Abstract

The objective of this study was to determine the best combination of extrusion process variables for the production of whole quality protein maize (EQPMF) and common bean (ECBF) flours to prepare a high antioxidant activity mixture (EQPMF + ECBF) suitable to produce a nutraceutical beverage with high acceptability elaborated with a traditional Mexican formulation. Processing conditions were obtained from a factorial combination of barrel temperature (BT = 120–170 °C) and screw speed (SS = 120–200 rpm). Response surface methodology was applied to obtain maximum values for antioxidant activity (A ox A) of the flour mixture (EQPMF + ECBF) and acceptability (A) of the nutraceutical beverage. The best combinations of extrusion process variables for EQPMF and ECBF to prepare an optimized mixture (60%EQPMF + 40%ECBF) were BT = 98 °C/SS = 218 rpm and BT = 105 °C/SS = 83 rpm, respectively. The optimized mixture had A ox A = 14,320 μmol Trolox equivalent (TE)/100 g sample dry weight (dw) and a calculated protein efficiency ratio (C-PER) of 2.17. A 200 ml portion of a beverage prepared with 25 g of the optimized flour mixture had A ox A = 3,222 μmol TE, and A = 89 (level of satisfaction “I like it extremely”). This nutraceutical beverage could be used as an alternative to beverages with low nutritional/nutraceutical value, such as those prepared with water, simple sugars, artificial flavoring and colorants, which are widely offered in the market.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The consumption of whole grains has been recommended because they are associated with the prevention of cardiovascular disease (CVD), type-2 diabetes, and some types of cancer [1, 2]. Maize (Zea mays L) is the most highly produced cereal in the world representing a major source of energy, protein and other nutrients for both human and livestock; however, the quality of maize proteins is poor because they are deficient in the essential amino acids lysine (Lys) and triptophan (Trp) [3]. Maize breeders of the International Maize and Wheat Improvement Center (CIMMyT) and the National Research Institute for Forestry, Agriculture and Livestock (INIFAP) in Mexico developed 26 hybrids and cultivars of quality protein maize (QPM), which have yields and other important agronomic traits similar to those of normal maize, but they almost double the Lys and Trp content and therefore the protein quality [4]. Phytochemicals such as phenolic compounds have also been reported in several maize genotypes and they have been associated with antioxidant activities [5, 6] and anticarcinogenic effects [7].

Common bean (Phaseolus vulgaris L) plays an important role in the diet of Latin American people, providing 20–40 % proteins, essential fatty acids, complex carbohydrates, vitamins and minerals; its consumption has been associated with reduced risk of cancer and heart diseases and these physiological effects may be due to some abundant phytochemicals, including polyphenolics [8, 9].

The proteins of maize and common bean complement one another by providing to each other significant amounts of the respective limiting amino acids [10]. Paredes-López et al. [11] reported the highest protein efficiency ratio (PER) value for a 60:40 mixture of maize and common bean; the PER value increased from 1 in maize and 1.4 in common bean to 2.4 in the mixture. Cuevas-Martínez et al. [12] determined the effect of white common bean addition on certain nutritional properties of tortillas of nixtamalized maize; they reported that after addition of 25 % common bean, the lysine and tryptophan content in tortillas increased from 56 to 36 % of the FAO profile to 95 and 84 %, respectively.

Extrusion is a high temperature/short time processing technology that offers versatility, high productivity, low operating costs, energy efficiency, high quality products and improved protein digestibility and biological value [4]. This technology has been used to elaborate several food products, including breakfast cereals, snacks, infant foods, and precooked flours [4, 13]. The use of extruded flours has several advantages since the extrusion process is accompanied by pre-gelatinization of starch granules, resulting in loss of the molecular order and the complete degradation of polymers with formation of highly soluble fragments. Therefore, suspensions of precooked flours by extrusion are able to increase rapidly their viscosity, with a low tendency to form lumps since starch granules have been modified showing high swelling capacity under both cold and hot conditions, which makes extruded flours highly recommended to prepare instant food products [14], such as beverages.

