Abstract

The decomposition of propane diluted in air has been investigated using a pulsed high-voltage dielectric barrier discharges reactor. Effects of the temperature (from 300 to 800 K) and humidity in air on propane conversion and on produced species are studied. CO and CO2 are the two main carbon species produced but other carbon species can be also obtained as functions of electrical parameters or temperature. Total decomposition of inlet propane to CO2 is possible when propane is diluted in wet air from 600 K. Thermal energy is an important parameter to limit the energy density injected in the plasma reactor and to reduce the total energetic cost keeping a high propane decomposition yield.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Non-thermal plasma (NTP) discharges are studied for the removal of volatile organic compounds (VOCs) contained in air at low concentration level [1–3]. VOCs’ are present in various places: synthetic materials, chemical industry, exhaust gas vehicles, house environment…. Most of these species are dangerous for human health and environment. Conversion rate of the VOCs’ and the nature of the products must to be taken into account to estimate the efficiencies of the processes. VOCs’ oxidation by NTP is an interesting technique to obtain good efficiencies, by considering conversion rates and produced species, with low energy costs in comparison to the traditional techniques (thermal or catalytic processes). Thus, many techniques have been developed to convert VOCs’ using NTP: electron beam, dielectric barrier discharges (DBD) and corona discharges [4–8] or other techniques combined with NTP such as: catalytic and photocatalytic processes [9–17]. Nevertheless, despite well-established implementations in non-combined NTP techniques, these processes can be improved to promote VOCs’ conversion and to reduce energetic costs and by-products. In a previous study, effects of the propane decomposition in wet air at 300 K using a pulsed high voltage DBD reactor have been compared to results obtained in dry air condition [18].

This present paper shows effects of the humidity in air on propane conversion and outlet by-products using a DBD reactor heated at different initial temperature. We show that the propane conversion using a heated DBD reactor implies a decreasing of the total energy cost in comparison to a DBD treatment at ambient temperature. A supplementary thermal energy added to the plasma treatment can lead to a high decreasing of the energy density in plasma to convert efficiently propane. Moreover, a heating permits to modify produced species in comparison to room temperature experiments at a given energy density. Effects of electrical parameters and temperature on the propane conversion and produced species are also studied for a temperature range from 300 to 800 K. CO and CO2 are the main carbon species produced. Oxygenated carbon species, C x H y O z (formaldehyde, acetaldehyde, etc.), have been also detected but no quantified. Moreover, in this paper, effects of O-atom and oxygenated radicals on propane conversion and produced species are also discussed.

Experimental

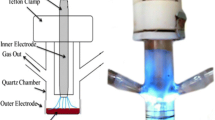

The experimental plasma reactor used is a wire to cylinder DBD type [18–20]. Figure 1 shows a schematic representation of the experimental device. The dielectric wall is a quartz tube (thickness: 1 mm). Inner and outer electrodes are a 2 mm diameter wire and an aluminium foil, respectively. The active volume plasma is about 16 cm3. The DBD reactor is set in an oven which allows a heating up to 800 K, in this study.

The pulsed voltage generator is a self-made generator [20] which delivers high voltages (up to 30 kV) into 80 ns (FWHM) and short rise time (40 ns) from charging voltage, Uch (up to 5 kV). Pulse repetition rates range, f, studied is between 15 and 200 Hz. Applied voltage and current measurements are displayed with an oscilloscope (Tektronix 6210A) through high voltage (Tektronix P6015A) and current (Tektronix TCP202) probes, respectively.

The inlet gas mixture is propane (1,100 ppm) diluted in dry air or in air saturated in water at 300 K (called wet air conditions in this paper), at atmospheric pressure. Air used in experiments is a synthetic air from N2 (79%) and O2 (21%) mixture. Gas mixture is injected through mass flow controllers with a total flow rate, Q, maintained at 1,000 sccm. Energy density, Ed, injected in the plasma reactor is expressed from: Ed = (Ep × f)/Q, where Ep is the discharge pulse energy.

