Abstract

Based on the coupled-mode theory, the mode transition and transmittance of LP modes in an LPFG with double-layer coatings are studied theoretically. As a refractive index sensor, this LPFG structure is designed for high sensitivity by selecting a suitable thickness and refractive index of the double-layer coatings. Date simulation indicates that the effective index of the LP cladding mode increases in steps with the first coating thickness, thus LP mode is guided to the overlay and the mode transition takes place, where the LP modes can be easily affected by the ambient. Thereby, the coated LPFG sensor should be designed to operate at the transition region. In addition, the effective refractive index of LP cladding modes also increases in steps with the refractive index of the second overlay. For the higher order LP modes, the transition regions are broaden and the dynamic responses are greater than the lower LP modes, which means the higher order LP modes can be used for lower index overlay sensing. Further, the transmittance spectrum, sensitivity and measurable dynamic range of this LPFG are analyzed. The sensitivity of the LPFG sensor is available to \(10^{3}\) with suitable overlay thickness and measurable dynamic range of the sensitive film refractive index is available to \(10^{-2}\). So the presented LPFG sensor enhances the design flexibility and enlarges the scope of application, which will likely be developed for high sensitivity LPFG sensors.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The coupling of the long-period fiber gratings (LPFGs) happens between the forward-propagating core mode and the cladding modes. The effective index of the cladding modes of LPFGs is very sensitive to change of ambient refractive index (RI), so LPFGs have been wildly applied in fields of chemical and biological sensors (Saurabh et al. 2012; Pilla et al. 2009; Corres et al. 2008). The behavior of an LPFG with Langmuir-Blodgett thin-film overlays was firstly investigated (Rees et al. 2002). It was found that the response of the LPFG with high refractive index overlays was sensitive to refractive indices higher than that of the cladding. Then a ethanol vapors sensor was prepared based on an LPFG coated a higher refractive index \(\text{ SnO}_{2}\) film (Gu et al. 2006). In addition, the cladding mode transition and transmission spectrum of a coated LPFG were studied based on the coupled-mode theory (Del Villar et al. 2005). It is implied that a suitable overlay thickness can make some of the cladding modes transit into the overlay, and interact with the measurand, which might be a better approach to design high sensitivity sensor.

For a chemical LPFG sensor, a special sensitive film is essential, whose optical parameters could vary with the surrounding gas, moisture, pH and so forth. The film refractive index may be higher or lower than that of the cladding. To resolve the response restriction of LPFG sensor with single-layer coating mentioned above, a novel LPFG with double-layer coatings is presented. It can be also acted as a refractive index sensor, and be tailored with structure design to satisfy the requirements of practical applications.

In this paper, the presented LPFG sensor is studied based on the coupled-mode theory (Anemogiannis et al. 2003). The transition of LP cladding modes is presented and the transmittance of this kind of LPFG is discussed. Data simulation shows that the resonant wavelength shifts with the minor variation of the sensitive film refractive index as the LPFG is located at the mode transition region. Further, the sensitivity and measurable dynamic range is observed. By selecting suitable optical parameters of double-layer coatings, high sensitivity and large measurable dynamic range of this LPFG sensor can be obtained. Compared with conventional LPFG sensor, the presented LPFG with double-layer coatings enhances the design flexibility, and will have more expansive applications.

2 Analysis of LP mode field in coated LPFG

2.1 Coupled-mode theory for LP modes

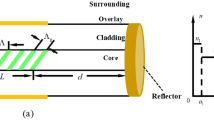

Figure 1a shows the structural diagram of an LPFG with double-layer coatings. The outmost layer is a chemical sensing film. In Fig. 1b, the refractive index profile of this LPFG is given. The refractive indices of the core, cladding, and double-layer coatings are \(n_{1}, n_{2}, n_{3}\) and \(n_{4}\), respectively; \(a_{1}, a_{2}, a_{3 }\) and \(a_{4 }\) are the radii of the core, cladding and double-layer coatings. The refractive index modulation \(\sigma \) of the core is the order of magnitude \(10^{-4}\).

