Abstract

We present a surface plasmonic resonance sensor composed of Ag strip pairs array embedded in the background material. The calculated results demonstrate that one of the transmission dips of the structure is very sensitive to the background materials. Meanwhile, the structure could achieve the sensitivity (nm/RIU) about 700 nm/RIU, when the slits width of Ag strip pairs is 10 nm.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In the past few years, surface plasmon has been widely studied, and there has been great interest in using plasmonic-based structure to create many notable applications, such as nanoscale sub wavelength waveguides (Bozhevolnyi et al. 2006; Berini 2000; Veronis and Fan 2007; Gosciniak et al. 2011), electromagnetically induced transparency (EIT) (Zhang et al. 2008; Papasimakis et al. 2008; Bai et al. 2010), plasmonic sensor (Li et al. 2012; Liu et al. 2010a, b). When interacting with electromagnetic radiation, the collective electronic oscillation in metal nanoparticles can give rise to localized surface plasmon resonance (LSPR) (Raether 1988). The LSPR strongly depends on the shape, material, size, and surrounding dielectric environment of the nanostructures (Li et al. 2012; Liu et al. 2010a, b). The latter dependence makes them especially attractive for refractive index sensing. Up to now, many different plasmonic nanostructures have been designed to optimize LSPR sensors with a large spectral shift for a given change in refractive index, including nanospheres, nanostarts, nanoshells, and etc. (Lal et al. 2007; Soennichsen and Alivisatos 2005; Park et al. 2008; Lassiter et al. 2008; Dmitriev et al. 2008; Larsson et al. 2007).

In this paper, we explore a plasmonic structure to achieve LSPR, where the structure comprises an array of Ag strip pairs placed within a background dielectric. The metal (Ag) strip pairs array form resonance cavities, which hold localized plasmonic mode, can localize the field energy better than periodic array of metal (Ag) block structure; the former holds much better performance. Next the research of the effect of background material change on transmission spectra shows that one of the transmission dips of the structure is very sensitive to the background materials. Finally, we discuss the sensitivity of the structure at different slits width of Ag strip pairs, we can obtain the sensitivity (nm/RIU) of the structure about 700 nm/RIU, when the slits width of Ag strip pair is 10 nm. Meanwhile we can conclude that the metal (Ag) strip pairs array structure may have potential applications of plasmonic sensing (Liu et al. 2010b).

2 Design and result

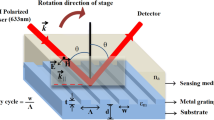

Figure 1a depicts the proposed plasmonic structure consisting of metal (Ag) strip pairs array placed within a background dielectric. Figure 1b illustrates the top view of the Ag strip pair arrays, \(\text{ L }_\mathrm{x}\) and \(\text{ W }_\mathrm{y}\) are the length and width of the metal (Ag) strip pairs, respectively. \(\text{ P }_\mathrm{x}\) and \(\text{ P }_\mathrm{y}\) are the period of the metal strip pairs array along x direction and y direction, respectively. Figure 1c is the sectional view of the plasmonic structure of x-z plane; the geometrical parameters are defined as in the figure: the slits width and the thickness of the Ag strip pairs are W and T, respectively.

We calculate the transmission spectra of Ag strip pairs array structure placed within a background dielectric of \(\text{ SiO }_{2}\) (refractive index \(\text{ n }=1.5\)), using the finite-difference time-domain (FDTD) method (Sullivan 2000) shown in Fig. 2a. As shown in Fig. 2A we also plot electric field intensity distributions of the transmission spectra dip at the wavelength locations A as marked in Fig. 2a. The computational domain comprises a single period of the structures with inhomogeneous mesh. The periodic boundary condition and perfect matched layer (PML) absorption boundary condition are used along the periodic direction and at the top and bottom boundaries, respectively. The complex optical constants of metal Ag are taken from experimental data (Johnson and Christy 1972). Light propagates along z direction with the polarization along the x direction for TM mode.