Ep = (½ C × V²) with C the capacitor values of the blumlein line high voltage generator, V the charging voltage of the capacitors.

A Fourier Transform Infra Red spectrometer (FTIR, Nicolet Magna IR 550 Series II), an ozone analyser (BMT 963) and a micro-Gas Chromatograph (Varian CP2002) have been used to detect and measure the outlet gas from the plasma reactor. The quantified species are C3H8, CO, CO2, CH4, C2H4 and O3.

Results

Propane Consumption

Figure 2 displays propane conversion rate as a function of the energy density (Ed) for different initial temperature (between 300 and 800 K) and dilution air conditions (propane in dry or in wet air). Neither propane conversion nor chemical reactions are observed without plasma even for a temperature equals to 800 K. Thus, this key result shows the essential effect of the plasma to initiate the propane decomposition.

An Ed increasing from 90 to 1,200 J L−1 leads to a rise of the propane conversion rate in all the temperature range studied. Water vapour in air has not effect on the propane conversion rate. Moreover, for a given Ed value, initial temperature is an important parameter which influences the propane consumption efficiency. Indeed, a propane conversion rate close to 100% is achieved with Ed decreasing from 750 to 90 J L−1 and temperature increasing from 300 to 800 K, respectively.

Produced Carbon Species

Propane conversion leads to the production of two main carbon species: CO and CO2. Figure 3 show CO concentration, [CO], versus the energy density in both air conditions. CO concentration levels depend on several parameters: Ed, temperature and adding water in air.

At 300 K, in both air conditions, when Ed increases from 90 to 1,200 J L−1, CO concentration increases from about 0 to 1,800 ppm in dry air condition and from 0 to 1,400 ppm in wet air condition, respectively. These results show that CO concentrations in wet air conditions are lower than those obtained in dry air conditions.

For T > 300 K, an increase of Ed leads to a rise of CO concentration up to a maximum, [CO]max, then [CO] decreases. The [CO]max value is strongly dependent on Ed which is linked to the temperature (e.g. 450 J L−1 at 450 K, 300 J L−1 at 600 K and 150 J L−1 at 800 K). Adding water to the inlet propane-air mixture has not significant effect on the Ed value corresponding to [CO]max.

On the other hand, the decrease of CO above the Ed value corresponding to [CO]max is dependent on the temperature and dilution air conditions. Indeed, when Ed increases, [CO] decreases more quickly when propane is diluted in wet air than in dry air conditions. For example, at 800 K and Ed > 750 J L−1, [CO] is close to zero (60 ppm) in wet air condition against 550 ppm in dry air. Moreover, at 800 K, CO is fully disappeared for Ed higher than 900 J L−1 in wet air conditions whereas [CO] is yet higher than 200 ppm in dry air for an Ed = 1,200 J L−1.

Outlet CO2 concentration, [CO2], as a function of Ed in both dilution air conditions and temperatures are displayed in Fig. 4.

An increase of Ed leads to a rise of CO2 concentration whatever temperature and propane dilution conditions. At a given Ed, an increase of CO2 is obtained when temperature rises: e.g. at Ed = 600 J L−1 in dry air, [CO2] varies from 900 to 2,900 ppm when temperature increases from 300 to 800 K, respectively.

Effects of adding water vapour in propane-air mixture on [CO2] strongly depend on T:

-

At 300 K, no water effect is observed on [CO2] in comparison to dry air conditions.

-

For T > 300 K, adding water in air leads to a rise of [CO2] at a given Ed higher than 450 J L−1 at 450 K; 300 J L−1 at 600 K and 150 J L−1 at 800 K.

