Abstract

The high power light emitting diode (LED) based on AlGaInP is tested on line at temperatures from 350 to 77 K. The experimental data are fitted to measure the relationship between temperature and the ideality factor, the forward voltage, the relative light intensity emitted by the LED, the carrier lifetime and the reverse recovery time of the device. These results show that temperature has a significant influence on different properties of such LED. Finally, it is important to note that an optimization among the different parameter values, while some increasing and others decreasing with temperature change, as indicated in the present study, is essential and must be considered for design involving the device, particularly, for any low temperature application.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

It is needless to emphasize that there are many instruments used in the field of defence and space research programmes which make use of IR, UV and visible radiation detection and emission. The performance and reliability of many of these instruments depend on the capabilities of the detectors and emitters under different conditions. It is expected that the performance of these devices should remain stable over a wide range of temperatures which may vary from room temperature to temperatures far below and above it. It is found that the carrier transport and recombination mechanisms of different types of solid state high performance light emitting diodes (LEDs) drastically change with temperature. There is not enough study on the performance of the commercially available LEDs from high to low temperature ambience. So, the data obtained from this study will be extremely useful to select the proper opto devices for designing and fabricating efficient instruments in various applications. One such high performance LED is AlGaInP based LED which is the object of the present study.

AlGaInP-based LEDs have a broad wavelength spectrum from green to red, and it is used widely as a light source for various applications of displays, traffic signals, signs, and illuminating of general lightings at different ambient temperatures (Lee et al. 2011; Kim et al. 2013; Lu et al. 2009). Recently the internal quantum efficiency for some such LEDs has reached nearly 99 %, but due to the substantial difference of the refractive index between the quaternary epitaxial layers (refractive index \(\sim \)3.3 at 635 nm) and air (refractive index \(\sim \)1) the external quantum efficiency is still low (Lee et al. 2011; Yen et al. 2013). Further although AlGaInP based devices have been successfully made, their junction properties have not yet been adequately examined. In such devices the opto-electrical characterization can provide important information about the current transport through the wide-band-gap \(p-n\) heterojunctions and layer materials. Such knowledge of the carrier transport mechanisms is essential for achieving a fundamental understanding and further improvement of the device performance. In spite of the significant research efforts invested by many groups, these carrier transport mechanisms are still not well understood. Several publications highlight on the change of ideality factor, forward voltage, relative light intensity, carrier lifetime and reverse recovery time of LEDs with temperature (Weling et al. 2011; Acharya and Vyavahare 1999; Dalapati et al. 2013; Bergman et al. 1995; Chen et al. 2012; Hull et al. 2008; Bolotnikov et al. 2007). These literatures show that the variations of these factors with temperature for different types of LED are not same. Golden Dragon LWW5SG datasheet show that for InGaAlP LEDs (Yellow and Amber Red) have the K coefficient between \(-3.0 \times 10^{-3}\) and \(-5.2 \times 10^{-3}\,\hbox {V/K}\), and the InGaN LEDs (Blue, Verde Green, and White) have the K coefficient of between \(-3.6 \times 10^{-3}\) and \(-5.2 \times 10^{-3}\,\hbox {V/K}\). Also Weling et al. (2011) reported that the average value of the K coefficient for GaN-based blue power LEDs is \(-6.4 \times 10^{-4}\,\hbox {V/K}\) and that’s for AlGaInP-based red power LEDs is \(-4.1 \times 10^{-3}\,\hbox {V/K}\). These results show that the K coefficient has different values for different types of materials. Hence, it is important to understand the physical significance of this variation.

In case of ideality factor n, it is observed that its value increases with lowering of temperature. Yan et al. (2010) reported that in GaN based blue LED n increases from 1.9 to 6.2 when the temperature is lowered from 300 to 100 K. In our previous work we observed that in AlGaAs based red LED, n varies from 1.88 to 2.37, when temperature decreases from 345 to 136 K.