Some researchers have extruded maize using lime to produce instant flours to elaborate tortillas as an alternative to the traditional nixtamalization process [4, 6, 12, 15, 16]. In Mexico, instant flours from nixtamalized maize, as well as flours from raw, roasted, germinated, and fermented maize are used to elaborate traditional beverages such as atole, pinole, tesgüino, and pozol [11]. Precooked legume flours have also been produced using the extrusion technology [17]; legumes are previously soaked in salt solutions (softening) to decrease the cooking time and the levels of some antinutritional factors.

Nutraceutical beverages represent one of the fastest annual growing markets worldwide with a compound annual growth rate of 13.6 % between 2002 and 2007 [18]. The main criterion for acceptance of this kind of drinks is taste; thus, formulation of high quality beverages with good taste is important for an adequate level of consumption, which is required for health promotion and disease prevention.

The objective of this study was to determine the best combination of extrusion process variables for the production of whole quality protein maize and common bean flours to prepare a high antioxidant activity mixture suitable to elaborate a nutraceutical beverage with high acceptability elaborated with a traditional Mexican formulation.

Materials and Methods

Materials

Quality protein maize (QPM) cv V-537C and common bean cv Azufrado Higuera were provided by the National Research Institute for Forestry, Agriculture and Livestock (INIFAP), Culiacán, Sinaloa, México.

Methods

Production of Extruded Quality Protein Maize (EQPMF) and Common Bean (ECBF) Flours

Extruded flours were prepared as reported by Gutiérrez-Dorado et al. [4] and Milán-Carrillo et al. [17]. Whole QPM or common bean kernels (1 kg lots) were grinded to obtain grits that passed through a 40-US mesh (0.425 mm) screen. QPM grits were mixed with lime (0.21 g lime/100 g grits) and water, while common bean grits were mixed with a salt solution [(0.25 g NaCl + 0.75 g NaHCO3)/100 ml distilled water], until both reached a moisture content of 28 g H2O/100 g wet grits. Each lot was packed in a polyethylene bag and stored for 12 h at 4 °C, followed by 1 h at 25 °C. Extrusion cooking was performed with a single-screw laboratory extruder model 20 DN (CW Brabender Instruments, Inc., NJ, USA) equipped with a 19 mm diameter screw, 20:1 length/diameter, 1:1 nominal compression ratio, and 3 mm die opening. Extrusion conditions were selected from a factorial combination of process variables: barrel temperature (BT = 120–170 °C) and screw speed (SS = 120–200 rpm) (Table 1). Extrudates were cooled, equilibrated (25 °C, 65 % RH), milled to pass through an 80-US mesh (0.180 mm) screen, and packed in plastic bags. Extruded whole QPM (EQPMF) and common bean (ECBF) flours were stored at 4 °C until use.

Beverage Preparation

Each flour mixture (25 g) was added with 6.4 g of low calorie sweetener (Azúcar BC Metco®), vanillin powder (1 g) and water (168 ml); the suspension was stirred with a domestic shaker (medium velocity), refrigerated (8–10 °C) and sensory evaluated for acceptability (A).

Proximate Composition

The official AOAC [19] methods 925.09B, 923.03, 920.39C and 960.52 were used to determine moisture, ashes, lipids and protein content, respectively. Carbohydrates were estimated by difference.

Extraction of Free and Bound Phenolic Compounds

Free phenolic compounds were extracted as reported by Dewanto et al. [20] with minor modifications. Briefly, 1 g of ground sample was blended with 10 ml of 80 % chilled ethanol for 10 min and then centrifuged at 2,500 g for 10 min; the supernatant was concentrated under vacuum at 45 °C and stored at −20 °C until evaluation. Bound phenolic compounds were extracted from the residue according to Adom and Liu [21] and Mora-Rochín et al. [6]. The residue was digested with 10 ml of 2 M NaOH at 95 °C for 30 min with previous removal of O2 using N2, followed by 1 h at 25 °C. The mixture was acidified (pH < 2) with 2 ml of 2 M HCl and extracted with hexane to remove lipids. The final solution was extracted five times with 10 ml of ethyl acetate; the fractions were pooled and dried under vacuum at 35 °C. Bound phenolic compounds were reconstituted in 2 ml of methanol–water (50:50, v/v). The extracts were frozen and stored at −20 °C until evaluation. All extractions were made by quadruplicate.

