ABSTRACT

Purpose

Stable vaccines with long shelf lives and reduced dependency on the cold chain are ideal for stockpiling and rapid deployment during public emergencies, including pandemics. Spray drying is a low-cost process that has potential to produce vaccines stable at a wide range of temperatures. Our aim was to develop a stable formulation of a recombinant H1N1 influenza hemagglutinin vaccine candidate and take it to pilot-scale spray-drying production.

Methods

Eight formulations containing different excipients were produced and assayed for antigen stability, powder characteristics, and immunogenicity after storage at a range of temperatures, resulting in the identification of four promising candidates. A pilot-scale spray-drying process was then developed for further testing of one formulation.

Results

The pilot-scale process was used to reproducibly manufacture three batches of the selected formulation with yields >90%. All batches had stable physical properties and in vitro potency for 6 months at temperatures from −20°C to +50°C. Formulations stored for 3 months elicited immunogenic responses in mice equivalent to a frozen lot of bulk vaccine used as a stability control.

Conclusions

This study demonstrates the feasibility of stabilizing subunit vaccines using a spray-drying process and the suitability of the process for manufacturing a candidate product.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

Vaccination is one of the most cost-effective means of preventing infectious diseases worldwide (1), but vaccines often lose potency and must be discarded after exposure to excessive high or low temperatures, especially in developing countries. Currently, vaccines typically have a shelf life of 2 to 3 years in a 2°C to 8°C cold chain and thus are not desirable for stockpiling due to both the need for stockpile turnover as products expire and the dependency on a cold chain in deployment. Aqueous formulation is the first choice when developing a new vaccine, for ease of preparation and administration; however, vaccines in solution are liable to chemical and physical degradation (2,3). Lyophilization is used to stabilize vaccines when aqueous formulations do not have an adequate shelf life inside the cold chain. As with liquid vaccines, most lyophilized vaccines must be maintained in a cold chain for storage and distribution. Because cold storage and transport impose a significant burden on vaccine logistics in both developed and developing nations, stable vaccines with extended shelf life and thermostability at a wide range of temperatures are highly desirable (4–10).

Recently, alternative drying processes such as spray drying, spray freeze drying, super-critical fluid drying, and vacuum foam drying have been investigated using a number of live and inactivated vaccines with the goal of improving both the thermostability of the vaccine and the versatility of the final formulation (11–15). Among these methods, spray drying is the most advanced and well-established technology in the pharmaceutical and food industries, having successfully produced drug excipients and food products in dry form since the early 1950s. The spray-drying process involves atomization of liquid into small droplets that are dispersed by preheated gas to form dry particles. The process is quick and easy to scale up and offers continuous rather than batch production. Spray-drying is an excellent alternative to standard lyophilization for the production of dry, stable vaccines (12,13). Although abundant published data demonstrate the feasibility of this approach for developing dry, stable biologicals, it has not gained a foothold in the vaccine industry (16–18). As aseptic spray dryers are being developed and introduced by several equipment manufacturers, it is important to evaluate scalability of the spray-drying process in developing thermostable vaccines, especially since most formulation development activities are conducted at laboratory scale.

To ensure a seamless transfer from laboratory-scale development to commercial production, a pilot-scale study is needed to help with the transition to current good manufacturing practices since batch characteristics may change during scale-up. The goal of scale-up is to ensure that all product quality attributes are optimized and do not change as larger-scale spray-drying equipment is used and the throughput is increased. It is essential to select a robust formulation early in development and to conduct early process development work with consideration of scale effects (19).

In this study, we report the development of a formulation and production process using the spray-drying method at pilot scale to stabilize a plant-produced recombinant hemagglutinin (rHA) influenza antigen, HAC1, as a model vaccine candidate.

MATERIALS AND METHODS

Materials

HAC1, the bulk drug substance (batch number CMB-BDS-0200-006), was manufactured at the Fraunhofer Center for Molecular Biotechnology’s Bioprocessing Facility in Newark, Delaware (20). It is a rHA protein encompassing amino acids 18-530 of A/California/04/09 H1N1 influenza strain (NCBI accession number ACQ76318.1). HAC1 was provided in phosphate-buffered saline (PBS), pH 7.0 ± 0.2. Trehalose was obtained from Alfa-Aesar in Ward Hill, Maryland. Dextran-40, gelatin hydrolysate enzymatic, sucrose, arginine, and polyvinylpyrrolidone (PVP-10) were purchased from Sigma-Aldrich in St. Louis, Missouri. Lecithin was obtained from Lipoid GmbH in Ludwigshafen, Germany.

Methods

Preparation of Formulations

To prepare the formulations, excipients were combined in appropriate ratios at 2X final concentration, filtered using 0.2 μm filters (VWR International, Radnor, Pennsylvania), and mixed 1:1 with HAC1 antigen to obtain a final concentration of 360 μg/mL HAC1 in the formulations. Eight formulations were tested in this study (Table I). All formulations had a pH in the range of 7.2 to 7.4.

