Abstract

Fertilizing based on soil test and crop nitrogen (N) demand is the key to optimize yields and minimize fertilizer cost. In 2008, a field experiment with different N rates was conducted with early rice near Yingtan City, Jiangxi Province, in southern China. Canopy normalized difference vegetation index (NDVI) with an active sensor and plant N uptake (PNU) were collected at key fertilization stages; and the sufficiency index (SI) was calculated as the ratio of under-fertilized and well-fertilized NDVI. Rice PNU and yield were positively correlated with NDVI and SI at the tillering and panicle initiation stages. Canopy SI improved the PNU and yield estimations when the relationship was validated with a different dataset. A spectrally-determined N topdressing model (SDNT) was established and used in combination with a target yield strategy and split-fertilization scheme. An allocation coefficient for plant N requirement to accommodate the potential for high yield and soil N supply was introduced. Optimum nitrogen use efficiency (NUE) at different growth stages was incorporated into the model. The model was validated with data from a 2009 plot experiment and three production fields in 2010. The difference of recommended N rate and yield between SDNT and the current yield curve recommendation method was 2.1 and −0.7 % at high planting density and −2.4 and −4.8 % at low planting density, respectively. Compared with farmers’ N management, the SDNT strategy resulted in similar or higher yield with reduced N rates, higher NUE and higher net profit in both 2009 and 2010. Because canopy NDVI can be obtained while sidedressing N fertilizer in a single field pass, the potential of SDNT to accommodate within-field spatial and temporal variability in N availability should improve N management in rice.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Rice is the second most widely cultivated cereal in the world and is a staple food of over half of the world’s population. China is by far the world’s largest producer of rice and accounts for 26 % of rice production in the world. About 34 % of the total rice output in China is from the early rice crop, which grows primarily in provinces along the Yangtze River and in the south. Early rice is typically planted from February to April and harvested in June or July. To achieve high yield, more fertilizer N than needed is commonly applied for rice production in China, resulting in low N use efficiency (NUE) of 30–35 % (Li et al. 1997; Peng et al. 2006). Excessive N in soil–plant systems has contributed to soil acidification due to acidity generated during nitrification (Guo et al. 2010). Excess N is also the main contributor to eutrophication of surface waters, nitrate contamination of groundwater and greenhouse gas emissions. Thus, fertilizing crops based on N requirements to enhance yields and at the meantime reduce environmental pollution has become a major challenge for scientists, environmental groups and agricultural policymakers worldwide.

Recently, the Chinese government launched a soil test campaign and is actively promoting “prescription fertilization” based on soil testing and yield potential. The fertilizer N required for rice in a typical season is estimated as the difference between total N needed by the crop and soil available N supply divided by an estimated NUE. The recommended N is then split into several applications during the growing season to ensure that N supply matches the crop need at critical growth stages. Experience shows that grain yields and farm income have both been increased by adopting the “prescription fertilization” strategy. However, the optimum allocations of fertilizer N for basal, tillering and panicle initiation (PI) recommended to farmers for high yielding early rice are inconsistent (Zhou 2007; Wu et al. 2007; Shi 1998; Xue et al. 2010a). For example, the following proportions have been suggested: 60–20–20 % (Zhou 2007), 50–25–25 % (Wu et al. 2007), 40–40–20 % (Shi 1998) and 35–40–25 % (Xue et al. 2010b) for basal, tillering and panicle initiation, respectively. The differences were mainly attributed to the variation in crop N demand and soil N supply due to complex environmental factors. It is evident that the amount of N needed at each stage, especially for the tillering and PI fertilization, varies with the crop growth status. Therefore, crop growth status assessment is the key to accurately determine N topdressing rate at different stages.

