Abstract

We present graphene metasurface based efficient and broadband solar absorber composed of a periodically arranged array of C-shaped metasurface placed above the dielectric layer. The proposed broadband graphene-based solar absorber is analyzed in terms of absorption characteristic with 82.7% absorption in the infrared region (280–380 THz), 86.5% absorption in the visible region (430–770 THz) and 92.99% absorption in Ultraviolet region (780–1000 THz). The simulation results are analyzed from 100 to 1200 THz in terms of absorption and reflection response with and without multiple graphene strips placed above the dielectric layer. The wide absorption band can be flexibly tuned from low-frequency band to high-frequency band by adjusting different design parameters of the proposed absorber. The proposed absorber design will be used as a building block for designing graphene-based sensors, optoelectronic devices, energy harvesting devices, and photovoltaic devices.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Metamaterial is an artificially engineered composite material that exhibits extraordinary electromagnetic properties and not easily available in nature (Smith et al. 2004). From past many years, metamaterial absorbers have gained considerable attention in applications such as solar energy harvesting (Ogawa and Kimata 2018; Liang et al. 2013), sensing (Cheng et al. 2016), thermal imaging (Liu et al. 2010), microstrip radiating structure (Patel et al. 2019a), etc., All these applications are achieved due to its exotic response of electromagnetic properties, such as negative refractive index, asymmetric transmission, and cross-polarization conversion. The metamaterial absorber is experimentally demonstrated and presented in Landy et al. (2008). Metamaterial absorber design is widely explored in the terahertz spectral range (Infrared, Visible and Ultraviolet region) by many researchers. Many such absorber structures are designed to work at single and multiband and thus fulfilling many practical applications such as solar harvesting and sensing. However, many application of Metamaterial is impeded by its losses and difficulties in 3D fabrication, especially in micro- and nano-scale. To develop multifunctional terahertz devices, the low cost and broadband absorber have important research value. Metasurfaces are two-dimensional (2D) or the planar version of metamaterials consisting of single-layer or few-layers. The planar structures with the thickness of subwavelength and can be readily fabricated using lithography and nano-printing methods. Due to their lightweight and ease of fabrication, they are broadly investigated and implemented in electromagnetic applications to suppress undesirable losses. Metasurface, with its exotic properties to manipulate EM waves are studied to design polarizer (Heidari and Sedighy 2018), and the multi-band (Cao and Cheng 2018; Cheng et al. 2018, 2019; Huang et al. 2018a), narrow or broadband absorbers (Niu et al. 2018; Cheng and Du 2019; Huang et al. 2018b; Chen et al. 2020; Patel et al. 2019b; Katrodiya et al. 2019).

The metasurface absorbers are mainly classified into three categories: multiband, narrowband and broadband absorbers. The structures are tailored with more than one resonators with different sizes and shapes together (Xu et al. 2018) or using multiple resonators on stacked structures to achieve multi-band and narrowband absorption(Gao et al. 2018; Zhang et al. 2019; Deng et al. 2018). These methods include the complicated process of fabrication that results in high cost. Therefore simple structures with single fabrication steps are having great importance (Yao et al. 2016; Arik et al. 2016). Major efforts have been put by researchers to achieve broadband absorption rather than a multiband and narrow band for terahertz application. To adapt the development of multifunction terahertz devices, the broadband absorbers with switchable absorptivity is important to research. It can be achieved by engineering the shape, size, thickness, and structure composed of a pattern array of metals placed above the dielectric spacer (Arik et al. 2017; Cao and Cheng 2019).