Laboratory-Scale Spray Drying

Spray drying was conducted on a laboratory-scale Buchi 290 mini spray dryer (Buchi Corporation, New Castle, Delaware) using a two-fluid nozzle where atomizing gas (nitrogen) and feed solution were introduced separately into the nozzle. The inlet temperature was maintained at 100°C and the outlet temperature ranged from 58°C to 62°C. The spray nitrogen gas pressure was set at 35 mm, which translates to 30 kPa, and the flow rate of the peristaltic pump was set at 2% (∼0.6 mL/min). The yield was calculated as the percentage of solids present in the feed solution that were recovered in the product collection vessel. Samples of spray-dried formulations were evaluated in various assays after storage at various temperatures. For these studies, post spray drying, the powders were transferred at ambient relative humidity to labeled 2-mL vials that were then capped, crimped, secondarily packaged in heat-sealed aluminum foil bags containing about 1 gm of desiccant, and stored under assigned temperature conditions.

Pilot-Scale Spray Drying

A two-fluid atomizer (Spraying System, Wheaton, Illinois) was used for atomization of the spray solution on a pilot-scale laboratory dryer BLD-1 (custom-built dryer, Bend Research, Inc., Bend, Oregon). Inlet temperature was maintained at approximately 100°C, which resulted in ∼58°C outlet temperature. The drying gas (nitrogen) was fed to the BLD-1 at a rate of 30 kg/hour, and the spray solution feed rate was 4 mL/minute. This method resulted in good yields of particles in the 0.5- to 30-μm diameter range, using a cyclone to remove smaller particles. Process optimization on the BLD-1 was conducted by spray drying a placebo formulation for Flu-001 (without antigen) at atomization conditions of 8 psig and 30 psig. As was done for the laboratory-scale experiments, samples of pilot-scale spray-dried material were evaluated after storage at temperatures and durations described in sections below. For these studies, spray-dried powder was transferred at <5% relative humidity into labeled 2-mL vials that were then capped, crimped, secondarily packaged in heat-sealed aluminum foil bags containing about 1 gm of desiccant, and stored under assigned temperature conditions.

Single Radial Immunodiffusion Assay

The potency of the HAC1 antigen in the laboratory-scale spray-dried formulations was evaluated using single radial immunodiffusion (SRID) assay as described previously (21), with slight modification. Samples were assayed immediately after spray drying and after 1 week of storage at 50°C. Sheep antiserum generated against HAC1 and a reference lot of HAC1 bulk protein stored at −80°C were used as reference antiserum and antigen, respectively. One percent agarose in Veronal buffer (Lonza Biologics Inc., Portsmouth, New Hampshire) containing an optimal amount of the reference antiserum was cast on an immunodiffusion plate (MP Biomedicals, Solon, Ohio). The reference antigen and reconstituted test samples were diluted in PBS to an initial concentration of 50 μg/mL and further diluted 1.5-, 2-, 3-, and 4-fold in PBS. Each dilution of the reference antigen and the test samples was loaded into punched wells in the gels containing the reference antiserum. After 48 h of incubation in a humidified chamber at ambient temperature, the gels were washed with distilled water and incubated in PBS overnight to remove unbound antigen and serum components. The gels were then incubated in 2% tannic acid to increase resolution of the precipitin rings. The diameters of the precipitin rings were measured, and the concentration of the test antigens were calculated based on the dose-response curve generated with the reference antigen.

The potency of HAC1 in three pilot-scale batches of the lead candidate formulation was evaluated by SRID assay (same method as for laboratory-scale material). The spray-dried powder, stored in vials as described above, was reconstituted in deionized water, and assays were conducted each month for 6 months on material stored at temperatures of −20°C, 4°C, 40°C, and 50°C.

Liquid Differential Scanning Calorimetry

The melting temperature (Tm) of the antigen in each formulation was evaluated by solubilizing the dried powders in deionized water. The assays were conducted on a CAP-DSC2 microcalorimeter (MicroCal, Northampton, Massachusetts). The HAC1 control sample was dialyzed overnight in PBS at pH 7.4. The dialysate and a placebo solution were used as reference solutions for the HAC1 control and the formulation differential scanning calorimetry (DSC) measurements, respectively. Three buffer-versus-buffer runs were performed prior to running the placebo-versus-vaccine sample. The temperature range scanned was 30°C to 80°C, using a scan rate of 240°C/hour. The instrument was operated in “passive feedback” mode with a filtering period of 16 s, a 15-minute pre-scan equilibration, and a refill temperature set to 35°C. The data were analyzed using Origin 7.0 software (OriginLab, Northampton, Massachusetts). Buffer or placebo reference scans were subtracted and the data normalized.

