Abstract

Leather tanning technology impacts negatively on the environment as a result of chemicals in the tannery effluents that increases the concentrations of chemical oxygen demand, Biological oxygen demand, total dissolved solids, total Kjeldahl Nitrogen and formation of Cr(VI) among others in the environment. This has led to the profiling of the industry by legislative bodies as a major source of pollution and hence urgent cleaner and eco-friendly innovative technologies are required that will mitigate the environmental pollution. Many studies have recommended green chemistry tanning protocols and systems involving plants since are non-carcinogenic, non-toxic, biodegradable, agro-renewable, sustainable and economical. Numerous studies have evaluated the potential of phytochemistry in leather tanning processes. However, these studies only focused on individual processes or individual plant phytochemicals. Hence this review compiles the selected plants, their phytochemical screening results, their applications in tanning process and their potential for leather tanning. The review has shown enormous capacity of plants and their phytochemicals that can replace synthetic inorganic materials in leather processing and guarantee quality. Plants have a greater applicability in this industry since they have multiple beneficial actions during processing and the final processed leather. Some plants can be used at all tanning processes due to wide variety of important phytochemicals and the final leather is more superior quality to the conventionally processed leather. Other studies have alluded to the possibility of some plant products that have the potential in the industry but yet to be utilized. Further studies have been recommended.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Leather tanning technology involves a series of operations and processes that significantly impact on the environment negatively (Devikavathi et al. 2014). For instance, pretanning and tanning operations are estimated to contribute approximately 90% of the total tannery pollution due to poor uptake and exhaustion rate of the heavy chemicals used such as chromium, syntans, oils, dyes, bactericides, resins, biocides, sodium, sulphide, lime, surfactants and fungicides (Aloy et al. 1976). The presence of these chemicals in the tannery effluents contribute highly to the concentrations of sulphates, chloride, chemical oxygen demand (COD), Biological oxygen demand (BOD), total dissolved solids (TDS), total Kjeldahl Nitrogen (TKN), among others, in the environment (Bayramoglu et al. 2006; Colak et al. 2010). Other chemicals such as ammonia, hydrogen sulphide, and volatile hydrocarbons, amines are emitted to the atmosphere. Formaldehyde are usually present in chemicals like synthetic tanning agents, resins, naphthalene based, oxazoline derivatives, phenol and sulphone compounds, dyeing auxiliaries, finishing chemicals and casein-based finishes. Although tanning and retanning is done using Cr(III) salts which are eco-friendly and no restriction on its use exists, cases of Cr(VI) formation due to oxidation have been reported (Devikavathi et al. 2014). Accelerated oxidation has been warranted by oxidation agents such as atmospheric oxygen, UV rays (photo ageing), extreme high or low pH (such as during neutralization and dyeing), extreme high or low humidity, temperatures higher than 80 °C (thermo ageing), fatliquoring (especially those with double bond, vegetable oils, animal oils) and natural waxes and resins used during dry finishing (Devikavathi et al. 2014; Dixit et al. 2015). Oxidation mechanisms involves radical formation and hydro peroxides. Cr(VI) is a highly toxic substance, whose presence in leather has contributed to the profiling of leather tanning processes as a major source of pollution (Devikavathi et al. 2014). Although synthetic dyes are comparatively cheap and efficient, the exhaustion rate of these synthetic dyes is between 65 and 90%, hence the rest of the unfixed dyes are discharged as effluents. These dyes produce carcinogenic and allergenic amines, therefore posing both environmental and human health hazard (Dixit et al. 2015). Due to the growing public awareness towards human and environmental health supported by the legislative policies with respect to environmental protection, sustainability and waste management, the tanning industry risks closure. Alternative and innovative production techniques that are cleaner and eco-friendly have been recommended among them green chemistry tanning protocols and technologies (Dixit et al. 2015). The use of plant products among the green chemistry tanning protocols is a promising venture since plants are non-carcinogenic, non-poisonous, biodegradable and non-hazardous (Saravanabhavan et al. 2004). They are also agro-renewable products, economical, cheap, sustainable and have outstanding performance in terms of quality of leather and also have multiple beneficial actions (Pervaiz et al. 2016a, b). Although, diverse studies have evaluated the potential of phytochemistry in leather tanning processes, these studies only focused on individual processes or individual plant phytochemicals. Hence this review compiles the selected plants, their phytochemical screening results, their applications in tanning process and their potential for leather tanning. Suggestions have also been made for further studies and optimization considerations.

Phytochemistry of selected plants relevant to leather tanning

Ethanoic extracts of Mimosa pudica Linn. shows the presence of alkaloids, flavonoids, cardrac glycosides, phenols, saponins, coumarins, terpenoids, quinines and tannins (Jagetia and Lalhmangaihi 2018; Gandhiraja et al. 2009). Free radical scavenging assays of the plant extracts demonstrated the potential of scavenging superoxide radicals, other free radicals and antioxidant activity due to the presence of phenols, alkaloids, flavonoids, cardiac glycosides, and saponins (Jagetia and Lalhmangaihi 2018). The bioactive components such as alkaloids, terpenoids, phenols, saponins, coumarins, quinines and tannins possess antimicrobial activity that can be handy in leather processes (Gandhiraja et al. 2009). The polyphenolic compounds such tannins are capable of precipitating proteins especially the collagen to form leather (Falcao and Araujo 2018). As a matter of fact, most of the properties and the applications of these tannins are attributed to the ability of their proanthocyanidins to form complexes with collagens via hydrogen bonding. Tannic acid is a polyphenol with hydrolysable gallotannin with numerous activities such as antimicrobial, radical scavenging, antioxidant and antibacterial (Saravanabhavan et al. 2004). The tannic acid has lower molecular weight which enhances efficient penetration and solubility as compared to other traditional vegetable tannins (Saravanabhavan et al. 2004; Fathima et al. 2006). Quercus macrolepis has been used in the production of harder, firmer, heavier and quite impermeable leather due to ellagitannins, whose main constituents are castalagin, vescalagin and pentagalloylglucose (Falcao and Araujo 2018). Galla chinensis and Galla turcica contains 50–70% of tannin of the gallotannin type, mainly of penta-undeca-galloylglucoses. A review on the phytochemical and pharmacological profiles of Castenea sativa Mill. have shown that it possesses both antibacterial, antifungal, antimicrobial, antiviral and antioxidant activities due to chemical compounds such as both condensed tannins (proanthocyanides) and hydrolysable tannins, flavonoids, lipids, gallic acid, proteins, fibres, ellagic acid, minerals, steroids, terpenoids, saponins, carbohydrates and free sugars (Sanz et al. 2010).