Traditionally, rice N requirements have been determined by tissue N concentration, chlorophyll content with a SPAD meter or a leaf-greenness color chart. These methods have been reported to be expensive and time consuming, and they also require multiple sampling and sometimes produce inaccurate crop N requirements (Blackmer and Schepers 1996). Remotely sensed crop spectral properties have been employed successfully to assess crop N status in terms of plant/leaf N concentration, estimating plant N uptake (Hansen and Schjoerring 2003; Xue et al. 2004; Nguyen and Lee 2006) and guiding N fertilization (Raun et al. 2002; Wood et al. 2003; Welsh et al. 2003; Raun et al. 2005). Raun et al. (2002) developed a functional algorithm (nitrogen fertilizer optimization algorithm, NFOA) that estimates midseason N requirements of winter wheat based on normalized difference vegetation index (NDVI) measurements. Their projected midseason N requirement was based on N demand for the predicted yield while taking into account seasonally dependent crop responsiveness to applied N. The evaluation of NFOA in winter wheat, corn and other crops showed an improved NUE or grain yield or profit when compared with the conventional N rate recommendation (Raun et al. 2002; Raun et al. 2005; Ortiz-Monasterio and Raun 2007; Tubana et al. 2008). Active sensors such as GreenSeeker™ and Crop Circle have been widely used to improve N management. Tubana et al. (2008) showed that a sensor-based optimization algorithm adjusted midseason N rate for corn and increased NUE. Typically, only one topdress fertilization is generally recommended in these spectrally-directed N fertilization approaches including NFOA because they were developed mainly for dryland corn and wheat crops. However, N loss is often greater through processes including ammonia volatilization, runoff and leaching for rice due to prolonged flooding (Xue et al. 2010b). To increase NUE and ensure an optimum yield for rice, N fertilizer is often topdressed two to three times at mid- and late-growth stages. Research by Xue and Yang (2008) introduced three site-specific approaches: NFOA, canopy density (leaf area index, LAI) and a nitrogen nutrition index (NNI) for making rice N topdressing recommendations based on canopy reflectance spectra in the Tai-lake region, China. They showed that these N recommendation approaches could be used in typical small rice fields after simple modification and calibration. These approaches reduced N rates without any yield losses thus increased NUE (Xue and Yang 2008). However, only fertilization at PI was recommended based on crop growth with the canopy reflectance approach in this study, fertilization at tillering was not considered because of the variation of crop growth caused by weather and field management practices (Xue and Yang 2008). Therefore, further study on how to improve the fertilizer prescription and adjust N topdressing according to the real-time crop growth status and soil N supply in rice is warranted. The objectives of this study were to: (1) develop a sensor-determined topdressing N model for rice based on the target yield approach and the split fertilization approach, and (2) to evaluate the model’s potential for application to early rice production in China.

Materials and methods

Experiment design

Four experiments were carried out in Yujiang County, Yingtan City, Jiangxi Province, China (28°15′30″N, 116°55′30″E) with early rice on a paddy soil derived from quaternary red clay. The soil had 31.5 g kg−1 organic matter, 1.66 g kg−1 total N, 0.35 g kg−1 total phosphorus, 30.3 g kg−1 total potassium, 145 mg kg−1 available N, 9.77 mg kg−1 available P and 108 mg kg−1 available K. The first 2 field experiments were carried out in 2008. Experiment 1 with different N rate treatments was conducted to explore the relationship between NDVI and rice PNU and establish the sensor-determined N topdressing model (SDNT). Experiment 2 was used to test the reliability and robustness of the PNU–NDVI and NDVI–yield model. To validate the SDNT model, the third field plot experiment (Exp. 3) and a field comparison experiment (Exp. 4) were conducted in 2009 and 2010, respectively.

Experiment 1

A split-plot arrangement of treatments with three complete replicate blocks was conducted in 2008 for early rice. The main plots were basal N rate treatments (30, 60 and 90 kg ha−1) and the split-plot included topdress N rates (0, 15, 45, 75 and 105 kg ha−1) at the tillering stage. The N rate at the PI stage was the same for all treatments (45 kg ha−1). A plot with no N applied was also included to calculate NUE. Therefore, there were 16 treatments and 48 plots in this experiment. The plot area was 21 m2. Phosphorus was applied before planting at 75 kg ha−1 and potassium at 150 kg ha−1 was split into two equal applications, half as basal before planting and half at PI. Japonica rice variety, Zhongxuan 181, was directly sowed on 27 April, 2008.

Experiment 2

Seven different controlled release fertilizer (CRF) treatments were arranged in a completely randomized design with three replicates. The fertilizer treatments were: CRF1 (N19–P11–K18), CRF2 (N26–P11–K11), CRF3 (N18–P12–K16), CRF4 (N23–P7–K20), CRF5 (N46–P0–K0), CRF6 (N15–P7–K13) and CRF7 (N20–P6–K10–Mg5). All these fertilizers were applied preplant at a rate of 150 kg N ha−1. Also, a conventional chemical fertilizer treatment with N fertilizer split into three times (applied at basal, tillering and PI stages) and a no-N treatment was included. Phosphorus and potassium rates were balanced among all treatments and brought to 110 kg ha−1 P2O5 and 142 kg ha−1 K2O by using superphosphate and potassium chloride, respectively. The preplant fertilizers were broadcast in the respective plots and incorporated by soil tillage. Urea applied as topdressing was distributed only for the conventional chemical fertilizer treatment at tillering and PI. The rice variety, sowing pattern and planting time were the same as for Exp. 1.