\(\text{ LP}_{0j}\) modes are calculated based on the coupled-mode theory and transfer-matrix formulation (Anemogiannis et al. 2003). The transverse electric-field component propagating along the \(z\)-axis is given by

where \(i=1, 2, 3\) and 4 stands for the core, cladding and double-layer coatings, respectively; \(A_i\) and \(B_i\) are arbitrary field expansion coefficients in \(i\)th layer; \(J_0 ({r\gamma _{0j,i} })\) and \(Y_0 \left( {r\gamma _{0j,i} } \right)\) are the Bessel functions of the first and second kind of order 0, while \(I_0 \left( {r\gamma _{0j,i} } \right)\) and \(K_0\left({r\gamma _{0j,i}}\right)\) are the modified Bessel functions of order 0. \(\beta _{0j} \) is the propagation constant of the LP \(_{0j }\) mode, \(\gamma _{0j,i} =\sqrt{k_0^2 n_i^2 -\beta _{0j}^2}\) is the magnitude of the transverse wave vector. According to the boundary conditions of electromagnetic fields and the method of transmission matrix, we can set up a transfer matrix equation. For the transfer matrix equation having a solution, the dispersion equation can be given as

After resolving Eq. (2), the effective indexes \(n_{\textit{eff}}\) (or \(\beta _{0j} =n_{\textit{eff}} k_0)\) of the \(\text{ LP}_{0j}\) modes can be calculated.

Supposing that the input field amplitude \(A_{01} (0)=1\), based on the coupled-mode theory, we can obtain the transmittance \(T_{\textit{LPFG}}\) of the gratings with length \(L\) (Del Villar et al. 2005)

where \(A_{01} (L)\) is the field amplitude at the end of the LPFG.

The obtained results present appreciable variations that are related to the values calculated with coupled-mode equations. However, if the modified first-order Bragg condition is applied, errors are lower than 0.1 % (Anemogiannis et al. 2003)

where \(\beta _{01}\) and \(\beta _{0j} \) are the propagation constants of the core and the \(jth\) cladding mode, respectively; \(\zeta _{01,01}\) and \(\zeta _{0j,0j} \) are the self-coupling coefficients of the core and the cladding modes; \(s_0\) is the coefficient of the first Fourier component of the grating function.

The sensitivity \(S\) of the refractive index sensor is defined as

where \(n\) is the refractive index of the sensitive film of the outmost layer.

2.2 Mode transition regions of coated LPFG

Figure 2 shows the effective refractive index of LP cladding modes versus the refractive index of the coating for an LPFG with a 1.2 \(\upmu \)m single-layer coating. It is found that the effective refractive index \(n_{\textit{eff}}^{cl} \) of LP cladding modes is almost unchanged while the coating refractive index is lower than that of the cladding. While the coating refractive index increases to the vicinity of 1.4447 (cladding index), the cladding effective refractive index shows obvious changes. The cladding effective refractive index of lower order mode will be larger than 1.4447. According to the theory of optical transfer, the mode effective refractive index in the cladding can not be larger than the cladding index (1.4447). So this mode no longer belongs to cladding mode, and propagates in the coating. On the other hand, the effective refractive index of the higher order cladding mode will be equal to that of proximate lower cladding mode, namely the previous higher mode is converted to present lower mode. Therefore, with the increment of the coating refractive index, the lower order modes are transferred to the coating, and the higher order modes replace the lower oreder modes order by order and continue to propagate in the cladding. This phenomenon is called mode transition.

3 Design structure of coated LPFG sensor

As mode transition take places, the mode in cladding will be transferred to the coating and this mode will be so easily affected by the surrounding measurand. So we can design the structure by selecting suitable coating optical parameters, make the coated LPFG locate in mode transition, and obtain a high sensitivity LPFG sensor.