Many metasurface absorbers are works on pre-defined frequency region due to its restrict permittivity and permeability. Hence, it is necessary to find material with flexible properties to design frequency tunable absorber (Chen et al. 2017). The periodic arranged array of C-shaped metasurface in the proposed absorber helps to enhance the coupling of energy from the EM incident field on the metasurface. Also, multiple graphene strips arranged in parallel placed above the dielectric layer, which helps to further enhance the bandwidth and absorption coefficient. Graphene is a two-dimensional, one-atom-thick surface densely packed arranged in a honeycomb lattice (Sorathiya et al. 2019). Due to interesting electronics carriage and tuneable properties of graphene, it is far better to use than those metals and semiconductors. Graphene, with its high conductivity and excellent mechanical properties it is used as a good applicant in solar absorber design (Thomas et al. 2019; Dave et al. 2018; Patel et al. 2018). To make design cost-effective, we had introduced the tungsten material in the proposed solar absorber instead of gold. Due to its high melting point compared to Gold (Au), Silver (Ag), Chromium (Cr), Copper (Cu) and even Titanium Nitride (TiN), it helps tungsten-based absorber to withstand with high temperature when absorbing photons of greater energy (Rana et al. 2018). Graphene-based plus shape metasurface is designed to improve the absorption result and achieve broadband behavior presented in Patel et al. (2019c). Pyramid array is used with a graphene surface to achieve broadband behavior is presented in Charola et al. (2019).

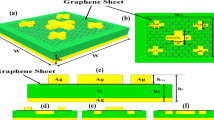

The broadband response of the absorber depends upon the complex design of metasurface and multiple layers of stacks thus the need for new solar absorber design which gives the broadband response with low fabrication cost. It can be easily fabricated due to its simple metasurface design and less costly due to tungsten materials used in it. The proposed structure of the graphene-based metasurface absorber is shown in Fig. 1a with a total thickness of 560 nm and a total length (L) of 2000 nm, respectively. The total size of broadband metasurface solar absorber is chosen to ensure that it achieves broadband absorption at the operating wavelength. Absorption characteristic is analyzed from 100 to 1200 THz for proposed solar absorber with broadband absorption response.

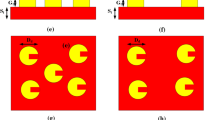

The C-shaped metasurface absorber design a Three-dimensional design b Two-dimensional design c The unit cell of the last row of C-shaped metasurface. The top layer with the thickness (H) of 30 nm and the bottom layer with the thickness (W) 200 nm made up of tungsten material. The dielectric layer with the thickness (T) of 330 nm which separates the top and bottom layer made up of silicon dioxide (SiO2). The total length (L) of the structure is kept 2000 nm. The unit cell of C-shaped with length (L1) is 310 nm, length (L2) is 200 nm and length (L3) is 110 nm. The distance (D) between two adjacent C-shaped is 660 nm and the distance from C-shaped to the edge of structure is 330 nm

2 Metasurface absorber design and modeling

The proposed metasurface absorber design is presented in Fig. 1. The design structure is divided into three main parts. The first part is the metallic resonator part consists of a C-shaped metasurface array placed on graphene strips. The second part is the dielectric layer made up of silicon dioxide (SiO2) layer which concentrates and absorbs incoming electromagnetic waves. The third part is the tungsten material used in the C-shaped metasurface and bottom layer which is used to absorb incoming electromagnetic waves. The experimental data of tungsten used in the proposed design is adopted from Palik (1998). The experimental data of silicon dioxide is set as a dielectric spacer to separate the top and bottom layer is adopted from Guo and Argyropoulos (2016). The use of tungsten material reduces the cost of the design as well as provide ease of fabrication.

The thickness (W) of the thin film at the bottom made up of tungsten has a 200 nm, opaque to incident light which prevents light transmission. The thickness (T) of the dielectric layer is 300 nm and the thickness (H) of the periodically arranged array of C-shape metasurface above dielectric layer is 30 nm as shown in Fig. 1b. An electromagnetic plane wave is inserted normally from z-direction in absorber such that periodic arranged nanostructure array is illuminated by the magnetic field parallel to the y-axis and electric field parallel to the x-axis as shown in Fig. 1a. As shown in Fig. 1c, the optimized geometric parameters of a unit cell for periodically arranged of C-shaped metasurface are L1 = 310 nm, L2 = 200 nm and L3 = L2 − L1 = 110 nm, where L1 and L2 are the length of single C in unit cell of the proposed absorber. The periodically arranged array of metallic resonators placed above the dielectric layer are equally spaced with the spacing distance of D is 660 nm and D/2 is spacing at outer the edges of the absorber as shown in Fig. 1c.

