Abstract

High-temperature phase-stable rice-like anatase TiO2 nanocrystals were synthesized by one-pot solvothermal method using soluble titania xerogel and isopropyl alcohol (IPA) as the precursor and the solvent, respectively. Sample characterization was carried out by powder X-ray diffraction, high-resolution transmission electron microscopy, field emission scanning electron microscope, X-ray photoelectron spectroscopy, and N2 adsorption–desorption isotherms. The results showed that TiO2 nanocrystals had rice-like shapes with an average size of 5 nm in width and 35 nm in length. The BET surface area was 153 m2/g. Unexpectedly, the rice-like TiO2 nanocrystals exhibited high-temperature phase stability, which could remain as pure anatase phase after calcinations at 1000 °C. Growth mechanism investigation revealed that the IPA solvent played a key role in nucleation and growth of rice-like anatase TiO2 nanocrystals. The photodegradation of rhodamine B demonstrated that rice-like anatase TiO2 nanocrystals exhibited enhanced photocatalytic activity under visible light irradiation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Over the past several decades, TiO2 nanocrystal has been recognized as one of the most promising semiconductor materials owing to its wide band gap, low cost, chemical stability, and environmental friendliness. These properties make it one of the most extensively investigated semiconductor oxides, which can be used as photocatalysts, photovoltaic electrodes, and gas sensors (Bai et al. 2014; Chen and Mao 2007; Fujishima et al. 2000; Nisar et al. 2013). As is well known, the relative properties of TiO2-based functional materials are mainly dependent on its microstructure and physical properties, such as morphology, crystal structure, surface area, and crystallinity. In general, TiO2 exists mainly in three crystal phases in nature: anatase, brookite, and rutile. Although rutile is the most thermodynamically stable phase at ambient pressure, anatase possesses the best photocatalytic activity because of the large band gap (3.2 eV) and strong oxidizing power. A high crystallinity of anatase TiO2, which possesses fewer surface defects, is one of the well-known critical factors in improving the photocatalytic performance. Thermodynamically, rutile is the most stable phase among diverse polymorphs of titania, and anatase can be readily transformed into rutile via a solid-state phase transformation (usually by calcination at above 550 °C in air). Although the high thermal treatment (>700 °C) could improve the crystallinity of TiO2, it leads to undesirable grain growth and the anatase–rutile phase transformation. Various attempts have been made to improve the crystallinity of anatase TiO2 and resist the anatase–rutile phase transformation, such as metal or nonmetal doping, or surface modification with metal oxides (i.e., Al2O3, NiO, and ZnO). For example, Sun et al. (2012) synthesized stable bi-phasic porous TiO2 nanoparticles with high crystallinity, large surface area, and small particle size through a post-treatment of ethylene diamine molecules, which are stable up to 800 °C. Grover et al. (2014) recently reported a pure and stable anatase TiO2, which could retain the anatase crystal phase (~100 %) by calcination at elevated temperatures (800–900 °C). However, synthesis of anatase TiO2 with thermal stability at higher temperature (≥1000 °C) is still a challenge.

Morphology control with well-defined shape is the other key factors role in determining the properties of designed devices (D’Arienzo et al. 2011; Zhou et al. 2011). Recently, rice grain-shaped anatase TiO2 nanocrystal has attracted increasing attention due to its high thermal stability and enhanced photoelectrochemical performances (Grover et al. 2014; Sun et al. 2012). Parmar et al. (2011) reported rapid synthesis of unique anisotropic single-crystalline rice-shaped TiO2 nanoparticles utilizing a mixture of Ti-isopropoxide [Ti(OPr)4], acetylacetone, and deionized water by a microwave-assisted hydrothermal procedure. The TiO2 nanorice exhibited an excellent photovoltaic efficiency of higher than 8 % as an anode of a dye-sensitized solar cell. Very recently, Li et al. (2014) prepared size-controllable and thermally stable rice-like brookite TiO2 particles with high phase purity through a hydrothermal process. They found that the rice-like brookite TiO2-scattering layers could improve the performances of the P25 film-based solar cells. Despite the above-mentioned successful demonstrations, there is still need to develop a new, convenient, and economic synthesis procedure that can readily produce rice-like anatase TiO2 nanocrystals with improved phase stability.

Herein, we report a facile solvothermal synthesis of elongated rice-like anatase TiO2 nanocrystals with high-temperature (1000 °C) stability using soluble titania xerogel (STX) as a precursor and isopropyl alcohol (IPA) as a solvent. The rice-like anatase TiO2 nanocrystals exhibited higher photocatalytic activity than that of P25 under visible light irradiation. To the best of our knowledge, this is the first time IPA is used as solvothermal solvent to synthesize high thermally stable, rice grain-shaped anatase TiO2 nanocrystals.