From Fig. 2, the mode transition would not take place as the refractive index is lower than that of the cladding for an LPFG with single-layer coating. So we can’t helping to know if the refractive index of a sensitive film is lower, how to come true high sensitivity sensing based on mode transition. In fact we can coat double-layer coatings on the cladding of an LPFG to resolve this solution.

3.1 First coating with higher refractive index

While the sensitive film index is lower than the cladding index, a coating with higher refractive index should be firstly coated on the cladding. Figure 3 shows the effective refractive index of LP cladding modes versus the first overlay thickness, where the first overlay index is 1.52, and the second overlay (outmost sensitive overlay) thickness and index are 0.5 \(\upmu \)m, 1.32 respectively. As the thickness of the first overlay increases to 0.5 \(\upmu \)m, the \(\text{ LP}_{02}\) mode is guided to the overlay, the effective refractive index is higher than 1.4447 as shown in Fig. 3. In addition, the cladding \(\text{ LP}_{03}\) mode will become \(\text{ LP}_{02}\), and LP\(_{04}\) will become \(\text{ LP}_{03}\), and so forth. The phenomenon repeatedly emerges as the thickness increases to 2.0 \(\upmu \)m, more modes are guided to the overlay and new re-organizations of the cladding modes take place. The modes transit into the overlay, and they are more easily affected by the ambient. Thus a high sensitivity LPFG sensor can be designed by optimizing the overlay thickness.

The thickness of the first coating located at the mode transition region can be observed in Fig. 3. Figure 4 shows the transmittance change of LPFG with the sensitive film index, in which the first coating thickness is selected to be 0.5 \(\upmu \)m according to Fig. 3. It is clear that the resonant wavelength shift obviously as a sensitive film index changes.

Figure 5 shows the effective refractive index of LP cladding modes versus the refractive index of the second overlay, where the first overlay thickness is 0.5 \(\upmu \)m. It can be seen that due to introduction of the first overlay with higher refractive index \(\text{ LP}_{02}\) mode in the cladding can be transferred to the overlay while the outmost sensitive overlay index decreases to 1.32. Further, the change of the effective refractive index of \(\text{ LP}_{0,10}\) happens only while the outmost sensitive overlay index is about 1.11. This means that for the higher order LP modes the transition regions are broadened and the dynamic responses are greater than the lower LP modes. So the higher order LP modes can be used for lower index overlay sensing.

3.2 First coating with lower refractive index

For a higher index sensitive film, an LPFG can be also applied for a refractive index sensor by coating the first overlay with lower index than that of the cladding. Figure 6 shows the effective refractive index of LP cladding modes versus the index of the second overlay for two different thicknesses 50 and 600 nm of the first overlay, where the first overlay index is 1.42, and the second overlay thickness is 500 nm. It is found that with the increase of the first overlay thickness, the mode transition happens from lower refractive index region to higher refractive index region, and the index interval of the mode transition is broaden, which means this LPFG can operate at high sensitivity in a widely index range (showed between two dashed lines) of the outmost sensitive overlay. In other words, the measurable dynamic range of this LPFG can be enlarged by controlling the overlay thickness.

For the sake of clarity, Fig. 7 shows the dependence of transmittance on wavelength for the refractive index of outmost sensitive film with 1 \(\upmu \)m thickness as the first overlay thickness and index are 250 nm and 1.32, respectively. Figure 8 shows the maximum sensitivity and measurable dynamic range for the sensitive film refractive index. For two observed wavelength 1627.5 and 1599.5 nm, the sensitivity are \(3.2 \times 10^{3}\) and \(9.3\times 10^{2}\), while the measurable dynamic range of overlay index are \(4.7 \times 10^{-3}\) and \(1.0 \times 10^{-3}\) (corresponding sensitivity is not lower than 20 % of maximum sensitivity).