Experiment 3

A split-plot arrangement of treatments was designed with three replications with the main plot being rice transplanting density: low density (LD) with 18 000 plants ha−1 and high density (HD) with 25 000 plants ha−1 and the subplots for N rates (N0: 0, N1: 105, N2: 150, N3: 195, N4: farmer’s N management rate of 240 kg ha−1 and N5: topdress N rate determined from the rice canopy NDVI with SDNT). The subplot area was 24 m2. Forty-five kg N ha−1 was incorporated into all N-rate plots before transplanting. Zhongzao 33, an indica variety, was transplanted on 23 April, 2009.

Experiment 4

Three fields (0.29, 0.17 and 0.11 ha) were chosen to apply the SDNT treatment on early rice in 2010. In order to compare it with farmer’s N management (FN), each field was split into two halves to accommodate the farmer’s and SDNT rate. To calculate NUE, a no-N plot of 2 m2 was established separately in each field. Other practices such as irrigation and pesticide management were identical for the two N management methods. The same variety as in Exp. 3, Zhongzao 33, was transplanted on 25 April, 2010.

Measurements and data collection

Canopy spectral reflectance

A GreenSeeker™ handheld optical sensor (NTech Industries, Inc., Ukiah, CA) was used to measure NDVI at a distance of 0.5 m above the rice canopy. The GreenSeeker™ sensor senses a 0.6 × 0.01 m area illuminated by the instrument. This measured area remains approximately constant over the range of 0.5–1.0 m above the canopy. The sensor unit has a self-contained illumination source in red (660 ± 10 nm) and near infrared (NIR) (767 ± 15 nm) bands. The device measures the fraction of emitted light that is returned to the sensor (reflectance) in each waveband. Five locations were measured in each plot and three replicate readings were taken at each location. These sensor readings were then averaged to represent the entire plot. For Exp. 1 and 2, reflectance data were collected on 15 May (tillering), 30 May (PI), 24 June (heading) and 5 July (grain filling); for Exp. 3, reflectance data were collected on 4 May (tillering), 13 May (PI) and 12 June (heading) and for Exp. 4, reflectance data were collected on 7 May (tillering) and 18 May (PI).

Based on reflectance measurements, NDVI and sufficiency index (SI) were calculated using the following equations:

where ρNIR is the fraction of emitted near-infrared (NIR) radiation from the sensed area; ρRed is the fraction of emitted red radiation from the sensed area; NDVI is the index value from each plot; NDVIWN is the reference NDVI value from plot with the highest N rate.

Plant growth, nitrogen uptake and yield

At the time of spectral measurement, five entire rice plants were destructively sampled. Plant samples were dried to a constant weight at 80 °C. Total N content was determined with the micro-Kjeldahl method (Allen 1931). The PNU was determined by multiplying the dry matter of each whole plant by the total N concentration. At maturity, all plants in the plots were harvested and threshed with a small grain thresher for Exp. 1, 2 and 3, while the whole field was harvested with a mechanical harvester for Exp. 4. Grain yield was determined and adjusted to a moisture content of 13.5 %.

Data analysis

Data from Exp. 1 were used to establish the relationship between NDVI and SI, and PNU and yield. Whenever a significant correlation (P < 0.01) was obtained, linear, exponential, power and logarithmic models were tested using regression analyses. Coefficient of determination (R 2) values and corresponding root mean squared error (RMSE) values of the best fit model are reported in Table 1. Finally, the best fit models were validated using independent data from Exp. 2. The RMSE and mean relative error (MRE) values associated with R 2 were used to assess the model performance. The RMSE values were calculated from predicted and actual values of the samples. Precision and accuracy recommended by Massart et al. (1988) were also calculated to assess the predictability of the regression models.

The sensor-determined N topdress model was then established based on the target yield approach and split fertilization strategy. The target yield was provided by the producers and it was often taken as the local highest yield achieved for the specific rice variety (Ling 2007). The performance of SDNT treatment was validated with Exp. 3 data and compared with the farmer’s N practice and traditional optimized N management based on the N–yield response function. The potential yield estimated with SI at tillering, PI and heading stages between FN and SDNT treatments were compared to evaluate the appropriateness of the fertilizer splits made using the SDNT approach. The SDNT approach was further validated with data obtained from Exp. 4. The relationship between N rate and yield under different planting density treatment was fitted with a quadratic function (Yield = a × N2 + b × N + c). Then the maximum yield (Ymax, Ymax = c − b2/4a) and corresponding optimum N rate (Nopt, Nopt = −b/2a) were calculated.