Determination of Total Phenolic and Antioxidant Activity (AoxA)

Phenolic contents of free and bound compounds extracts were determined using the colorimetric method described by Singleton et al. [22]. Briefly, 20 μl of each extract was oxidized with 180 ml of Folin-Ciocalteu reagent (Sigma Chemical Co., St Louis, MO, USA). After 20 min, absorbance of the resulting blue color was measured at 750 nm using a Microplate Reader (Synergy™ Multi-Detection, BioTek, Inc., Winooski, VT, USA). A calibration curve was prepared using gallic acid (Sigma Chemical Co., St Louis, MO, USA) as standard and total phenolics were expressed as milligrams of gallic acid equivalents (mg GAE) per 100 g of sample (dw). All determinations were made by triplicate.

Free and bound hydrophilic antioxidant activities were determined using the oxygen radical absorbance capacity (ORAC) assay. Extracts were evaluated against a standard of Trolox with Fluorescein as a probe as described by Ou et al. [23]. Peroxyl radicals were generated by 2,2-azobis (2-amidinopropane) dihydrochloride, and fluorescent loss was monitored in a Micro-plate reader (Synergy™). The excitation and emission were set at 485 and 538 nm, respectively. Data was expressed as μmol of Trolox equivalent (TE)/100 g of dry weight sample. All measurements were made by triplicate.

Essential Amino Acid Analysis, in Vitro Protein Digestibility (IVPD), Chemical Score (CS) and Calculated Protein Efficiency Ratio (C-PER)

Essential amino acid composition was determined using the method described by López-Cervantes et al. [24] using an analytical scale (4.6 mm × 250 mm) hypersil ODS C18 colum (SGE, Dandenong, Australia) kept at 38 °C and connected to an HPLC system (GBC, Dandenong, Australia) equipped with a fluorescence detector >LC 5100 set at 270 and 316 nm for excitation and emission, respectively. Tryptophan was detected at 280 nm with an ultraviolet detector. The IVPD was determined according to Hsu et al. [25] using a multi-enzyme system. The chemical score (CS) was calculated as follows: \( \mathrm{CS}=\left( {\mathrm{content}\ \mathrm{of}\ \mathrm{the}\ \mathrm{most}\ \mathrm{limiting}\ \mathrm{EAA}/\mathrm{REAAR}} \right) \times 100 \); where EAA is the essential amino acid and REAAR is the recommended amino acid requirement for 10–12 year old children [26]. C-PER was calculated as described by Satterlee et al. [27] and summarized by the AOAC [19]. This procedure is based on the IVPD and the EAA composition of the optimized mixture. All determinations were made by triplicate.

Sensory Evaluation

The total number of beverages tested was 30, based on the different extrusion conditions used (Table 1). A different beverage (20 l) was prepared every day and evaluated after 30 min by a panel of 80 non-trained judges (25 °C, 50–60 % relative humidity, day-light fluorescent lights). Samples were rated for acceptability (A) based on a 100 mm bidirectional scale LAM (labeled affective magnitude) [−100 (maximum value of imaginable dislike) to +100 (maximum value of imaginable like); zero (like me or dislike me) is the central point]. These values were transformed to a scale from zero to 100 [0 = maximum value of imaginable dislike, 100 = maximum value of imaginable like; 50 = I do not like, nor dislike]. This transformation was performed to obtain a predictive mathematical model for A [28].