Modulated Differential Scanning Calorimetry

A TA Q2000 modulated differential scanning calorimetry (mDSC) instrument (TA Instruments, New Castle, Delaware) was used to measure glass transition temperature (Tg) of the spray-dried powders. Sample masses of 5 mg to 15 mg were prepared under dry conditions (15°C to 25°C, <5% relative humidity). Loose powder or compacts were added to a tarred DSC pan and equilibrated overnight (>15 h) at <5% relative humidity. Analyses were performed using open pans to expel water during the scan, and hermetic 30-μL PerkinElmer pans were used for closed-pan water content analysis. The typical scan range was −40°C to 170°C for dry analysis. Program settings included a scan rate of 2.5°C/min with modulation ±1.5°C/min, a dry nitrogen purge gas at 50 mL/min, and data sampling at an interval of 0.20 sec/point.

Karl Fischer Assay

Karl Fischer (KF) assay was used to measure the moisture content of the spray-dried powders using a coulometric KF oven with a Metrohm 774 oven sample processor and a Metrohm 851 Titrando (Metrohm, Riverview, Florida). The Titrando was filled with Fluka 34739 Hydranol Coulomat AG oven solvent. During each run, system suitability was tested to confirm that the standard was within 1% of the label claim (theoretical 5.2 wt%). The KF standard (Hydranol® 34693) was provided by Sigma in St. Louis, Missouri. Data were evaluated using the Tiamo 2.2 analysis (Metrohm control and database software).

Scanning Electron Microscopy

Scanning electron microscopy (SEM) was performed by placing the spray-dried sample onto a glue tab (Ted Pella, Inc., Redding, California; product no. 16079, adhesive tab) on a new aluminum specimen post (Ted Pella, Inc., Redding, California; product no. 16111, specimen mount, aluminum, 1/2-inch slotted head, 1/8-inch pin). The specimen post was sputter coated using a Hummer 6.2 sputter coater (Anatech Limited, Battle Creek, Michigan) with an AuPd target for 8 min at approximately 15 to 20 mA. Samples were imaged using a Hitachi S-3400 N SEM instrument chamber.

Powder X-Ray Diffraction

Powder X-ray diffraction (PXRD) analysis was performed using a Bruker AXS XRPD X-ray diffractometer (Bruker Corporation, Germany) with a positional auto-sampler arm. Samples were loaded on a zero-background holder (ZBH) sample cup with single-crystal silicon sample surface and were exposed to the ambient environment. Approximately 10 mg to 20 mg of spray-dried powder were added to the center of a ZBH sample cup and flattened on the ZBH sample surface using a clean glass microscope slide. The following conditions were used for the spray-dried powders: continuous-mode detector scan at 2 theta (θ) scale; 4°C to 40°C; 0.04/step, 2.4 sec/step; fixed tube angle of 3; and generator setting of 45 kV/40 mA.

Immunogenicity Studies in Mice

To evaluate the effect of the formulation components and spray-drying process on the immunogenicity of the HAC1 vaccine, laboratory-scale spray-dried formulations were evaluated for immunogenicity in mice. Groups of ten 6- to 8-week old BALB/c mice (Harlan Laboratories Inc., Indianapolis, Indiana) were immunized intramuscularly on study days 0 and 21 with spray-dried HAC1 formulations reconstituted in water for injection (Thermo Scientific, Waltham, Massachusetts) or HAC1 in saline stored at −80°C as a reference control. For each test formulation, the HAC1 was administered at a dose of 9 μg with or without 0.3% Alhydrogel® (Accurate Chemical and Scientific, Westbury, New Jersey) containing 1.5 mg/mL of aluminum (75 μg per dose). Animals in the negative control groups received saline plus Alhydrogel® only. Serum samples were collected prior to each immunization and 3 weeks after the second immunization, corresponding to study day 42. Serum samples were assessed individually in a hemagglutination inhibition (HAI) assay to evaluate the functional antibody response elicited by each spray-dried formulation of HAC1 using turkey red blood cells and A/California/07/09 (NYMC X-179A, CDC#2009713114) virus as described previously (22).

To assess immunogenicity after pilot scale-up of the lead formulation, samples of three batches of the spray-dried vaccine were assayed in groups of mice as described for the laboratory-scale formulations. Samples stored in vials as described above were tested at T = 0 and also after 3 months of storage (T = 3). The samples tested were part of the same material that was stored at −20°C, 4°C, 40°C, and 50°C for the 6-month stability test. To evaluate the batch-to-batch consistency and thermostability of spray-dried HAC1 processed at a pilot scale, two doses—9 and 0.9 μg—of HAC1 were tested in the presence of 0.3% Alhydrogel® containing 1.5 mg/mL aluminum (75 μg/dose).

RESULTS

Formulation Development

Eight formulations (Table I), each containing 360 μg/mL HAC1, were spray dried on a laboratory-scale dryer. The typical batch size of the formulation prepared on the laboratory-scale Buchi was 10 mL for initial screening and 65 mL for a 2-month thermostability study. The process yield of all formulations was ∼75% to 85%. The mean particle size (D [4, 3]) measured for the placebo formulations was 7.2 μm at 8 psig and 3.4 μm at 30 psig. All spray-dried powders were pale white in color and free flowing with no visible aggregates.