The periodically arranged three graphene strips in parallel with the size of width (G) and length (L) placed above the dielectric layer is 200 to 2000 nm respectively. The thickness of the graphene monolayer sheet to be considered as a 0.34 nm. The surface conductivity (\({\sigma }_{s}\)) equation of graphene is described as the sum of the interband and intraband electron transition contribution given by Kubo formula (Guo and Argyropoulos 2016) shown from Eqs. (1–4).

The permittivity of graphene depends on the thickness of graphene monolayer sheet (\(\Delta (0.34nm)\)), angular frequency (\(\omega\)), permittivity of vacuum \(({\varepsilon }_{o})\) and surface conductivity \(({\sigma }_{s})\).Different parameters of graphene surface conductivity \(({\sigma }_{s})\) also depend upon temperature (T) in kelvin, \({k}_{B}\)(1.38e-23 J/K)is the Boltzmann constant, \({\text{h}}\)(6.62e-34 J.s) is the Planck's constant, \(e\)(1.6e-19 C) is electron charge value, electron–phonon, \(\Gamma\) (11e-3 [1/S]) is scattering rate and also \({\mu }_{C}\)(0.3 eV) is chemical potential. Graphene's chemical potential is given by \(\mu _{{C = }} {\text{h}}V_{F} \sqrt {\pi CV_{{DC}} /e}\), \({V}_{DC}\) is a gate voltage, t is dielectric layer thickness, \({\text{C}}\) is the capacitance is given by \({\text{C}} = \varepsilon _{d} \varepsilon _{0} /t\), \({\varepsilon }_{d}\) is dielectric layer static permittivity and t is dielectric layer thickness.

The effectiveness of absorption is very important and is measured over here by the following equations (Akimov and Koh 2010):

where, \({\text{Q}}_{{{\text{abs}}}}\) is spectral power absorbed by each element, A(ω) is optical absorption, \({\text{Q}}_{{{\text{abs}}}}^{{{\text{tot}}}}\) is total power absorbed and \({\text{Q}}_{{{\text{inc}}}}\) is spectral power coming from the sun and incident on the surface. The simulated reflection (R) and absorption (A) spectra of designed absorber with the above-mentioned parameters as shown in Fig. 2a, b. The relation between reflection(R), absorption (A) and transmission (T) is

a Absorption and b Reflection spectrum of the response of absorber with and without multiple graphene strips placed above the dielectric layer. The average absorption is 75.6% from 100 to 1200 THz is achieved by arranging multiple strips of graphene shown by the red line. The response of average absorption without the multiple graphene strips is 71.9% from 100 to 1200 THz shown by the blue line

where, \(R\left(\omega \right)\) and \(T\left(\omega \right)\) both are frequency (ω) dependent parameters represents reflection and transmission. Besides, both \(R\left(\omega \right)\) and \(T\left(\omega \right)\) can be expressed in term of S-parameters as \(R\left(\omega \right)\)=\({\left|{S}_{11}\right|}^{2}\) and \(T\left(\omega \right)\)=\({\left|{S}_{21}\right|}^{2}\).Due to the bottom layer made of tungsten helps to reduce transmission co-efficient (T (ω) ≈ 0) as the thickness of the tungsten layer is much larger than its skin depth. The periodic array of C-shaped metasurface is tailored to reduce reflection such that to increase the absorption of the proposed solar absorber.

3 Results and discussion

The proposed absorber design is analyzed through the Finite Element Method (FEM) based numerical simulation using COMSOL 5.4 Multiphysics simulator. The proposed unit cell floquet boundary condition is applied in the X and Y direction. The transverse electric field applied from port-1 from ± Z direction and response of the design is computed at port-2. The ports to be considered as periodic for simulation for proposed design to observe the absorbtion characteristic from 100 to 1200 THz. The comparative plots of absorption (A) and reflection (R) of periodically arranged metallic resonators with and without multiple graphene strips are shown in Fig. 2a, b, respectively. From Fig. 2a, the average absorption is achieved with the multiple graphene strips is 75.6% and without the multiple graphene strips is 71.9%. The comparative analyses in terms of the infrared, visible and ultraviolet region with and without the multiple graphene strips are presented in Table 1. From Table 1, it is clear that the addition of multiple graphene strips achieves more average absorption in all three regions (Infrared, visible and ultraviolet region). The design presented here is also giving a better response compared to the previously published similar design (Rufangura and Sabah 2017; Liu et al. 2018; Sang et al. 2019).