The essential oils of Thymus vulgaris (Thyme) and Oreganum minutiflorum (oregano) contain p-cymene, thymol, 1,8-cineole, linalool, geraniol, sabienene hydrate, α-terpinene, caryophyllene, borneol, carvacrol, rosmarinic, acetic acids and α-pinene and γ-terpinene which have expressed strong fungicidal, antibacterial and anti-inflammatory activities (Klaric et al. 2007; Ozkan et al. 2010). These oils offer high phenolic content, reducing/antioxidant and free scavenging, fungicidal and antimicrobial, activities due to the phenolic metabolites such as rosmarinic and acecetic acids (Capecka et al. 2005). The essential oils of Eucalyptus globulus contains flavonoids, terpenoids, saponins, and reducing sugars which are have shown strong activities such as free radical scavenging and antimicrobial (Mishra et al. 2010).

Terminalla chebula Retzius contains chebulin, ellargic acid, gallic acid, chebulinic acid, ethyl gallate, punicalagin, terchebin, terflavin, luledin, tannic acid, total phenolic, triterpenoids, alkaloids, flavonoids, anthraquinones, glycosides and tannins (Tariq and Reyaz 2012; Upadhyay et al. 2014). The plant reportedly possesses multiple activities such as antioxidant, antibacterial, antifungal, antiviral, antimicrobial, among others (Tariq and Reyaz 2013; Upadhyay et al. 2014). Lavandula officianalis L. has organic compounds such as linalool oxide, α-pinene, α-terpinene, coumarins, tannins, borneol, camphene, menthol, eucarvone, terpinolene, β-caryophllene, viridiflorol, 1,8-cineole, sabinene, β-pinene, tannins, coumarins, flavaonoids, fitosterols, rosmarinic acid and related derivatives (Miri 2018). The chemical constituents of Lawsonia inermis Linn. include lawsone (2-hydroxy-1, 4-naphthoquinone), mucilage, mannite, gallic acid, tannic acid, carbohydrates, cardiaglycosides, terpenoids, tannins, quinones, saponins, flavonoids, resins, alkanoids, phenolics, catechin, quertrin, β-sisterol glycoside, coumarins, xanthones and leucocyadin (Mahmoud et al. 1980; Musa and Gasmelseed 2012). Lawsone in the henna leaves is the main coloring substance and this component confers the leaves with a variety of pleiotropic effects such as antioxidant, antibacterial, antifungal, and antimicrobial activities (Musa and Gasmelseed 2012). Hydrolysable gallotannins extracted from Caesalpinia spinosa (tara) possess strong antibacterial and antioxidant potency (Aquilar-Gavez et al. 2014).

Species of Acacia such as nilotica, arabica, seyal and catechu have shown presence of rich secondary metabolites such as tannins, sterols, glycosides, alkaloids, saponins, resins, phenolic acids, carbohydrates, proteins, amino acids, anthraquiones, and flavonoids, terpenes, and other therapeutic compounds that have shown marked fungicidal, antioxidant, antibacterial activities especially against both gram-positive and negative bacteria (Negi and Dave 2010). Uncaria gambier [Roxb.] contains tannins, catechins (complex flavonoids), alkaloids, sterol, resins, proteins, amino acids, carbohydrates and phenolic compounds; components which have shown excellent antibacterial, free radical scavenging and antioxidant activities (Amir et al. 2012). Camellia sinensis (tea) possesses bioactive compounds such as alkaloids, flavonoids, steroids, terpenoids, carotenoids, benzoic acid, ascorbic acid, tocopherols, folic acid, and tannins consisting of catechin (flavonol) and gallic acids (Tariq and Reyaz 2012). Majority of these metabolites are active components for antioxidant, antimicrobial, antifungal and antibacterial activities (Tariq and Reyaz 2012). Phytochemical screening and determination of phenolic content and antioxidant activity of Cassia singueana reveals the presence of alkaloids, sterols, coumarins, saponins, triterpenes, anthraquinones, quinoids, glycosides, carbohydrates and tannins which confer strong antioxidant, free radical scavenging and antimicrobial activities (Adzu et al. 2003). Bixa orellana seed contains tannins and a mixture of eight colorants of carotenoid type such as bixin and nor-bixin (Das et al. 2007). Ricinus communis, commonly known as castor plant, contains important triglyceride components such as ricinoleate, linoleate and oleate. Azadirarachta indica contains a variety of phytochemicals such as alkanoids, flavonoids, saponins, resins, glycosides, terpenoids, triglycerides, tannins and steroids with high antioxidant and antibacterial effects (Affiang et al. 2018).

Applications of selected plants in leather tanning processes

Leather tanning processing involves mainly four operations: pretanning, tanning, post tanning and dry finishing operations. Pretanning operations involve processes such as soaking, liming and pickling while post tanning operations include processes as dyeing and fatliquoring (Nalyanya et al. 2018).

Applications of plant products at pretanning operations

Soaking is a process aimed at restoring the original water content and accelerating the wetting of the fibre surface and synthetic antimicrobial agents that curtail putrefying bacterial activity using chemicals as detergents, surfactants, biocides and alkalis such as sodium polysulphide. Colak (2006) extracted tannins from quebracho, mimosa, gallnut, chestnut and valonia and examined their antibacterial activities on leather at soaking process. Tannins from gallnut and chestnut, used as additives, showed more antimicrobial activity against bacteria in the soaking float during the first 8 h while gallnut tannins were still effective at 24 h of soaking. On the other hand, tannin extracts from valonia and quebracho supported bacterial growth. The stronger activity of tannins extracted from gallnut and chestnut were attributed to the higher content of tannins. The results of the study demonstrated that gallnut and chestnut are viable alternative agents for soaking process. Zengin et al. (2014) investigated the effect of tannic acid on microorganisms on leather at soaking. The results showed that application of 0.5 and 1% tannic acid concentrations was more effective than the commercial bactericides (benzisothiazolinon as the active ingredient) on the market probably due to their phenolic structure. Use of tannic acid for soaking process resulted in lower COD, and TKN values of the effluents. This system provides an alternative that’s both environmental friendly due to low pollution and cheaper. Bacterial loads of soaking baths and the CODs at different concentrations are shown in Table 1.