In Vitro HAC1 Antigen Conformational Stability and Powder Analysis

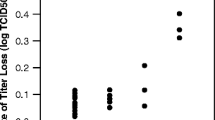

The potency of the HAC1 antigen in eight spray-dried formulations, immediately post spray drying and after 1 week at 50°C, was measured using a SRID assay (Fig. 1a). The data show large process loss after 1 week for formulation Flu-002, with >50% loss in antigen content but little to no loss for other spray-dried formulations (within the experimental variability of the SRID assay).

Stability tests for eight formulations of HAC1. Results are shown for testing before, immediately after, and 1 week after laboratory-scale spray drying. Samples tested after 1 week were stored in capped vials at 50°C. (a) Single radial immunodiffusion assay for potency. Only the potency loss for Flu-002 is significant (p = 0.05) (b) Melting temperatures. Because Flu-007 and Flu-008 had cloudy, emulsion-like appearances, Tm could not be determined for these formulations. Tm: melting temperature HAC1: hemagglutinin antigen vaccine candidate.

Analysis of Tm showed that formulations Flu-002 and Flu-004 had lower values both pre- and post-spray drying when compared with the Tm of the HAC1 control (Fig. 1b). Melting temperatures for HAC1 antigen in other formulations were equal to or higher than that of the HAC1 PBS control, suggesting the conformation of the HAC1 antigen was either maintained or enhanced. Because Flu-007 and Flu-008 had cloudy, emulsion-like appearances, Tm could not be determined.

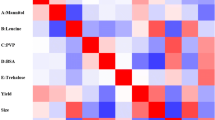

The physical properties of all eight spray-dried HAC1 formulations were characterized by DSC and SEM to test the Tg and morphology of the powders, respectively. All trehalose-containing formulations (Flu-001, Flu-002, Flu-003, Flu-006, Flu-007, and Flu-008 in Table I) had a high Tg (>110°C), while the sucrose-based formulations (Flu-004 and Flu-005) had a lower Tg of ∼60°C, as shown in Fig. 2. SEM results indicated that all spray-dried powders had shriveled, raisin-like morphology with no evidence of fused particles or particles with crystalline structure (data not shown). Most particles had a diameter between 5 and 10 μm (Fig. 3). This was also consistent with the results of PXRD analysis on all spray-dried powders where a broad amorphous halo characteristic of highly amorphous, non-crystalline material was detected (data not shown).

Based on the combined in vitro results from SRID, Tm, and physical powder assays, Flu-001, Flu-003, Flu-006, and Flu-007 were selected for testing after storage at elevated temperatures for up to 2 months. Results from the SRID assay on stored samples showed that all four formulations protected the antigen against heat damage at 50°C throughout the 2-month storage period (Table II). The four formulations maintained their amorphous character with a high Tg of >100°C at storage temperatures of 40°C or 50°C. All formulations maintained moisture content of ∼4% (w/v) at both temperatures. SEM images show no apparent morphological changes for Flu-003 and Flu-007 after storage. However, Flu-001 and Flu-006 showed particle fusion and smoothing over the 2-month period at 50°C, suggesting their solid state changed upon storage at this temperature (Fig. 3).

Immunogenicity of HAC1 Spray-Dried Formulations in Mice

Four trehalose-based spray-dried formulations (Flu-001, Flu-003, Flu-006, and Flu-007) produced using a laboratory-scale dryer were selected based on initial stability results from in vitro antigen and powder assays and further evaluated for immunogenicity in mice. Serum HAI antibody responses in mice after the primary immunization were either undetectable or just above the detection level (1:20) in all animals. No HAI antibody was detected in pre-immune sera (data not shown). After the second immunization (study day 42), all four formulations elicited equivalent levels of serum HAI antibody titers (Fig. 4). Addition of Alhydrogel® to each formulation significantly enhanced the immunogenicity of the spray-dried HAC1. There were no significant differences observed in HAI titers among the groups of mice that received the different spray-dried formulations plus Alhydrogel® or among the groups of mice that received the spray-dried formulations without Alhydrogel® (n = 10, one-way ANOVA followed by Turkey’s post-test, p > 0.05). In addition, HAI titers in groups immunized with each spray-dried HAC1 formulation plus Alhydrogel® were equivalent to those obtained from the group immunized with the HAC1 control antigen plus Alhydrogel® (p > 0.05).

Serum hemagglutination inhibition antibody responses in mice on study day 42 elicited by 9 μg of four different laboratory-scale spray-dried HAC1 formulations with or without Alhydrogel® containing 1.5 mg/mL of aluminum (75 μg per dose). Data are shown as mean titer with standard error of the mean, with the numbers in the graph indicating percent responders per group that generated serum HAI titers of ≥1:40. Controls were unformulated HAC1 bulk protein in phosphate-buffered saline. N = 10 for each group. HAI: hemagglutination inhibition Alum: Alhydrogel® adjuvant.