Materials and methods

All reagents used in our experiments are of analytic purity and used without further purification. The STX was synthesized following our previous work (Meng et al. 2012). Briefly, 15 mL of tetrabutyl titanate (TBT) was added into 15 mL of trifluoroacetic acid (TFA) solution (50 wt%) under stirring in ice-bath. After stirring for 3 h, a clear solution was obtained. The solution was placed at room temperature for 3 days and a yellowish gel was obtained. Then, the yellowish gel was dried at 60 °C overnight to obtain the STX,. Subsequently, 0.1 g of STX was dissolved in 30 mL IPA at room temperature and then the solution was transferred into a Teflon-lined autoclave and heated at 180 °C for 24 h. After cooling down to room temperature, white products were collected by centrifugation and washed for several times with distilled water and ethanol. The final product was dried at 70 °C for 10 h and labeled as I180-24. The samples synthesized in IPA at 160 and 180 °C for 5 h were labeled as I160-5 and I180-5, respectively. For comparison, TiO2 nanoparticles were synthesized using different solvents including water, n-propanol, and ethanol. In order to investigate the phase stability, solvothermally synthesized TiO2 samples in IPA were calcined at 900–1000 °C for 2 h under ambient conditions using a muffe furnace at a heating rate of 5 °C/min and labeled as I180-900 and I180-1000.

The crystal phases of the resulting products were characterized by powder X-ray diffraction (XRD, Rigaku D/max 2400 diffractometer with Cu Kα radiation, λ = 1.54178 Å) at a scanning rate of 2°/min. The morphologies and sizes of the TiO2 nanoparticles were observed on a JEOL S-4300F field emission scanning electron microscope (SEM) at 15 kV and JEOL JEM-2010 transmission electron microscope at 200 kV. X-ray photoelectron spectroscopy (XPS) was performed on the Thermo Scientific ESCA Lab 250Xi using 200 W monochromated Al Kα radiation. The 500 μm X-ray spot was used for XPS analysis. The base pressure in the analysis chamber was about 3 × 10−10 mbar. Typically, the hydrocarbon C1s line at 284.8 eV from adventitious carbon is used for energy referencing. N2 adsorption–desorption isotherms were obtained by means of a Micromeritics ASAP 2040 system at liquid nitrogen temperature (77 K). Before carrying out the measurement, 0.1 g sample was out-gassed under vacuum for 6 h at 250 °C. Pore volume and size distributions were derived from the desorption branches of the isotherms by the Barrett–Joyner–Halenda (BJH) model, and the Brunauer–Emmett–Teller (BET) equation was used to calculate the specific surface area from the adsorption data.

The photocatalytic activity was evaluated by degradation of rhodamine B (RhB) under visible light irradiation. 30 mg of TiO2 nanocrystals was added into 30 mL of aqueous solution of RhB (30 mg/L) in a 100-mL-Pyrex glass vessel. Prior to irradiation, the suspension was kept in the dark overnight to insure the establishing of an adsorption/desorption equilibrium, and the equilibrium concentration was fixed as the initial concentration (C 0). The irradiation source was a 300 W Xe lamp (Philips) with a 420-nm cutoff filter to ensure irradiation by visible light only. At given intervals of illumination (every 0.5 h), the RhB concentration variations (C t) were monitored using Shimadzu UV1601-PC UV–Vis spectroscopy at the maximum absorption wavelength of 554 nm. For comparison, commercial TiO2, Degussa P25, and RhB solution without any photocatalysts were also examined under an identical condition.

Results and discussions

Soluble titania xerogel synthesized in the present work can be quickly dissolved in IPA, water and other polar organic solvents, such as ethanol, acetone, tetrahydrofuran, and so on. In our previous work, we have proved that TFA bonded to the titanium center in a bidentate bridging or chelating fashion (see Scheme 1B, C) in xerogel samples (Meng et al. 2012). The solubility of STX in organic solvents provides a large amount of manipulation variety for controlling synthesis of TiO2 nanoparticles via solvothermal method due to the slow hydrolysis and condensation rate under nonaqueous condition.

