Abstract

Purpose

Although probiotics are of a major potential therapeutic interest, their efficacy is usually limited by poor bioavailability of viable microorganisms on site. The aim of this study was to protect the probiotic Saccharomyces boulardii from degradation in order to ensure a greater number of viable yeast in the colon.

Methods

Alginate microspheres coated with or not with chitosan were used to encapsulate the yeast by an extrusion method. The efficiency of encapsulation was assessed both in vitro and in vivo.

Results

In vitro, less than 1% of the non-encapsulated probiotic survived after 120 min at pH 1.1, whereas the majority of encapsulated yeast cells remained entrapped within both types of microspheres. Further exposure to a pH 6.8 allowed the release of about 35% of viable yeasts. In vivo, the percentage of viable yeast excreted over 96 h after a single oral dose of 2 × 108 cfu/100 g in rats was 2.5% for non-encapsulated yeast and reached 13.3 and 9.0% of the dose administered for the uncoated and chitosan-coated microspheres, respectively.

Conclusions

Given the dose-dependent efficacy of S. boulardii and the efficiency of microencapsulation in protecting the yeast from degradation, alginate microspheres could be of great interest in therapeutic applications of the yeast.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

The concept that live microorganisms which, when administered in adequate amounts, confer a health benefit on the host is defined by the term “probiotic”. Increasing scientific interest in probiotic strategy in modulating intestinal inflammation (1) has been encouraged by the positive results obtained from the application of probiotics for the prevention and treatment of conditions such as pouchitis of ulcerative colitis (2,3). Among the most widely available probiotics, S. boulardii is a yeast, clinically effective for the prevention and treatment of infectious enteritis and Clostridium difficile-associated enterocolopathies (4–9). Beside its use as an anti-diarrhoeal agent, pilot studies suggest that S. boulardii may also exhibit beneficial effects on other intestinal pathologies like Crohn’s disease (10) and ulcerative colitis (11). A commercialized form of the yeast is available as a freeze-dried powder obtained from the aqueous suspension of the yeast. For these microorganisms to exert their beneficial effects, they have to survive gastrointestinal transit and reach their site of action alive. Hence, the efficacy of S. boulardii correlates with stool concentrations of viable yeast in patients with recurrent Clostridium difficile disease (12). A major barrier to the survival of ingested live cells is the acidic environment of the stomach. S. boulardii is commonly presented as a yeast genetically resistant to gastric acidity (13). However, exposure to a low pH of 2 for one hour is lethal to 25% of the probiotic (14). In addition, Bléhaut et al. (15) have shown that the viability of freeze-dried S. boulardii is challenged after oral administration in man and in rat and that less than 1% of the live yeasts administered orally are recovered in the faeces. In a recent study (S. Graff, et al., unpublished data), we observed that the resistance of the yeast to the challenging gastrointestinal conditions is dependent on the dose. Hence, the percentage of survival in the rat faeces can be increased up to 18% with doses of 4 × 109 cfu/100 g bw about ten times higher than those formerly tested (15). However, the adaptation of such high dosages for humans remains speculative. Another alternative is to utilise microencapsulation which is the method of choice for improving the viability of probiotics in food as well as in simulated gastrointestinal conditions (16–22). In addition, multi-unit delivery systems like microspheres distribute more uniformly in the gastrointestinal tract than monolithic forms and represent an efficient approach to target the colon (23,24).

Our hypothesis was that the encapsulation of S. boulardii in microspheres could protect the yeast from destruction in the gastrointestinal tract and therefore increase intestinal delivery of the viable probiotic. In order to test this hypothesis, uncoated microspheres and chitosan-coated microspheres were prepared and characterised, and their capacity to protect the viability of the probiotic was evaluated during gastrointestinal transit, simulated in vitro and explored in vivo in healthy rats.

MATERIALS AND METHODS

Materials

The aqueous suspension of S. boulardii (75% water, 25% fresh extract) and a freeze-dried powder (FD) obtained from the former were supplied by Biocodex (Gentilly, France). Sodium alginate (Satialgin® S 60) was supplied by SKW Biosystems (Boulogne Billancourt, France). Acrylic acid copolymer Eudragit® S 100 was obtained from Degussa (Darmstadt, Germany). Chitosan (practical grade) from crab shells was supplied by Sigma Aldrich (L’Isle d’Abeau Chesnes, France). Of note, the materials which compose the microspheres are regarded as safe in humans and alginic acid and chitosan hydrochloride are registered in the European Pharmacopoeia while methacrylic acid copolymers are registered in the US Pharmacopoeia.