The NUE was calculated using the differences between N-fertilized treatments and no-N plots, as described by Cassman et al. (1998). Terms used were AEN (agronomic efficiency of applied N, kg grain yield increase per kg N applied) and REN (apparent recovery efficiency of applied N, kg N taken up per kg N applied). Cost-benefit analysis was also performed. The net profit, which is the dollar per ha the farmer earned due to N fertilizer, was calculated according to the following equation.

where, GYF is grain yield with N fertilizer, GY0 is the grain yield without N fertilizer. Prices used were the local market prices in 2009: $275 per ton for rice grain, $264 per ton for urea, $322 per ton for potassium chloride and $73 per ton for monocalcium phosphate. In 2010, the price of rice grain, urea and potassium chloride increased to $322, $293 and $352 t−1, respectively. Water, electricity and pesticide costs were consistent for all treatments in both 2009 and 2010. The net profit values did not include the cost of labor for sensor data collection. In 2009, one-way ANOVA was used to compare the difference between SDNT and FN treatments, while in 2010 paired-sample T tests were used. All statistical analyses were performed using SPSS 13.0.

Sensor-determined N topdress (SDNT) model of rice

The yield goal based total N requirement is defined as

where, GYT (kg ha−1) is the target yield which is often taken as the highest yield in the region (8 500 kg ha−1 was set for Jiangxi Province) and Nh is the amount of N required to produce 1 kg rice grain (kg kg−1). A value of 0.018 was adopted for Nh based on the results of Ling et al. (2005) and Exp. 1 in 2008. The basal N was set to be 35 % of the total N.

Topdressing N is often split into two applications, once at tillering for the purpose of stimulating the development of tillers and a second time at the PI stage for the purpose of promoting spikelet initiation and grain filling. Thus, N applied at tillering (Nt) only needs to meet the rice N requirements from tillering to the PI stage and it was calculated by the following formula. The 45 % ratio was based on the results of Exp. 1 and Ling (2007).

The following models were used to derive N topdress rates at the tillering and PI stages:

where, NRt and NRp are the N rate for tillering and PI, respectively; NSt and NSp represent the soil N supply from tillering to PI and PI to maturity, respectively. The NSt and NSp values were set at 20.5 and 27 kg ha−1, respectively, according to the PNU of the no-N treatment in Exp. 1. The NUEt and NUEp terms quantify NUE between tillering and PI, and from PI to maturity, respectively. These values were determined from the maximum yield treatment in Exp. 1 and were at 42.8 and 50 %, respectively.

Results

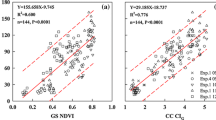

The relation between NDVI, SI and rice PNU and yield

The PNU of N treated plots was significantly higher than the control and increased with the N rate (Fig. 1). More specifically, PNU for the 240 N kg ha−1 treatment was 4.5, 10.0, 3.5 and 3.3 times greater than that of the no-N treatment at tillering, PI, heading and grain filling stages, respectively. The NDVI and SI also increased with increasing N rate at each growth stage, but the difference of NDVI and SI between the highest N treatment and the control was not as large as that of PNU. Significant positive correlation was found between canopy NDVI, SI and PNU at each growth stage (Fig. 1) with R 2 ranging from 0.84 to 0.96 (n = 48). For NDVI–PNU, exponential regression models fitted the data best at the tillering and PI stages, while the power model and logarithmic model were best at the heading and grain filling stages, respectively. However, a linear model was the best fit for all stages for PNU–SI (Table 1). The relationship between PNU and reflectance value became weaker after heading. This might be attributed to the impact of the rice head and other non-green plant material such as old leaves on reflectance values.

The reflectance values at key developing stages were also well correlated with yield and the relationship became weaker as the rice matured (Table 1). Therefore, different regression equations should fit yield–NDVI relationships at different stages separately. While using the normalized NDVI (SI), the data for PI, heading and filling stages fitted well to a non-linear function for yield–SI (Fig. 1). This suggests that normalization of NDVI values from under-fertilized area to well-fertilized reference areas at each stage could eliminate the influence of growth stages on yield prediction with reflectance values.

Validation of the relationship of NDVI, SI with PNU and yield

Independent test data from the different controlled-release fertilizer experiment (Exp. 2) were used to test the reliability and robustness of PNU and yield estimation model with NDVI and SI for early rice. Results showed that the established regression equations predicted rice PNU satisfactorily, especially for the key fertilization stages of tillering and PI using either NDVI or SI. The predicted and measured PNU was closely distributed along the 1:1 line, with the precision of 0.906 and 0.961, accuracy of 1.041 and 0.959, RMSE of 2.454 and 5.637, and MRE of 0.074 and −0.052 for tillering and PI stages, respectively (Table 2). For yield prediction, the PI stage was the best among the four stages with the slope nearest to 1.0 and the intercept closest to 0.0, the lowest RMSE and MRE and the highest precision and accuracy. On the other hand, the tillering stage was the worst time to predict yields (R 2 was only 0.46 and MRE was 0.10). The NDVI–yield model over-estimated yields at all stages, with a positive MRE ranged from 0.04 to 0.10 (Table 2). The use of SI improved PNU and yield prediction evidenced by lower RMSE compared to that of using NDVI (Table 2).