When STX was added into IPA, a clear solution was obtained within several minutes (Fig. 1A). The observation of Tyndall light scattering demonstrated the formation of colloidal dispersion. The colloidal solution can remain stable for 6 months without precipitating. After the solvothermal treatment at 180 °C for 24 h, a milk-like suspension was obtained. Figure 1B clearly shows the typical TEM image of TiO2 nanocrystals. It can be easily seen that rice-like TiO2 nanocrystals with a uniform size distribution are obtained. The TiO2 nanorices have an average particle size of 8 nm in width and an average of 25 nm in length. HRTEM image (insert in Fig. 1B) shows clear crystalline lattice fringes, 0.352 and 0.475 nm, which correspond to the (101) and (002) atomic planes of anatase TiO2, respectively. Figure 1C shows the nitrogen adsorption–desorption isotherms and the corresponding pore size distribution curves of rice-like TiO2 nanocrystals. The isotherm exhibits typical type IV pattern with hysteresis loop, a typical characteristic of mesoporous materials. The pore size distribution calculated from the desorption branch of the nitrogen isotherm by the BJH method shows a narrow range of 3.0–5.0 nm with a maximum pore diameter of about 4.2 nm (see inset of Fig. 1C). These mesopores are formed by the aggregation of primary particles. The narrow pore distributions also imply that the prepared rice-like TiO2 nanoparticles have a uniform particle size distribution. The BET surface area is measured to be 153 m2/g, which is about three times higher than that of P25 powder (50 m2/g). The results of nitrogen adsorption/desorption experiments indicate that the rice-like TiO2 nanocrystals synthesized in IPA have large specific surface area, which is helpful for the improvement of photocatalytic activity.

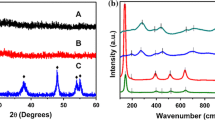

The structure of TiO2 nanocrystals was further investigated by XRD. Figure 2a shows the XRD patterns of the rice-like anatase TiO2 synthesized in IPA. It is clear that the solvothermally synthesized TiO2 nanocrystals are pure anatase. According to the Scherrer’s equation, the average particle size is about 25 nm, which is consistent with the TEM results. Figure 2b, c shows the XRD patterns of the calcinated samples at 900 and 1000 °C for 2 h, respectively. Unexpectedly, the rice-like TiO2 nanocrystals remained pure anatase phase calcinated at 900 °C for 2 h. More interestingly, no clear rutile characterized peak (2θ = 27.4°) appeared even when the calcining temperature was increased up to 1000 °C. Only noticeable increase in intensity and decrease in broadness for the (101) peak at 2θ = 25.3° were observed when the calcination temperature was increased from 900 °C to 1000 °C. The average particle size was increased from 25 to 47 nm after annealing at 1000 °C for 2 h calculated by Scherrer equation. This suggested that no anatase–rutile phase transformation occurred for rice-like TiO2 nanocrystals when calcined at high temperature (1000 °C).

In general, the anatase–rutile phase transformation is kinetically defined, and the reaction rate is determined by parameters such as particle shape/size, purity, and reaction conditions. Anatase nanocrystals coarsen, grow, and then transform to rutile only when a critical size is reached. Therefore, phase transformation is dominated by factors such as defect concentration, grain boundary concentration, and particle packing. In the present work, there are two possible reasons for the high-temperature anatase stability of TiO2 nanorices. One reason can be attributed to the presence of trifluoroacetate complex, which can cause the fluorination of the anatase crystals under thermal decomposition. Figure 3b shows the high-resolution XPS spectrum of F1s region. The F1s peak located at around 684.4 eV is a typical value for fluorinated TiO2 systems such as ≡Ti–F species on the TiO2 crystal surface. No signal for F in the lattice of TiO2 (BE = 688.5 eV) is found, suggesting that F element only exists in surface fluoride (≡Ti–F). Therefore, the fluorinated clusters may repel each other and thus slow down the nuclear and growth rate of rutile phase.

Besides the effect of trifluoroacetate complex, the unique rice-like shape with fewer interfaces is another important factor in affecting the anatase to rutile phase transformation. A reduction in anatase–anatase interface can slow the phase transformation, especially when this transformation is governed by the interface nucleation. Figure 4 shows the SEM images of TiO2 nanorices before and after sintering at 1000 °C for 2 h. The particle size was increased to about 50 nm after calcinations, which was consistent with XRD data. The packing characteristics of the rice-like TiO2 nanocrystals limited the interface nucleation of the rutile phase and effectively retard the phase transformation at a relatively high temperature. Therefore, the rice-like shape TiO2 with fewer interfaces played crucial roles in anatase–rutile phase transformation.