Preparation of Microspheres

Four grams of acrylic acid copolymer and 1.8 g of sodium alginate were dissolved in 70 ml of phosphate buffer solution at pH 8.0. The aqueous suspension of S. boulardii (viability = 6.44 ± 0.35 × 1010 cfu g−1 of yeast) was added in the amount of 40 g. The suspension mixture was extruded using the Inotech Encapsulator® IE-50 (Inotech AG, Dottikon, Switzerland) as described by Serp et al. (25). Laminar jet break-up was induced by applying a sinusoïdal frequency of 765 Hz with a defined amplitude of 3 to the 300 μm nozzle. A suspension flow rate of 11 ml min−1 and an electrical potential of 1 kV were maintained throughout the extrusion process. The microspheres were allowed to harden for at least 30 min in 0.1 M CaCl2 solution at pH 4 under continuous magnetic stirring. Of note, scale-up of the vibration technology can be achieved by multiplication of the single nozzle configuration. Scale-up from laboratory to industrial scale could be considered using an industrial-scale multinozzle encapsulation plant.

Half of the batch of microspheres was rinsed twice with 0.1 M CaCl2 solution and coated by immersion in chitosan solution (0.4% (w/v) in 1% (v/v) glacial acetic acid) for 30 min under magnetic stirring.

The uncoated microspheres (UM) and chitosan-coated microspheres (CCM) were collected, rinsed twice with sterile water and dried in an oven for 4 days at 25°C. Preparation yield (Y) was calculated as follows:

Where W t is the final dry weight of the microspheres obtained after drying (UM) or coating and drying (CCM) and W 0 is the initial weight of dried material contained in the volume of suspension processed. Results were expressed as percentages.

Characterisation of Microspheres

The microspheres were characterised after drying.

The equivalent diameter (ED, µm) and the shape factor (SF) were assessed using optical microscopy (Labophot-2A, Nikon, Tokyo, Japan) and Visiolab 1000 version V2-50 software (Biocom, Les Ulis, France) according to the following equations:

Where A is the area and P is the perimeter of the microspheres. Data were collected from 50 microspheres in each sample.

The viable yeast content in the microspheres was determined by a disintegration method in pH 6.8 phosphate buffer solution. Samples of the resultant suspension were removed and assayed after serial 10-fold dilutions by a plate culture method on Sabouraud and chloramphenicol agar at +30°C for 72 h. Then, colonies on plates were enumerated and expressed as cfu g−1 of yeast (detection limit was 102 cfu g−1). Entrapment efficiency was calculated after drying by dividing the number of viable yeast recovered by dissolution of the microspheres in pH 6.8 buffer solution by the number of viable yeast in the aqueous suspension of S. boulardii used for the preparation. Results were based on triplicate determinations and expressed as a percentage. The number of viable yeast per gram of microspheres was calculated by dividing the number of viable yeast recovered by dissolution of the microspheres in pH 6.8 buffer solution by the mass of microspheres tested. Results were based on triplicate determinations and expressed as cfu g−1 of microspheres.

In Vitro Study

A dissolution test apparatus (Prolabo, Fontenay sous Bois, France) (paddle method according to USP 1), was used for evaluating the viability of non-encapsulated yeast as well as entrapped yeast in 500 ml of pH 1.1 and pH 6.8 media at +37 ± 0.5°C and 100 rpm.

The freeze-dried yeast was tested in 0.1 N HCl (pH 1.1) (2 g l−1 corresponding to 4.84 ± 0.37 × 1010 cfu l−1) mimicking the pH conditions in the stomach. Samples of the medium were collected at 0, 5, 15, 30, 60 and 120 min in order to determine the yeast viability using the plate culture method described above. Experiments were carried out in triplicate. Results were expressed in log cfu g−1 of yeast.

In order to evaluate the survival of the entrapped yeast, uncoated microspheres (3.57 g l−1 corresponding to 2 g l−1 of yeast or 6.84 ± 0.40 × 1010 cfu l−1) and chitosan-coated microspheres (3.66 g l−1 corresponding to 2 g l−1 of yeast or 6.88 ± 0.26 × 1010 cfu l−1) were placed in 0.1 N HCl for 2 h. After incubation, microspheres were removed, filtered and rinsed twice with sterile water. The washed microspheres were then placed in pH 6.8 phosphate buffer for 2 h. Samples were collected at 5, 15, 30, 60 and 120 min in each medium. The viable yeasts were enumerated using the plate culture method described above. Experiments were carried out in triplicate. Results were expressed in log cfu g−1 of yeast.

In Vivo Study

Animal care and experimentation complied with both French (D2001-486) and European Community regulations (Official Journal of the European Community L 358 12/18/1986) and the last author of the manuscript is authorized by the French government to perform experimental research on rodents (authorization N°75-456, 10/10/2001). The protocol of the study was agreed by Regional Ethical Committee (N°P2.CC.016.06, 07/03/2006).