In general, relative light intensity (L) emitted by the LEDs is found to increase with lowering of temperature. For the temperature change from 293 to 243 K, the relative light intensity of the InGaN based blue LEDs increased by about 9 % whereas for AlGaInP based red power LEDs it increases about 10 %, on average (Weling et al. 2011). In our previous work we also observed a similar trend of the variation of relative light intensity with temperature for AlGaAs based red LED, where a 16 % increase has been observed for a temperature change from 345 to 136 K (Dalapati et al. 2013). Since the variation of n is sensitive to temperature (Chand and Kumar 1996), and is also not same for all LEDs, more number of LEDs should be characterized so that a theoretical basis of this variation can be addressed.

Several efforts have been made recently in order to develop both theoretically and experimentally the technique, which utilizes the open-circuit voltage decay (OCVD) process for determining the minority carrier lifetime (\(\uptau \)) of a LED (Dalapati et al. 2013; Bergman et al. 1995; Tapajna et al. 2004; Bhattacharya et al. 1985). Bergman et al. (1995) reported that in GaAs/AlGaAs double heterostructures \(\uptau \) for acceptor concentration (\(\hbox {N}_{\mathrm{A}}\)) \(4 \times 10^{17}\hbox { cm}^{-3}\) varies from 150 to 20 nS for the temperature change 700–100 K. Also, the change of same for AlGaAs based red LED is 163.48–19.76 nS for the temperature change 345–136 K. This variation of \(\uptau \) clearly indicates that it is very sensitive to temperature and decreases with temperature and decrease of \(\uptau \) means that more recombination is taking place i.e. the light output of LED is increasing. So, it will be of interest to find the correlation between L and \(\uptau \), which will be discussed in Sect. 3.2.2.

Already we have mentioned that such LEDs have various applications, so another important parameter for operation is its switching time. The reverse recovery time (\(\hbox {t}_{\mathrm{rr}}\)) measurements are very important for this purpose. Several workers also measured the value of \(\hbox {t}_{\mathrm{rr}}\) for different diodes and its variation with temperature (Chen et al. 2012). The measurements of \(\hbox {t}_{\mathrm{rr}}\) for different commercial LEDs are essential for their diverse applications in different temperature regimes.

In this work we have measured all these parameters for AlGaInP based LED and their variation with temperature which will have important implication for low temperature applications. Moreover, the experimental data obtained in this investigation may have a huge importance to design such optoelectronic devices where the variation of these parameters with temperature may be minimized in further attempt.

2 Experimental details

In our investigations we used one AlGalnP based red LED (LL2508JQHR4-A02, 100 deg.) procured from RS Components, having a peak wavelength 624 nm. The LED was placed inside a bath type optical cryostat designed in our laboratory (Dalapati et al. 2013; Manik et al. 2000). With special care, liquid nitrogen was poured inside the liquid chamber of the cryostat which was pre-evacuated to a pressure \(10^{-4}\) Torr by using a high vacuum pumping unit (Model No. PU-2 CH-8, manufactured by Vacuum Products & Consultants) to avoid moisture on the sample. The temperature measurement in the range 350–77 K was done by using a Chromel-Alumel thermocouple (TC). The TC output was recorded by a Keithley 2000 multimeter with accuracy of the order of \(\pm 0.14\,\hbox {K}\). I–V measurements were performed by Keithley 2400 source measure unit. For optical output measurement, we use a BPX 61 photodetector (having minimum and maximum detecting wavelengths are 400–1,100 nm) which was reversely biased with a 2.5 V DC source and with a 390 K sensing resistance in series. The LED was driven with different values of current in the mA range. The details of the experimental set up are available in our previous work (Dalapati et al. 2013; Manik et al. 2000).

3 Results and discussion

3.1 Forward I–V characteristics

In order to have a better understanding of the effect of temperature on the electronic properties of such device, the forward bias current–voltage (I–V) measurements are done. The forward lnI versus V characteristics of the LED at various temperatures in the range of 350–77 K are given in Fig. 1. Two successive linearly dependent segments with different slopes can be observed based on bias levels, which are defined as low-bias (I) (below 1.75 V) and medium-bias (II) (above 1.75 V) regions respectively.