Sivakumar et al. (2016) investigated the antimicrobial activity of Terminalia Chebula Retz. nuts combined with common salts mixed in the same ratio as alternative preservation of leather. The synergistic action of the combination 10% each (% w/w of raw skin) provided a short term preservation of raw skin/hide up to 45 days without any degradation/putrefaction. Conventionally, salt preservation employs 40–50% of common salt. Hence this preservation system reduced the amount of common salt by 75% and thereby reducing TDS content, COD and BOD. The antimicrobial activity suggests that synergistic composition of myrobalan powder and common salt in similar proportion have a better activity against wide range of micro-organism as compared to individual effect of either myrobalan powder or common salt.

Pickling process is intended to prevent the swelling of the pelt by lowering the pH to 2.8–3.0 in preparation for tanning process using salts (sodium chloride), formic acid, and sulphuric acid (Nalyanya et al. 2015). Synthetic, organic crosslinking agents and surfactants are often added at this point assist in the subsequent stages. A study by Colak et al. (2010) investigated different concentrations of tannic acid against some microorganisms at pickling process of leather making as additives. Leather samples treated with 0.1, 0.5, 1, 2 and 3% of tannic acid were assessed on yeast, bacteria and moulds. All concentrations of tannic acid exhibited antimicrobial activity against all bacteria, yeast and moulds studied; and the activities were stronger as compared to that of commercial synthetic bactericides used at all concentrations. The antimicrobial activity increased with concentrations, the most effective concentration being at 3%. Using tannic acid at pickling process, the values of COD and TKN in the effluents are expected to reduce markedly. Bayramoglu et al. (2006) examined the applicability of Origanum minutiflorum (Oregano) essential oils as a fungicide additive on leather during leather pickling and tanning processes. The fungal activity of essential oils against common moulds species were compared with two other common commercial fungicides; the 2-Thiocyano-methylthiobenzotiazole (TCMTB) and N-octyl-isothiazolinone (N-OITZ). Leathers treated with the extracted essential oils were more resistant to moulds than those treated with the commercial fungicides. The antifungal activity of these essential oils increased with their concentrations. The essential oils from the three species of Oregano were applied on leather as alternative bactericides (Bayramoglu 2007). The three species recorded superior activity as additives compared to all the concentrations of (7–25%) commercial bactericides.

Applications of plant products at tanning operations

Chromium tanning accounts for more than 90% of the global tannages while the rest is done using vegetables, syntans, aldehydes, oils and other mineral tannages (Devikavathi et al. 2014; Nalyanya et al. 2018). The dominancy of chromium tanning lies in its high capability, during olation process, to form polymeric oxydrillic-bridged compounds that are allowed to coordinate and crosslink the collagen protein whose carboxyl groups that act as ligands into the chromium complex themselves (Covington 2011). Retanning using chromium increases the free, soluble (unbound), extractible and total chromium concentration that get easily converted to Cr(VI) during oxidation (Fuck et al. 2011). Therefore, plant products with appropriate tannin content can serve a green alternative to the chromium salts. Due to high content of hydroxyl groups, tannins react with collagen molecules via multiple hydrogen bonding at the peptide links. Similarly, the polyphenols in tannins fix to the carboxylic and amino acid groups especially the condensed tannins which have been found to form strong and stable covalent bonds between the collagen molecules and the aromatic carbon groups in the tannins via the quinoid structures. The polyphenolic tanning matrix created expels much of the water matrix of the collagen supramolecular structure at the hydroxyproline residue sides thereby increasing the number of covalent bonds (Beghetto et al. 2013). These makes the resulting leather imputriscible, mechanically strong and hydrothermally stable.

Saravanabhavan et al. (2004) carried out a study in which tannic acid was combined with zinc and silica as a white chrome-free tanning system to manufacture garment leathers. The optimum concentrations of zinc, tannic acid and silica were found to be 10, 10 and 5%, respectively. The tanning system increased the exhaustion of Zinc to 90%. The BOD, COD and TDS loads of the effluents greatly reduced by 96, 94, and 74%, respectively, as compared with the spent vegetable tan liquor while 44, 67, and 88%, respectively, as compared with chrome tan liquor (control) as shown in Table 2.

Another study by Fathima et al. (2004) devised a tanning system in which tannic acid was combined with Aluminium sulphate and sodium metasilicate of concentrations 10, 5, and 5%, respectively. The exhaustion rate of aluminum increased to more than 98% and a significant reduction in the COD and TDS was reported compared to the conventional vegetable tanning system. Later in 2006, Fathima and others combined tannic acid with tetrakis hydroxymethyl phosphonium Sulphate (THPS) as an alternative cleaner tanning system. Alongside the versatile upper and garment leathers, the environmental assessment tests showed that COD of the spent liquor was higher compared to that of the conventional chrome tanning due to unfixed tannic acid and THPS while there was a decrease in TDS. Since tannic acid is easier to degrade, this system a viable alternative to chrome tanning. Furthermore, THPS has low toxicity to both human and environmental health, low recommended treatment level, rapid breakdown in environment, and no bioaccumulation (Fathima et al. 2004). Furthermore, Colak et al. (2014) applied tannic acid for retanning wet blue leathers and examined the activity of tannic acid in curtailing the formation of Cr(VI) and formaldehyde compounds. From the results, 3% offer of tannic reduced the level of Cr(VI) to values lower than 3 ppm, fulfilling the eco-label criteria for footwear. The reduction rate for Cr(VI) and formaldehyde was up to 98% and 45.3%, respectively, which was achieved after applying 3% tannic acid. The formaldehyde concentrations were highest in control samples (44.9 mg/kg) but the levels progressively reduced as concentrations of tannic acid applied increased. All the concentrations of tannic acid (0.1, 0.5, 1, 2 and 3%) maintained the formaldehyde concentrations under restricted limits. The study recommended the protective effect of tannic acid against formation of Cr(VI) and formaldehyde, attributed to its capacity to absorb UV light with a peak of maximum absorption spectrum below 250 nm.