Twenty four male Wistar rats (201–225 g) purchased from Charles River (L’Arbresle, France) were housed individually in a controlled temperature environment (21 ± 1°C) with a 12-h light–dark cycle and were allowed water and a standard powdered yeast-free chow diet (UAR A04, Safe, Augy, France) ad libitum for a 6-day acclimatization period. After this period, they were housed in metabolic cages and body weight and food intake were recorded daily over 8 days (D-1 to D6). At D0, the animals were randomized into three groups and received a single dose of 2 × 108 cfu/100 g bw of S. boulardii provided as either the freeze-dried yeast (7 mg/100 g bw), uncoated microspheres (9.8 mg/100 g bw) or chitosan-coated microspheres (10.2 mg/100 g bw), mixed with 20% (6 g) of their standard chow diet intake (determined from D-1 intake). This temporary food restriction allowed the yeast + food mixture to be totally ingested by the rats and the remaining 80% of food (24 g) was given 6 h post-administration.

Fresh faecal samples were collected aseptically by pressing on the extremity of the colon of the rats at D0 (before treatment and 6 hours post-administration), D1, D2, D3, D4 and D6. Samples were crushed in 0.9% NaCl solution and viable yeasts were enumerated using the plate culture method as described above. Total faeces were collected and weighed at the same times and the cumulated amounts of viable yeast cells excreted over four days was calculated. Results were expressed as cfu per rat.

Statistical Analysis

Results were presented as mean ± SEM. Statistical analysis was performed using the F test followed by the t test, except for comparison of the in vivo excretion of viable yeast for which a one-way ANOVA followed by the Bonferroni–Dun test was used. Differences between means were considered significant at p < 0.05.

RESULTS

Characteristics of Microspheres

UM were monodisperse with an equivalent diameter close to the nozzle size, and a spherical shape. Coating with chitosan significantly increased the equivalent diameter, altered the shape factor, and led to a decrease in preparation yield (Table 1).

The initial number of viable S. boulardii in aqueous suspension used to prepare the microspheres was 6.44 ± 0.35 × 1010 cfu g−1 of yeast. After encapsulation, the number of viable yeasts recovered in pH 6.8 phosphate buffer was 3.42 ± 0.27 × 1010 cfu g−1 of yeast in the UM and 3.44 ± 0.13 × 1010 cfu g−1 of yeast in the CCM and entrapment efficiency was similar for both formulations. The number of viable yeasts per gram of microsphere was 2.16 ± 0.17 × 1010 cfu in the UM and 2.13 ± 0.08 × 1010 cfu in the CCM.

In Vitro Evaluation

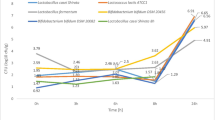

The viability of freeze-dried (FD) yeast in 0.1 N HCl (Fig. 1A) decreased significantly from 2.42 ± 0.18 × 1010 to 5.98 ± 1.18 × 109 cfu g−1 of yeast in the first 5 min (p < 0.05 vs time 0) and was less than 1% of yeast after 120 min (3.01 ± 0.41 × 107 cfu g−1, p < 0.05 vs time 0).

In vitro survival of freeze-dried yeast (A, FD) in 0.1 N HCl (pH 1.1) for 2 h and survival of yeast released from uncoated (B, UM) and chitosan-coated microspheres (C, CCM) in 0.1 N HCl for 2 h followed by pH 6.8 phosphate buffer (PB) for 2 h (n = 3 for each assay). D Comparison between mean amounts of viable yeast in 0.1 N HCl followed by pH 6.8 phosphate buffer in vitro. *p < 0.05 freeze-dried yeast vs initial viability at 0 min, **p < 0.05 UM and CCM vs number of viable yeast released at 120 min in 0.1 N HCl.

The initial release of viable yeasts from microspheres in 0.1 N HCl was fast and reached a maximum value of 5.23 ± 4.16 × 108 cfu g−1 of yeast (1.76 ± 1.40 × 108 cfu g−1 of microsphere) at 5 min for the UM (Fig. 1B) and 1.19 ± 0.38 × 108 cfu g−1 of yeast (2.30 ± 0.70 × 107 cfu g−1 of microsphere) for the CCM (Fig. 1C) at 15 min. This initial release was followed by a decrease in probiotic viability to the lowest values of 6.50 ± 1.74 × 107 cfu g−1 of yeast at 15 min for the UM and to 1.50 ± 1.12 × 107 cfu g−1 of yeast at 60 min for the CCM. The release of viable yeasts was partial (<1%) in this medium and achieved a relative plateau up to 120 min for both types of microspheres. In pH 6.8 phosphate buffer solution, the UM and the CCM were totally disintegrated after 5 min leading to a significant total release of 1.21 ± 0.41 × 1010 cfu g−1 of viable yeast (4.07 ± 1.37 × 109 cfu g−1 of microsphere) and 7.02 ± 1.34 × 109 cfu g−1 of viable yeast (2.32 ± 0.44 × 109 cfu g−1 of microsphere), respectively. No significant difference could be shown between both forms which released about 35% of viable yeast after 2 h at pH 6.8 (Fig. 1D).