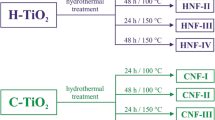

In order to investigate the growth mechanism of rice grain-shaped anatase TiO2 nanocrystals, TiO2 nanocrystals were synthesized at different temperatures and times in IPA. As shown in Fig. 5a, rice grain-shaped TiO2 nanocrystals with size of an average of 3 nm in width and an average of 12 nm in length were formed at 160 °C for 1 h. With the increasing solvothermal temperature and time, the TiO2 nanorice grew gradually, and the size increased to 5 nm in width and to an average of 20 nm in length (Fig. 5b, c, d). This suggests that IPA has a template effect on the nucleation of rice-like TiO2 nanocrystals at the early stage of growth, which will be discussed in later section.

To further understand the unique role of IPA in the growth of TiO2 nanorices, different solvent systems were used to synthesize the TiO2 nanoparticles. Figure 6 shows the TEM images of TiO2 nanoparticles prepared in n-propanol, ethanol, and water, respectively. In n-propanol, floccus-like structure was obtained, which was radically different from that in isopropanol. However, rectangular-shaped TiO2 nanoparticles with uniform size were observed in ethanol, which have a length of about 11 nm and a width of about 5 nm. In the case of water, TiO2 nanoparticles with random shapes were obtained. The results show that IPA has a unique effect on the nucleation and the growth of rice-like TiO2 nanocrystals.

The effect of alcohol solvent on synthesis of anatase TiO2 nanocrystal has been reported by several authors. Wang et al. (2002) reported that the amount and configuration of CH2 in alcohols played key role in controlling the crystal structures, grain sizes, and morphologies of the products. Liao et al. (2009) used peroxotitanate complex solution as precursor to prepare TiO2 nanocrystal colloids with different shapes and sizes. They found that ethanol shows much stronger adsorption onto the (001) plane, which depressed the growth rate along the [001] direction, and the rectangular shape was formed. Recently, Wu and Tai (2013) investigated the solvent effects on the crystallization of anatase nanoparticles using eight different alcohols. The results showed that the solvent properties, such as the dielectric constant and boiling point, were considered in terms of their correlation to the crystallite size and shape. In our work, the selective adsorption of IPA on Ti-(OOCCF3)4 octahedral complexes may play a key role in nuclear and growth of rice-like TiO2 nanocrystals. The growth mechanism of TiO2 nanocrystals using Ti-(OOCCF3)4 octahedral complexes as precursor in different alcohol solvents is under further investigation.

The thermal stabilities of the synthesized TiO2 nanocrystals in different solvents are shown in Fig. 7. As discussed above, only anatase peaks appeared in the sample synthesized in IPA after calcinations at 900 °C for 2 h (Fig. 7A, a). However, both anatase and rutile peaks were observed in the samples synthesized in ethanol, n-propanol, and water due to anatase–rutile phase transformation (Fig. 7A, b, c, d). This suggests that the samples synthesized in ethanol, n-propanol and water have lower thermal stability, especially in water. Most of anatase phase transformed into rutile phase for the sample synthesized in water after calcinations. The TEM images (Fig. 7B, C) clearly show that the particle size is less than 50 nm for the sample prepared in IPA, while the particle size is more than 100 nm for the sample obtained in water due to the anatase–rutile phase transformation and the growth of rutile phase. The above results demonstrate that IPA can induce the growth of rice-like TiO2 nanocrystals, and the unique shape in turn endows the anatase TiO2 nanocrystals with high thermal stability and retard the anatase–rutile phase transformation.

The photocatalytic performances of rice grain-shaped anatase TiO2 nanocrystals were evaluated by photodegradation of RhB under visible-light irradiation. Figure 8 compares the photocatalytic activity of rice-like TiO2 nanocrystals synthesized at different temperatures and times. As shown in Fig. 8, the rice-like anatase TiO2 nanocrystals prepared in IPA exhibited higher RhB photodegradation rate than that of P25, and the sample synthesized at 180 °C for 24 h showed the highest photoactivity. As mentioned above, the rice-like TiO2 nanoparticles have large surface area, which facilitated the adsorption and decomposition of pollutant. Meanwhile, the rice grain-shaped TiO2 nanocrystals with sharp corners and edges have more active sites on the surfaces, which also can enhance the photocatalytic activity (Peng et al. 2010). Moreover, the photocatalytic activity is slightly enhanced when increasing the solvothermal temperature from 160 °C to 180 °C, which may be due to the higher crystallinity. After calcinations, the samples I180-900 and I180-1000 show lower photoactivity than P25 because the particle size was greatly increased during the heating process. Other calcined samples synthesized in ethanol, n-propanol, and water (not shown here) also exhibited lower photoactivity than P25, regardless of the ratio of anatase to rutile.

