Abstract

The paper presents the results of an experiment on the effect of cold plasma (He + O2 and He + Air) generated in a radio frequency cold atmospheric plasma jet on the process of germination of onion cv. Wolska (Allium cepa L.) seeds. In order to determine the impact of the gas flow on the seed surface, CFD simulations and Schlieren imaging were performed and surface characteristics were studied using a digital microscope. Plasma treatment of the seeds was carried out four times (2, 5, 10 and 15 s) with one control group. Pre-sowing plasma stimulation of seeds improved the germination capacity and germination energy for all tested groups in comparison to the control. The best germination capacity and energy were obtained for seeds stimulated with 10 s of plasma treatment. Analysis of the data showed a statistically significant impact of plasma treatment on the onion seed’s germination parameters. Plasma treatment did not induce significant changes on the seed surface, as microscope images showed but length of all plasma-treated seedlings increased in comparison to control.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Due to the possibility of generating non-equilibrium plasma with a relatively low temperature, cold atmospheric plasma (CAP) jets are now widely applied in bioengineering [1,2,3,4,5,6,7,8,9]. A promising application of plasmas in agriculture is improving seed germination processes [1, 10,11,12,13,14,15,16,17,18,19]. Plasma can increase germination directly by stimulation of biological processes in seeds, and indirectly as a result of biological decontamination from pathogens. Regarding direct stimulation, the plasma can interact via radiation, temperature, and influence of the reactive oxygen and nitrogen species’ bio-chemistry. These factors can cause an increase in the amount of chlorophyll and polyphenols [10], a modulated activity of antioxidants [11, 12] or a modification of DNA regulation [13]. In studies on the treatment of Thuringian Mallow (Lavatera thuringiaca L.) seeds with a dielectric barrier discharge (DBD) and with a GlideArc reactor, the observed increase in germination was associated with changes in the structure of the seed shell surface [16, 20]. This effect origins from an etching of the outer layers of the shell by the plasma, which can change the seed’s wettability and improve water absorption [10, 14,15,16, 21]. Regarding indirect stimulation caused by decontamination, seed germination is improved by removing harmful organisms (bacteria, fungi) and creating a favorable microbial flora. Plasma helps reducing harmful bacteria such as B. cereus, E. coli or Salmonella [17,18,19] and fungi that are dangerous for plants, including F. nivale, F. culmorum, T. roseum, A. flavus and A. clavatus [1, 22]. A study by Schnabel et al. found that the shape of the examined objects determines the contact of the material with active plasma species [19]. The distribution of gas flow over the treated surface is particularly relevant in CAP jets, where gas dynamic forces play an important role. The fluid-dynamic behaviour of a jet often is determined by computer simulations, e.g., using computational fluid dynamics (CFD) [23,24,25,26,27]. A method for the experimental determination of gas distribution is Schlieren imaging (German Schlieren—streak) which is widely used in plasma diagnostics [4, 28,29,30,31,32,33]. Schlieren imaging is based on the observation of the change in contrast of an image, originating from the deflection of light rays due to refractive index changes in the observed gas volume by type and temperature variations in the flowing gas.

The aim of the present study is to determine the effect of the length of plasma treatment on the germination parameters in seeds of onion cv. Wolska (Allium cepa L.). Onion cv. Wolska is one of the most important vegetables in terms of production worldwide [34]. The experiments were performed with non-thermal plasma generated in a radio frequency (RF) plasma jet using different gas mixtures. In order to determine the gas flow on the seed surface, CFD simulations and Schlieren imaging were performed and surface characteristics were studied using a digital microscope. Short treatment times were selected for the plasma treatment, motivated by an economical point of view.

Materials and Methods

Cold Plasma Parameters

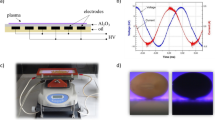

The plasma was generated in capacitively coupled RF jet reactor, a so called atmospheric pressure plasma jet (APPJ) with a high voltage electrode inside its nozzle.