Ozkan et al. (2017) studied the inhibitory activity on Cr(VI) formation in chrome tanned leathers of two condensed vegetable tannins: quebracho (72% tannin) and mimosa (72% tannin) and four hydrolysable tannins; tara (48% tannin), chestnut (72.5% tannin), valonia (68% tannin) and sumac powder (20.8%) combined with copper mordant of 0.5 and 1% and copper standalone. The study involved using tannins combined with copper mordants and using copper alone. The results showed that both using copper alone and combining copper with vegetable tannins inhibited Cr(VI) formation even after photo ageing, keeping Cr(VI) level below the permissible limit. On average, 13.1 ppm of Cr(VI) were detected in leathers without either copper or vegetable tannins. Some high levels of Cr(VI) were also detected in leathers treated with 1% of mimosa, quebracho and chestnut without copper mordant. On the other hand, both 0.5% and 1% of copper mordant alone or combined with vegetable tannins were successful to keep Cr(VI) levels below detection limit in all the leathers.

Sirvaityte et al. (2011) extracted essential oils from Lavandulae officinalis as alternative preservative for leathers tanned using mimosa and quebracho tannins and their mixtures. The essential oils of Lavandulae officinalis increase resistance of the leathers to Ps. Aeruginosa. Leathers tanned with mimosa tannin is more resistant than tanned with quebracho or mixture of mimosa and quebracho tannins. The antibacterial effect decreases during 1 week of storage and chrome free leather becomes nonresistant to B. cereus. Compared with leathers painted with E. globulus, the antibacterial effect of lavender was stronger than that of E. globulus. Sirvaityte et al. (2012) applied thyme essential oils as an alternative preservative for chrome tanned leather at concentration rates from 0.05 to 5% of the wet blue mass. Gram-positive bacteria were found to be more sensitive to the essential oils of thyme than gram-negative bacteria. The essential oils showed stronger protection against bacteria than that of the conventional (thiocyanomethylthio) benzothiazole after 4 weeks. Resistance to bacteria’s action increased with concentrations of essential oils and the optimized concentrations of at least 3%. A concentration of 5% showed the highest resistance to E. coli. Although the study recommended the use of the essential oils mixed with reduced amounts of synthetic biocide, the resistance is sufficient without the synthetic bactericide.

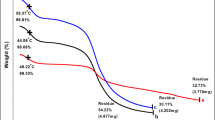

Bayramoglu et al. (2008) used 4% green tea and Vinca rosea extracts to inhibit formation of formaldehyde in leather during retanning process. Both extracts were effective in eliminating formaldehyde but green tea showed far better effect. The effect can be improved by using different extraction techniques or increasing the amount of the extracts used in the process. Since the effect of formaldehyde elimination is based on antioxidant effect, the two vegetal extracts can potentially be used to eliminate or minimize the Cr(VI) formation in leather. Ozgunay et al. (2012) determined the antioxidant activity of henna and valonia using FRAP and TEAC/ABTS methods against the formation of Cr(VI) and formaldehyde formation in wet blue leathers. The antioxidant powers were found to be 2.3 and 2.4 mmol/L, respectively, for henna while 48.1 mmol/L and 28.0 mmol/L, respectively, for valonia. The results from the study showed that the amounts of both Cr(VI) and free formaldehyde reduced considerably in both henna and valonia-treated leathers as compared to control (photoaged without any treatments) (see Table 3).

Aravindhan et al. (2015) investigated the inhibitory activity against formation of formaldehyde in leather of an alternative chrome tanning system involving a combination of tara and THPS. The environmental impact assessment showed a significant reduction in TDS and a slight increase COD due to presence of unfixed tara and THPS as compared to control chrome tanning. The optimized concentration of tara was found to be 10% and the order of combination to be tara followed by THPS. Both tara-THPS and THPS-tara tanned leathers showed almost 99% scavenging activity against formaldehyde due to the antioxidant activity of both Tara and THPS.

Musa and Gasmelseed (2013a) determined tannin content extracted from Acacia nilotica pods (garads) and applied the tannins combined with Aluminium for leather tanning. The extracted tannin content was found to be 30%. The tanning involved two protocols; garad tanning followed by Aluminium (garad-Al), and Aluminium tanning followed by garads (Al-garad). The uptake of garad tannin in garad-Al tanning system with 20% followed by 2% of Al2O3 was found to be better than Al-Garad tanning system. Consequently, Aluminium enhances the exhaustion of the garad tannins. The system also resulted into decreased discharge of COD by 13%, BOD by 51% and TDS by 56% in the spent liquor and waste water as compared with control spent liquor (using garad tanning system alone) (see Table 4).

Another tanning system was designed by Musa and Gasmelseed (2013b) using 20% garad tannin combined with 4% Oxazolidine. Based upon the results, the exhaustion of garad improved by 10%. Consequently, the COD, BOD and TDS of the spent liquor processed using both Garad-Oxazolidine and Oxazolidine-Garad tanning systems were lower than that for liquor from garad tanning (control). Conclusively, better results require that the order of combination to be garad followed by Oxazolidine (see Table 5).

Hussein (2017) determined the tannin content in Acacia seyal (taleh) bark and utilized the extracts as an alternative retanning system for garment leathers. The optimized conditions for extraction were; temperature of 50 °C, solvent ratio of 6:1 and leaching time of 1 h. Tannin content determined was 28.9%. This tannin content gives an impressive and promising pretanning, tanning and retanning agent to replace the hazardous chrome tanning.

A study by Nurbalia (2016) on the characteristics identification of gambier as a possible leather tanning agent additive showed that the catechins in this plant are a natural ingredient for antioxidant effect. The tannin content was more than 50%, hence a promising pretanning, tanning or retanning agent in the leather tanning industry.

Seabra et al. (2017) investigated the influence of solvent additive on aqueous extraction of tannin from Pinus pinaster bark in order to be used in leather tanning. Solvent additives used were sodium hydroxide (0.5, 1.0 and 1.5%), formic acid (0.5, 1.0 and 1.5%) and ethanol (5, 10 and 15%). Extractions were performed with and without the addition of sodium sulfite (1.0%). The optimized solvent additive for phenolic and condensed tannins was ethanol which achieved 34.8% of gallic acid equivalents and 62.8% of catechin monohydrate equivalents and favorable pH value of 3.5. The extracts had relatively low viscosity which is ideal for leather tanning system since the low pH is already an appropriate for tanning without use of acids and bases. This is a value-added scheme that is meant to improve the extraction of tannins from the plants. This is a potential alternative protocol for tanning and retanning agents.