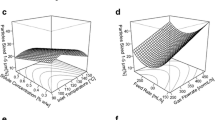

Process Scale-Up

Based on antigen stability and powder analyses of the eight formulations produced at laboratory scale, formulation Flu-003 was selected for pilot scale-up. Details of the selection process for Flu-003 are presented in the Discussion section. Process scale-up involved initial comparison of atomization pressures at 8 psig versus 30 psig on a pilot-scale dryer while keeping the same inlet temperature of 100°C, as used on the laboratory-scale Buchi dryer. The powders produced at 8 psig had somewhat larger particle sizes and fewer fines (small particles). Because these characteristics generally result in powders that flow better and are less likely to be affected by static electrical charges, the 8 psig atomization pressure was selected for producing the pilot-scale formulation. Three pilot-scale batches of Flu-003 were spray dried using 500-mL volume with the yield ≥90% (∼50 g) on the pilot-scale dryer. The batches were analyzed for antigen stability, physical properties, and immune response in mice to test the robustness of the formulation and the process transfer from laboratory scale to pilot scale.

In Vitro HAC1 Antigen Stability and Powder Analysis

The three pilot-scale batches of spray-dried HAC1 formulation Flu-003 were tested for their potency using SRID assay. The results showed that all batches had little or no potency loss during spray drying and maintained their HAC1 content at all time points and temperatures tested throughout the 6-month stability study (Figs. 5a–d).

The physical properties of three pilot-scale batches of Flu-003 spray-dried formulations were characterized using KF, mDSC, PXRD, and SEM (Table III). All three batches maintained an amorphous state with water content of 4.00 ± 0.5% and Tg of 120°C at all time points and all storage temperatures. SEM showed no morphologic variation and no sign of crystallization across all three pilot lots for all temperatures and time points (data not shown). These results suggest that formulation Flu-003 stabilizes the antigen during the spray-drying process and also after storage at elevated temperatures.

Immunogenicity of the HAC1 Spray-Dried Vaccine in Mice

The immunogenicity data on Flu-003 showed that HAI antibody responses in mice after the primary immunization were either undetectable or just above the detection level (1:20) in all animals, and no HAI antibody was detected in pre-immune sera (data not shown). After the second immunization (study day 42) with the time-zero samples, there were no significant differences in HAI titers among groups immunized with three different pilot batches of Flu-003 at a dose of 9 μg or when compared to the control HAC1 antigen (N = 10, one-way ANOVA, p > 0.05) (Fig. 6a).

Serum hemagglutination inhibition antibody responses in mice after immunization with two doses of pilot-scale spray-dried Flu-003 (study day 42) before and after storage at different temperatures. All vaccine preparations included Alhydrogel® containing 1.5 mg/mL of aluminum (75 μg per dose). Data are shown as mean titer with standard error of mean. Numbers in the graphs indicate percent responders per group that generated serum HAI titers of ≥1:40. (a) T = 0: three batches of Flu-003, each given at two levels of antigen (9.0 μg and 0.9 μg); (b) T = 3: pooled pilot-scale batches of Flu-003 administered at two levels of antigen (9.0 μg and 0.9 μg) after storage at indicated temperatures for 3 months. HAI: hemagglutination inhibition.

The selection of dose was based on results from the previous HAC1 dose-escalation study in mice where the 0.9 μg dose is below the plateau of immune response (23). In this study, the lower dose (0.9 μg) of HAC1 was tested to investigate if immunization at a decreased dose of antigen would reveal inconsistency in the immunogenicity of the three pilot batches. As seen earlier (20), where doses of HAC1 that contain less than 1 μg in an Alhydrogel® formulation elicit lower HAI titers as well as a lower proportion of responders per group, this study shows similar data where lower responses were obtained in the lower-dose groups (23). However, results showed that there were no significant differences (p > 0.18) in HAI titers among groups that received 0.9 μg of the pilot batches stored under different storage temperatures or when the responses were compared to the group receiving 0.9 μg of control HAC1 antigen (N = 10, one-way ANOVA, p > 0.05) (Fig. 6a).

The results of the immunogenicity study of the three pilot batches after 3 months of storage at different temperatures (−20°C, 4°C, 40°C, and 50°C) showed no significant differences in HAI antibody titers among all groups of mice that received HAC1 (Fig. 6b) at both doses, 9 μg (p > 0.095) and 0.9 μg (p > 0.18). In addition, the HAI antibody titers obtained from these groups of animals were equivalent to those generated with material prior to storage (Fig. 6a, T = 0). These results demonstrate consistency of the three pilot batches of Flu-003 as well as the stability of the HAC1 antigen in the Flu-003 formulation for at least 3 months at temperatures ranging from -20°C to 50°C.