Different design parameters are varied to observe its effect on the absorption and reflectance response. The characteristic of absorption changes with change in graphene width (G), Design structure length (L), thickness (H) of metallic resonators, thickness (T) of dielectric layer, C-shape metasurface length (L1) and width (L2) are presented from Figs. 3, 4, 5, 6, 7, 8. The graphene strips width (W) is varied from 0.1 to 0.6 μm to observe its effect on the response of reflectance and absorption in the range of 100 to 1200 THz. The change in the width of graphene strips does not change the absorption much as shown in Fig. 3.

The total design structure length (L) is varied from 1.5 to 2.5 μm for both the designs (with graphene and without graphene) and the results are presented in Fig. 4. The absorption results are better for the middle range of 1.7–2.1 μm. The absorption range is more for graphene design compared to the design without graphene. The more absorption is achieved in the range of 450–1050 THz if the metallic resonators are placed above the graphene strips. The use of graphene increases the concentration of the light in the absorbing layer and thus the absorption is increased for the graphene design.

The thickness of metallic resonators is a very important part because by increasing the thickness the reflectance increases which reduces the absorption. The thickness is varied from 0.02 to 0.05 µm keeping other parameters constant to observe its effect on reflectance and absorption is presented in Fig. 5. As shown in Fig. 5a the absorption increases with increases in the thickness of metallic resonators. The metallic resonators placed above the graphene sheets show more absorption between 980 and 1100 THz compare to without graphene strips.

The thickness of the dielectric layer made up of silicon dioxide plays an important role in the absorption of the metasurface absorber. The thickness increase keeps the absorption high for a certain level and then the absorption does not increase much after that level. The increase in thickness also increases the size and affect its cost at the production level. The height of the SiO2 layer is varied from 0.2 to 0.4 μm and results are presented in Fig. 6. The absorption is achieved more in-between 0.3 and 0.4 μm. The absorption is almost the same for both designs with and without the graphene strips.

The C-Shape metasurface length and width are also varied to observe its effect on results. The absorption and reflectance results are presented in Figs. 7, 8. The change in length and width of the C-shape metasurface changes its structure and thus the metamaterial properties (permittivity and permeability) change which affects the reflectance and absorption results. The efficiency of absorption increases with an increase in the length (L1) of C-shaped design as shown in Fig. 7. There are two bands clearly shown in Fig. 7a where maximum absorbtion is achieved, the first band between 290 and 370 THz and the second band is 470 to 1100 THz. The absorption and reflectance results for different metasurface width (L2) is presented in Fig. 8. The results of absorption slightly decrease as the width of the metasurface (L2) increases. The increase in the width covers most of the dielectric layer and thus reflection increases and absorption decreases.

The graphene monolayer strips placed above dielctric layer and below C-shaped rectangular sawtooth metasurface to achieve more absorbtion. The absorbtion and reflectance respose of proposed absorber is observed by changing the chemical potential (μc) from 0.3 to 1.1 eV. As shown in Fig. 9, the change in chemical potential doen’t effect the absorbtion response in the range of 100–1200 THz.

The change in absorbtion characteristic is observed with change in the thickness of graphene monolayer strips placed above dielectric layer and below C-shaped rectangular sawtoooths from 0.34 to 1.14 nm as shown in Fig. 10. The increase in graphene layers thickness leads to increase in more absorbtion with less reflection as shown in Fig. 10.