(Color online). a, b Transmission spectra of the Ag strip pair array structure and the metal (Ag) block array structure, respectively. A, B The electric field intensity distributions at the wavelength locations A and at the wavelength locations B marked in a and b, respectively. The parameters for the structure in Fig. 1 and inset in Fig. 2 b are as follows: \(\text{ Lx }= \text{ Wy }=120\,\text{ nm }, \text{ P }_\mathrm{x}=\text{ P }_\mathrm{y} =350\,\text{ nm },\,\text{ W }= 30\,\text{ nm },\,\text{ T }=120\,\text{ nm }\)

For reference, we also calculate the transmission spectra and the electric intensity distributions of a periodic array of the metal (Ag) block (shown in Fig. 2b, B) placed within a background dielectric of \(\text{ SiO }_{2}\) (refractive index \(\text{ n }=1.5\)). The inset in Fig. 2b is the geometry structure of the periodic array of the metal (Ag) block. And the geometric parameters for metal (Ag) block array are the same with Ag strip pair array structure. For the periodic array of the metal (Ag) block, there is no cavity. We can see from Fig. 2B that the field energy only distributes at the corner of the bottom surfaces of the Ag block. Whereas for the Ag strip pair array structure, one Ag strip pair makes up a metal-dielectric-metal waveguide terminated by dielectric mirrors on both sides. Thus, one cavity can be configured in the metal-dielectric-metal slit. In the cavity the excited surface plasmon polarization transmits back and forth to shape the localized plasmonic mode. And the energy for these excited modes is distributed mainly in the slit as shown in Fig. 2A. And we also can see from Fig. 2A that the energy distributes on the top and bottom surfaces of the Ag strips, which demonstrates that the Ag strip pair array structure can localize the field energy better than periodic array of the metal (Ag) block structure. As we can see from Fig. 2a, b that the transmission dip of Ag strip pair array structure is much sharper and narrower than that of periodic array of the metal (Ag) block structure, thus the Ag strip pair array structure holds much better performance. Since the metal (Ag) strip pair array structure can only be driven surface plasmon resonances by the normally incident plane electromagnetic (EM) wave with polarization along the x direction(TM polarization), in the following we only discuss the results of plasmonic structure consisting of Ag strip pair array for the case of the normally incident plane EM wave with polarization along the x direction throughout the article.

Figure 3 shows the transmission spectra of our structure at different refractive index. The parameters of the structure in simulation are same with Fig. 2. We can detect the change of the background material by measuring the shift of the transmission dip. When the refractive index of the background materials increases from \(\text{ n }=1.0\) to \(\text{ n }=2.0\), there is a distinct variation of the transmission dip to longer wavelength. The sensitivity (nm/RIU) of the Ag strip pair array structure, which is the variation in resonance wavelength per unit change of refractive index, is about 550 nm/RIU. For further explaining the quantification, we use the “figure of merit” (FOM) to evaluate the sensor (Sherry et al. 2006). In our structure, the resonance linewidth at half-maximum of the transmission dip is about 11 nm when the refractive index of the background materials is 2.0 and a FOM about 50 is obtained.

We also calculate the sensitivity of the structure [the background material is \(\text{ SiO }_{2}\) (refractive index \(\text{ n }=1.5\))] at different slits width of Ag strip pairs as shown in Fig. 4. As the slits width increases from 10 to 50 nm, the sensitivity decreases slowly. We can achieve the sensitivity (nm/RIU) of the structure about 700 nm/RIU, when the slits width of Ag strip pair is 10 nm.

3 Conclusion

In conclusion, we have presented an Ag strip pair array structure placed within a background dielectric to achieve localized surface plasmon resonance for sensing. The simulated results demonstrate that the designed structure can be used to achieve high performance sensors. This will be a promising way for surface plasmon resonance applications toward sensing in a nanoenvironment.

