Abstract

The present study investigates the angular responses, sensitivity, detection accuracy and quality parameter of surface plasmon resonance biosensor configuration which is coated with graphene layer for the detection of Pseudomonas and Pseudomonas-like bacteria. The proposed biosensor uses attenuated total reflection method to detect the change in refractive index near the sensor surface. By comparing these results with the conventional gold layer surface plasmon resonance biosensor, it is observed that the overall performance of the proposed biosensor is improved by introducing the graphene layer. Also, the dependence of sensitivity on the number of graphene layers for the proposed sensor is plotted and analyzed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Surface plasmons (Sps) are the collective oscillation of electrons at the surface of metals such as gold (Au), silver (Ag) and aluminum (Al) etc. When the incident light illuminates the metal-dielectric interface, an electron density oscillation occurs and as a result, Sps are excited and the evanescent wave is generated, which is exponentially decayed along the normal direction (Roh et al. 2011). This phenomenon is known as surface plasmon resonance (SPR) and the resonance condition is established when the wave vectors of incident light and the Sps coincide. These wave vectors depend on refractive indices of the dielectric, metal and the sensing medium. In sensing medium, a change in concentration of bio-molecules will produce a local change in the refractive index (RI) near the metal surface. The change in RI can be optically measured by attenuated total reflection (ATR) method (Reather 1988). The resonance condition depends on the incident angle, wavelength of the light and the dielectric constants of both metal and dielectric (Homola et al. 1999; Homola 2003). Kretschmann’s configuration is the most widely used approach for SPR sensing (Kretschmann and Raether 1968; Otto 1968; Kretschmann 1971). In the Kretschmann’s configuration; a high refractive index prism is coated with a metal layer touching the sensing medium. SPR sensing has many advantages such as high sensitivity i. e. the sensitivity can be employed to measure the change in refractive index within a small nano-scale layer of the analyte using label free technique (Homola 2003; Shuwan et al. 2011; Gupta and Verma 2009).

In most SPR sensor applications the plasmon supporting material is gold (Hutter and Fendler 2004) or silver (Akimov et al. 2010), as they readily support plasmon modes at visible light frequencies. But, gold is usually preferred because it is resistant to oxidation and corrosion in different environments. But, the main drawback is biomolecules adsorb poorly on gold, which limits the sensitivity of the conventional SPR biosensor. However, there are several methods to improve the adsorption such as using nanoparticles,nanoholes, metallic nanoslits, and biomolecular recognition elements (BRE) (Zhao et al. 2006).

Recently, some new materials such as metamaterials and negative index materials have emerged as promising options to enhance the performance of these sensors (Taya and Shabat 2011; Prajapati et al. 2013; Kullab et al. 2012). It is very difficult to fabricate negative index materials and optical metamaterials with small feature size (less than 300 nm). Due to the limitations of current nanolithography tools, fabricated metamaterials do not really enter the meta-regime where the unit-cell size is orders of magnitude smaller than the wavelength (Noginov and Podolskiy 2012).

Very recently, in order to improve the performance of biosensor, researchers have proposed and fabricated SPR based fiber optic sensor coated with graphene layers (Kim et al. 2012, 2013; Verma et al. 2011). Fabrication of graphene material is much simpler than metamaterials and negative index materials. Graphene is a single-atom thin planar sheet of sp\(_{2}\) carbon atoms perfectly arranged in a honeycomb lattice. Graphene and graphene oxide provide good support for biomolecule adsorption due to their large surface area and rich \(\pi \) conjugation structure, making them suitable dielectric top layers for SPR sensing (Szunerits et al. 2013).

Recently Wu et al. (2010) reported that, one atom thick graphene layer absorbed 2.3 % of the incident light at wavelength of 6.33 nm and each additional layer of graphene absorbs the same amount. This is due to its electronic properties, the electrons acting like massless charge carriers with very high mobility. It is seen that every additional layer of graphene results in a shift to higher resonance angle.

Despite these advances much more work needs to be done before SPR biosensors become commercially viable option for sensing. Moreover the attachment of marine Pseudomonas spices to variety of surfaces was investigated and it was found that these bacteria are attached not only on special carbon sources (nicotine, toluene etc.) but also on some hydrophobic plastics (Teflon, polyethylene) with little or no surface charge (Fletchert and Loeb 1979; Lavers et al. 2000).