The normalized surface current density with a unit of A/m is presented in Fig. 11 for four different frequencies (a) 200 THz (b) 600 THz (c) 800 THz and (d) 1000 THz. The concentration of current shown by the arrow is observed around the C-shape metasurface and on the dielectric layer. The current distribution is increasing for the middle frequencies of 600 THz and 800 THz. A normalized electric field response is presented in Fig. 12 for four different frequencies (a) 200 THz (b) 600 THz (c) 800 THz and (d) 1000 THz. The normalized electric field response clearly shows the concentration of electric energy around the C-shape metasurface for the 200 THz frequency range. The absorption is also better for the 400 THz frequency response. As we move into the ultraviolet range the electric energy concentration around the C-Shape metasurface is decreasing.

4 Conclusion

In summary, periodic array of C-shaped metasurface is placed above the multiple graphene strips and dielectric layer (SiO2) to achieve a broadband response. The results in the form of absorption, reflectance, electric field, and magnetic field are presented to show the broadband response. The absorption result of graphene design is compared with a simple design and previously published similar designs. From the comparison, it is clear that the multiple graphene strips design gives better results compared to other designs. The average absorption of 86.1%, 86.5%, and 92.99% is achieved for the infrared region, visible region and ultraviolet region respectively. The results are also observed by changing different design parameters. The change in width (W) of graphene strips is not having much effect on the results but the increase in C-shape metasurface length (L1) increases the absorption. The increase in width (L2) decreases the absorption. The proposed broadband and efficient solar absorber can be used as a building block for sensors, photovoltaic devices, and energy harvesting devices.

References

Akimov, Y.A., Koh, W.S.: Resonant and nonresonant plasmonic nanoparticle enhancement for thin-film silicon solar cells. Nanotechnology 21(23), 235201 (2010). https://doi.org/10.1088/0957-4484/21/23/235201

Arik, K., Abdollahramezani, S., Farajollahi, S., Khavasi, A., Rejaei, B.: Design of mid-infrared ultra-wideband metallic absorber based on circuit theory. Optics Commun. 381, 309–313 (2016). https://doi.org/10.1016/j.optcom.2016.07.014

Arik, K., AbdollahRamezani, S., Khavasi, A.: Polarization insensitive and broadband terahertz absorber using graphene disks. Plasmonics 12(2), 393–398 (2017). https://doi.org/10.1007/s11468-016-0276-4

Cao, C., Cheng, Y.: Quad-band plasmonic perfect absorber for visible light with a patchwork of silicon nanorod resonators. Materials 11(10), 1954 (2018). https://doi.org/10.3390/ma11101954

Cao, C., Cheng, Y.: A broadband plasmonic light absorber based on a tungsten meander-ring-resonator in the visible region. Appl. Phys. A 125(1), 15 (2019). https://doi.org/10.1007/s00339-018-2310-1

Charola, S., Patel, S.K., Parmar, J., Ladumor, M., Vigneshwaran, D.: Broadband graphene-based metasurface solar absorber. Microw. Optic. Technol. Lett. (2019). https://doi.org/10.1002/mop.32156

Chen, M., Sun, W., Cai, J., Chang, L., Xiao, X.: Frequency-tunable terahertz absorbers based on graphene metasurface. Optics Commun. 382, 144–150 (2017). https://doi.org/10.1016/j.optcom.2016.07.077

Chen, F., Cheng, Y., Luo, H.: A broadband tunable terahertz metamaterial absorber based on single-layer complementary gammadion-shaped graphene. Materials 13(4), 860 (2020). https://doi.org/10.3390/ma13040860

Cheng, Y., Du, C.: Broadband plasmonic absorber based on all silicon nanostructure resonators in visible region. Opt. Mater. 98, 109441 (2019). https://doi.org/10.1016/j.optmat.2019.109441

Cheng, Y., Mao, X.S., Wu, C., Wu, L., Gong, R.: Infrared non-planar plasmonic perfect absorber for enhanced sensitive refractive index sensing. Opt. Mater. 53, 195–200 (2016). https://doi.org/10.1016/j.optmat.2016.01.053

Cheng, Y., Zhang, H., Mao, X.S., Gong, R.: Dual-band plasmonic perfect absorber based on all-metal nanostructure for refractive index sensing application. Mater. Lett. 219, 123–126 (2018). https://doi.org/10.1016/j.matlet.2018.02.078