Field validation of SDNT of rice

The SDNT was developed using the data from Exp. 3 conducted in 2009, and PNUt and PNUp were estimated using SI. Then the amount of topdressing N was determined with the SDNT. The model results showed that the N rates recommended differed with rice planting density. The N rate recommended at the tillering and PI stages for low density (LD) averaged 110.6 and 59.8 kg N ha−1, respectively, which were 13.8 and 16.9 kg ha−1 higher than the corresponding stages for the high density (HD) treatment (Table 3). The difference mainly resulted from the higher NDVI measured from the HD treatment. The recommended N rate also varied among plots with the same planting density, with the coefficient of variation of 3.7–16.1 %. The variation was lower under LD than that under HD.

Although the N amounts generated from the SDNT for both LD and HD were lower than the FN management, comparable grain yield under HD and even higher yield under LD were achieved (Table 4) with less N applied. The AEN and REN were significantly higher than those of FN treatments. In addition, the net benefit resulted from the SDNT strategy was increased by $60.4 ha−1 for LD due to the higher grain yield and $16.2 ha−1 for HD due to the decreased fertilizer cost over the FN practice.

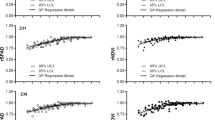

The relationships between N rates and grain yields fit nicely with quadratic functions for both LD and HD (Fig. 2). The Ymax and Nopt calculated from the N–yield curve and from SDNT are presented in Table 5. No significant differences were found in N rate and yield between the SDNT and N–yield curve approaches. This suggests that the SDNT-based target yield has the potential to be used for rice crop N demand assessment.

The NDVI at tillering, PI and heading stage and estimated potential yield with NDVI–yield model of FN and SDNT treatments are shown in Table 2. Under LD, the NDVI of SDNT treatments at tillering and PI stages was lower than FN treatment, so did the estimated potential yield. However, NDVI at heading stage of the SDNT treatment was slightly higher than the FN treatment, and the estimated potential yield of SDNT was 8 497 kg ha−1, higher than that of FN treatment. The measured yield at harvest confirmed the accuracy of SDNT prediction (Table 5). Under HD, the NDVI of SDNT at all stages was higher than FN treatment, but the ultimate yield was nearly identical for both treatments. However, the recommended topdressing N rate by SDNT was lower than FN for both LD and HD, suggesting the split fertilization of SDNT was appropriate and superior to the FN treatment. This also indicated that fertilizing the rice crop according to crop nutrient demand with canopy reflectance could adjust the crop growth timely for higher yields.

Validation of the SDNT approach for rice

The applicability of SDNT was field validated in 2010. The yield of SDNT was significantly higher than that of FN in the same field (Table 6). The yield of SDNT increased about 5.7 % (420 kg ha−1) for field 1, 7.8 % (578 kg ha−1) for field 2 and 4.8 % (348 kg ha−1) for field 3 over FN. However, the N rate was slightly decreased from 183 kg ha−1 under FN to 166.5 kg ha−1 of field 1, 181.5 kg ha−1 of field 2 and 157.5 kg ha−1 of field 3 using the SDNT approach. The yield improvement with the SDNT approach was mainly attributed to more panicles than FN (15.3 % more for field 1, 7.3 % for field 2 and 11.6 % for field 3). The AEN ranged from 13.2 to 14.3 kg kg−1 under FN treatment, but it was improved to 17.0–18.0 kg kg−1 by the SDNT approach.

The economical return of farmers depends not only on the AEN but also on the quantity of N applied. The net profit of rice in 2010 was increased due to higher grain price in comparison with 2009, and was $901.9 ha−1 on average for SDNT and $753.2 ha−1 on average for FN (Table 6). The SDNT treatment increased the average yield and net profit by 6.11 and 19.7 % with 7.9 % less N applied when compared with FN in 2010.