The plasma jet consists of a cylindrical external grounded electrode made of stainless steel and an inner rod electrode (see Fig. 1). The inner electrode’s diameter is 5 mm and the discharge gap between inner and outer electrode is 1.5 mm. The outer diameter of the nozzle is 14 mm, with a total reactor length not exceeding 120 mm. The visible part of the discharge coming out of the outer electrode edge is approx. 2 mm.

The power source was a AG 1021 radio frequency generator (T&C Power Conversion, USA) with integrated amplifier and meter of forward and reflected power, designed for ultrasonic and plasma applications. In order to increase the voltage to a level enabling ignition of the discharge, an air-core transformer with a 1:12 winding ratio was used. Compensating inductance and obtaining resonance on the secondary side of the transformer for changing impedance of the discharge was made possible by a capacitor connected in parallel (Fig. 2).

The voltage and current output from the power supply were recorded with a Tektronix TDS 2024B oscilloscope. A Tektronix P6015A probe was used to measure the voltage. The current signal, due to the impact of high frequency interference, was measured through the voltage drop over a low-induction 10 Ω resistor Rip (VISHAY LTO100F10E00JTE3) using Tektronix P2220 probe.

To exclude effects of streamer contact to the seeds, which alter the seed surface drastically [16, 20], it was decided to use a helium plasma jet, which generates a glow discharge. Two types of gas mixtures were used: helium with oxygen and helium with air, both in a ratio of 3:2 and a total flow of 710 l/h. The reactive species that are generated are expected to be qualitatively similar to the ones generated in a streamer type plasma. Glass tube variable area flow meters (Zakłady Automatyki „ROTAMETR”, Poland) were used to regulate the flow. For both mixtures, at a load power of 45 W (forward 47 W), voltage and current signal had a sinusoidal shape. Due to slightly different impedance for each gas mixture, the effective voltage values were 1062 V and 1013 V for mixtures containing oxygen and air, respectively.

For both gas mixtures, a series of measurements were made for exposure times of 2, 5, 10 and 15 s. For each of the experimental conditions, 7 g of onion cv. Wolska seeds were evenly distributed on the surface of a 60 mm diameter Teflon strainer placed in a 40 mm high glass tube (Fig. 3). The distance between the seed surface and the plasma jet tip was 2 cm. For this distance, the maximum gas temperature measured with the DT-847U meter (Yu Ching Technology, China) and type K thermocouple was 100 °C and 110 °C for helium with oxygen and for helium with air gas mixture, respectively. Due to the short processing time and the open container, the surface of the seed temperature measured with thermocouple immediately after treatment did not exceed 35 °C for all conditions.

Flow simulations were performed in the laminar flow CFD module of the COMSOL Multiphysics software, using the finite element method in two-dimensional, axisymmetric geometry. Due to the homogeneous gas flow inside the reactor, only the nozzle tip with a length of 4 cm was included in the geometry, while maintaining its actual shape and dimensions. In the simulation of gas flow over the surface of the seeds, the seeds’ shape was approximated as a system of spheres and cubes with dimensions similar to real grains. The gas flow velocity was selected as a parameter that allows estimation of the spread and concentration of active plasma particles. In the simulations, the seeds were placed on the strainer located above a lumen with a flat bottom.

The flow simulation was validated against flow characteristics measurements obtained by a Schlieren imaging setup in a Z configuration [29]. For the Schlieren measurements, a C1285R12M CMOS camera (Thorlabs, USA) was used to record the images. In order to obtain an image of the average gas flow for times similar to those of plasma treatment, an average over 100 frames for each measurement was taken at a speed of 16.9 frames per second. During the measurement, the digital camera was pointed perpendicularly to the gas flow, in an optical Schlieren Setup along one axis.

To determine the morphology of the samples, a VHX-5000 digital microscope (KEYENCE, Japan) was used. Images of the samples were taken immediately after plasma treatment.

The concentration of selected nitrogen and oxygen compounds was measured using an IBRID 6 m (Industrial Scientific Corporation, USA) for nitrogen dioxide and nitric oxide concentration, and an A-21ZX sensor (Eco Sensors, USA) for ozone concentration. For these measurements, the gas was pumped from the location of the seeds through a 7 cm tube (Fig. 3). Due to the inertia of the sensors and the need for a pumping system, the results were recorded with a 1-s offset relative to the ignition of the discharge.

