-0480-y