In Vivo Evaluation

During the assay, rat body weight as well as food intake were similar between the three groups (data not shown).

In all animals, faecal samples collected prior to S. boulardii administration (time 0) did not contain any yeast. In all groups, five days after the single oral dose of the probiotic, no viable yeast could be detected in the faeces. The excretion profile of viable S. boulardii was dependent on the type of yeast administered. Concerning the freeze-dried yeast, no viable cells could be detected 6 h post-administration. The excretion of viable yeast cells was maximal at 24 h and decreased up to 96 h (Fig. 2A). The excretion of viable yeast after microsphere ingestion was faster than that of the freeze-dried yeast. Viable S. boulardii could be detected as soon as 6 h post-administration in three out of the eight rats having received UM (Fig. 2B) and in four out of the eight rats having received CCM (Fig. 2C). In both cases, the excretion was maximum at 24 h and decreased up to 72 h.

Excretion profile of viable S. boulardii (log cfu) by Wistar rats after a single oral dose of 2 × 108 cfu/100 g body weight of either the freeze-dried yeast (A, FD) or uncoated (B, UM) and chitosan-coated microspheres (C, CCM) (individual values of eight rats in each group). D Comparison between mean amounts of viable yeast recovered in faeces 6 h, 1, 2, 3 and 4 days post-dose. Detection limit was 2 log cfu. *p < 0.05 uncoated microspheres (UM) vs freeze-dried yeast (FD).

In each group, more than 99% of the total viable yeasts excreted were recovered in the faeces 24 h after the single oral dose of 2 × 108 cfu/100 g bw and the number of viable yeast recovered from the UM was significantly higher than that of the freeze-dried yeast (p < 0.05) (Fig. 2D). The cumulated amount of viable yeast excreted after 96 h, was 1.26 ± 0.72 × 107, 6.42 ± 2.74 × 107 and 4.99 ± 3.60 × 107 cfu (p < 0.05 UM vs freeze-dried yeast) corresponding to 2.5, 13.3 and 9.0% of the dose administered for the freeze-dried yeast, the UM and the CCM, respectively.

DISCUSSION

In the present study, which to the best of our knowledge, is the first one exploring the behaviour of an encapsulated probiotic in vivo, encapsulation of S. boulardii in alginate microspheres significantly protected the viability of the yeast cells when they were exposed to an acidic medium in vitro, and significantly increased intestinal delivery of the viable probiotic in healthy rats.

Little data has been published with regards to the microencapsulation of yeasts (26–29) but numerous microencapsulation strategies have been evaluated for their ability to protect probiotics from environmental stresses (26,27,30–32) most of them using alginate which presents the benefits of being non-toxic, biodegradable and biocompatible (33). In our study, the mild formulation conditions used to produce alginate microspheres in all-aqueous media by cross-linking sodium alginate with Ca2+ divalent cations allowed the encapsulation of the yeast with minimum effect on their viability and a good entrapment efficiency rate. However, when alginate was used alone to formulate microspheres loaded with S. boulardii, aggregation and sticking between microspheres were important at the time of drying. Further crushing of dried aggregates had a negative impact on the sphericity of the microspheres. The enteric acrylic copolymer Eudragit® S100 was subsequently combined with alginate. Based on its pH-dependent solubility, it was dissolved at pH 8; sodium alginate was dissolved and the yeasts were suspended thereafter. Eudragit® S100 became part of the alginate microsphere core through precipitation at pH 4 in the CaCl2 hardening solution. The use of 4% (w/v) of Eudragit® S100 minimized aggregation and sticking between microspheres and was therefore adopted although no further resistance to acid conditions could be observed (data not shown). This latter point could be easily explained by the fact that pH-dependent polymers like Eudragit® have to form continuous insulating coatings in order to achieve gastroresistance.

Film coating of alginate microspheres with Eudragit® was not tested for technical reasons. Obtention of coating solutions of such polymers requires pHs between 5.5 to 7.5 (depending on the grade considered) which would be unusable in the coating of alginate microspheres which desintegrate at such pH values. Immersion in either organic solutions or aqueous suspensions at a lower pH could neither be envisaged due to issues of toxicity with regard to the yeast for the former and inefficiency in methodology for the latter. Spray methods were also excluded because of high temperature requirements which would be incompatible with thermolabile yeasts such as S. boulardii.