Further, we can analysis the transmission characteristics for the refractive index of outmost sensitive film under two different thicknesses 50 and 600 nm of the first overlay, and obtained the maximum sensitivity and measurable dynamic range. It can be concluded that with the increase of the first overlay thickness, the maximum sensitivity and measurable dynamic range for the sensitive film refractive index of this LPFG show obvious changes due to the change of mode transition interval. The maximum sensitivity increases from \(1.4 \times 10^{2}\) to \(4.6 \times 10^{3}\), and the measurable dynamic range for the sensitive film refractive index decreases from \(10^{-2}\) to \(2.0 \times 10^{-4}\).

4 Conclusion

An LPFG with double-layer coatings is presented and its sensing property and structure design are studied based on the coupled-mode theory. As the first coating thickness or the second coating refractive index increases, the mode transition happens periodically. The resonant wavelength is very sensitive to the change of the refractive index of the second coating while this LPFG is located at the mode transition region. For the higher order LP modes, the transition regions are broaden and the dynamic responses are greater than the lower LP modes, so the higher order LP modes can be used for lower index overlay sensing. By selecting a suitable thickness of the first coating, the sensitivity of LPFG sensor is available to \(10^{3}\), and the measurable dynamic range of the sensitive coating refractive index is available to \(10^{-2}\). This novel LPFG sensor with double-layer coatings overcomes the limitation of traditional coated LPFG in which the refractive index of sensitive coating must be higher than that of the cladding, and enlarges its scope of application, which allows it to be used far more widely.

References

Anemogiannis, E., Glytsis, E.N., Gaylord, T.K.: Transmission characteristics of long-period fiber gratings having arbitraryazimuthal/radial refractive index variations. J. Lightwave Technol. 21, 218–227 (2003)

Bhatia, V., Vengsarkar, A.M.: Optical fiber long-period grating sensors. Opt. Lett. 21, 692–694 (1996)

Corres, J.M., Del Villar, I., Matias, I.R., Arregui, F.J.: Two-layer nanocoatings in long-period fiber gratings for improved sensitivity of humidity sensors. IEEE Trans. Nanotechnol. 4, 394–400 (2008)

Del Villar, I., Matias, I.R., Arregui, F.J., Achaerandio, M.: Nanodeposition of materials with complex refractive index in long-period fiber gratings. J. Lightwave Technol. 23, 4192–4199 (2005)

Falciai, R., Mignani, A.G., Vannini, A.: Long period gratings as solution concentration sensors. Sens. Actuators B 74, 74–77 (2001)

Gu, Z.T., Xu, Y.P., Gao, K.: Optical fiber long-period grating with solgel coating for gas sensor. Opt. Lett. 31, 2405–2407 (2006)

James, S.W., Tatam, R.P.: Optical fibre long-period grating sensors: characteristics and application. Meas. Sci. Technol. 15, R49–R61 (2003)

Pilla, P., Foglia Manzillo, P., Malachovska, V., Buosciolo, A., Campopiano, S., Cutolo, A., Ambrosio, L., Giordano, M., Cusano, A.: Long period grating working in transition mode as promising technological platform for labelfree biosensing. Opt. Exp. 17, 20039–20050 (2009)

Rees, N.D., James, S.W., Tatam, R.P., Ashwell, G.J.: Optical fiber long-period gratins with Langmuir-Blodgett thin-film overlays. Opt. Lett. 27, 686–688 (2002)

Saurabh M.T., Wojtek J.B., Predrag M., Raja C., Andy N., Mona T., Mohammed Z.: Long period grating based biosensor for the detection of Escherichia coli bacteria. Biosens. Bioelectron. 35, 308–312 (2012)

Acknowledgments

This work is supported by National Science Foundation of China (Grant No. 60777035), the Scientific Research Key Project Fund (Grant No. 208040), Innovation Project (Grant No. 11ZZ131) of Shanghai Municipal Education Committee, and Shanghai Leading Academic Discipline Project (Grant No. S30502).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gu, Z., Luo, T. & Gao, K. Structure design of refractive index sensor based on LPFG with double-layer coatings. Opt Quant Electron 45, 761–768 (2013). https://doi.org/10.1007/s11082-013-9659-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11082-013-9659-3