In this study, SPR biosensor has been proposed in which graphene is coated on the gold surface of conventional SPR biosensor for the detection of Pseudomonas and Pseudomonas-like bacteria. The attachment of bacteria to affinity surfaces is an important phenomenon in this SPR sensor. Also, the results of SPR biosensor have been compared with those obtained for conventional SPR biosensor. This paper is analytical in its approach and is only a preliminary study and as such does not deal with the vastly interesting question of the effect of metal surface roughness on sensitivity of the proposed SPR sensor. Considering that, some noteworthy results have been obtained. The authors hope to follow up the study by considering the aspects of metal surface roughness on sensitivity of other SPR sensor in future communications. The paper is organized as follows: Sect. 2 contains the necessary formula along with theoretical background of the proposed sensor. In Sect. 3, the obtained results are discussed and compared. Finally conclusion is drawn in Sect. 4.

2 Theoretical background

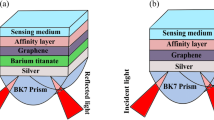

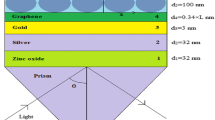

Figure 1a shows the schematic diagram of a proposed SPR biosensor configuration. The \(k\)th layer (\(k\) is from 2 to \(N-1\)) has thickness \(d_{k}\) and refractive index \(n(\lambda )\). The wavelength (\(\lambda \)) of excitation light source is taken as 633 nm. Here, first layer is prism with refractive index \(n_{s}=n_{prism}= 1.723\). The metal layer with refractive index \(n_{m} = 0.19683+ i 3.0905\) and thickness of \(d_{m} = 50\) nm is attached on the top of glass prism (Palik 1985). It is assumed that the graphene is a dielectric material with isotropic refractive index and light polarization does not affect graphene refractive index because of the universal opacity of graphene at optical frequencies. The refractive index of graphene \((n_{g})\) calculated at 633 nm wavelength is given by \(n_{g}= 3+ i 1.149106\) and thickness of layer is given by \(d_{g}= \hbox {L}\times 0.34\) nm, where L is the number of graphene layers (Bruna and Borini 2009). For the detection of Pseudomonas, consider three different affinity layers each layer having refractive index \((n_{a})\) and thickness \(d_{a}\), when submerged in water produces a local increase in the refractive index of \(\Delta n\) at the graphene surface. In order to compare the results of proposed configuration, with that of conventional sensor, conventional SPR biosensor configuration is also investigated as shown in Fig. 1b. All parameters are same in both the configurations except for the graphene layer present in proposed SPR biosensor. It is clearly shown in Fig. 1a.

A light of wavelength (\(\lambda \)) passes through the prism and is totally reflected at the prism-metal interface, generating an evanescent wave. This evanescent wave penetrates through the gold layer and propagates along the \(x\) direction with propagation constant \(k_x =n_{prism} (\frac{2\pi }{\lambda })\sin \theta \). The propagation constant \(k_{x}\) can be adjusted in to order match to that of the Sps by controlling the angle of incidence \(\theta \). The interaction between the light wave and surface Plasmon in the ATR method can be calculated using the Fresnel multilayer reflection theory for \(p\)-wave (transverse magnetic wave) (Yamamoto 2002). The plot of total reflected intensity \((R)\) versus angle of incidence \((\theta )\) is known as SPR curve.

To produce an SPR curve, consider a generalized \(N\)-layer model as shown in Fig. 1. The tangential fields at the first boundary are related to those at the final boundary by

For \(p\)-wave at boundary \(k\),

and

where

From Eq. 3, after some straightforward steps, the reflection coefficient for \(p\)-wave incident light is given by

Finally, the reflectivity \(R\) of a given multilayer structure is given by \(R=\left| {r_p}\right| ^{2}\). The performance of SPR sensors may be characterized on the basis of its sensitivity, detection accuracy and quality parameter. Sensitivity of the proposed SPR biosensor is measured as the ratio of small change in the refractive index of cover region \(\delta n_{c}\) to the change in resonance condition \(\delta \theta _{res}\) in the reflectance curve; therefore the sensitivity is given as \(S=\frac{\delta \theta _{res} }{\delta n_c}\). The signal to noise ratio (SNR) also known as detection accuracy, can be determined by the reflectivity curve and is given by \(SNR=\frac{\delta \theta _{res} }{\delta \theta _{0.5} }\) where, \(\delta \theta _{0.5}\) is the spectral width of the SPR curve corresponding to 50 % reflectivity. The quality parameter \((Q)\) of the sensor depends upon the sensitivity and the spectral width of the SPR curve is given by \(Q=\frac{S}{\delta \theta _{0.5} }\).