Response Surface Methodology (RSM) Experimental Design, Statistical Analysis and Optimization

A central composite experimental design was chosen for RSM, with four factors (BTQPM = Barrel temperature for QPM, SSQPM = Screw speed for QPM, BTCB = Barrel temperature for common bean, SSCB = Screw speed for common bean) and five variation levels [barrel temperature (BT = 95, 120, 145, 170, 195 °C) and screw speed (SS = 80, 120, 160, 200, 240 rpm)] (Table 1). Applying the stepwise regression procedure, non-significant terms (p > 0.1) were deleted from a second order polynomial and a new polynomial was used to obtain a predictive model for each response variable [29].

The desirability method described by De la Vara and Domínguez [30] was applied to determine the best combination of extrusion process variables (BTQPM, SSQPM, BTCB, SSCB). The two fitted models for the two dependent variables (A ox A, A) were evaluated at any point X = (X1, X2) of the experimental zone; two values were predicted for each model, Ŷ1 (X) and Ŷ2 (X). Each Ŷi (X) was transformed into a value di (X), which falls in the range (0, 1) and measures the desirability degree of the response in reference to the optimum value intented to be reached. In this case, we wanted all response variables to be as high as possible. The global desirability for the two response variables was determined from the two individual desirabilities with the mathematical function D = (d1d2)1/2, where the ideal optimum value is D = 1; an acceptable value for D can be between 0.6 and 0.8. The statistical software Design Expert version 7.0.0 (Stat-Ease, Minneapolis, MN, USA) was used for the RSM analyses.

Results and Discussion

Predictive Models for Antioxidant Activity (A ox A) and Acceptability (A)

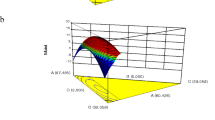

The A ox A experimental values of the flour mixtures (60 % EQPMF + 40 % ECBF) varied from 10,092 to 13,755 μmol TE/100 g sample (dw) and the A values of the nutraceutical beverages prepared from these mixtures varied from 37 to 87 (Table 1). Analysis of variance showed that A ox A was significantly (p < 0.1) dependent on linear terms of BTQPM, BTCB and SSCB, and the quadratic term of SSQPM. A was significantly (p < 0.1) dependent on linear terms of BTQPM, BTCB, and SSCB, and BTQPM-SSQPM, SSQPM-BTCB, and SSQPM-SSCB interactions. Predictive models using uncoded variables for the response variables (A ox A, A) were:

The regression models explained 85 and 90.8 % of the total variability (p < 0.0001) in A ox A and A, respectively, and the lack of fit was not significant (p > 0.05). These values indicated that the experimental models were adequate and reproducible.

Optimization

The common maximum values for the two dependent response variables were obtained at a global desirability (D) value of 1, as a result of the best combination of extrusion process variables for the production of QPM (EQPMF: BTQPM = 98 °C/SSQPM = 218 rpm) and common bean (ECBF: BTCB = 105 °C/SSCB = 83 rpm) flours to prepare a mixture (60%EQPMF + 40%ECBF) with high antioxidant activity and suitable to elaborate a beverage with high acceptability (Suppl. Fig 1). The D value obtained was higher than that considered to be acceptable (0.6 < D < 0.8) [30]. The mixture was recognized as the optimized mixture and it was used to determine physicochemical, nutritional and antioxidant properties.

Nutritional Properties of the Optimized Mixture

The EAA content of the optimized mixture was higher than the requirements for 10–12 year old children (Table 2); its EAA score was 100, and did not present limiting EAA. The mixture had IVPD and C-PER values of 80.2 % and 2.17, respectively (Table 2). These values are close to those reported by Serna-Saldívar et al. [16] for extruded maize and decorticated sorghum tortillas fortified with defatted soybean and sesame meals; these authors recommended the use of in vitro techniques as fast, accurate indicators of protein digestibility and protein efficiency ratio. Milán-Carrillo et al. [13] prepared an infant food based on a mixture of extruded QPM (21.2 %) and chickpea (78.8 %) flours; this food had IVPD and C-PER values of 84.5 % and 1.85, respectively.