From the Shockley’s diode equation, it is in sharp contrast to the prediction that the slopes of I–V characteristics of the AlGalnP LED at low- and medium-bias regions are almost insensitive to temperatures, indicating a nondiffusion-recombination mechanism (Yan et al. 2010). The forward I–V characteristics in these two bias regions are expressed by a standard diode equation,

where n is diode ideality factor, \(\hbox {I}_{0}\) is reverse saturation current, \(q\) is electron charge, \(V \) is applied voltage, K is Boltzmann’s constant and \(T\) is absolute temperature.

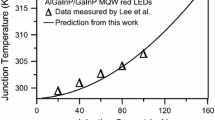

The ideality factor n is derived from the slope 2.3(nKT/q) of medium-bias (II) region. The typical values of n are 1.20 at 350 K and 5.46 at 77 K. However, it should be noted from Fig. 2 that below 205 K the ideality factor n approaches 2 and above, which suggests that, at high temperature the diffusion component starts to play a role in the total diode current and at lower temperature (below 205 K) the tunneling component gradually becomes dominant. The variation of n is shown in Fig. 2 and listed in Table 1.

From the Fig. 2 it is clearly seen that the ideality factor is very sensitive to temperature and decreases with its increase.

If we neglect the value of LED series resistance changing with temperature, then for a constant input current the relationship between the forward voltage of the LED and temperature can be described as (Weling et al. 2011; Han et al. 2012)

where T is the temperature inside the oven and \(\hbox {T}_{0}\) is the room temperature, \(\hbox {V}_{\mathrm{fT}}\) is the value of forward voltage at T, \(\hbox {V}_{\mathrm{fT0}}\) is the value of forward voltage at \(\hbox {T}_{0}\) and K is the temperature coefficient of forward voltage. The value of K coefficient is calculated by fitting the data of experiment results shown is Fig. 2 and listed in Table 1. The average value of the K coefficient is \(-1.79 \times 10^{-3}\,\hbox { V/K}\). This means that if the temperature of LED chip is increased by 1 K, the forward voltage of the LED decreases by \(-1.79 \times 10^{-3}\,\hbox { V}\). Hence, the determination of K coefficient is very important not only for designing of LED but also for understanding of the underlying physics of the variation of forward voltage.

3.2 Change of relative light intensity and carrier lifetime with temperature

3.2.1 Relative light intensity measurement

In our earlier work we had performed the intensity-temperature measurement for AlGaAs based LED at a fixed driving current of 15 mA. Here we have performed the same measurement for AlGaInP based LED at various constant driving currents, namely, 15, 20 and 30 mA. The intensity of the LED is measured in terms of photovoltage and each measured value has been obtained by keeping it fixed against the corresponding temperature for one minute approximately. Variation of the relative light intensity emitted by the LED with temperature is shown in Fig. 3 and listed in Table 2.

Figure 3 shows that the relative light intensity increases as the temperature is decreased and below 200 K the rate of change of intensity is comparatively low. There are several publications which also showed for different LEDs the variation of intensity with temperature has similar trends, but change of the intensity pattern and the amount of change are not same for all LEDs. So, it is important to obtain the intensity-temperature data for various commercial LEDs. In our sample when the temperature decreases from 350 to 77 K, the relative light intensity of the LED increases by about 9 % on average.

3.2.2 Carrier lifetime measurement

The OCVD technique is one of the widespread methods for determining carrier life time in the bulk of the diode structures (Dalapati et al. 2013; Bhattacharya et al. 1985). Open-circuit voltage decay wave shapes, for the wide temperature ranges 350–77 K, for the 1.71 KHz frequency supply, have been measured. Figure 4 shows the OCVD wave shape at different temperatures.

When the diode bias circuit is opened, subsequent excess carrier recombination is detected by monitoring the open circuit voltage and this shows that, the direct pulse generator output is superimposed on the OCVD curve. The pulse width and the pulse repetition frequency were always adjusted to allow the OCVD curve to fall to the ground level before the appearance of the next forward biasing pulse, as shown in Fig. 4. The decay is characterized by two distinct regions. The first vertical drop is due to the series resistance of the LED and the next division on the horizontal time axis clearly demonstrates an almost linear portion, which is followed by a decay towards the zero voltage. This portion is complicated due to the combined effect of the junction voltage decay and the junction capacitance discharge.