Germination Energy and Capacity

Experimental material consisted of onion cv. Wolska seeds (Allium cepa L.) with a seed purity of Standard ST. Seed germination was conducted in accordance with ISTA recommendations of 2017 [35] by placing the seeds on germination paper. Germination experiments were conducted by placing the seeds in 5 rows of 20 seeds on each of the four germination papers (BP germination). A total of 400 seeds for each parameter were used in the experiments. The seeds were covered with paper and then rolled into a roll. The experiment on seed germination was carried out in a CTC256 climatic chamber (Memmert GmbH + Co KG, Germany) at a temperature of 20 ± 1 °C. Five groups of seeds were studied, each group with a different plasma treatment time: 2, 5, 10 and 15 s, and untreated seeds as control group. The distance between plasma jet tip and seeds was set to 20 mm for all seed groups.

The number of sprouts was determined every 24 h. The fraction of germinated seeds (number of sprouts) after 6 days of germination was defined as germination energy (GEN), while the fraction of germinated seeds after 12 days of germination was defined as germination capacity (GC). Both, germination energy and germination capacity, were expressed as a fraction of the germinated seeds G after a certain time t and calculated from the following equation:

where n is the number of seeds germinated at time t and nT, the total number of sown seeds.

Measurement results were analyzed statistically, using Statistica 10 (StatSoft Inc., USA). A Tukey test (p < 0.05) was used to investigate the effect of the treatment time on germination energy.

Results and Discussion

Figure 4 shows a comparison of gas flow images obtained using simulation and Schlieren imaging. Due to the geometry of the APPJ’s electrodes, the gas propagates in the form of a column with a diameter not exceeding the outer diameter of the nozzle (Fig. 4b), which is also well visible in the simulation for gas velocities higher than 6 m/s (Fig. 4a). The initially hollow column fills at a distance of 5 mm to the nozzle. With the discharge, for distances greater than 1.5 cm, the shape and width of the gas stream was only slightly different from the flow pattern of the gas itself (Fig. 4c). For this reason, the simulations of the gas flow above the surface of the seeds were considered sufficiently correct to depict the conditions of plasma treatment. For different gas mixtures, no significant differences in gas flow were observed.

The flow simulations showed that in a setup where seeds were spread out on the flat bottom of a vessel, sharp surfaces of seeds and the side wall of the vessel cause flow irregularities near the center and the edge of the vessel. Flow irregularities as shown in Fig. 5 were visible for different amounts of seeds. The gas mainly flowed over the upper surface of the seeds. Near the side walls of the vessel, it turned back towards the reactor, potentially causing uneven seed processing.

Better contact of the feed gas with the bottom surface of seeds was obtained in a setup where seeds were positioned on a strainer (Fig. 6). In this case, the strainer’s holes significantly increased the gas flow around the seeds, mainly near the axis of the reactor (Fig. 6a). Despite the fact that the stream flowed around all the seeds, its velocity was much lower due to the larger gas distribution area (Fig. 6b). Based on the obtained results and assumed short treatment time, it was decided that further tests would be carried out using a strainer system allowing slightly better contact of working gas with seeds.

Table 1 presents the concentrations of selected oxygen and nitrogen compounds as a function of time after ignition of the discharge. Comparing obtained results, it can be seen that there is large difference between the mixtures containing oxygen and air.

Ozone density increases with increasing time after plasma ignition for the mixture of helium and oxygen, while little ozone is produced for the discharge with air admixture.

With air admixture, more NO can be detected, pointing towards the nitrogen dominated chemistry. It can be assumed that for air admixture, more reactive nitrogen species are generated, that the meters cannot detect. This can also explain the unexpected lower concentration of NO2 for air admixture in comparison to the NO2 concentration for oxygen admixture, which must origin from interaction with ambient air species. [36, 37]. In the case of continuous seed treatment, accumulation of active particles and their higher final concentrations can be expected.