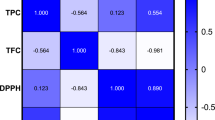

Total Phenolic Content and Antioxidant Activity of the Optimized Mixture

The total phenolic content (free and bound) of unprocessed and optimized mixtures was 393.96 and 358.31 mg GAE)/100 g sample (dw), respectively. Most of the phenolics (79–80 %) occurred in the bound or attached to cell wall form. Extrusion cooking decreased in 9.05 % the total phenolic content of the unprocessed mixture. The optimized mixture of extruded whole QPM and common bean flours retained more than 97 % the antioxidant activity measured by ORAC in the unprocessed mixture (Table 2). Özer et al. [31] studied the effect of screw speed, feed moisture content and feed rate on the total phenolic concentration and antioxidant activity of an extruded snack (chickpea + corn + oat + cornstarch + carrot + raw hazelnut) processed at 110 °C; the extrusion conditions did not change the total phenolic concentration in the samples but the total antioxidant activity decreased (33.8–45.11 %) as the screw speed increased (280–330 rpm) and the moisture content decreased (13–11 %). Delgado-Licon et al. [32] evaluated the influence of extrusion on the bioactive compounds and the antioxidant activity of bean + corn mixtures. The best extrusion procedure was achieved using feed moisture content, barrel temperature and screw speed of 16.3 %, 142 °C and 90 rpm, respectively, resulting in the highest contents of polyphenols and flavonoids, and antioxidant activity. Mora-Rochín et al. [6] produced extruded pigmented Mexican maize flours for preparing tortillas; they used a feed moisture content of 28 % (w/w), BT = 85 °C/SS = 240 rpm and found that extruded tortillas lost 6.21–23.8 % and 6.28–24.8 % of the total phenolic and antioxidant activity associated with raw grains, respectively.

Formulation, Nutrimental Composition, Energy Content and Antioxidant Activity of the Nutraceutical Beverage

The formulation of 200 ml portions of 30 different beverages prepared from different flour mixtures (Table 1) and the beverage prepared from the optimized flour mixture was based on those of traditional beverages widely consumed in Mexico, which are produced from different grain flours (rice, barley, etc.). The preparation of these traditional beverages consists of adding about 150 g of toasted barley or rice (grains must be soaked and grinded) to one liter of water (sometimes could be added with a small amount of milk), sugar, some drops of vanilla (optional), and then mixed to homogenize the ingredients; these beverages are usually refrigerated (4–8 °C) before consumption. They present a considerable amount of precipitated flour at the bottom of the recipient, but they are very demanded in Mexico despite the fact they need to be shaken before drinking. For preparation of the beverage from the optimized flour mixture, sensory tests were conducted to define the proper amounts for each ingredient (data not shown). The Mexican norm NMX-F-439-1983 for foods and non-alcoholic beverages was also considered. This norm defines a nutritious beverage when it contains at least 1.5 % protein or protein hidrolyzates with a quality equivalent to that of Casein; it also establishes that the beverage must contain 10 to 25 % of the main ingredient used to prepare it; these beverages can also contain up to 2 % ethanol, edulcorants, flavouring agents, carbon dioxide, juices, fruit pulp, vegetables or legumes and other additives authorized by the Health and Assistance Secretary of Mexico. All the formulations used in this study contained 12.5 % of the flour mixture and 1.8 % proteins of good quality. Besides, these beverages contained low calorie sweetener for two reasons: 1) to satisfy the recommendations of the Health and Assistance Secretary of Mexico, regarding the fact that a 200 ml portion of a beverage (food) must contain no more than 100 kcal, and 2) to maintain a high sensory acceptance.

The 200 ml portion of the beverage prepared with 25 g of the optimized mixture contained 3.52 g proteins, 0.97 g lipids, 18.8 g carbohydrates and 98 kcal. This portion covers 27.1 % and 18.5 % of the daily protein requirements for children 1–3 and 4–8 years old, respectively. The nutraceutical beverage (200 ml) showed a total antioxidant activity of 3,222 μmol TE, equivalent to 64–105 % of the recommended (3,000 to 5,000 μmol TE) daily intake for antioxidants [2]. The non-trained panelists evaluated the acceptability of the beverage with an average value of 89 (“I like it extremely”). It is expected that this acceptability allows an adequate beverage consumption to provide health benefits.