3 Results and discussion

The reflectivity is calculated and plotted with the help of MATLAB for both the configurations. The excitation of surface electromagnetic wave is recognized as the angle at which minimum reflected intensity is occurred and this minimum angle is taken as the resonance angle. Figure 2 represents the reflectance curve of proposed SPR biosensor and the conventional SPR biosensor using \(p\)-wave polarization. From Fig. 2, It is seen that resonance angle obtained for the proposed biosensor is \(67.017152^{{\circ }}\), which is higher than the angle of total internal reflection that occurs between prism and water \((54.3447^{{\circ }})\). Reflectance curve is also obtained for conventional SPR sensor and the observed resonance angle is \(66.51352^{{\circ }}\). Thus the deepest dip of proposed sensor at resonance angle corresponds to the surface electromagnetic wave propagating at the graphene/ affinity layer interface. It is clear from Fig. 2 that SPR biosensor with graphene layer has low loss and maximum surface mode excitation compared to conventional SPR biosensor.

In Fig. 3, the three different affinity layers for the detection of Pseudomonas having refractive indices 1.4370 [poly (trifluoroethyl methacrylate)], 1.49268 (toluene) and 1.5265 (nicotine) are selected. It is seen that from the Fig. 3, as the cover refractive index changes from nc \(=\) 1.33 to nc \(=\) 1.40 the dip of reflectance shifts towards higher value of incident angle. This will be the sign of bacteria and shift in the angle is totally dependent on the concentration and mobility of bacteria. The attachment of bacteria to affinity surfaces is an important phenomenon in this biosensor. When the bacteria is attached to the affinity surface the refractive index of cover medium changes, and this change in refractive index is dependent on the culture concentration of the bacteria and its mobility. Finally, it is concluded that if the refractive index of the affinity surface \((na= 1.5265)\) is large then the dip is sharp and more reliable information is obtained regarding the detection of Pseudomonas and other bacteria.

From Fig. 4, it is seen that, for conventional SPR sensor, the maximum reflectance change is 0.05498, while the net contrast of the proposed SPR biosensor is obtained as 0.09544. In other words, proposed SPR biosensor has sensitivity 1.73 times greater than that of conventional SPR sensor.

Figure 5 shows the SPR reflectance curve for conventional SPR biosensor, it is seen that as the refractive index of the cover medium changes from 1.33 to 1.40, the corresponding resonance curve shifts from \(65.98^{{\circ }}\) to \(68.14^{{\circ }}\). Figure 3a shown the SPR reflectance curve for proposed graphene layer based SPR biosensor at same parameter which used in conventional SPR biosensor; it is observed that as the refractive index of the cover medium changes from 1.33 to 1.40. The corresponding resonance curve shifts from \(66.50^{{\circ }}\) to \(68.87^{{\circ }}\). Thus, the resonance dip is shifted towards higher angle of incidence with graphene layer, which guarantees a wider dynamic range of effective range of measureable refractive index.

Here it is observed that the sensitivity, detection accuracy and quality parameter of proposed SPR biosensor with graphene layer are much higher than the conventional SPR biosensor without graphene layer. The comparisons of these two SPR sensors are shown in Table 1. Thus, it is observed that graphene based SPR biosensor is better than the conventional SPR biosensor in terms of sensitivity, detection accuracy and quality parameter as shown in Table 1.

In Fig. 6, the resonance angle increases with the increase in graphene layers. Also, the reflectance curve becomes broader and shallower with increase in graphene layers. These changes in SPR resonance angle, the curve width, and the intensity of reflectance resemble the dramatic variation of Sps, due to absorptive plasmon damping and it has already been shown by Wu et al. (2010) and Pockrand (1978). Similar absorptive plasmon damping associated with graphene layers is responsible for the obtained SPR changes. Higher resonance angle and correspondingly broader and shallower SPR curves are unavoidable because degradation of the sensitivity may be caused with increase in graphene layers. Thus, it should be emphasized that single layer or bilayer of graphene is preferable in proposed SPR sensor.

4 Conclusion

The angle interrogation methods for resonance condition are used to study the proposed SPR sensor. The reflected light is measured as the function of angle of incidence with fixed value of wavelength and thickness of constituent material layers. A sharp dip of reflected light is observed at resonance angle due to sufficient excitation of SPs. The sensitivity, signal to noise ratio and quality parameter of proposed SPR sensor are studied and compared with that of conventional SPR sensor. It is observed that the graphene based SPR sensor improved the performance parameters compared to conventional SPR sensor due to good adsorption of bacteria on graphene near the sensor surface.