Cheng, Y., Luo, H., Chen, F., Gong, R.: Triple narrow-band plasmonic perfect absorber for refractive index sensing applications of optical frequency. OSA Contin. 2(7), 2113–2122 (2019). https://doi.org/10.1364/OSAC.2.002113

Dave, V., Sorathiya, V., Guo, T., Patel, S.K.: Graphene-based tunable broadband far-infrared absorber. Superlattices Microstruct. 124, 113–120 (2018). https://doi.org/10.1016/j.spmi.2018.10.013

Deng, H., Mathai, C.J., Gangopadhyay, S., Gao, J., Yang, X.: Ultra-broadband infrared absorption by tapered hyperbolic multilayer waveguides. Opt. Express 26(5), 6360–6370 (2018). https://doi.org/10.1364/OE.26.006360

Gao, H., Peng, W., Chu, S., Cui, W., Liu, Z., Yu, L., Jing, Z.: Refractory ultra-broadband perfect absorber from visible to near-infrared. Nanomaterials 8(12), 1038 (2018). https://doi.org/10.3390/nano8121038

Guo, T., Argyropoulos, C.: Broadband polarizers based on graphene metasurfaces. Opt. Lett. 41(23), 5592–5595 (2016). https://doi.org/10.1364/OL.41.005592

Heidari, M.H., Sedighy, S.H.: Broadband wide-angle polarization-insensitive metasurface solar absorber. JOSA A 35(4), 522–525 (2018). https://doi.org/10.1364/JOSAA.35.000522

Huang, M., Cheng, Y., Cheng, Z., Chen, H., Mao, X., Gong, R.: Based on graphene tunable dual-band terahertz metamaterial absorber with wide-angle. Optics Commun. 415, 194–201 (2018a). https://doi.org/10.1016/j.optcom.2018.01.051

Huang, M.L., Cheng, Y.Z., Cheng, Z.Z., Chen, H.R., Mao, X.S., Gong, R.Z.: Design of a broadband tunable terahertz metamaterial absorber based on complementary structural graphene. Materials 11(4), 540 (2018b). https://doi.org/10.3390/ma11040540

Katrodiya, D., Jani, C., Sorathiya, V., Patel, S.K.: Metasurface based broadband solar absorber. Opt. Mater. 89, 34–41 (2019). https://doi.org/10.1016/j.optmat.2018.12.057

Landy, N.I., Sajuyigbe, S., Mock, J.J., Smith, D.R., Padilla, W.J.: Perfect metamaterial absorber. Phys. Rev. Lett. 100(20), 207402 (2008). https://doi.org/10.1103/PhysRevLett.100.207402

Liang, Q., Wang, T., Lu, Z., Sun, Q., Fu, Y., Yu, W.: Metamaterial-based two-dimensional plasmonic subwavelength structures offer the broadest waveband light harvesting. Adv. Optic. Mater. 1(1), 43–49 (2013). https://doi.org/10.1002/adom.201200009

Liu, X., Starr, T., Starr, A.F., Padilla, W.J.: Infrared spatial and frequency selective metamaterial with near-unity absorbance. Phys. Rev. Lett. 104(20), 207403 (2010). https://doi.org/10.1103/PhysRevLett.104.207403

Liu, B., Tang, C., Chen, J., Xie, N., Tang, H., Zhu, X., Park, G.S.: Multiband and broadband absorption enhancement of monolayer graphene at optical frequencies from multiple magnetic dipole resonances in metamaterials. Nanoscale Res. Lett. 13(1), 153 (2018). https://doi.org/10.1186/s11671-018-2569-3

Niu, X., Qi, D., Wang, X., Cheng, Y., Chen, F., Li, B., Gong, R.: Improved broadband spectral selectivity of absorbers/emitters for solar thermophotovoltaics based on 2D photonic crystal heterostructures. JOSA A 35(11), 1832–1838 (2018). https://doi.org/10.1364/JOSAA.35.001832

Ogawa, S., Kimata, M.: Metal-insulator-metal-based plasmonic metamaterial absorbers at visible and infrared wavelengths: a review. Materials 11(3), 458 (2018). https://doi.org/10.3390/ma11030458

Palik, E. D. (Ed.). (1998). Handbook of optical constants of solids (Vol. 3). Academic Pres, Cambridge.