Applications at post tanning operations

Dyeing process confers a desirable permanent color to the leather (Musa and Gasmelseed 2013a, b; Nalyanya et al. 2018). Based on coloring ability of some plant phytochemicals, several plant extracts have shown excellent potential in leather dyeing process. Berhanu and Ratnapandian (2017) extracted and optimized dyes from Cassia singueana bark and used them on dyeing tanned leather with mordants of Aloe vera juice and mango bark extracts. The optimized parameters for high strength dye were at temperature of 95 °C, concentration of 60 g/L and a duration of 1 h. Good to excellent fastness were achieved and better colour fastness was obtained in the case of leather premordanted with Aloe vera juice. Similarly, the value of yellowness for premordanted leather with Aloe Vera juice was highest. The colour change was also achieved by varying the mordants used. Mordants of Aloe vera and mango bark gave the best shades, excellent rubbing and perspiration and very good light fastness with premordanting. Musa et al. (2010) investigated the possibility of using henna extracts synergistically combined with THPS as a green tanning system for garment leathers. The optimum concentration and protocol of tanning system was 20% henna and 1.5% THPS applied in that order. The system resulted in a significant reduction in discharges of TDS, CODs and BODs in the spent liquor and wastes. On the other hand, THPS improves the exhaustion of henna. Musa et al. (2008) applied extracts from air-dried henna leaves as a wet blue leather retanning agent against wattle retanning. From the trial, the dried leaf powder yielded tannin content range of 10.2–12%, 5–10% gallic acid and 0.01–0.02% essential oils. The environmental impact tests on the spent liquor showed a significant decrease in COD and BOD as compared with the control spent liquor (wattle retannage). As expected however, the TDS content increased with henna treatment (Table 6).

Leathers treated with henna showed better dyeing quality implying the extracts can be used as a premordant as well. Due to lawsome (2-hydroxy 1,4 naphthoquinone), a coloring matter in henna, Musa et al. (2009) used leaves extracts to dye leather. The optimum extraction conditions were found to be maceration of ground henna leaves in water, at a temperature greater than 80 °C for 1 h in water bath without agitation. The depth of the color increased with henna concentration while variation in color and light fastness was achieved by suitable mordants that improved the absorption and hence uptake. The dye uptake slightly decreased with henna offer and pH. From the exhaustion results, the appropriate pH for henna dyeing was 4 and high temperatures of 60 °C. The 20 and 25% concentration offer gave better shades and hence 20% was observed to be sufficient. The dye was found to confer good rub and perspiration fastness characteristics while light fastness was moderate at these offers. The exhaustion rate at high temperature poses a challenge given that leather is sensitive to high temperatures. Hence leather dyeing using henna appears a viable option that can replace synthetic dyestuffs. Abba et al. (2013) compared the pure and sulphonated dyes extracted from henna and Cola nitida plants. They extracted the dyes using chloroform and acetone as solvents and the extracts were sulphonated using chlorosulphonic acid. The dyeing properties of henna were found to be superior to kolanut dyes. The exhaustion ranged from 52 to 85.04%, fixation from 50.72 to 63.32% and migration from 48.85 to 82.33%. For both dyes, sulphonated dyes showed better results even for dyeing properties and fastness ratings compared to crude extracts. Similarly, sulphonated dyes showed better exhaustion, fixation and migration. Although not yet explored, the tannin content in henna leaves is sufficient for leather tanning process while the non-tannin components can be beneficial to bring about filling action in the leather matrix. Hence, this is a promising ingredient in leather tanning technology for various processes, owing to its rich phytochemical components.

Numerous plant extracts with dyeing potential such as Arbutus unedo L. leaves, Arucaria angustifolia leaves, Callistemon citrinus L. flowers and leaves, Ficus benghalensis Linn. roots, Iresine paniculata L. leaves, Mangifera indica L. bark, Moringa oleifera Lam., Morus alba Linn. leaves, Musa cuminate L. bark, Nerium oleander L. flower, Polyalthea longifolia Sonn., Punica granatum L. fruit peel, Syzygium cumini L. bark, Rosa damascenes miller petals and Tagetes erecta L. flowers have been studied (Pervaiz et al. 2016a, b, 2017). These plants produced different yields of dyes and shades. Bottle bush flowers produced the highest yield while aerial roots the least yield. Leaves, flowers and aerial roots yielded light and soft shades such as yellow, grey and light green while barks yielded dark and light shades. Soft pleasing shades were obtained with the T. erecta dye. It has been demonstrated that it’s possible to vary the colour of leather by using dyes from different plants and different plant parts. Further variations can be achieved by using appropriate premordants and mordants. Dyes showed fair to good evenness on both corium and grain sides of the leather and good to excellent results on colour fastness. In all these studies, the dyed leather showed appropriate colour value, strength and fastness properties. Sundari (2015) used extracts from Mucuna pruriens as a dyeing agent of chrome tanned leather. The optimized conditions that yielded 47% were at a temperature of 60 °C, for 1 h and a feed to solvent ratio of 1:5 and 0.75 mm particle size. As inferred from the reflectance and visual assessment, the dyed leather showed better colour value, fastness and strength properties. Based on significant quantity of tannins, alkaloids, flavonoids, carbohydrates, glycosides, terpenoids, phenols and a blue colour substance, Kusumawati et al. (2016) established the possibility of using Indigofera tinctoria L. (indofera) to dye milkfish leather. The substance has tannin which also improves the quality of the tanned leather. Although the three indigo concentrations in this study (20, 25, and 30%) showed significant effect to rub resistance, fastness to perspiration, 25% concentration yielded the best results based on rub resistance. Out of the three indofera extract concentrations; 20, 25, and 30%, concentration of 25% showed the best quality in terms of physical performance. Beta vulgaris contains betalains (red cyanins), betanins and xanthins (yellow) which have shown to possess antimicrobial and antioxidant activities (Nayak et al. 2006; Sivakumar et al. 2008). The red cyanins represents more than 75% of the total color present in beetroot. Sivakumar et al. (2008) extracted dyes from beet root and applied them for dyeing leather. Use of ultrasound was found to significantly improve the efficiency of extraction. The ethanol to water of 1:1 with 80 W ultrasonic power for 3 h of contact were optimum for better yield. The coloring ability of extracted beet dye has been tested on substrates such as leather and paper and found to be suitable for dyeing. Ultrasound is also found to be beneficial in natural dyeing of leather with improved rate of exhaustion. Both the dyed substrates have better color values for ultrasonic beet extract as inferred from reflectance measurement.