Further coating with chitosan was tested in an attempt to improve resistance of the microspheres (34,35) since this polycationic polymer can increase the stability of alginate microspheres and is able to minimise the loss of encapsulated material through ionic cross-linking with sodium alginate (30,36). However, coating with chitosan increased the size of microspheres, worsened aggregation and sticking between microspheres and led to a decrease in preparation yield. Although it delayed the initial burst release of the yeast in acidic medium in vitro, it was inefficient in significantly improving yeast protection in vivo. In accordance with previous studies (35,37) the enlargement of microspheres suggested the formation of a chitosan layer due to ionic bonding between chitosan and alginate. The formation of this coating could explain the delayed release of yeasts in 0.1 N HCl compared to the uncoated microspheres. However, this protection was limited to the early phase of exposure in the acidic medium. The total yeast release after 2 h was similar between the chitosan-coated microspheres and the uncoated microspheres which could be as a result of the ionic interactions between the carboxyl residues of alginate and the amino groups of chitosan not being complete to form the required polyelectrolyte complex. This could be due to the low pH value of the coating solution necessary to allow precipitation of Eudragit® S100. Indeed, Gaserod et al. (38) proved that an increase in pH had a positive effect on the binding of chitosan-alginate gel beads especially above a value of 5–6. Thus, at pH 4, amino groups in the polymer backbone of chitosan could not be totally ionised limiting the formation of the semi-permeable membrane around calcium alginate. In addition, the alteration in the shape of the microspheres was probably due to the crushing necessary to separate chitosan–coated microspheres aggregated after drying and could also have altered the integrity of the chitosan barrier. Nonetheless, uncoated as well as coated microspheres proved their efficiency in protecting S. boulardii viability: the release of viable probiotic remained below 1% of the total encapsulated yeasts after 2 h in acidic medium, and reached about 35% after 5 min in pH 6.8 phosphate buffer solution. Two reasons could explain the global loss of viable yeasts. The first one is a possible loss of material occurring when the microspheres were removed from the acidic medium, filtered, rinsed twice and then placed in phosphate buffer. The second one is probably a partial loss of viability of the yeasts released in acidic medium, as previously shown in vitro for non-encapsulated yeasts (14). Encapsulated yeasts were partially released in acidic medium and their number decreased before plateauing up to 120 min. One hypothesis to explain this phenomenon could be that following the initial release which probably corresponds to the yeasts entrapped onto the surface of the microspheres and is concomittant with a significant loss of viability, an apparent equilibrium is achieved with the amount of S. boulardii released equalling the decrease in probiotic viability. Despite this phenomenon, microencapsulation was efficient in preserving S. boulardii viability in challenging acidic condition in vitro.

The possible impact of bile on non-encapsulated and microencapsulated S. boulardii was not tested in the present work. Data about the sensitivity of S. boulardii to bile salts show that S. boulardii is more sensitive to bile salts than S. cerevisiae. The literature published on microencapsulation of probiotics with alginate reports controversial data regarding bile exposure. Some authors reported the efficiency of the microencapsulation method to increase the survival of the probiotic microorganisms in simulated gastric juice and bile solution (39) whereas others did not observe any increased survival of the microencapsulated probiotics in acid and bile salt conditions (21). What we can indirectly deduce from our in vivo data is that microencapsulation with alginate is efficient in significantly preserving S. boulardii viability in the gastrointestinal tract regardless of acid or bile salt-induced degradation.