DISCUSSION

The spray-drying process is a continuous, scalable, and well-established technology in the pharmaceutical industry, capable of producing bulk powders from gram to ton quantities in an hour. Compared with lyophilization, this process is more flexible and economical in terms of equipment installation, investment, and running operations for producing bulk powders. Taken to a commercial level, spray drying to provide vaccine thermostability has the potential to extend the reach of vaccines in parts of the world with less-reliable infrastructure. Improved thermostability of vaccines also can help to reduce dependence on the cold chain, improving stockpiling efforts in the event of a pandemic or biothreat situation. However, to take a thermostable spray-dried vaccine to commercialization, validation of scale-up is necessary to ensure that the product maintains the intended attributes when produced in large volumes. Scale-up is not a linear process and can prove challenging due to differences in batch size, run time, particle size, and temperature gradient, all of which can impact the stability of products, especially vaccines.

Selection of excipients for developing stable vaccine formulations typically involves iterative testing of excipients for various characteristics using a combination of biophysical assays. In contrast, this study employed an empirical approach of testing formulations rather than individual excipients with the goal of developing a robust formulation that could withstand the variable conditions encountered during large-scale production. In the first study phase, eight formulations containing sugars and polymers in varying ratios were spray dried at laboratory scale using excipients and the optimized process conditions determined previously in PATH’s laboratory for other similar subunit/inactivated vaccine candidates (17,18). HAC1 has been reported to be most stable at pH between 7.0 and 8.0 (24). We used PBS because research on inhaled spray-dried influenza vaccine has shown that this buffer maintains the conformation of proteins during the drying process (11). We attribute the high yields (>70%) for all formulations to the choice of excipients, which were based on our previous studies, the optimization of atomization conditions—which produced fewer fine particles, and the cyclone conditions, which eliminated the fines that were produced. It has been shown that combining properties of select excipients can provide a synergy of functionality improvements—for example, in powder flow properties and hence improved recovery—while masking the undesirable properties of individual excipients (25).

The selection of formulation Flu-003 for scale-up was based on a combination of in vitro evaluation of antigen content (process loss and stability), antigen structure, and powder properties as well as in vivo immunogenicity testing. After spray drying, most formulations, with the exception of Flu-002, maintained their antigen content, suggesting that only minimal damage was incurred during the drying process. However, further investigation based on protein conformation analysis using Tm revealed that formulations Flu-002 and Flu-004, which contained arginine, had a lower Tm, indicating a reduced stability of antigen in these formulations. Tm is the temperature at which the native (folded) and denatured (unfolded) antigen states (conformations) are equally populated. Unfolded protein molecules are, in general, highly prone to aggregation, which reduces their functionality. Although the role of arginine and its contribution to protein stability is not clear, published reports cite arginine as a useful excipient in suppressing heat-induced protein aggregation via nonspecific adsorption (26). In this study, while arginine lowered the melting temperature of HAC1 in Flu-002 and Flu-004, it is not clear if the extent of loss is sufficient to suggest denaturation of the protein. Other formulations (Flu-001, Flu-003, and Flu-006) either maintained or raised the Tm, suggesting the potential to resist unfolding and thus lower the chance of forming aggregates, resulting in a more stable vaccine.

Powder properties also play a critical role in maintaining long-term stability of vaccines. Proteins stored in an amorphous, glassy state have limited molecular mobility. As a result, diffusion-controlled reactions, including protein unfolding/aggregation and chemical degradation, are reduced, and the protein exhibits stability over longer time periods (4,5,27). The spray-drying process produces amorphous powders; however these may become unstable due to moisture conditions, chemical interactions, or temperature changes and may transform into a more stable crystalline form, which is detrimental for a vaccine antigen. In order to improve the stability of the amorphous form, polymer excipients such as dextran, PVP-40, and hydrolyzed gelatin were included in formulations to increase the Tg of the binary mixture (sugar-polymer). Higher Tg can maintain protein stability in a glassy state at high temperatures, thus increasing thermostability. Our spray-drying process produced dry, free-flowing amorphous powders with varying Tg in the range of 60°C to 120°C. The two sucrose-based formulations (Flu-004 and Flu-005) had a Tg of ∼60°C, whereas trehalose-based formulations (Flu-001, Flu-003, Flu-006, and Flu-008) had a Tg of ≥110°C, clearly demonstrating the potential for increased stability offered by trehalose-containing formulations. This observation is consistent with published literature identifying trehalose as one of the most suitable sugars for protecting proteins from denaturation during dehydration and storage due to its high Tg (28,29).