Bordingnon et al. (2012) determined the effect of temperature during fixation and addition of tocopherol on dye’s diffusion and fixation of urucum extracts. The dye showed commendable surface coating of the leather, good penetration, good bath exhaustion and equalization in the dyeing. Selvi et al. (2013) then used extracts from urucum seeds to dye and finish leather. The dyed and finished leather exhibited better coloring properties with dye exhaustion of 81%. The intense shade on both grain and corium was uniform due to smaller particle size of dye molecules (225 nm). Results demonstrated a viable option of dyeing and finishing leather using urucum instead of synthetic dyestuffs.

Fatliquoring process involves introducing fatty matters or/combination of fatliquoring agents such as sulphonated or sulphate oils that react with the fibrous structure of collagen to replace natural oils lost in beamhouse and tanning processes (Zengin et al. 2012; Nalyanya et al. 2018). The fatliquors based on vegetable or animal oils enhances the conversion of Cr(III) to Cr(VI) due to the unsaturated carbon–carbon bonds in the fatty acids both free and esterified (Fuck et al. 2011; Devikavathi et al. 2014). Ma et al. (2017) extracted surfactants from vegetable oil, dissymmetric gemini sulfosuccinate surfactant (DGSS) and compared its performance on leather with oils synthesized from petrochemicals. The surfactants exhibited outstanding environmental friendliness and superior surface activity than oils from petrochemicals (Table 7). The results also showed that DGSS significantly reduces the surface tension and shows good emulsification ability, good wetting ability and poor foaming performance. The leather treated with 8% of DGSS as a fatliquor was comparable to leather treated with 14% of commercial fatliquoring agent hence use of oils from DGSS reduces TDS. DGSS showed better fatliquoring effect (softness) better than the oils from petrochemicals.

Tawfik et al. (2017) extracted oil from the castor plant using Soxhlet extraction method and hexane solvent. The extracted oil was converted to fatliquors by sulphation process using sulphuric acid. It is a triglyceride in which approximately 90% of fatty acid chains are ricinoleate. The values of free fatty acid, specific gravity, refractive, acid, saponification and iodine values of both the crude and refined castor oil produced were determined and found to meet the standards leather fatliquors. Another study by Affiang et al. (2018) extracted oil from neem seeds using Sohlet extraction method and applied it on goat leather as alternative ecofriendly fatliquors. The oil was sulphated using sulphuric acid and sodium hydroxide to keep the pH at 5.0. The leather processed using the neem oil fatliquors was comparable to leather processed using imported palm oil in terms of performance. Oils extracted from Citrullus colocynthis contains secondary metabolites such as oleic, linoleic, stearic and palmitic acids that possess antimicrobial, antifungal, and antibiotic properties. Based on fungicidal property, Sahu et al. (2017) extracted oils from Citrullus colocynthis and sulphonated them with sulphuric acid at varied temperatures. It was found out that Citrullus colocynthis is a rich source of fatliquor due to high percentage of unsaturation oil.

Bielak and Sygula-Cholewinska (2017) investigated the durability of antimicrobial effect on leather fatliquored using thyme (oregano) and Cinnamomum zeylanicum (cinnamon) essential oils at percentage concentrations of 5%. Results showed that the antimicrobial activity of the essential oils from the plants against E. coli, S. aureus and C. albicans strains lasts for more than 3 years after fatliquoring. The vigor and period of the activity as bactericides and fungicides, together with the commendable optimum concentration of 5% places these bioactive substances as promising and viable green alternative phyto-biocide for leather preservation during finishing process.

Conclusions and future prospects

The review establishes that indeed significant researches have been done to identify appropriate plants that can replace the conventional leather making agents and the potential of phytochemistry in leather processing is enormous. Numerous plants and extracts have been determined for every leather tanning process. Plants have a greater applicability in this industry since they have multiple beneficial actions during processing and the final processed leather. Some plants can be used at all tanning processes due to wide variety of important phytochemicals and the final leather is more superior quality to the conventionally processed leather. Other studies have alluded to the possibility of some plant products that have the potential in the industry but yet to be utilized. In this review, the green technology of using plants envisages low waste or cleaner technologies that decrease the effluent pollution load, and avoid use of harmful chemicals and produce solid wastewater that can be treated easily since they are degradable. This review confirms the potential that can yield new leads in the leather processing agents. It is clear that both the technologies of complete replacement synthetic inorganic tanning system and combinations of synthetic and plant phytochemicals can be adopted by the industry to keep abreast with quality consistency of the leather and environmental regulations.

Most part of this review was limited to the evaluation of the technologies of plants that help mitigate environmental concerns. In the perspective of leather tanning industry, production of leather within the stringent environmental regulations only is insufficient. Alongside the green chemistry that guarantees reduced pollution, the industry is also tasked with producing leather with more functionalities and greater variety of property profiles at lower cost in order to meet customers’ duration and performance requirement. Therefore, it’s also crucial to consider the processability of the plants, their impact on the performance of final leather and the shelf life of the products. Therefore, individual plants must be investigated thoroughly under different conditions to ascertain that the products meet all requirements. Optimization of the extraction methods can be determined for each plant phytochemical components to maximize their quality and quantity in the application of leather tanning processes such as particle size, temperature, methanol content and time on the extraction of phytochemicals. Most dyes perform better with metal mordants which are less eco-benign. Therefore, more studies are required to overcome the challenge of metallic mordants. For dyeing, different colors can be achieved by using different mordants and different parts of the plant. Using plants which are renewable and biodegradable in leather tanning technologies envisages the cheaper and sustainable leather processing.