References

Bai, Q., Liu, C., Chen, J., Cheng, C., Kang, M., Wang, H.T.: Tunable slow light in semiconductor metamaterial in a broad terahertz regime. J. Appl. Phys. 107, 093104 (2010)

Berini, P.: Plasmon polariton waves guided by thin lossy metal films of finite width: bound modes of symmetric structures. Phys. Rev. B 61, 10484 (2000)

Bozhevolnyi, S.I., Volkov, V.S., Devaux, E., Laluet, J.Y., Ebbesen, T.W.: Channel plasmon subwavelength waveguide components including interferometers and ring resonators. Nature 440, 508 (2006)

Dmitriev, A., Haegglund, C., Chen, S., Fredriksson, H., Pakizeh, T., Kaell, M., Sutherland, D.S.: Enhanced nanoplasmonic optical sensors with reduced substrate effect. Nano Lett. 8, 3893 (2008)

Gosciniak, J., Holmgaard, T., Bozhevolnyi, S.I.: Theoretical analysis of long-range dielectric-loaded surface plasmon polariton waveguides. IEEE. J. LT. 29, 1473 (2011)

Johnson, P.B., Christy, R.W.: Optical constants of the noble metals. Phys. Rev. B. 6, 4370 (1972)

Lal, S., Link, S., Halas, N.J.: Nano-optics from sensing to waveguiding. Nat. Photonics 1, 641 (2007)

Larsson, E.M., Alegret, J., Kaell, M., Sutherland, D.S.: Sensing characteristics of NIR localized surface Plasmon resonances in gold nanorings for application as ultrasensitive biosensors. Nano Lett. 7, 1256 (2007)

Lassiter, J.B., Aizpurua, J., Hernandez, L.I., Brandl, D.W., Romero, L., Lal, S., Hafner, J.H., Nordlander, P., Halas, N.J.: Close encounters between two nanoshells. Nano Lett. 8, 1212 (2008)

Li, G., Chen, X.S., Li, O., Shao, C.X., Jiang, Y., Huang, L.J., Ni, B., Hu, W.D., Lu, W.: A novel plasmonic resonance sensor based on an infrared perfect absorber. IOP. J. Phys. D Appl. Phys. 45, 205102 (2012)

Liu, N., Mesch, M., Weiss, T., Hentschel, M., Giessen, H.: Infrared perfect absorber and its application as plasmonic sensor. Nano Lett. 10, 2342 (2010)

Liu, N., Weiss, T., Mesch, M., Langguth, L., Eigenthaler, U., Hirscher, M., Sönnichsen, C., Giessen, H.: Planar metamaterial analogue of electromagnetically induced transparency for plasmonic sensing. Nano Lett. 10, 1103 (2010)

Papasimakis, N., Fedotov, V.A., Zheludev, N.I., Prosvirnin, S.L.: Metamaterial analog of electromagnetically induced transparency. Phys. Rev. Lett. 101, 253903 (2008)

Park, T.H., Mirin, N., Lassiter, J.B., Nehl, C.L., Halas, N., Nordlander, P.: Graphene oxide papers modified by divalent ions—enhancing mechanical properties via chemical cross-linking. ACS Nano 2, 25 (2008)

Raether, H.: Surface Plasmons on Smooth and Rough Surfaces and on Gratings. Springer, Berlin (1988)

Sherry, L.J., Jin, R., Mirkin, C.A., Schatz, G.C., Van Duyne, R.P.: Localized surface plasmon resonance spectroscopy of single silver triangular nanoprisms. Nano Lett. 6, 2060 (2006)

Soennichsen, C., Alivisatos, A.P.: Gold nanorods as novel nonbleaching plasmon-based orientation sensors for polarized single-particle microscopy. Nano Lett. 5, 301 (2005)

Sullivan, D.M.: Electromagnetic Simulation Using the FDTD Method. IEEE Press, New York (2000)

Veronis, G., Fan, S.: Modes of subwavelength plasmonic slot waveguides. IEEE J. LT. 25, 2511 (2007)

Zhang, S., Genov, D.A., Wang, Y., Liu, M., Zhang, X.: Plasmon-induced transparency in metamaterials. Phys. Rev. Lett. 101, 047401 (2008)

Acknowledgments

An earlier version of this paper was presented at the 12th International Conference on Numerical Simulation of Optoelectronic Devices (NUSOD 2012). This work was supported by the Program of Shanghai Normal University (DXL125) and supported by the National Natural Science Foundation of China under Grant 61205052.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, Z., Wang, C., Wang, L. et al. Surface plasmonic resonance sensor by metal strip pair arrays. Opt Quant Electron 45, 707–712 (2013). https://doi.org/10.1007/s11082-013-9682-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11082-013-9682-4