The carrier lifetime can be expressed by the relation (Dalapati et al. 2013; Bhattacharya et al. 1985)

The value of \(\frac{dV_{OC} }{dt}\) was calculated from the linear portion of the OCVD curves at different temperatures and listed in Table 2. The values of n are taken from Table 1 and the corresponding values of lifetime have been calculated using Eq. (3). The change of the carrier lifetime with temperature is shown in Fig. 5 and presented in Table 1.

Figure 5 shows that the carrier lifetime decreases from 141.33 to 105.2 nS, when temperature changes from 350 to 228 K and from 103.67 to 99.51 nS, when temperature changes from 205 to 77 K. From Figs. 3 and 5 it is clear that both carrier lifetime (\(\uptau \)) and relative intensity (L) vary with temperature. We have experimentally obtained the values of L and \(\uptau \) which are plotted in the curve L versus \(\frac{1}{\uptau }\) and are shown in Fig. 6. A relation between L and \(\uptau \) has been obtained which is given by (Dalapati et al. 2013; Vanderdoesdebye and Blok 1976)

where, \(\upeta \) is the efficiency of the device and \(\hbox {n}_\mathrm{c}\) is the carrier density. The relation shows that the intensity is dependent on three factors. If we assume that the changes of the efficiency \(\upeta \) and the carrier density \(\hbox {n}_\mathrm{c}\) with temperature are negligible compared to that of carrier lifetime then the above relation, Eq. (4) shows that intensity is inversely proportional to carrier lifetime. However, L is a function of both current and temperature. So, with the current held fixed, L and \(\uptau \) are inversely related. For three different values of current, 15, 20 and 30 mA, the relative intensity and its variation with temperature have been measured. In all cases, the obtained data may be approximately fitted to straight lines with the slope values 0.028, 0.034 and 0.031 respectively which are shown in Fig. 6. So, this agreement verifies the relation, Eq. (4) for different current values.

3.3 Reverse recovery characteristics

The reverse–recovery test of the LED was performed using the setup shown in Fig. 7 and this setup is used for study the transient behavior of the diode when it is switched from forward bias (position \(A\)) to reverse bias (position \(B\)). The resistor in the circuit limits the initial reverse current.

In switching condition, a voltage equation for the circuit may be written as

where, \(V_{d}\) is the voltage drop across the LED, \(V_{R} = I_{r}R_{rh}\) is the voltage drop across resistance and \(V_{r}\) is the reverse source voltage.

Also the reverse current \(\hbox {I}_{\mathrm{r}}\), can be expressed as

Due to the junction capacitance of the diode, the diode does not allow sudden changes in the voltage, and the gradient of the carrier densities remain constant because the reverse current is limited and kept constant right after switching. In the time interval \(0+ \le \hbox { t} \le \hbox { t}_{\mathrm{s}}\) (\(\hbox {t}_{\mathrm{s}}\) is storage time) the reverse current \(\hbox {I}_{\mathrm{r}}\) is almost constant. However, after the time \(\hbox {t}_{\mathrm{s}}\), the voltage across the junction will start to decrease faster and \(\hbox {I}_{\mathrm{r}}\) decreases to its steady state value once the excess carriers are removed from the diode. The current transient response for the reverse recovery period at different temperatures is shown in Fig. 8.

Table 1 shows the reverse recovery time \(\hbox {t}_{\mathrm{rr}}\) at different temperatures extracted from Fig. 8. It can be seen that \(\hbox {t}_{\mathrm{rr}}\) decreases significantly by a factor of nearly 1.6 from 9.1 to 5.5 nS, when the temperature decreases from 350 to 77 K which is also shown in Fig. 9. Chen et al. (2012) reported that for 4H–SiC junction barrier Schottky (JBS) diodes the reverse recovery time vary from 44 to 52 nS when the temperature is increased from 298 to 573 K. The reverse recovery time is found to change linearly with temperature, as is evident from the straight line fit of the observed data in Fig. 9, and becoming more efficient at lower temperature. For an order of magnitude comparison \(\hbox {t}_{\mathrm{rr}}\) is smaller by a factor \(\sim \)10 from that of the carrier lifetime \(\uptau \) for the present device.