Conclusions

The best combinations of extrusion process variables for the production of extruded whole quality protein maize (EQPMF) and common bean (ECBF) flours to prepare a mixture (60 % EQPMF + 40 % ECBF) with high antioxidant activity, and suitable to elaborate a beverage with high acceptability using a traditional Mexican formulation were 98 °C/218 rpm and 105 °C/83 rpm, respectively. The optimized mixture had a C-PER value of 2.17 and 14,320 μmol TE/100 g sample (dw). A 200-ml portion of the beverage prepared with the optimized mixture contributed with 64–105 % of the recommended daily intake for antioxidants. This nutraceutical beverage could be used as an alternative to beverages with low nutritional/nutraceutical value, such as those prepared with water, simple sugars, and artificial flavoring and colorants, which are widely offered in the market.

References

Liu RH (2007) Whole grain phytochemicals and health. J Cereal Sci 46:207–219

USDA (2010) Antioxidants and Health. ACES publications, pp 4

FAOSTAT (2011) Statistical database; Online reference http://faostat.fao.org/site/567/ DesktopDefault.aspx?PageID = 567#ancor. Accessed October 28, 2011

Gutiérrez-Dorado R, Ayala-Rodríguez AE, Milán-Carrillo J et al (2008) Technological and nutritional properties of flours and tortillas from nixtamalized and extruded quality protein maize (Zea mays L). Cereal Chem 85:808–816

Lopez-Martínez LX, Oliart-Ros RM, Valerio-Alfaro G et al (2009) Antioxidant activity, phenolic compounds and anthocyanins content of 18 strains of Mexican maize. LWT Food Sci Technol 42:1187–1192

Mora-Rochín S, Gutiérrez-Uribe JA, Serna-Saldívar SO et al (2010) Phenolic content and antioxidant activity of tortillas produced from pigmented maize processed by conventional nixtamalization or extrusion cooking. J Cereal Sci 52:502–508

Anselmi C, Centini M, Granata P et al (2004) Antioxidant activity of ferulic acid alkyl esters in a heterophasic system. J Agric Food Chem 52:6425–6432

Aparicio-Fernández X, García-Gasca T, Yousef GG et al (2006) Chemopreventive activity of polyphenolics from black jamada bean (Phaseolus vulgaris L.) on HeLa and HaCaT cells. J Agric Food Chem 54:2116–21229

Bazzano L, He J, Ogden LG et al (2001) Legume consumption and risk of coronary heart disease in US men and women. Arch Intern Med 161:2573–2578

Grajales-García EM, Osorio-Díaz P et al (2012) Chemical composition, starch digestibility and antioxidant capacity of tortilla made with a blend of quality protein maize and black bean. Int J Mol Sci 13:286–301

Paredes-López O, Guevara-Lara F, Bello-Pérez LA (2006) Los Alimentos Mágicos de las Culturas Indígenas Mesoamericanas. Fondo de Cultura Económica. ISBN 968-16-7567-3 México, DF pp 32–34, 81–88

Cuevas-Martínez D, Moreno-Ramos C, Martínez-Manrique E et al (2010) Evaluación nutricional y textural de tortillas de maíz-frijol blanco nixtamalizadas. Interciencia 35:828–832

Milán-Carrillo J, Alarcón-Valdez C, Gutiérrez-Dorado R et al (2007) Nutritional properties of quality protein maize and chickpea extruded based weaning food. Plant Foods Hum Nutr 62:31–37

Vasanthan T, Yeung J, Hoover R (2001) Dextrinization of starch in barley flours with thermostable alpha-amylase by extrusion cooking. Starch-Stärke 53:616–622

Bazúa CD, Guerra R, Sterner H (1979) Extruded corn flour as an alternative to lime treated corn flour for tortilla preparation. J Food Sci 44:940–941