Figure 7 shows images of seed surfaces obtained from an optical microscope for dry seeds treated with plasma operated with a mixture of helium and oxygen. Neighbouring walls of the surface layer cells are of irregular polygonal shape (usually penta- and hexagonal). The size of the cells also varies slightly. Compared to the control sample, no significant changes in surface structure were observed, which can be attributed to the relatively short processing time. A pronounced rough pattern on the external wall surface of a single cell can be observed on the control seeds (Fig. 7a). This roughness diminishes slightly for the longer treatment times of 10-s and 15-s (Fig. 7d, e), which can be related to water content loss. This change could be correlated with desiccation due to the exposure to elevated temperatures and the drying impact of gas flow on the seeds.

Figures 8 and 9 present the dynamics of the process of germination of onion seeds treated with the plasma jet operated with helium and oxygen admixture (Fig. 8) and with helium and air admixture (Fig. 9).

During 12 days observation period, for both gas mixtures, 10 s plasma treatment time was clearly predominant in comparison to the control and to the other used treatment times. Up to 5th day, the number of germinated seeds was even several folds higher than the control for 10 s treatment. With time, this discrepancy become less visible, what indicates, that plasma can promote faster initiation of germination process (also via surface roughness change leading to faster water uptake) and stimulate first phase of germination.

An analysis clearly showed that cold plasma treatment influenced the onion seeds’ germination parameters. He + O2 plasma treatment led to statistically significant changes in GEN after seed exposure of 2-, 5-, and 10-s, compared to the control. The GC of the analyzed seeds changed only after the 10-s stimulation (Table 2). While the drop in seed germination fraction for the treatment of 5 s for a helium–oxygen mixture is unexpected, it is very evident that for both gas mixtures, the most favorable time was 10 s, where the GEN increased by 34% and the GC increased by 9% compared to the control sample.

Plasma treatment with helium and air mixtures produced statistically significant changes in germinability after 10-s and 15-s exposure, compared to the control (Table 3). The germination rate of the analyzed seeds changed after the 2-s and 10-s plasma treatment. Also in this case, the best results were obtained for 10 s, where the GEN increased by 24% and the GC by 4% in relation to the control sample.

Taking into account all the days of germination, the standard deviation of the results for the various plasma treatment conditions is relatively small (not exceeding 3.5% for GEN and GC at any condition) and does not differ significantly from the deviation obtained for the control (Figs. 8 and 9). This confirms the approach to treat seeds on a strainer for a uniform treatment associated with sufficient contact of the gas with the seed surface on all sides. Due to the small distance of the seeds to the plasma jet nozzle, too high reactive oxygen and nitrogen stress and too high temperature may, however, negatively affect the germination process. It can be seen from the results obtained for 15 s plasma treatment, where despite a significant increase in germination for the first days, both GEN and GC decrease compared to the control.

Figure 10 shows the impact of the plasma on the seedlings’ growth for the treatment time with the highest germination parameters (10 s).

At the beginning of the seedlings’ growth, the impact of the plasma treatment was minor. At the later phase, on the 7–8th day of vegetation period, the change of behavior of seedlings after pre-sowing plasma stimulation was observed. The longest seedlings were observed for 10 s plasma treatment on the 12th day. With He + O2 gas mixture, onion seedlings were 35.4 mm longer than control, which is promising. 13.8 mm longer seedlings were obtained in the least beneficial combination for He + O2 at 15 s treatment. For the case of He + Air, the seedlings were 27.5 mm and 15.4 mm longer than control and the weakest treatment combination, respectively. Better growth of seedlings can be assumed to be caused by the elimination of harmful microorganisms from seeds’ surface, by an increase of water uptake of the seeds and by a metabolomic response to the reactive oxygen and nitrogen species [15, 38, 39].

Low temperature plasma has a positive impact on seeds: they germinate faster, form healthier, more vigorous seedlings and better crops. This effect may be due to the stimulating capacity of the plasma delivering various oxygen radicals, charged particles, ions and UV light [40,41,42]. This treatment plays a crucial role in a broad spectrum of plant development and physiological processes in plants, including the promotion of seedling growth.