The inlet carbon contained in C3H8 is totally oxidized in CO2 at 800 K in both air conditions. Thus, the CO2 concentration is equal to the total inlet carbon: [CO2] = 3·[C3H8] i . When propane is diluted in wet air, total oxidation is only observed at 450 K and 600 K for Ed values higher than 900 and 750 J L−1, respectively. In the case of a partial oxidation, [CO2] < 3·[C3H8] i , other carbon species are also produced. Thus, C2H4 and CH4, produced directly from the propane decomposition, can be only quantified if T > 600 K. Maximum concentrations of CH4 and C2H4 are about 36 ppm and 141 ppm, respectively (at 800 K and Ed = 90 J L−1). In wet air conditions, CH4 and C2H4 concentrations are equal to 37 and 35 ppm, respectively, in the same T and Ed conditions. For Ed > 90 J L−1 in both air conditions, C2H4 and CH4 become undetectable whatever the temperature.

C2H4 and CH4 are not the main by-products species containing carbon atoms, oxygenated carbon species such as formaldehyde or acetaldehyde are also observed in FTIR spectra (Fig. 5). FTIR spectra show that temperature has a strong effect on by-products natures and amounts.

Discussion

Energy Cost

To evaluate the plasma process efficiency, the energy cost must be taken into account. The total energetic cost, tEd, of the propane conversion process is expressed using the following expression: tEd = E th + Ed with Ed, the electrical energy density defined in the experimental section and E th, the thermal energy supplied when the temperature is higher than 300 K.

Eth corresponding to the heating of the DBD reactor is calculated from the total flow rate and the inlet gas mixture heat capacity, Cp. Thus, calculated Eth are equal to 120, 180 and 220 J L−1 at 450, 600 and 800 K, respectively.

Figure 6 shows propane conversion rates as a function of tEd in wet air conditions.

From an energy point of view, a high propane conversion rate obtained with a moderate heating (i.e. 600 K) and a low Ed is more interesting than a propane treatment at 300 K with a high Ed. Indeed, for total propane consumption, an increase of the temperature from 300 to 600 K leads to a high decrease of the total energetic cost from 750 to 350 J L−1, respectively.

Taking into account both DBD electrical power and additional heating power, the total power corresponding to a 100% propane conversion is determined from experiments (Fig. 7).

Total power to convert efficiently propane is highly depending on the temperature: from 12.6 to 5.2 W at 300 and 800 K, respectively. At 300 K, no additional heating is used, so heating power is equals to zero. In order to obtain a propane conversion close to 100%, we show that the main consumed power is the heating power when the temperature is higher than 600 K.

This underlines the plasma effect on the actives species production and that the heating can strongly influenced chemistry ways.

Propane Consumption

Propane consumption can be described by reactions between propane and active species (such as O, OH or H) produced from decomposition of H2O and O2 by electron impact in plasma discharge. In thermal processes, rate constants of O2 decomposition are lower than 10−40 cm−3 molecule−1 s−1 even at 800 K (Eq. 1) [21]. H2O decomposition requires high temperatures to be initiated but its rate constant is weak even at 2,000 K (Eq. 2) [22]. No data on H2O dissociation rate constant is described in the literature below 2,000 K.

Once active species are produced, they can react with propane to produce n-C3H7 (Eq. 3) [23]. In dry air conditions, propane consumption is possible only by O-atom. A temperature increasing leads to a rise of the rate constant and consequently to an increase of the propane consumption which corresponds to experimental results presented in paragraph 3.

On the other hand, when inlet propane is diluted in wet air some supplementary reactions between C3H8 and OH or H (Eqs. 4, 5) [23, 24] can explain C3H8 consumption. Constant rates of reactions implying OH or H and C3H8 are highly dependent on the temperature.

Rate constants of propane and O2 reaction (Eq. 6) [23] are lower (<8.35 10−25 cm−3 molecule−1 s−1) than constant rates for O, OH and H reactions (Eqs. 3–5) in the temperature range from 300 to 800 K.

Thus, a high efficiency of the propane conversion can be obtained with reactions between C3H8 and O, OH or H compared to the reaction between C3H8 and O2.