Based on in vitro antigen and powder assays, four trehalose-based formulations (Flu-001, Flu-003, Flu-006, and Flu-007) were identified as stabilizing the antigen in dry form. Although there appeared to be no difference between Flu-007 and Flu-008 with respect to powder properties or antigen stability, Flu-007 was chosen for further study in order to test the contribution of different polymer types in long-term storage of the dry vaccine. Similarly, Flu-001, containing only trehalose as the stabilizing excipient, was included to understand how polymers improve the shelf life of dry vaccine products. Immunogenicity studies with Alhydrogel® as an adjuvant demonstrated that all four formulations elicited similar immune responses to each other as well as to the bulk vaccine control. This suggests that the spray-drying process did not have a negative effect on the immunogenicity of the HAC1 antigen. In addition, all four formulations were assessed for adsorption to Alhydrogel® using SDS-PAGE and Western blot analysis of formulation supernatants (data not shown). Results of this analysis demonstrated that there was no impact on the antigen’s adsorption to the aluminum adjuvant in the presence of each formulation. However, SEM analysis of samples showed particle fusion after storage for 2 months at 50°C for Flu-001 and Flu-006, indicating a potential impact on re-dispersability at the time of vaccine preparation and administration. In Flu-007, lecithin was added as an additional stabilizing excipient to protect the antigen from temperature-induced surface denaturation encountered in the spray-drying process. Although Flu-007 maintained antigen stability and powder properties similar to those of Flu-003 under elevated temperatures, it contained an additional excipient that did not appear to offer any benefit over Flu-003. Additional excipients will also have an impact on total cost of goods for the final product. Thus, after evaluation of all characteristics of the eight formulations, Flu-003 was chosen for pilot scale-up.

In the second phase of this study, three batches of Flu-003 were spray dried on a pilot-scale dryer to test process scalability and reproducibility using conditions identified on the laboratory-scale spray dryer. The batch size of the spray-dried HAC1 vaccine on the pilot-scale spray dryer was 50 g, approximately 100-fold larger than the batch size dried at laboratory scale (∼0.5 g). All three batches maintained antigen content and powder properties throughout the 6-month stability study at all storage temperatures. The spray-dried powders induced equivalent immune responses to the bulk HAC1 vaccine control after being stressed at temperatures up to 50°C for 3 months, suggesting that the pilot-scale spray-drying process did not alter the immunogenicity of the HAC1 antigen and that Flu-003 was highly thermostable. The pilot-scale results replicated the findings observed with spray-dried vaccine powders prepared at laboratory scale.

CONCLUSION

This study demonstrated that the spray-drying process is a viable technology for producing stable HAC1 vaccines with extended shelf life and/or with less dependence on a cold chain. The formulation selected for scale-up was stable at temperatures ranging from −20°C to 50°C for up to 6 months, the longest time point tested in this study, and the production process is amenable to industrial-scale production. The stability profile of the spray-dried vaccine makes the technology an attractive option for producing vaccines for stockpiling as well as for routine immunizations in regions where the cold chain is inadequate.

Abbreviations

- DSC:

-

Differential scanning calorimetry

- HAI:

-

Hemagglutination inhibition

- KF:

-

Karl Fischer moisture content analysis

- mDSC:

-

Modulated differential scanning calorimetry

- PBS:

-

Phosphate-buffered saline

- PXRD:

-

Powder X-ray diffraction

- SEM:

-

Scanning electron microscopy

- SRID:

-

Single radial immunodiffusion

- Tg :

-

Glass transition temperature

- Tm :

-

Melting temperature

- ZBH:

-

Zero-background holder

REFERENCES

World Health Organization (WHO), United Nations Children’s Fund, World Bank. State of the world’s vaccines and immunization. 3rd ed. Geneva: WHO; 2009.

Wang W. Instability, stabilization, and formulation of liquid protein pharmaceuticals. Int J Pharm. 1999;185(2):129–88.

World Health Organization (WHO). Temperature sensitivity of vaccines. Geneva: WHO; 2006.

Wang W. Lyophilization and development of solid protein pharmaceuticals. Int J Pharm. 2000;203(1–2):1–60.

Saluja V, Hinrichs WL, Frijlink HW. Dried influenza vaccines: over the counter vaccines. Hum Vaccin. 2010;6(10):854–6.

Schlehubera L, McFadyena I, Yu S, Carignana J, Duprex WP, Forsyth WR, et al. Towards ambient temperature-stable vaccines: the identification of thermally stabilizing liquid formulations for measles virus using an innovative high-throughput infectivity assay. Vaccine. 2011;29(31):5031–9.

Chen D, Kristensen D. Opportunities and challenges of developing thermostable vaccines. Expert Rev Vaccines. 2009;8(5):547–57.

Kristensen D, Chen D, Cummings R. Vaccine stabilization: research, commercialization, and potential impact. Vaccine. 2011;29(41):7122–4.

Mustien JB, Lemon SM, Wright PF. Development of a more thermostable poliovirus vaccine. J Infect Dis. 1997;175 Suppl 1:S247–53.

Braun LJ, Jezek J, Peterson S, Tyagi A, Perkins S, Sylvester D, et al. Characterization of a thermostable hepatitis B vaccine formulation. Vaccine. 2009;27(34):4609–14.