References

Abba H, Musa H, Ado A (2013) Comparative properties of pure and sulphonated dyes extracted from henna (Lawsonia inermis (Linnaeus) and Kolanut (Cola nitida (Vert.) Schott & Endl.) plants. Ife J Sci 15:429–434

Adzu B, Abbah J, Vongtau H et al (2003) Studies on the use of Cassia singueana in malaria ethnopharmacy. J Ethnopharmacol 88:261–267

Affiang SD, Ggamde G, Okolo VN et al (2018) Synthesis of sulphated-fatliquor from neem (Azadirachta Indica) seed oil for leather tannage. Am J Eng Res 7:215–221

Aloy M, Folachier A, Vulliermet B (1976) Tannery and pollution. Centre Technique D Cuir, Lyon, France, pp 230–260

Amir M, Mujeejb M, Khan A et al (2012) Phytochemical analysis and in vitro antioxidant activity of Uncaria gambier. Int J Green Pharm 6:67–72

Aquilar-Gavez A, Noratto G, Chambi F et al (2014) Potential of tara (Caesalpinia spinosa) gallotannins and hydrolysates as natural antibacterial compounds. Food Chem 156:301–304

Aravindhan R, Madhan B, Rao RJ (2015) Studies on tara-phosphonium combination tannage: approach towards a metal free eco-benign tanning system. JALCA 110:80–88

Bayramoglu EE (2007) Unique biocide for the leather industry: essential oil of oregano. JALCA 102:347–352

Bayramoglu EE, Gulumser G, Karaboz I (2006) Ecological and innovative fungicide for leather industry: essential oil of Origanum minutiflorum. JALCA 101:96–104

Bayramoglu EE, Korgan A, Kalender D et al (2008) Elimination of free formaldehyde in leather by Vinca rosea and Camellia sinesis extracts. JALCA 103:89–127

Beghetto V, Zancanaro A, Scrivanti A, Matteoli U, Pozza G (2013) The leather industry: chemistry insight part I: an overview of the industrial process. Sci Foscari. https://doi.org/10.7361/SciCF-448

Berhanu T, Ratnapandian S (2017) Extraction and optimization of natural dye from Hambo Hambo (Cassia singueana) plant used for coloration of tanned leather materials. Adv Mater Sci Eng 2017:7516409

Bielak E, Syguła-Cholewinska J (2017) Antimicrobial effect of lining leather fatliquored with the addition of essential oils. Biotechnol Food Sci 81:149–157

Bordingnon S, Gutterres M, Velho SK et al (2012) Novel natural dyes for eco-friendly leather articles. J Aqeic 63:93–100

Capecka E, Mareczek A, Leja M (2005) Antioxidant activity of fresh and dry herbs of some Lamiaceae species. Food Chem 93:223–226

Colak SM (2006) Soaking with tannins: the biocidal activity of vegetable tannins used in the soaking float. J Soc Leather Technol Chemists 90:193–196

Colak SM, Yapici BM, Yapici AN (2010) Determination of antimicrobial activity of tannic acid in pickling process. Rom Biotechnol Lett 15:5325–5330

Colak SM, Dandar U, Kilic E (2014) Antioxidant effect of tannic acid on formation of formaldehyde and hexavalent chromium compounds in leather. Tekstil ve Konfeksiyon 24:105–110

Covington AD (2011) Tanning chemistry. RSC Publishing, Cambridge

Das D, Maulik SR, Bhattacharya SC (2007) Dyeing of wool and silk with Bixa orellana. Indian J Fibre Text Res 32:366–372

Devikavathi G, Suresh S, Rose C, Muralidharan C (2014) Prevention of carcinogenic Cr (VI) formation in leather- a three pronged approach for leather products. Ind J Chem Technol 21:7–13

Dixit S, Yadav A, Dwivedi PD, Das M (2015) Toxic hazards of leather industry and technologies to combat threat: a review. J Cleaner Prod 87:39–49

Falcao L, Araujo MEM (2018) Vegetable tannins used in the manufacture of historic leathers. Molecules 23:1081

Fathima NN, Saravanabhavan S, Rao RJ et al (2004) An eco-benign tanning system using aluminium, tannic acid, and silica combination. JALCA 99:73–781

Fathima NN, Aravindhan R, Rao JR et al (2006) Tannic acid-phosphonium combination: a versatile chrome-free organic tanning. JALCA 101:161–168

Fuck WF, Gutteres M, Marcilio NR et al (2011) The influence of chromium supplied by tanning and wet finishing processes on the formation of Cr(VI) in leather. Braz J Chem Eng 28:221–228

Gandhiraja N, Sriram S, Meenaa V et al (2009) Studying different chemicals components of Mimosa pudica. Ethnobot Leafl 13:618–624

Hussein SA (2017) Utilization of tannins extract of Acacia seyal Bark (Taleh) in Tannages of leather. J Chem Eng Process Technol 8:334

Jagetia GC, Lalhmangaihi C (2018) Phytochemical profiling and antioxidant activity of Lajwanti Mimosa pudica Linn. in vitro. Int J Plant Stud 1:1–13

Klaric MS, Mastelic KJ, Pieckova E et al (2007) Antifungal activity of thyme (Thymus vulgaris L.) essential oil and thymol aginst moulds from damp dwellings. Lett Appl Microbiol 44:36–42

Kusumawati F, Riyadi PH, Rianingsih L (2016) Applications indigo (Indigofera tinctoria L.) as natural dyeing in milkfish [Chanos chanos (Forsskal, 1775)] skin tanning process. Aquatic 7:92–99

Ma J, Gao J, Wang H et al (2017) Dissymmetry gemini sulfosuccinate surfactant from vegetable oil: a kind of environmentally friendly fatliquoring agent in the leather industry. CS Sustain Chem Eng 5:10693–10701

Mahmoud ZF, Salam NA, Khafagy SM (1980) Constituents of henna leaves—Lawsonia inermis L. growing in Egypt. Fitoterapia 51:153–155

Miri S (2018) Phytochemistry, antioxidant and lipid peroxidation inhibition of the oils of Lavandula officianalis L. in Iran. Int J Food Prop 21:2550–2556

Mishra AK, Sahu N, Mishra A et al (2010) Phytochemical screening and antioxidant activity of essential oil of eucalyptus leaf. Pharmacogn J 2:25–28

Musa AE, Gasmelseed GA (2012) Characterization of Lawsoniainermis (Henna) as a vegetable tanning material. J For Prod Ind 1:35–40