Conclusion

In summary, we have developed a facile route for the synthesis of high-temperature phase-stable rice-like anatase TiO2 nanocrystals via solvothermal method. The IPA played a template-effect for the nucleation and growth of rice grain-shaped anatase TiO2 nanocrystals. The rice grain-shaped anatase TiO2 nanocrystals with large surface area exhibited higher photocatalytic activity for RhB degradation under visible light irradiation.

References

Bai Y, Mora-Seró I, De Angelis F, Bisquert J, Wang P (2014) Titanium dioxide nanomaterials for photovoltaic applications. Chem Rev. doi:10.1021/cr400606n

Chen X, Mao SS (2007) Titanium dioxide nanomaterials: synthesis, properties, modifications, and applications. Chem Rev 107:2891–2959. doi:10.1021/Cr0500535

D’Arienzo M et al (2011) Photogenerated defects in shape-controlled TiO2 anatase nanocrystals: a probe to evaluate the role of crystal facets in photocatalytic processes. J Am Chem Soc 133:17652–17661. doi:10.1021/ja204838s

Fujishima A, Rao TN, Tryk DA (2000) Titanium dioxide photocatalysis. J Photochem Photobiol C Photochem Rev 1:1–21

Grover IS, Singh S, Pal B (2014) Stable anatase TiO2 formed by calcination of rice-like titania nanorod at 800 °C exhibits high photocatalytic activity. RSC Adv 4:24704–24709. doi:10.1039/c4ra01850h

Li K, Xu J, Shi W, Wang Y, Peng T (2014) Synthesis of size controllable and thermally stable rice-like brookite titania and its application as a scattering layer for nano-sized titania film-based dye-sensitized solar cells. J Mater Chem A 2:1886–1896. doi:10.1039/c3ta13597g

Liao J, Shi L, Yuan S, Zhao Y, Fang J (2009) Solvothermal synthesis of TiO2 nanocrystal colloids from peroxotitanate complex solution and their photocatalytic activities. J Phys Chem C 113:18778–18783. doi:10.1021/jp905720g

Meng X et al (2012) Facile synthesis of direct sunlight-driven anatase TiO2 nanoparticles by in situ modification with trifluoroacetic acid. J Nanopart Res 14:1–7. doi:10.1007/s11051-012-1176-y

Nisar J, Topalian Z, De Sarkar A, Österlund L, Ahuja R (2013) TiO2-based gas sensor: a possible application to SO2. ACS Appl Mater Interfaces 5:8516–8522. doi:10.1021/am4018835

Parmar KPS, Ramasamy E, Lee J, Lee JS (2011) Rapid ([similar]10 min) synthesis of single-crystalline, nanorice TiO2 mesoparticles with a high photovoltaic efficiency of above 8%. Chem Commun 47:8572–8574. doi:10.1039/c1cc12150b

Peng H, Wang X, Li G, Pang H, Chen X (2010) Facile synthesis of rice-like anatase TiO2 nanocrystals. Mater Lett 64:1898–1901. doi:10.1016/j.matlet.2010.05.053

Sun F et al (2012) Fabrication of rice-like porous anatase TiO2 with high thermal stability and enhanced photocatalytic performance. ChemCatChem 4:844–850. doi:10.1002/cctc.201100448

Wang C, Deng Z-X, Zhang G, Fan S, Li Y (2002) Synthesis of nanocrystalline TiO2 in alcohols. Powder Technol 125:39–44. doi:10.1016/S0032-5910(01)00523-X

Wu Y-C, Tai Y-C (2013) Effects of alcohol solvents on anatase TiO2 nanocrystals prepared by microwave-assisted solvothermal method. J Nanopart Res 15:1–11. doi:10.1007/s11051-013-1686-2

Zhou ZY, Tian N, Li JT, Broadwell I, Sun SG (2011) Nanomaterials of high surface energy with exceptional properties in catalysis and energy storage. Chem Soc Rev 40:4167–4185. doi:10.1039/C0cs00176g

Acknowledgments

This work is supported by the National Natural Science Foundation of China (No. 51203094), the Joint program of Beijing Natural Science Foundation and Beijing Academy of Science and Technology (No. L140005), Beijing NOVA Program (Z131101000413038), and Beijing Local College Innovation Team Improve Plan (IDHT20140512).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lv, L., Chen, Q., Liu, X. et al. Facile synthesis of high-temperature (1000 °C) phase-stable rice-like anatase TiO2 nanocrystals. J Nanopart Res 17, 222 (2015). https://doi.org/10.1007/s11051-015-3028-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-015-3028-z