Produced Species

CO and CO2 yields, Y CO and \( Y_{{{\text{CO}}_{2} }} \) respectively are expressed by:

where [CO] and [CO2] are the outlet concentrations of CO and CO2, respectively. [C3H8]consumed is the consumed propane concentration; [C3H8]consumed = [C3H8]inlet − [C3H8]non-consumed· Y CO and \( Y_{{{\text{CO}}_{2} }} \) as functions of tEd are displayed in Fig. 8a, b, respectively.

At 300 K, in both air conditions, Y CO increases when tEd rises. However, Y CO values in wet air are lower than in dry air ones whatever tEd. For example, at tEd = 1,200 J L−1, Y CO = 42 versus 55% in wet and dry air, respectively. In these latter energy cost and dilution air conditions, CO is the main produced carbon species. For T ≥ 450 K, CO yield strongly depends on tEd: when tEd is increasing, Y CO increases up to a maximum value (upper than 80%), which is dependent on the temperature, then Y CO decreases. The maximum Y CO value is achieved more quickly when T increases: 570 J L−1 at 450 K, 400 J L−1 at 600 K.

Adding water in inlet gas mixture has an effect above the maximum Y CO value: Y CO depletion is faster in wet air conditions that in dry air conditions.

For high tEd values, there is a decrease of the converted carbon into CO. Y CO can be close to zero for the higher temperature. This shows that CO is not the final carbon species produced even if 80% of the inlet carbon can be converted in CO at low tEd values. Then, inlet carbon contained in propane is converted in another species containing C-atom such as CO2. For \( Y_{{{\text{CO}}_{2} }} \) higher than 50%, the main produced carbon species from propane conversion is CO2 and when \( Y_{{{\text{CO}}_{2} }} \) is equal to 100%, the total propane oxidation into CO2 occurs in the DBD reactor.

At 300 K, \( Y_{{{\text{CO}}_{2} }} \) and Y CO profiles are similar: \( Y_{{{\text{CO}}_{2} }} \) increases from 10 to 60% when tEd increases from 50 to 1,200 J L−1, respectively. However, CO2 yields are unaffected by adding water in the inlet propane-air mixture. In both air conditions, inlet carbon can be efficiently converted in CO2: \( Y_{{{\text{CO}}_{2} }} \) > 50% for tEd upper than 700 J L−1 at 450 K; 500 J L−1 at 600 K and 250 J L−1 at 800 K.

\( Y_{{{\text{CO}}_{2} }} \) = 100% can be reached in wet air conditions for tEd values depending on temperature: 1,200 J L−1 at 450 and 600 K and from 750 J L−1 at 800 from 450 K. Conversely, in dry air condition, total oxidation is only obtained at 800 K with tEd higher than 750 J L−1. Temperature is a key parameter in both studied propane-air mixtures: when T increases from 300 to 800 K, CO2 yields strongly rise from 46 to 97%, respectively.

Carbon Balance

Total carbon by-products (mainly C x H y O z ) concentration can be estimated from measured outlet carbon species concentrations (CO, CO2, CH4, C2H4 and non-consumed propane). Indeed, carbon species are missing in the carbon balance if the measured carbon, MC, is lower than the inlet carbon. MC is expressed in the following equation:

Figure 9 displays MC/inlet carbon ratio, R = MC/(3·[C3H8] i ), as functions of tEd and the temperature in both air conditions.

In both air conditions, between 300 and 600 K, when tEd increases, R decreases down to a minimum level then increases up to R ≈ 1 (corresponding to MC ≈ 3·[C3H8] i ). The lowest R value corresponds to the maximum missing carbon amount in the carbon balance. This lowest R is due to the highest production of C x H y O z . Above the minimum MC/(3·[C3H8] i ) ratio, carbon by-products are consumed or less produced corresponding to R increasing up to about 1.

At 300 K, by-products are promoted when propane is diluted in wet air. In this case, R is lower than in dry air conditions. In wet air, tEd needs to be moved towards higher values to convert propane in only CO and CO2. For T ≥ 450 K, adding water to the inlet gas mixture has almost no effect on the MC/inlet carbon ratio value; same by-products amounts are observed in both air conditions.