However, the minimum switching time of the diode depends not only on the minority carrier lifetime, but also its initial reverse current (Keserlioglu and Erkaya 2011). Hence, the designers of such devices should provide a path for the initial reverse current pulse of the diode to have the diode switch faster.

4 Conclusion

All experimental data show that temperature has significant influence on the properties of AlGaInP-based LED. The ideality factor n is found to increase with lowering of temperature. It is well known that if the value of n lies between 1 and 2, the total diode current is dominated by the diffusion component and beyond 2, the tunneling component becomes important. It is seen from Table 1 for the present device the diffusion process is the major one upto 200 K and below it the tunneling component gradually increases with the value of n becoming larger and nearly by a factor of five, as temperature approaches 77 K, from that of its value at room temperature. This change is quite remarkable compared to those of many other LED. In case of relative light intensity it is observed that it increases with lowering of temperature (see Fig. 3) i.e. it seems to benefit the LED applications. But the rising of forward voltage with temperature makes design of the driving circuit difficult. It is because a maximum voltage is set inside the protection circuit to prevent the LED from breakdown, and the rising voltage might cross this maximum value of voltage. Moreover, heating as well as dissipation of energy becomes a problem. In such a case the LED cannot work well even worse cannot be lighted up. However, in the present case, although the LED at low temperature has a higher forward voltage, for example, 1.74 V at 350 K and 2.12 V at 77 K, the rising forward voltage do not seriously affect the LL2508JQHR4-A02 characteristics because the LED at low temperature has a higher efficiency. This clearly points to the need and importance of optimization between competing factors. The OCVD measurement curves show that the voltage drop due to series resistance decreases with decreasing temperature and due to this reason the slope as well as the carrier lifetime (\(\uptau \)) increases with temperature. The values of \(\uptau \) vary from 141.33 to 99.51 nS when the temperature decreases from 350 to 77 K. The results show a good agreement with the relation given by Eq. (4) and hence it may be concluded that L is inversely proportional to \(\uptau \), when the changes of \(\upeta \) and \(\hbox {n}_\mathrm{c}\) with temperature are negligible. The switch tests demonstrate that the AlGaInP-based LED has a fast switch speed and it is further increasing with lowering of temperature and is indicated by the reverse recovery time (\(\hbox {t}_{\mathrm{rr}}\)) shown in the last column of Table 1. All these data will be especially helpful for application in opto-sensors, particularly, in below room temperature ambiences like the polar region, middle and upper atmospheres, and similar other environments.

We further observe that the sudden change in the values of ideality factor, relative light intensity and carrier lifetime with temperature seems to indicate a common cause which plays a significant role below 200 K. A critical analysis of the data presented will provide further important insight into the physical processes at work in the device. In our future investigation we intend to probe the implications of our present study for AlGaInP as well as other LED diodes.

References

Acharya, Y.B., Vyavahare, P.D.: Temperature characteristics of the device constant (n) of a light emitting diode. Solid State Electron. 43, 645–647 (1999)

Bergman, J.P., Hallin, C., Janzhn, E.: Temperature dependence of the minority carrier, lifetime in GaAs/AIGaAs double heterostructures. J. Appl. Phys. 78, 4808–4810 (1995)

Bhattacharya, D.K., Abhai, M., Swarup, P.: Determination of recombination center position from the temperature dependence of minority carrier lifetime in the base region of pn junction solar cells. J. Appl. Phys. 57, 2942–2947 (1985)

Bolotnikov, A.V., Muzykov, P.G., Grekov, A.E., Sudarshan, T.S.: Improvement of 4H-SiC power p-i-n diode switching performance through local lifetime control using boron diffusion. IEEE Trans. Electron Devices 54, 1540–1544 (2007)

Chand, S., Kumar, J.: On the existence of a distribution of barrier heights in Pd2Si/Si Schottky diodes. J. Appl. Phys. 80, 288–294 (1996)