Amorij JP, Huckriede A, Wilschut J, Frijlink HW, Hinrichs WL. Development of stable influenza vaccine powder formulations: challenges and possibilities. Pharm Res. 2008;25(6):1256–73.

Maa YF, Ameri M, Shu C, Payne LG, Chen D. Influenza vaccine powder formulation development: spray-freeze-drying and stability evaluation. J Pharm Sci. 2004;93(7):1912–23.

Seville PC, Li HY, Learoyd TP. Spray-dried powders for pulmonary drug delivery. Crit Rev Ther Drug Carrier Syst. 2007;24(4):307–60.

Cape SP, Villa JA, Huang ET, Yang TH, Carpenter JF, Sievers RE. Preparation of active proteins, vaccines and pharmaceuticals as fine powders using supercritical or near-critical fluids. Pharm Res. 2008;25(9):1967–90.

Jangle RD, Pisal SS. Vacuum foam drying: an alternative to lyophilization for biomolecule preservation. Indian J Pharm Sci. 2012;74(2):91–100.

Jin TH, Tsao E, Goudsmit J, Dheenadhayalan V, Sadoff J. Stabilizing formulations for inhalable powders of an adenovirus 35-vectored tuberculosis (TB) vaccine (AERAS-402). Vaccine. 2010;28(27):4369–75.

Chen D, Kapre S, Goel A, Suresh K, Beri S, Hickling J, et al. Thermostable formulations of a hepatitis B vaccine and a meningitis A polysaccharide conjugate vaccine produced by a spray drying method. Vaccine. 2010 Jul 12;28(31):5093–9.

Ohtake S, Martin RA, Yee L, Chen D, Kristensen D, Lechuga-Ballesteros D, et al. Heat-stable measles vaccine produced by spray drying. Vaccine. 2010;28(5):1275–84.

DuBose E, Settell D, Baumann J. Efficient scale-up strategy for spray-dried amorphous dispersions. Drug Dev Deliv. October 2013;13(8):54–62.

Shoji Y, Chichester JA, Jones M, Manceva SD, Damon E, Mett V, et al. Plant-based rapid production of recombinant subunit hemagglutinin vaccines targeting H1N1 and H5N1 influenza. Hum Vaccin. 2011;7(Suppl):41–50.

Shoji Y, Chichester JA, Bi H, Musiychuk K, de la Rosa P, Goldschmidt L, et al. Plant-expressed HA as a seasonal influenza vaccine candidate. Vaccine. 2008;26(23):2930–4.

Shoji Y, Farrance CE, Bautista J, Bi H, Musiychuk K, Horsey A, et al. A plant-based system for rapid production of influenza vaccine antigens. Influenza Other Respir Viruses. 2012;6(3):204–10.

Shoji Y, Jones MR, Mett V, Chichester JA, Musiychuck K, Sun X, et al. A plant-produced H1N1 trimeric hemagglutinin protects mice from a lethal influenza virus challenge. Hum Vaccin Immunother. 2013;9(3):553–60.

Iver V, Livanage MR, Shoji Y, Chichester JA, Jones RM, Yusibov V, et al. Formulation development of a plant-derived H1N1 influenza vaccine containing purified recombinant hemagglutinin antigen. Hum Vaccin Immunother. 2012;8(4):453–64.

Surawase RK, Surana SS, Maru AD, Malpure PS. Development of directly compressible co-excipient by spray drying technique. Int J Pharm Phytopharmacol Res. 2011;1(1):35–47.

Arakawa T, Ejima D, Tsumoto K, Obeyama N, Tanaka Y, Kita Y, et al. Suppression of protein interactions by arginine: a proposed mechanism of the arginine effects. Biophys Chem. 2007;127(1–2):1–8.

Roos YH. Importance of glass transition and water activity to spray-drying and stability of dairy powders. Lait. 2002;82:475–84.

Kaushik JK, Bhat R. Why is trehalose an exceptional protein stabilizer? An analysis of the thermal stability of proteins in the presence of the compatible osmolyte trehalose. J Biol Chem. 2003;278(29):26458–65.

Leslie SB, Israeli E, Lighthart B, Crowe JH. Trehalose and sucrose protect both membranes and proteins in intact bacteria during drying. Appl Environ Microbiol. 1995;61(10):3592–7.

ACKNOWLEDGMENTS AND DISCLOSURES

This work was supported with funding from the Defense Threat Reduction Agency. The authors wish to thank Patricia Logan, Amy Wales, and Marjorie Murray for their assistance in the development of this article, Megan Coffin and Dione Gray for their technical assistance with the immunogenicity studies, and Dr. John Sumida for the sample testing.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, C., Shoji, Y., McCray, S. et al. Stabilization of HAC1 Influenza Vaccine by Spray Drying: Formulation Development and Process Scale-Up. Pharm Res 31, 3006–3018 (2014). https://doi.org/10.1007/s11095-014-1394-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-014-1394-3