Patel, S.K., Ladumor, M., Sorathiya, V., Guo, T.: Graphene-based tunable grating structure. Mater. Res. Express 6(2), 025602 (2018). https://doi.org/10.1088/2053-1591/aaea9a

Patel, S.K., Shah, K.H., Kosta, Y.P.: Frequency-reconfigurable and high-gain metamaterial microstrip-radiating structure. Waves Random Complex Media 29(3), 523–539 (2019a). https://doi.org/10.1080/17455030.2018.1452309

Patel, S., Charola, S., Parmar, J., Ladumor, M.: Broadband metasurface solar absorber in the visible and near-infrared region. Mater Res Express 6(8), 086213 (2019b). https://doi.org/10.1088/2053-1591/ab207d

Patel, S.K., Charola, S., Jani, C., Ladumor, M., Parmar, J., Guo, T.: Graphene-based highly efficient and broadband solar absorber. Opt. Mater. 96, 109330 (2019c). https://doi.org/10.1016/j.optmat.2019.109330

Rana, A.S., Mehmood, M.Q., Jeong, H., Kim, I., Rho, J.: Tungsten-based ultrathin absorber for the visible regime. Sci. Rep. 8(1), 2443 (2018). https://doi.org/10.1038/s41598-018-20748-9

Rufangura, P., Sabah, C.: Graphene-based wideband metamaterial absorber for solar cells application. J. Nanophotonics 11(3), 036008 (2017). https://doi.org/10.1117/1.JNP.11.036008

Sang, T., Gao, J., Yin, X., Qi, H., Wang, L., Jiao, H.: Angle-insensitive broadband bbsorption enhancement of graphene using a multi-grooved metasurface. Nanoscale Res. Lett. 14(1), 105 (2019). https://doi.org/10.1186/s11671-019-2937-7

Smith, D.R., Pendry, J.B., Wiltshire, M.C.: Metamaterials and negative refractive index. Science 305(5685), 788–792 (2004). https://doi.org/10.1126/science.1096796

Sorathiya, V., Patel, S.K., Katrodiya, D.: Tunable graphene-silica hybrid metasurface for far-infrared frequency. Opt. Mater. 91, 155–170 (2019). https://doi.org/10.1016/j.optmat.2019.02.053

Thomas, L., Sorathiya, V., Patel, S.K., Guo, T.: Graphene-based tunable near-infrared absorber. Microw. Optic. Technol. Lett. 61(5), 1161–1165 (2019). https://doi.org/10.1002/mop.31712

Xu, J., Li, R., Wang, S., Han, T.: Ultra-broadband linear polarization converter based on anisotropic metasurface. Opt. Express 26(20), 26235–26241 (2018). https://doi.org/10.1364/OE.26.026235

Yao, G., Ling, F., Yue, J., Luo, C., Ji, J., Yao, J.: Dual-band tunable perfect metamaterial absorber in the THz range. Opt. Express 24(2), 1518–1527 (2016). https://doi.org/10.1364/OE.24.001518

Zhang, H., Zhang, H., Yang, J., Liu, J.: Ultra-broadband infrared metasurface absorber. Opt. Express 27(4), 5346–5350 (2019). https://doi.org/10.1364/OE.27.005346

Acknowledgements

The authors would like to express their sincere thanks to Prof. Dr. Truong Khang Nguyen, Division of Computational Physics, Institute for Computational Science, Ton Duc Thang University, Ho Chi Minh City, Vietnam for giving his value suggestion, comments and support to complete this work as effective.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Patel, S.K., Charola, S., Parmar, J. et al. Broadband and efficient graphene solar absorber using periodical array of C-shaped metasurface. Opt Quant Electron 52, 250 (2020). https://doi.org/10.1007/s11082-020-02379-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11082-020-02379-5