Discussion

Four field experiments were carried out to develop a method for rice N recommendation using field canopy reflectance. Different N treatments were used to obtain the variability of crop N status within the experimental fields in order to calibrate the regressive NDVI–PNU and NDVI–yield models. Results showed that rice PNU and yield at the key fertilization stage could be estimated by canopy NDVI with good precision, similar to previous studies in rice, wheat and other cereal crops (Lukina et al. 2001; Xue and Yang 2008). However, using direct NDVI values instead of those incorporating the GDD (growth degree days) and days after planting to assess crop growth and to predict yield is only good for the site and year, and the regression should be recalibrated when it is used for a different site-year. Therefore, the NDVI was often normalized with a N-rich reference, and sufficient index or response index was calculated to enhance the N diagnosis recommendations (Broge and Leblanc 2000; Schmidt et al. 2011; Singh et al. 2011; Clay et al. 2012). Compared with the direct NDVI measurements, SI improved the PNU and yield prediction, although the validation datasets came from the same year, soil and rice variety with the calibration datasets. This suggests that normalization of NDVI values from under-fertilized areas compared to well-fertilized reference areas at each key fertilization stage could eliminate the influence of soil, variety and other impact factors, and provide more valuable information than NDVI alone for making N recommendations. Similar results were also found in winter wheat (Clay et al. 2012). However, both well-fertilized and under fertilized areas should have the similar moisture conditions if a water stress existed (Clay et al. 2012). The latest researches in USA even correlated economic optimum N rate (EONR) directly to SI, and found that SI obtained with the active sensor provided as good or better indicator of EONR than presidedress nitrate test or SPADrelative (SPADcontrol/SPADreferences), which provides an opportunity to easily adjust in-season-N application spatially in maize (Schmidt et al. 2009; Schmidt et al. 2011).

The target yield strategy was used to estimate crop N need to ensure enough N for high yield production in this study. This approach can overcome the shortcomings of under-estimating N recommendation at low N levels prescribed by NFOA due to the lower yield potential with no additional fertilization (Singh et al. 2011). In order to better match the N supply with plant demand, split fertilization strategy is widely used in China. Therefore, the allocation coefficient of rice N requirement and soil N supply at different growth stages was introduced into the SDNT treatment in this study. In addition, different NUE at different development stages were adopted to calculate the actual N rate for the SDNT treatment due to its great variability with application time. According to previous studies, NUE for basal fertilizer and tiller fertilization was 24 and 26 %, while 67 % for panicle fertilization in rice (Ding et al. 2004; Zheng et al. 2008). Singh et al. (2011) also suggested that NUE should be fine-tuned since it pertained only to the corrective N dose. Thus, sensor-determined N management may have the potential to achieve the high yield and improve NUE, which was demonstrated by experiments conducted in 2009 and 2010. Experiments carried out by Dobermann et al. (2002) also showed that field-specific management of N increased yields and NUE in the majority of the 179 irrigated rice farms they studied in Asia. Furthermore, the comparison of estimated potential yield at each sampling time between SDNT and FN treatments showed that the SDNT approach was better in assessing crop growth status and in achieving higher yield than the FN treatment with relative lower N rates under low density and high density (Table 3). The temporal and spatial variability provided with the GreenSeeker™ sensor makes it an attractive tool for developing N recommendations for rice with the SDNT model; especially, it is suitable for small intensively-cultivated fields (no more than 1 ha in size) in China and other developing countries. However, a recent study to determine whether it is necessary to obtain optical reflectance measurements from each field to make accurate in-season N application recommendations for winter wheat showed that the region- and field-based sampling systems were no better than break-even with the historical extension advice, and this was due to the imprecise relationship between yield and optical reflectance response to N (Roberts et al. 2013). Using the SDNT model, the N demand was determined with target yield rather than by N-rich strips and may avoid the phenomenon of no yield responses to additional N due to the weather or other reasons. The parameters in the SDNT model, including the allocation coefficient of crop N demand among different developing stages and NUE at different stages, were determined mainly with a two-year dataset and should be investigated under more soil types with more rice varieties to improve the robustness and sensitivity of the model.

Conclusion

Canopy NDVI measured with an active sensor (GreenSeeker™) was significantly correlated with rice N uptake (PNU) and yield. Sufficiency index (SI), the ratio between the under-fertilized NDVI and the NDVI value from well-fertilized treatments, could improve PNU and yield estimation compared with the direct NDVI values. The SI–PNU relationship at key fertilization stages (tillering and panicle initiation) was successfully used to guide topdressing N fertilizer determination. Combined with the traditional target yield strategy and split fertilization strategy, a sensor-determined N model to improve the N rate for topdressing at key fertilization stages was established and validated. The model can increase rice yield with lower N rates, higher NUE and higher net income than current farmer practices. However, the parameters of the model should be optimized and the robustness and sensitivity of model should be tested with more data.