Serna-Saldívar SO, Canett R, Vargas J et al (1988) Effect of soybean and sesame addition on the nutritional value of maize and decorticated sorghum tortillas produced by extrusion cooking. Cereal Chem 65:44–48

Milán-Carrillo J, Reyes-Moreno C, Camacho-Hernández IL, Rouzaud-Sandez O (2002) Optimization of extrusion process to transform hardened chickpeas (Cicer arietinum L) into a useful product. J Sci Food Agric 82:1718–1728

Heckman MA, Sherry K, González de Mejía E (2010) Energy drinks: An assessment of their market size, consumer demographics, ingredient profile, functionality, and regulations in the United States. Compr Rev Food Sci F 9:303–307

AOAC (1999) Official Methods of Analysis, 16th edn. Association of Official Analytical Chemists, Washington, DC

Dewanto V, Wu X, Adom KK, Liu RH (2002) Thermal processing enhances the nutritional value of tomatoes by increasing total antioxidant activity. J Agric Food Chem 50:3010–3014

Adom KK, Liu RH (2002) Antioxidant activity of grains. J Agric Food Chem 50:6182–6187

Singleton VL, Orthofer R, Lamuela-Raventos RM (1999) Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent. Method Enzymol 299:152–178

Ou B, Hampsch-Woodill M, Prior RL (2001) Development and validation of an improved oxygen radical absorbance capacity assay using fluorescein as the fluorescent probe. J Agric Food Chem 49:4619–4926

Lopez-Cervantes J, Sanchez-Machado DI, Rosas-Rodriguez JA (2006) Analysis of free amino acids in fermented shrimp waste by high-performance liquid chromatograph. J Chromatogr 1105:106–110

Hsu HW, Vavak DI, Saterlee ID, Miller GA (1977) A multienzyme technique for estimating protein digestibility. J Food Sci 42:1269–1273

FAO/WHO/UNU Expert Consultation (1985) Energy and protein requirements. WHO Tech Rep Ser No 724. Word Health Organization: Geneva

Satterlee LD, Kendrick JG, Marshall HF et al (1982) In vitro assay for predicting protein efficiency ratio as measured by rat bioassay: Collaborative study. J Assoc Off Anal Chem 65:798–809

Cardello AV, Schutz HG (2004) Research note numerical scale-point locations for constructing the LAM (labeled affective magnitude) scale. J Sens Stud 19:341–346

Khuri AA, Cornell JA (1987) Response surfaces: Designs and analyses. Marcel Dekker Inc, New York, NY, USA, pp 1–17:254

De la Vara SR, Domínguez DJ (2002) Métodos de superficie de respuesta; un estudio comparativo. Revista de Matemáticas: Teoría y Aplicaciones 1(9):47–65

Özer EA, Herken EN, Güzel S, Ainsworth P, İbanoğlu S (2006) Effect of extrusion process on the antioxidant activity and total phenolics in a nutritious snack food. Int J Food Sci Tech 41:289–293

Delgado-Licon E, Martínez-Ayala AL, Rocha-Guzmán NE et al (2009) Influence of extrusion on the bioactive compounds and the antioxidant capacity of the bean/corn mixtures. Int J Food Sci Nutr 60:522–532

Acknowledgements

This research was supported by Fondo Mixto CONACyT-Gobierno del Estado de Sinaloa (2008), CECyT-Sinaloa (2009), Programa de Fomento y Apoyo a Proyectos de Investigación (PROFAPI), Universidad Autónoma de Sinaloa (2009–2010) and Fundación Produce Sinaloa, A.C. (2010–2011).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 105 kb)

Rights and permissions

About this article

Cite this article

Reyes-Moreno, C., Argüelles-López, O.D., Rochín-Medina, J.J. et al. High Antioxidant Activity Mixture of Extruded Whole Quality Protein Maize and Common Bean Flours for Production of a Nutraceutical Beverage Elaborated with a Traditional Mexican Formulation. Plant Foods Hum Nutr 67, 450–456 (2012). https://doi.org/10.1007/s11130-012-0324-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11130-012-0324-y