Musa AE, Gasmelseed GA (2013a) Eco-friendly vegetable combination tanning system for production of hair-on shoe upper leather. J For Prod Ind 2:5–12

Musa AE, Gasmelseed GA (2013b) Development of eco-friendly combination tanning system for the manufacture of upper leathers. Int J Adv Ind Eng 1:9–15

Musa AE, Madhan B, Madhulatha W et al (2008) Henna extract: can it be an alternative retanning agent? JALCA 103:188–193

Musa AE, Madhan B, Madhulatha W et al (2009) Coloring of leather using henna-natural alternative material for dyeing. JALCA 104:183–190

Musa AE, Madhan B, Kanth SV et al (2010) Cleaner tanning process for the manufacture of upper leathers. Clean Technol Environ Policy 12:381–388

Nalyanya KM, Rop RK, Onyuka A et al (2015) Influence of UV radiation on the viscoelastic properties and dynamic viscosity of bovine hide using dynamic mechanical analysis. J Therm Anal Calorim 123:363–370

Nalyanya KM, Rop RK, Onyuka AS, Birech Z et al (2018) Effect of crusting operations on the physical properties of leather. Leather Footw J 18:283–294

Nayak CA, Chethana S, Rastogi NK et al (2006) Enhanced mass transfer during solid–liquid extraction of gamma irradiated red beetroot. Radiat Phys Chem 75:173–1778

Negi BS, Dave BP (2010) In vitro antimicrobial activity of Acacia catechu and its phytochemical analysis. Indian J Microbiol 50:369–374

Nurbalia E (2016) Characteristics identification Gambier (Uncaria Gambier Roxb) as leather tanning agent. Int Conf Technol Innov Soc 2016:62–67

Ozgunay H, Afsar A, Colak S et al (2012) Investigations on determination of antioxidant properties of certain plant products and their effects on the prevention of Cr(VI) and formaldehyde formation in leather. In: ICAMS 2012–4th international conference on advanced materials and systems

Ozkan G, Baydar H, Erbas S (2010) The influence of harvest time on essential oil composition, phenolic constituents and antioxidant properties of Turkish oregano (Origanum Onites L.). J Sci Food Agric 90:205–209

Ozkan CK, Ozgunay H, Kalender D (2017) A novel way to avoid Cr(VI) formation in leather: copper mordanting. J Soc Leather Technol Chem 101:94–95

Pervaiz S, Mughal TA, Khan FZ (2016a) Green fashion colours: a potential value for Punjab leather industry to promote sustainable development. Pak J Contemp Sci 1:28–36

Pervaiz S, Mughal TA, Najeebullah M et al (2016b) Extraction of natural dye from Rosa damascena Miller.—a cost effective approach for leather industry. Int J Biosci 8:83–92

Pervaiz S, Mughal TA, Khan FZ et al (2017) Environmental friendly leather dyeing using Tagetes erecta L. (Marigold) waste flowers. Int J Biosci 10:382–390

Sahu B, Rathinam A, Javid MA et al (2017) Preparation of fatliquor having antifungal activity using the oil of Citrullus colocynthis for application in leather applications. J Indus Crop Prod 10:553–557

Sanz M, Cadahia E, Esteruelas E et al (2010) Phenolic compounds in chestnut (Castanea sativa Mill.) heartwood: effect of toasting at cooperage. J Agric Food Chem 58:9631–9640

Saravanabhavan S, Fathima NN, Rao JR et al (2004) Combination of white minerals with natural tannins chrome-free tannage for garment leathers. J Soc Leather Technol Chem 88:76–81

Seabra IJ, Chim RB, Salgueiro P et al (2017) Influence of solvent additives on the aqueous extraction of tannins from pine bark: potential extracts for leather tanning. J Chem Technol Biotechnol 94:1169–1182

Selvi AT, Aravindhan R, Madhan B, Rao RJ (2013) Studies on the application of natural dye extract from Bixa orellana seeds for dyeing and finishing of leather. Indus Crop Prod 43:84–86

Sirvaityte J, Siugzdaite J, Valeika V (2011) Application of commercial essential oils of eucalyptus and lavender as natural preservative for leather tanning industry. Rev Chim (Bucharest) 62:884–893

Sirvaityte J, Siugzdaite J, Valeika V et al (2012) Application of essential oils of thyme as a natural preservative in leather tanning. Proc Estonian Acad Sci 61:220–227

Sivakumar V, Prakash PR, Rao PG, Ramabrahmam BV, Swaminathan G (2008) Power ultrasound in fatliquor preparation based on vegetable oil for leather application. J Cleaner Prod 16:549–553

Sivakumar V, Mohan R, Rangasamy T et al (2016) Antimicrobial activity of Terminalia chebula Retz. (Myrobalan). Indian J Nat Prod Resour 7:65–68

Sundari N (2015) Extraction and optimization of Mucura pruriens for dyeing of leather. Pol J Chem Technol 17:57–63

Tariq L, Reyaz A (2012) Phytochemical analysis of Camellia sinensis leaves. Int J Drug Dev Res 4:311–316

Tawfik HM, Gasmelseed GA, Mohammed FEF (2017) Using characterization and synthesis of fatliquor from Sudanese Castor Oil. Int J Eng Sci Res Technol 6:11–16

Upadhyay A, Agrahari P, Singh DK (2014) A review on the pharmacological aspects of Terminalia chebula. Int J Pharmacol 10:289–298

Zengin ACA, Crudu M, Maier SS, Deselnicu V, Albu L, Gulumser G, Bitlisli BO, Basaran B, Mutlu MM (2012) Eco-leather: chromium-free leather production using titanium, oligomeric melamine, formaldehyde resin and resorcinol tanning agents and the properties of the resulting leathers. Ekoloji 21:17–25

Zengin ACA, Colak SM, Zengin G et al (2014) Eco-friendly soaking process using tannic acid as an alternative bactericide. Arch Environ Prot 40(1):3–12

Acknowledgements

The study was performed with the financial support from National Research (NRF)-Kenya for PHD Research Grant 2016/2017.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nalyanya, K.M., Rop, R., Onyuka, A. et al. Recent use of selected phytochemistry to mitigate environmental challenges facing leather tanning industry: a review. Phytochem Rev 18, 1361–1373 (2019). https://doi.org/10.1007/s11101-019-09651-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11101-019-09651-x