Abbreviations

- AEN:

-

Agronomic efficiency of applied nitrogen

- EONR:

-

Economic optimum N rate

- FN:

-

Farmer’s N management

- HD:

-

High density

- LD:

-

Low density

- MRE:

-

Mean relative error

- NDVI:

-

Normalized difference vegetation index

- NFOA:

-

Nitrogen fertilizer optimization algorithm

- NUE:

-

Nitrogen use efficiency

- PI:

-

Panicle initiation

- PNU:

-

Plant nitrogen uptake

- REN:

-

Recovery efficiency of applied N

- RMSE:

-

Root mean squared error

- SDNT:

-

Sensor-determined N topdressing model

- SI:

-

Sufficiency index

References

Allen, W. F. (1931). A micro-Kjeldahl method for nitrogen determination. Oil and Fat Industries, 8, 391–397.

Blackmer, T. M., & Schepers, J. S. (1996). Aerial photography to detect nitrogen stress in corn. Journal of Plant Physiology, 148, 440–444.

Broge, N. H., & Leblanc, E. (2000). Comparing predictive power and stability of broadband and hyperspectral vegetation indices for estimation of green leaf area index and canopy chlorophyll density. Remote Sensing of Environment, 76, 156–172.

Cassman, K. G., Peng, S., Olk, D. C., Ladha, J. K., Reichardt, W., Doberman, A., et al. (1998). Opportunities for increased nitrogen use efficiency from improved resource management in irrigated rice systems. Field Crops Research, 56, 7–38.

Clay, D. E., Kharel, T. P., Reese, C., Beck, D., Carlson, C. G., Clay, S. A., et al. (2012). Winter wheat crop reflectance and nitrogen sufficiency index values are influenced by nitrogen and water stress. Agronomy Journal, 104, 1612–1617.

Ding, Y. F., Liu, S. H., Wang, S. H., Wang, Q. S., Huang, P. S., & Ling, Q. H. (2004). Effects of the amount of basic and tillering nitrogen applied on absorption and utilization of nitrogen in rice. Acta Agronomica Sinica, 30, 739–744. (In Chinese with English abstract).

Dobermann, A., Witt, C., Abdulrachman, S., Gines, H. C., Nagarajan, R., Son, T. T., et al. (2002). Site-specific nutrient management for intensive rice cropping systems in Asia. Fields Crops Research, 74, 37–66.

Guo, J. H., Liu, X. J., Zhang, Y., Shen, J. L., Han, W. X., Zhang, W. F., et al. (2010). Significant acidification in major Chinese croplands. Science, 19, 1008–1010.

Hansen, P. M., & Schjoerring, J. K. (2003). Reflectance measurement of canopy biomass and nitrogen status in wheat crops using normalized difference vegetation indices and partial least squares regression. Remote Sensing of Environment, 86, 542–553.

Li, Q. K., Zhu, Z. L., & Yu, T. R. (1997). Fertilizer issues in the sustainable development of China agriculture (pp. 23–25). Nanchang: Jiangxi Science and Technology Press. (in Chinese).

Ling, Q. H., Zhang, H. C., Dai, Q. G., Ding, Y. F., Ling, L., Su, Z. F., et al. (2005). Study on precise and quantitative N application in rice. Scientia Agricultura Sinica, 38, 2457–2467. (In Chinese with English abstract).

Lukina, E. V., Freeman, K. W., Wynn, K. J., Thomason, W. E., Mullen, R. W., Klatt, A. R., et al. (2001). Nitrogen fertilization optimization algorithm based on in-season estimates of yield and plant nitrogen uptake. Journal of Plant Nutrition, 24, 885–898.

Massart, D. L., Vandeginste, B. G. M., Deming, S. M., Michotte, Y., & Kaufman, L. (1988). Chemometrics: A textbook. Amsterdam: Elsevier.

Nguyen, H. T., & Lee, B. (2006). Assessment of rice leaf growth and nitrogen status by hyperspectral canopy reflectance and partial least square regression. European Journal of Agronomy, 24, 349–356.

Ortiz-Monasterio, J. I., & Raun, W. R. (2007). Reduced nitrogen and improved farm income for irrigated spring wheat in the Yaqui Valley, Mexico, using sensor based nitrogen management. Journal of Agricultural Science, 145, 215–222.

Peng, S. B., Byresh, R. J., Huang, J. L., Yang, J. C., Zou, Y. B., Zhong, X. H., et al. (2006). Strategies for overcoming low agronomic nitrogen use efficiency in irrigated rice systems in China. Field Crops Research, 96, 37–47.

Raun, W. R., Solie, J. B., Johnson, G. V., Stone, M. L., Mullen, K. W., Freeman, K. W., et al. (2002). Improving nitrogen use efficiency in cereal grain production with optical sensing and variable rate application. Agronomy Journal, 94, 815–820.