Chen, F.P., Zhang, Y.M., Zhang, Y.M., Tang, X.Y., Wang, Y.H., Chen, W.H.: Temperature-dependent characteristics of 4H SiC junction barrier Schottky diodes. Chin. Phys. B 21, 037304–037308 (2012)

Dalapati, P., Manik, N.B., Basu, A.N.: Effect of temperature on the intensity and carrier lifetime of an AlGaAs based red light emitting diode. J. Semicond. 34, 092001–092005 (2013)

Han, K., Liu, M., Fan, S., Shen, H.: Improved electrical measurement method for junction temperature of light emitting diodes. http://pe.org.pl/articles/2012/3b/39.pdf (2012)

Hull, B.A., Sumakeris, J.J., O’Loughlin, M.J., Zhang, Q., Richmond, J., Powell, A.R., Imhoff, E.A., Hobart, K.D., Rivera-Lopez, A., Hefner, A.R.: Performance and stability of large-area 4H-SiC10-kV junction barrier Schottky rectifiers. IEEE Trans. Electron Devices 55, 1864–1870 (2008)

Keserlioglu, M.S., Erkaya, H.H.: Simulation of storage time versus reverse bias current for p\(^{+}\)n and pin diodes. Turk. J. Electr. Eng. Comput. Sci. 19, 87–96 (2011)

Kim, M.S., Lee, H.K., Yu, J.S.: Device characteristics and thermal analysis of AlGaInP-based red monolithic light- emitting diode arrays. Semicond. Sci. Technol. 28, 025005–025012 (2013)

Lee, H.K., Lee, D.H., Song, Y.M., Lee, Y.T., Yu, J.S.: Thermal measurements and analysis of AlGaInP/GaInP MQW red LEDs with different chip sizes and substrate thicknesses. Solid State Electron. 56, 79–84 (2011)

Lu, W., Zhang, T., He, S.M., Zhang, B., Li, N., Liu, S.S.: Light-emitting diodes for space applications. Opt. Quant. Electron. 41, 883–893 (2009)

Manik, N.B., Basu, A.N., Mukherjee, S.C.: Characterisation of the photodetector and light emitting diode at above liquid nitrogen temperature. Cryogenics 40, 341–344 (2000)

Tapajna, M., Pjencak, J., Vrbicky, A., Harmatha, L., Kudela, P.: Application of open circuit voltage decay to the characterization of epitaxial layer. J. Electr. Eng. 55, 239–244 (2004)

Vanderdoesdebye, J.A.W., Blok, L.: Room temperature minority carrier lifetime and efficiency of p-type \(\text{ GaAs }_{1-x}\text{ P }_{x}\). J. Lumin. 14, 101–113 (1976)

Weling, G., Xuejiao, J., Fei, Y., Bifeng, C., Wei, G., Ying, L., Weiwei, Y.: Characteristics of high power LEDs at high and low temperature. J. Semicond. 32, 044007–044009 (2011)

Yan, D., Lu, H., Chen, D., Zhang, R., Zheng, Y.: Forward tunneling current in GaN-based blue light-emitting diodes. Appl. Phys. Lett. 96, 083504–083506 (2010)

Yen, C.H., Liu, Y.J., Yu, K.H., Lin, P.L., Chen, T.P., Chen, L.Y., Tsai, T.H., Huang., N.Y., Lee., C.Y., Liu, C.: On an AlGaInP-based light emitting diode with an Indium–Tin–Oxide (ITO) direct ohmic contact structure. Res. Express@NCKU 23, 1–4 (2013)

Acknowledgments

The authors acknowledge the Defence Research Development Organization (DRDO), India, for financial assistance, and one of the authors, P. Dalapati is thankful to DRDO for the award of a research fellowship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dalapati, P., Manik, N.B. & Basu, A.N. Influence of temperature on the performance of high power AlGaInP based red light emitting diode. Opt Quant Electron 47, 1227–1238 (2015). https://doi.org/10.1007/s11082-014-9980-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11082-014-9980-5