Conclusions

Pre-sowing short time plasma stimulation of seeds improved the germination dynamics for both studied cases of helium oxygen and helium air plasma treatment. The highest germination parameters were obtained for seeds stimulated with plasma for the exposure time of 10-s, for which statistically significant differences in both germination energy and germination capacity were observed. The results of gas flow imaging allow to conclude that the use of a strainer leads to a better contact of all seed sides with reactive oxygen and nitrogen species generated in the reactor. Microscopy imaging of the seed surfaces did not show significant differences in their structure, showing that the short plasma treatment applied in this study does not harm the cellular structure of the seeds.

The positive effect of plasma treatment for shorter times gives hope for the possibility of using similar reactors in the future. For better profitability, argon can be used instead of helium, and positive results obtained for air mixture gives the chance to use commonly available compressed air. In addition, in order to ensure uniform surface treatment of all seeds from all sides, mixing the seeds during treatment is recommended.

Availability of Data and Material

All data generated or analysed during this study are included in this published article.

References

Zahoranová A, Henselová M, Hudecová D et al (2016) Effect of cold atmospheric pressure plasma on the wheat seedlings vigor and on the inactivation of microorganisms on the seeds surface. Plasma Chem Plasma Process 36:397–414. https://doi.org/10.1007/s11090-015-9684-z

Kovalová Z, Tarabová K, Hensel K, MacHala Z (2013) Decontamination of streptococci biofilms and Bacillus cereus spores on plastic surfaces with DC and pulsed corona discharges. EPJ Appl Phys. https://doi.org/10.1051/epjap/2012120449

Neretti G, Tampieri F, Borghi CA et al (2018) Characterization of a plasma source for biomedical applications by electrical, optical, and chemical measurements. Plasma Processes Polym 15:1800105. https://doi.org/10.1002/ppap.201800105

Lu X, Naidis GV, Laroussi M et al (2016) Reactive species in non-equilibrium atmospheric-pressure plasmas: generation, transport, and biological effects. Phys Rep 630:1–84. https://doi.org/10.1016/j.physrep.2016.03.003

von Woedtke Th, Reuter S, Masur K, Weltmann K-D (2013) Plasmas for medicine. Phys Rep 530:291–320. https://doi.org/10.1016/j.physrep.2013.05.005

Chu PK, Chen JY, Wang LP, Huang N (2002) Plasma-surface modification of biomaterials. Mater Sci Eng R Rep 36:143–206. https://doi.org/10.1016/S0927-796X(02)00004-9

Puač N, Živković S, Selaković N et al (2014) Long and short term effects of plasma treatment on meristematic plant cells. Appl Phys Lett 104:214106. https://doi.org/10.1063/1.4880360

Puač N, Petrović ZL, Malović G et al (2006) Measurements of voltage–current characteristics of a plasma needle and its effect on plant cells. J Phys D Appl Phys 39:3514–3519. https://doi.org/10.1088/0022-3727/39/16/S09

Hensel K, Kučerová K, Tarabová B et al (2015) Effects of air transient spark discharge and helium plasma jet on water, bacteria, cells, and biomolecules. Biointerphases 10:029515. https://doi.org/10.1116/1.4919559

Ji S-H, Choi K-H, Pengkit A et al (2016) Effects of high voltage nanosecond pulsed plasma and micro DBD plasma on seed germination, growth development and physiological activities in spinach. Arch Biochem Biophys 605:117–128. https://doi.org/10.1016/j.abb.2016.02.028

Hayashi N, Ono R, Shiratani M, Yonesu A (2015) Antioxidative activity and growth regulation of Brassicaceae induced by oxygen radical irradiation. Jpn J Appl Phys 54:06GD01. https://doi.org/10.7567/JJAP.54.06GD01

Henselová M, Slováková Ľ, Martinka M, Zahoranová A (2012) Growth, anatomy and enzyme activity changes in maize roots induced by treatment of seeds with low-temperature plasma. Biologia 67:490–497. https://doi.org/10.2478/s11756-012-0046-5

Nakano R, Tashiro K, Aijima R, Hayashi N (2016) Effect of oxygen plasma irradiation on gene expression in plant seeds induced by active oxygen species. PMED. https://doi.org/10.1615/PlasmaMed.2016019093