Moreover, the tEd range with MC/inlet carbon ratio is lower than one highly depends on the temperature: R < 1 from 0 up to 1,200 J L−1 at 300 K, up to 600 J L−1 at 450 K and up to 300 J L−1 at 600 K or 800 K. So, by-products amounts can be easily controlled by avoiding a high energetic cost when the temperature.

Active Species Discussion

The MC/inlet carbon ratio variation as a function of tEd seems to be linked to the ozone concentration profile as shown in Fig. 10.

On the whole tEd range, [O3] is maximum when R is minimum and when [O3] decreases, R increases. At a given temperature, MC/inlet carbon ratio and O3 concentration have opposite behaviours when tEd increases.

At 300 K in wet air condition, carbon balance (with mainly CO and CO2) is obtained with a higher value than 90% if tEd > 900 J L−1. This case corresponds to a total ozone disappearance. At higher temperature, we observe that O3 completely disappears (consumed or not produced) whatever tEd values. In both air conditions, at 300 K, O3 concentration decreases for tEd higher than 300 J L−1. This depletion could be explained by an increase of the temperature inside the reactor due to high Ed values delivered by discharge electrodes.

Initial active species (such as O, H and OH) are produced in the bulk plasma from O2 and H2O decomposition. Then, these active species can react with O3 (Eqs. 7–11) [25–28]. Ozone consumption becomes more efficient when the temperature increases: rate constants are increasing when O3 is decomposed or reacts with O-atom, H, OH or HO2 (Eqs. 7–11). Effects of the temperature on ozone consumption rate constants are in agreement with experimental O3 concentrations. Unfortunately, some data on rate constants are missing in the literature at 800 K (Eq. 11).

In wet air conditions, OH and H can be more easily produced from H2O decomposition. Reactivity of these species with O3 explain the strongest experimental O3 concentration decreasing compared to dry air conditions (Eqs. 9–11). Thus, O3 consumption seems to be linked to the radical (H, OH and HO2) concentrations.

From the previous simplified O3 consumption mechanism (Eqs. 7–11), we observe that active species (OH, HO2) can be produced when O3 is consumed. Moreover, when [O3] decreases, more O-atoms are available in the bulk plasma because O-atoms are less consumed to produce O3 or O-atoms concentration increases from O3 conversion (Eq. 7). The increase of the active species amount can explain the decrease of the carbon by-products production which corresponds to a rise of the MC/inlet carbon ratio. Indeed, if we consider HCHO, as a representative oxygenated carbon by-product molecule, CO and CO2 can be produced from reactions between HCHO and active species. A simplified mechanism is presented from Eqs. 12–17 [22, 29].

when HCHO and other C x H y O z species are entirely converted in CO and CO2, the MC/inlet carbon ratio is equal to 1.

Conclusion

In this study, treatments of low propane concentrations (1,100 ppm) in wet or dry air by a non thermal plasma reactor as function of the temperature are performed. We show that a moderate heating (up to about 600 K) is very interesting to achieve a low energetic cost with a high propane conversion rate (about 100%) and to control outlet gas concentration. Main produced species containing carbon are CO and CO2 with concentrations easily controlled by varying parameters as inlet gas mixture composition, temperatures and energy density. Moreover, by-products amounts are as functions of the energy density injected in the plasma and the temperature.

Other main remarks concluding can be deduced from this study:

-

No conversion without plasma is observed even at 800 K. Electrons are the reaction initiators to produce first active species in the DBD streamers: O, OH, O3 from O2 and H2O decomposition.

-

In wet air condition, ozone and by-products consumption increases to reach a total oxidation of the inlet carbon injected which is converted in CO2.

-

A heating leads to a change of produced species at a specific energetic cost. A high decrease of the C x H y O z species produced is observed when the temperature increases from 300 to 800 K.