References

Akimov, Y.A., Koh, W.S., Sian, S.Y., Ren, S.: Nanoparticle-enhanced thin film solar cells: metallic or dielectric nanoparticles? Appl. Phys. Lett. 96(7), 073111 (2010)

Bruna, M., Borini, S.: Optical constants of graphene layers in the visible range. Appl. Phys. Lett. 94(3), 031901 (2009)

Fletchert, M., Loeb, G.I.: Influence of substratum characteristics on the attachment of a marine pseudomonad to solid surfaces. Appl. Environ. Microbiol. 37(1), 67–72 (1979)

Gupta, B.D., Verma, R.K.: Surface plasmon resonance-based fiber optic sensors: principle, probe designs, and some applications. J. Sens. 2009, 1–12 (2009)

Homola, J., Yee, S.S., Gauglitzand, G.: Surface Plasmon resonance sensors: review. Anal. Sens. Actuators B 54, 3–15 (1999)

Homola, J.: Present and future of surface Plasmon resonance biosensors. Anal. Bioanal. Chem. 377, 528–539 (2003)

Hutter, E., Fendler, J.H.: Exploitation of localized surface plasmon resonance. Adv. Mater. 16(19), 1685–1706 (2004)

Kim, J., Kasture, M., Hwang, T., Kulkarni, A., Amin, R., Park, S., Kim, T., Gosavi, S.: Graphene-based waveguides: novel method for detecting biological activity. Appl. Biochem. Biotechnol. 167, 1069–1075 (2012)

Kim, J.A., Hwang, T., Dugasani, S.R., Amin, R., Kulkarni, R., Park, S.H., Kim, T.: Graphene based fiber optic surface plasmon resonance for bio-chemical sensor applications. Sens. Actuators B 187, 426–433 (2013)

Kretschmann, E., Raether, H.: Radiative decay of non-radiative surface plasmons excited by light. Z. Naturforsch. 23A, 2135–2136 (1968)

Kretschmann, E.: The determination of the optical constants of metals by excitation of surface plasmons. Z. Phys. 241, 313–324 (1971)

Kullab, H.M., Taya, S.A., El-Agez, T.M.: Metal-clad waveguide sensor using a left-handed material as a core layer. J. Opt. Soc. Am. B 29(5), 959–964 (2012)

Lavers, C.R., Itoh, K., Wu, S.C., Murabayashi, M., Mauchline, I., Stewart, G., Stout, T.: Planar optical waveguides for sensing applications. Sens. Actuators B 69, 85–95 (2000)

Noginov, M.A., Podolskiy, V.A. (eds.): Tutorials in Metamaterials. CRC Press, Boca Raton, FL (2012)

Otto: Excitation of surface plasma waves in silver by the method of frustrated total reflection. Z. Physik 216, 398–410 (1968)

Palik, E.D. (eds.): Handbook of Optical Constants of Solids , vol. 1. Academic press, (1985)

Pockrand, I.: Surface plasma oscillations at silver surfaces with thin transparent and absorbing coatings. Surf. Sci. 72(3), 577–588 (1978)

Prajapati, Y.K., Yadav, A., Singh, V., Saini, J.P.: Effect of metamaterial layer on optical surface plasmon resonance Sensor. Int. J. Light Electron Opt. 124(18), 607–3610 (2013)

Reather, H.: Surface Plasmons on Smooth and Rough Surfaces and on gratings, vol. 111. Springer, Berlin (1988)

Roh, S., Chung, T., Lee, B.: Overview of the characteristics of micro- and nano-structured surface plasmon resonance sensor. Sensors 11, 1565–1588 (2011)

Shuwan, Z., Ken-Tye, Y., Indrajit, R., Xuan-Quyen, D., Xia, Y., Feng, L.: Areviewonfunctionalized gold nanoparticles for biosensing applications. Plasmonics 6, 491–506 (2011)

Szunerits, S, Maalouli, N., Wijaya, E, Vilcot, J.-P., Boukherroub, R.: Recent advances in the development of graphene-based surface plasmon resonance (SPR) interfaces. Anal. Bioanal. Chem. 405, 1435–1443 (2013)

Taya, S.A., Shabat, M.M.: Sensitivity enhancement in optical waveguide sensors using metamaterials. Appl. Phys. A 103, 611–614 (2011)

Verma, R., Gupta, B.D., Jha, R.: Sensitivity enhancement of a surface plasmon resonance based biomolecules sensor using graphene and silicon layers. Sens. Actuators B 160, 623–631 (2011)

Wu, L., Chu, H.S., Koh, W.S., Li, E.P.: Highly sensitive graphene biosensors based on surface plasmon resonance. Opt. Express 18(14), 14395–14400 (2010)

Yamamoto, M.: Surface plasmon resonance (SPR) theory: tutorial. Rev. Polarogr. 48, 209 (2002)

Zhao, J., Zhang, X., Yonzon, C.R., Haes, A.J., Van Duyne, R.P.: Localized surface plasmon resonance biosensors. Nanomedicine 1, 219–228 (2006). doi:10.2217/17435889.1.2.219

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Verma, A., Prakash, A. & Tripathi, R. Performance analysis of graphene based surface plasmon resonance biosensors for detection of pseudomonas-like bacteria. Opt Quant Electron 47, 1197–1205 (2015). https://doi.org/10.1007/s11082-014-9976-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11082-014-9976-1