Kitazaki S, Sarinont T, Koga K et al (2014) Plasma induced long-term growth enhancement of Raphanus sativus L. using combinatorial atmospheric air dielectric barrier discharge plasmas. Curr Appl Phys 14:S149–S153. https://doi.org/10.1016/j.cap.2013.11.056

Ling L, Jiafeng J, Jiangang L et al (2014) Effects of cold plasma treatment on seed germination and seedling growth of soybean. Sci Rep 4:5859. https://doi.org/10.1038/srep05859

Pawłat J, Starek A, Sujak A et al (2018) Effects of atmospheric pressure plasma jet operating with DBD on Lavatera thuringiaca L. seeds’ germination. PLoS ONE 13:e0194349. https://doi.org/10.1371/journal.pone.0194349

Kim J-W, Puligundla P, Mok C (2016) Effect of corona discharge plasma jet on surface-borne microorganisms and sprouting of broccoli seeds. J Sci Food Agric 97:128–134. https://doi.org/10.1002/jsfa.7698

Butscher D, Van Loon H, Waskow A et al (2016) Plasma inactivation of microorganisms on sprout seeds in a dielectric barrier discharge. Int J Food Microbiol 238:222–232. https://doi.org/10.1016/j.ijfoodmicro.2016.09.006

Schnabel U, Niquet R, Krohmann U et al (2011) Decontamination of microbiologically contaminated specimen by direct and indirect plasma treatment. Plasma Processes Polym 9:569–575. https://doi.org/10.1002/ppap.201100088

Pawłat J, Starek A, Sujak A et al (2018) Effects of atmospheric pressure plasma generated in GlidArc reactor on Lavatera thuringiaca L. seeds’ germination. Plasma Process Polym 15:1700064. https://doi.org/10.1002/ppap.201700064

Bafoil M, Jemmat A, Martinez Y et al (2018) Effects of low temperature plasmas and plasma activated waters on Arabidopsis thaliana germination and growth. PLoS ONE 13:e0195512. https://doi.org/10.1371/journal.pone.0195512

Kopacki M, Pawłat J, Terebun P, et al (2017) Efficacy of non-thermal plasma fumigation to control fungi occurring on onion seeds. In: 2017 international conference on electromagnetic devices and processes in environment protection with seminar applications of superconductors (ELMECO AoS), pp 1–4

Logothetis DK, Papadopoulos PK, Svarnas P, Vafeas P (2016) Numerical simulation of the interaction between helium jet flow and an atmospheric-pressure “plasma jet”. Comput Fluids 140:11–18. https://doi.org/10.1016/j.compfluid.2016.09.006

Miyagawa Y, Tanaka M, Ikeyama M et al (2006) Analysis of plasma and neutral gas flow inside of a PET bottle under PIII condition by particle-in-cell/Monte Carlo simulation. Nucl Instrum Methods Phys Res, Sect B 242:341–345. https://doi.org/10.1016/j.nimb.2005.08.049

Yin F, Hu S, Yu C, Li L (2007) Computational simulation for the constricted flow of argon plasma arc. Comput Mater Sci 40:389–394. https://doi.org/10.1016/j.commatsci.2007.01.008

Verlackt CCW, Boxem WV, Bogaerts A (2018) Transport and accumulation of plasma generated species in aqueous solution. Phys Chem Chem Phys 20:6845–6859. https://doi.org/10.1039/C7CP07593F

Sakiyama Y, Graves DB (2009) Neutral gas flow and ring-shaped emission profile in non-thermal RF-excited plasma needle discharge at atmospheric pressure. Plasma Sources Sci Technol 18:025022. https://doi.org/10.1088/0963-0252/18/2/025022

Schmidt-Bleker A, Reuter S, Weltmann K-D (2015) Quantitative schlieren diagnostics for the determination of ambient species density, gas temperature and calorimetric power of cold atmospheric plasma jets. J Phys D Appl Phys 48:175202. https://doi.org/10.1088/0022-3727/48/17/175202