In vivo, a higher number of viable yeasts was excreted in the faeces after a single oral dose of alginate microspheres loaded with S. boulardii than after freeze-dried yeast administration. Our data about the in vivo fate of non-encapsulated freeze-dried S. boulardii were in accordance with the disposition kinetics of the yeast previously studied in man and rat (15) and the poor survival of the probiotic after gastrointestinal transit was confirmed. Microencapsulation provided an efficient protection against degradation which could result from two associated mechanisms. The first one is the resistance of the microspheres in acidic medium discussed above, that could favour a second mechanism implying an acceleration of the transit rate of the yeast. Indeed, viable S. boulardii appeared in the faeces as soon as 6 h after the administration of the microencapsulated yeasts while no viable probiotic could be detected 6 h after ingestion of the non-encapsulated yeasts. One could suppose that the transit rate of S. boulardii within the gastrointestinal tract could be influenced by the size of the microspheres (330–350 µm) which is approximately 30 times the size of the probiotic (8–10 µm) and their heavier density. Tuleu et al. (40) have shown that the heavier the density, the longer the gastric emptying and the gastro-colonic transit time of non-disintegrating pellets in rats; this latter parameter was also influenced by size of the pellets. However, size and density factors are not sufficient in explaining the differences in the gastrointestinal transit rate since the microspheres loaded with S. boulardii are biodegradable and disintegrate as soon as an adequate pH value is reached within the intestine. Interestingly, Bléhaut et al. (15) have observed that live S. boulardii cells move faster in the gastrointestinal tract than dead cells. It could be hypothesised that the resistance of microspheres in acidic medium of the stomach would allow the release of a higher number of viable yeasts within the intestine; through a quicker transit time these live cells would sustain a shorter exposure to challenging in vivo conditions and thereby survive in a greater number. Chitosan coating brought no additional benefit over uncoated microspheres in vivo and total gut transit time was in the same range for both types of microspheres regardless of chitosan coating and differences in equivalent diameters. Due to its mucoadhesive properties, chitosan could theoretically have delayed the transit time of the coated micropheres. However, it was not the case in our study possibly because the adhesive properties of chitosan decreased with cross-linking with alginate (33).

Uncoated microspheres proved to be more efficient than the chitosan-coated microspheres in protecting S. boulardii in vivo, producing a 13% survival rate in rats. This value was achieved with a single oral dose of 2 × 108 cfu/100 g bw, that is to say a dose more than ten times lower than doses which proved to be efficient in experimental pathological situations (41,42). Given the dose-dependent efficacy of S. boulardii for several of its protective effects (41–43) on the one hand, and the fact that microencapsulation can increase intestinal delivery of viable probiotic by about 5.5 fold on the other hand, alginate microspheres could represent a valuable dosage form for S. boulardii administration which may lead to an improvement in efficacy. More investigations will be necessary to explore the efficiency of microencapsulated S. boulardii in pathological situations.

CONCLUSION

Microencapsulation of S. boulardii in alginate microspheres significantly limits the degradation of the yeast in the gastrointestinal tract after a single oral administration in vivo in rat. Coating microspheres with chitosan provides no additional benefit. Microencapsulation could be of a major interest in therapeutic applications of the yeast since the efficiency of S. boulardii is dose-dependent for several of its protective effects. By increasing the number of viable yeasts reaching the lower intestine, microspheres could enhance the activity of S. boulardii in several bowel diseases.

Abbreviations

- CCM:

-

Chitosan-coated microspheres

- ED:

-

Equivalent diameter

- FD:

-

Freeze-dried yeast

- SF:

-

Shape factor

- UM:

-

Uncoated microspheres

References

S. Ghosh, D. van Heel, and R. J. Playford. Probiotics in inflammatory bowel disease: is it all gut flora modulation? Gut. 53:620–622 (2004).

P. Gionchetti, F. Rizzello, U. Helwig, A. Venturi, K. M. Lammers, P. Brigidi, B. Vitali, G. Poggioli, M. Miglioli, and M. Campieri. Prophylaxis of pouchitis onset with probiotic therapy: a double-blind, placebo-controlled trial. Gastroenterology. 124:1202–1209 (2003).

T. Mimura, F. Rizzello, U. Helwig, G. Poggioli, S. Schreiber, I. C. Talbot, R. J. Nicholls, P. Gionchetti, M. Campieri, and M. A. Kamm. Once daily high dose probiotic therapy (VSL#3) for maintaining remission in recurrent or refractory pouchitis. Gut. 53:108–114 (2004).

E. Bergogne-Berezin. Ecologic impact of antibiotherapy. Role of substitution microorganisms in the control of antibiotic-related diarrhea and colitis. Presse Med. 24:145–156 (1995).

J. P. Buts, G. Corthier, and M. Delmee. Saccharomyces boulardii for Clostridium difficile-associated enteropathies in infants. J Pediatr Gastroenterol Nutr. 16:419–425 (1993).

L. V. McFarland, C. M. Surawicz, R. N. Greenberg, G. W. Elmer, K. A. Moyer, S. A. Melcher, K. E. Bowen, and J. L. Cox. Prevention of beta-lactam-associated diarrhea by Saccharomyces boulardii compared with placebo. Am J Gastroenterol. 90:439–448 (1995).

L. V. McFarland, C. M. Surawicz, R. N. Greenberg, R. Fekety, G. W. Elmer, K. A. Moyer, S. A. Melcher, K. E. Bowen, J. L. Cox, Z. Noorani, et al. A randomized placebo-controlled trial of Saccharomyces boulardii in combination with standard antibiotics for Clostridium difficile disease. JAMA. 271:1913–1918 (1994).