References

Oda T, Kumada A, Tanaka K, Takahashi T, Masuda S (1995) J Electrostat 35:93

Penetrante BM, Bardsley JN, Hsiao MC (1997) Jpn J Appl Phys 36:5007

Yamamoto T (1997) J Electrostat 42:227

Hill SL, Kim HH, Futamura S, Whitehead JC (2007) In: Proceedings 28th international conference on phenomena in ionized gases (28th ICPIG) Prague (Czech Republic) 1308 contributed papers on CD Rom

Blin-Simiand N, Jorand J, Belhadj-Miled Z, Pasquiers S, Postel C (2006) In: Proceedings of 5th international symposium on non-thermal plasma technology for pollution control and sustainable development (ISNTPT-5) Oleron Island (France). Contributed papers on CD Rom

Magureanu M, Mandache NB, Parvuslescu VI (2007) Plasma Chem Plasma Process 27:679

Jarrige J, Vervisch P (2006) J Appl Phys 99:113303

McAdams R (2001) J Phys D Appl Phys 34:2810

Kim HH, Ogata A, Futamura S (2007) In: Proceedings 28th international conference on phenomena in ionized gases (28th ICPIG) Prague (Czech Republic) 1312, contributed papers on CD Rom

Francke KP, Miessner H, Rudolph R (2000) Catal Today 59:411

Subrahmanyam Ch, Renken A, Kiwi-Minsker L (2007) Chem Eng J 134:78

Van Durme J, Dewulf J, Sysmans W, Leys C, Van Langenhove H (2007) Appl Catal B-Environ 74:161

Roland U, Holzer F, Kopinke FD (2002) Catal Today 73:315

Kang H, Choi B, Son G, Foster DE (2006) JMSE Int J Ser B 49(2):419

Guaitella O, Thevenet F, Puzenat E, Guillard C, Rousseau A (2008) Appl Catal B-Environ 80:296

Huang HB, Ye DQ, Fu ML, Feng FD (2007) Plasma Chem Plasma Process 27:577

Hao XL, Zhou MH, Zhang Y, Lei LC (2006) Plasma Chem Plasma Process 26:455

Aubry O, Khacef A, Cormier JM (2006) In: Proceedings of 10th international symposium on high pressure, low temperature plasma chemistry, HAKONE X, Saga (Japan) 7P-07, contributed papers

Motret O, Aubry O, Thuillier C, Lascaud M, Met C, Cormier JM (2005) In: Proceedings of 17th international symposium plasma chemistry, Toronto (Canada) 578, contributed papers on CD Rom

Khacef A, Cormier JM, Pouvesle JM (2002) J Phys D Appl Phys 35:1491

Tsang W, Hampson RF (1986) J Phys Chem Ref Data 15:1087

Baulch DL, Cobos CJ, Cox RA, Esser C, Frank P, Th Just, Kerr JA, Pilling MJ, Troe J, Walker RW, Warnatz J (1992) J Phys Chem Ref Data 21:411

Tsang W (1988) J Phys Chem Ref Data 17:887

Atkinson R (1986) Int J Chem Kinet 18(5):555

Heirmel JM, Coffee TP (1979) Combust Flame 35:117

Atkinson R, Baulch DL, Cox RA, Crowley JN, Hampson RF, Hynes RG, Jenkin ME, Rossi MJ, Troe J (2004) Atmos Chem Phys 4:1461

Yu HG, Varandas AJC (1997) J Chem Soc Faraday Trans 93:2651

Ju LP, Han KL, Varandas AJC (2007) Int J Chem Kinet 39:148

Vasudevan V, Davidson DF, Hanson RK (2005) Inter J Chem Kinet 37:98

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aubry, O., Cormier, JM. Improvement of the Diluted Propane Efficiency Treatment Using a Non-thermal Plasma. Plasma Chem Plasma Process 29, 13–25 (2009). https://doi.org/10.1007/s11090-008-9161-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-008-9161-z