Traldi E, Boselli M, Simoncelli E et al (2018) Schlieren imaging: a powerful tool for atmospheric plasma diagnostic. EPJ Techn Instrum 5:4. https://doi.org/10.1140/epjti/s40485-018-0045-1

Darny T, Pouvesle J-M, Fontane J et al (2017) Plasma action on helium flow in cold atmospheric pressure plasma jet experiments. Plasma Sources Sci Technol 26:105001. https://doi.org/10.1088/1361-6595/aa8877

Pei X, Ghasemi M, Xu H et al (2016) Dynamics of the gas flow turbulent front in atmospheric pressure plasma jets. Plasma Sources Sci Technol 25:035013. https://doi.org/10.1088/0963-0252/25/3/035013

Kelly S, Golda J, Turner MM, der Gathen VS (2015) Gas and heat dynamics of a micro-scaled atmospheric pressure plasma reference jet. J Phys D Appl Phys 48:444002. https://doi.org/10.1088/0022-3727/48/44/444002

Boselli M, Colombo V, Ghedini E et al (2014) Schlieren high-speed imaging of a nanosecond pulsed atmospheric pressure non-equilibrium plasma jet. Plasma Chem Plasma Process 34:853–869. https://doi.org/10.1007/s11090-014-9537-1

(2018) FAOSTAT. http://www.fao.org/faostat/en/#data/QC. Accessed 11 Nov 2019

(2017) International Rules for Seed Testing. International Seed Testing Association

Dasan BG, Onal-Ulusoy B, Pawłat J et al (2017) A new and simple approach for decontamination of food contact surfaces with gliding arc discharge atmospheric non-thermal plasma. Food Bioprocess Technol 10:650–661. https://doi.org/10.1007/s11947-016-1847-2

Machala Z, Tarabova B, Hensel K et al (2013) Formation of ROS and RNS in water electro-sprayed through transient spark discharge in air and their bactericidal effects. Plasma Processes Polym 10:649–659. https://doi.org/10.1002/ppap.201200113

Bormashenko E, Grynyov R, Bormashenko Y, Drori E (2012) Cold radiofrequency plasma treatment modifies wettability and germination speed of plant seeds. Sci Rep 2:741. https://doi.org/10.1038/srep00741

Randeniya LK, de Groot GJJB (2015) Non-thermal plasma treatment of agricultural seeds for stimulation of germination, removal of surface contamination and other benefits: a review. Plasma Process Polym 12:608–623. https://doi.org/10.1002/ppap.201500042

Yodpitak S, Mahatheeranont S, Boonyawan D et al (2019) Cold plasma treatment to improve germination and enhance the bioactive phytochemical content of germinated brown rice. Food Chem 289:328–339. https://doi.org/10.1016/j.foodchem.2019.03.061

Babajani A, Iranbakhsh A, Oraghi Ardebili Z, Eslami B (2019) Seed priming with non-thermal plasma modified plant reactions to selenium or zinc oxide nanoparticles: cold plasma as a novel emerging tool for plant science. Plasma Chem Plasma Process 39:21–34. https://doi.org/10.1007/s11090-018-9934-y

Meng Y, Qu G, Wang T et al (2017) Enhancement of germination and seedling growth of wheat seed using dielectric barrier discharge plasma with various gas sources. Plasma Chem Plasma Process 37:1105–1119. https://doi.org/10.1007/s11090-017-9799-5

Funding

Information that explains whether and by whom the research was supported. This study was supported by LUT research fund, Polish-Slovak Bilateral Cooperation Programme (PlasmaBioAgro) PPN/BIL/2018/1/00065 + SK-PL-18-0090, NCN-M-Era.Net2, project no. UMO-2016/22/Z/ST8/00694- PNANO4BONE, KONNECT project, COST Action PlAgri CA19110 and CEEPUS CIII-AT-0063.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Code Availability

Not applicable.

Ethics Approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Terebun, P., Kwiatkowski, M., Starek, A. et al. Impact of Short Time Atmospheric Plasma Treatment on Onion Seeds. Plasma Chem Plasma Process 41, 559–571 (2021). https://doi.org/10.1007/s11090-020-10146-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-020-10146-3