C. M. Surawicz, G. W. Elmer, P. Speelman, L. V. McFarland, J. Chinn, and G. Van Belle. Prevention of antibiotic-associated diarrhea by Saccharomyces boulardii: a prospective study. Gastroenterology. 96:981–988 (1989).

C. M. Surawicz, L. V. McFarland, R. N. Greenberg, M. Rubin, R. Fekety, M. E. Mulligan, R. J. Garcia, S. Brandmarker, K. Bowen, D. Borjal, and G. W. Elmer. The search for a better treatment for recurrent Clostridium difficile disease: use of high-dose vancomycin combined with Saccharomyces boulardii. Clin Infect Dis. 31:1012–1017 (2000).

M. Guslandi, G. Mezzi, M. Sorghi, and P. A. Testoni. Saccharomyces boulardii in maintenance treatment of Crohn’s disease. Dig Dis Sci. 45:1462–1464 (2000).

M. Guslandi, P. Giollo, and P. A. Testoni. A pilot trial of Saccharomyces boulardii in ulcerative colitis. Eur J Gastroenterol Hepatol. 15:697–698 (2003).

G. W. Elmer, L. V. McFarland, C. M. Surawicz, L. Danko, and R. N. Greenberg. Behaviour of Saccharomyces boulardii in recurrent Clostridium difficile disease patients. Aliment Pharmacol Ther. 13:1663–1668 (1999).

J. P. Buts, and P. Bernasconi. Saccharomyces boulardii: basic science and clinical applications in gastroenterology. Gastroenterol Clin North Am. 34:515–532 (2005).

J. L. Fietto, R. S. Araujo, F. N. Valadao, L. G. Fietto, R. L. Brandao, M. J. Neves, F. C. Gomes, J. R. Nicoli, and I. M. Castro. Molecular and physiological comparisons between Saccharomyces cerevisiae and Saccharomyces boulardii. Can J Microbiol. 50:615–621 (2004).

H. Bléhaut, J. Massot, G. W. Elmer, and R. H. Levy. Disposition kinetics of Saccharomyces boulardii in man and rat. Biopharm Drug Dispos. 10:353–364 (1989).

L. Truelstrup Hansen, P. M. Allan Wojtas, Y. L. Jin, and A. T. Paulson. Survival of Ca-alginate microencapsulated Bifidobacterium spp. in milk and stimulated gastrointestinal conditions. Food Microbiol. 19:35–45 (2002).

K. Adhikari, A. Mustapha, I. U. Grun, and L. Fernando. Viability of microencapsulated bifidobacteria in set yogurt during refrigerated storage. J Dairy Sci. 83:1946–1951 (2000).

R. C. W. Hou, M. Y. Lin, M. M. C. Wang, and J. T. C. Tzen. Increase of viability of entrapped cells of Lactobacillus delbrueckii ssp. bulgaricus in artificial sesame oil emulsion. J Dairy Sci. 86:424–428 (2002).

W. C. Lian, H. C. Hsiao, and C. C. Chou. Viability of microencapsulated bifidobacteria in simulated gastric juice and bile solution. Int J Food Microbiol. 86:293–301 (2003).

J. H. Cui, J. S. Goh, P. H. Kim, S. H. Choi, and B. J. Lee. Survival and stability of bifidobacteria loaded in alginate poly-l-lysine microparticles. Int J Pharm. 210:51–59 (2000).

K. Sultana, G. Godward, N. Reynolds, R. Arumugaswamy, P. Peiris, and K. Kailasapathy. Encapsulation of probiotic bacteria with alginate-starch and evaluation of survival in simulated gastrointestinal conditions and in yoghurt. Int J Food Microbiol. 62:47–55 (2000).

W. Krasaekoopt, B. Bhandari, and H.C. Deeth. Survival of probiotics encapsulated in chitosan-coated alginate beads in yoghurt from UHT and conventionally treated milk during storage. LWT. 39:177–183 (2006).

M. L. Lorenzo-Lamosa, C. Remunan-Lopez, J. L. Vila-Jato, and M. J. Alonso. Design of microencapsulated chitosan microspheres for colonic drug delivery. J Control Release. 52:109–118 (1998).

A. Lamprecht, H. Yamamoto, H. Takeuchi, and Y. Kawashima. Microsphere design for the colonic delivery of 5-fluorouracil. J Control Release. 90:313–322 (2003).

D. Serp, E. Cantana, C. Heinzen, U. Von Stockar, and I. W. Marison. Characterization of an encapsulation device for the production of monodisperse alginate beads for cell immobilization. Biotechnol Bioeng. 70:41–53 (2000).

K. Koyama, and M. Seki. Cultivation of yeast and plant cells entrapped in the low-viscous liquid-core of an alginate membrane capsule prepared using polyethylene glycol. J Biosci Bioeng. 97:111–118 (2004).