Raun, W. R., Solie, J. B., Stone, M. L., Martin, K. L., Freeman, K. W., Mullen, R. W., et al. (2005). Optical sensor-based algorithm for crop nitrogen fertilization. Communications of Soil Science and Plant Analysis, 36, 2759–2781.

Roberts, D. C., Brorsen, B. W., Solie, J. B., & Raun, W. R. (2013). Is data needed from every field to determine in-season precision nitrogen recommendations in winter wheat? Precision Agriculture, 14, 245–269.

Schmidt, J. P., Dellinger, A. E., & Beegle, D. B. (2009). Nitrogen recommendations for corn: an on-the-go sensor compared with current recommendation methods. Agronomy Journal, 101, 916–924.

Schmidt, J. P., Beegle, D. B., Zhu, Q., & Sripada, R. (2011). Improving in-season nitrogen recommendations for maize using an active sensor. Field Crops Research, 120, 94–101.

Shi, P. F. (1998). Brief report of optimizing nitrogen fertilization on direct sowing early rice. Plant Nutrition and Fertilizer Science, 4(3), 319–320. (In Chinese with English abstract).

Singh, B., Sharma, R. K., Jat, M. L., & Martin, K. L. (2011). Assessment of the nitrogen management strategy using an optical sensor for irrigated wheat. Agronomy for Sustainable Development, 31, 589–603.

Tubana, B. S., Arnall, D. B., Walsh, O., Chung, B., Solie, J. B., Girma, K., et al. (2008). Adjusting midseason nitrogen rate using a sensor-based optimization algorithm to increase use efficiency in corn. Journal of Plant Nutrition, 31, 1393–1419.

Welsh, J. P., Wood, G. A., Godwin, R. J., Taylor, J. C., Earl, R., Blackmore, S., et al. (2003). Developing strategies for spatially variable nitrogen application in cereals, part II: Wheat. Biosystems Engineering, 84, 495–511.

Wood, G. A., Welsh, J. P., Godwin, R. J., Taylor, J. C., Earl, R., & Knight, S. M. (2003). Real-time measures of canopy size as a basis for spatially varying nitrogen applications to winter wheat sown at different seed rates. Biosystems Engineering, 84, 513–531.

Wu, W. G., Zhang, S. H., Zhao, J. J., Wu, G. C., Li, Z. F., & Xia, J. (2007). Nitrogen uptake, utilization and rice yield in the north of double-cropping rice region as affected by different nitrogen management strategies. Plant Nutrition and Fertilizer Science, 13(5), 757–764. (in Chinese with English abstract).

Xue, L. H., & Yang, L. Z. (2008). Recommendations for nitrogen fertilizer topdressing rates in rice using canopy reflectance spectra. Biosystems Engineering, 100, 524–534.

Xue, L. H., Cao, W. X., Luo, W. H., & Dai, T. B. (2004). Monitoring leaf nitrogen status in rice with canopy spectral reflectance. Agronomy Journal, 96, 135–142.

Xue, L. H., Qin, X., Li, G. H., & Yang, L. Z. (2010a). Effect of basal and tiller nitrogen rates on population dynamics, nitrogen uptake and utilization, and yield formation of direct-seeding early rice. Soil, 42, 681–688. (in Chinese with English abstract).

Xue, L. H., Yu, Y. L., & Yang, L. Z. (2010b). Nitrogen balance and environmental impact of paddy field under different N management methods in Taihu Lake region. Environmental Science, 32, 222–227. (In Chinese with English abstract).

Ling, Q. H. (2007). Theory and technology of precise and quantitative cultivation in rice (pp. 100–103). Beijing: China Agriculture Press. (in Chinese).

Zheng, Y. M., Ding, Y. F., Wang, Q. S., Li, G. H., Wang, H. Z., & Wang, S. H. (2008). Effect of nitrogen applied before transplanting on tillering and nitrogen utilization in rice. Acta Agronomica Sinica, 34, 513–519. (In Chinese with English abstract).

Zhou, B. (2007). Influence on yielding of nitrogen application of early season rice cultivation. Journal of Hebei Agricultural Sciences, 11(3), 14–20. (in Chinese with English abstract).

Acknowledgments

This work was partially supported by the National Natural Science Foundation (No. 40901104 and No. 41171235), and the Innovation Key Program of the Chinese Academy of Sciences (KZCX2-YW-QN406; KSCX1-YW-09-08).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xue, L., Li, G., Qin, X. et al. Topdressing nitrogen recommendation for early rice with an active sensor in south China. Precision Agric 15, 95–110 (2014). https://doi.org/10.1007/s11119-013-9326-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11119-013-9326-5