Q. Wen-Tao, Y. Wei-Ting, X. Yu-Bing, and M. Xiaojun. Optimization of Saccharomyces cerevisiae culture in alginate–chitosan–alginate microcapsule. Biochem Eng J. 25:151–157 (2005).

F. Talebnia, C. Niklasson, and M. J. Taherzadeh. Ethanol production from glucose and dilute-acid hydrolyzates by encapsulated S. cerevisiae. Biotechnol Bioeng. 90:345–353 (2005).

F. Talebnia, and M. J. Taherzadeh. In situ detoxification and continuous cultivation of dilute-acid hydrolyzate to ethanol by encapsulated S. cerevisiae. J Biotechnol. 25:377–384 (2006).

J. S. Lee, D. S. Cha, and H. J. Park. Survival of freeze-dried Lactobacillus bulgaricus KFRI 673 in chitosan-coated calcium alginate microparticles. J Agric Food Chem. 52:7300–7305 (2004).

C. Iyer, M. Phillips, and K. Kailasapathy. Release studies of Lactobacillus casei strain Shirota from chitosan-coated alginate-starch microcapsules in ex vivo porcine gastrointestinal contents. Lett Appl Microbiol. 41:493–497 (2005).

A. Ainsley Reid, J. C. Vuillemard, M. Britten, Y. Arcand, E. Farnworth, and C. P. Champagne. Microentrapment of probiotic bacteria in a Ca(2+)-induced whey protein gel and effects on their viability in a dynamic gastro-intestinal model. J Microencapsul. 22:603–619 (2005).

M. George, and T. E. Abraham. Polyionic hydrocolloids for the intestinal delivery of protein drugs: Alginate and chitosan—a review. J Control Release. 114:1–14 (2006).

A. K. Anal, D. Bhopatkar, S. Tokura, H. Tamura, and W. F. Stevens. Chitosan-alginate multilayer beads for gastric passage and controlled intestinal release of protein. Drug Dev Ind Pharm. 29:713–724 (2003).

A. K. Anal, and W. F. Stevens. Chitosan-alginate multilayer beads for controlled release of ampicillin. Int J Pharm. 290:45–54 (2005).

K. Y. Lee, and T. R. Heo. Survival of Bifidobacterium longum immobilized in calcium alginate beads in simulated gastric juices and bile salt solution. Appl Environ Microbiol. 66:869–873 (2000).

D. W. Lee, S. J. Hwang, J. B. Park, and H. J. Park. Preparation and release characteristics of polymer-coated and blended alginate microspheres. J Microencapsul. 20:179–192 (2003).

O. Gaserod, O. Smidsrod, and G. Skjak-Braek. Microcapsules of alginate-chitosan-I A quantitative study of the interaction between alginate and chitosan. Biomaterials. 19:1815–1825 (1998).

V. Chandramouli, K. Kailasapathy, P. Peiris, and M. Jones. An improved method of microencapsulation and its evaluation to protect Lactobacillus spp. in simulated gastric conditions. J Microbiol Methods. 56:27–35 (2004).

C. Tuleu, C. Andrieux, P. Boy, and J. C. Chaumeil. Gastrointestinal transit of pellets in rats: effect of size and density. Int J Pharm. 180:123–131 (1999).

P. Girard, Y. Pansart, I. Lorette, and J. M. Gillardin. Dose-response relationship and mechanism of action of Saccharomyces boulardii in castor oil-induced diarrhea in rats. Dig Dis Sci. 48:770–774 (2003).

P. Girard, Y. Pansart, M. C. Coppe, and J. M. Gillardin. Saccharomyces boulardii inhibits water and electrolytes changes induced by castor oil in the rat colon. Dig Dis Sci. 50:2183–2190 (2005).

G. Philippe-Taine, L. Coroler, R. H. Levy, and J. M. Gillardin. Dose dependent preventive effect of Saccharomyces boulardii on clindamycin induced alterations in intestinal aerobic flora of the hamster. Microb Ecol Health Dis. 15:126–130 (2003).

Acknowledgments

This work was supported by Biocodex, France. The authors acknowledge Pr M. J. Butel and her team for free access to the Microbiology Laboratory, Université Paris Descartes, Dr G. Dumortier and Dr P. Boy for their contribution to the statistical analysis of the data, and Pr L. Cynober for his thoughtful comments and sound advice.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Graff, S., Hussain, S., Chaumeil, JC. et al. Increased Intestinal Delivery of Viable Saccharomyces boulardii by Encapsulation in Microspheres. Pharm Res 25, 1290–1296 (2008). https://doi.org/10.1007/s11095-007-9528-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-007-9528-5