Abstract

Poly(2-hydroxyethyl methacrylate-co-N-methacryloyl-(l)-glutamic acid) p(HEMA–MAGA) nanospheres have been synthesized, characterized, and used for the adsorption of Cd2+ ions from aqueous solutions. Nanospheres were prepared by surfactant free emulsion polymerization. The p(HEMA–MAGA) nanospheres were characterized by SEM, FTIR, zeta size, and elemental analysis. The specific surface area of nanospheres was found to be 1,779 m2/g. According to zeta size analysis results, average size of nanospheres is 147.3 nm with poly-dispersity index of 0.200. The goal of this study was to evaluate the adsorption performance of p(HEMA–MAGA) nanospheres for Cd2+ ions from aqueous solutions by a series of batch experiments. The Cd2+ concentration was determined by inductively coupled plasma-optical emission spectrometer. Equilibrium sorption experiments indicated a Cd2+ uptake capacity of 44.2 mg g−1 at pH 4.0 at 25 °C. The adsorption of Cd2+ ions increased with increasing pH and reached a plateau value at around pH 4.0. The data were successfully modeled with a Langmuir equation. A series of kinetics experiments was then carried out and a pseudo-second order equation was used to fit the experimental data. Desorption experiments which were carried out with nitric acid showed that the p(HEMA–MAGA) nanospheres could be reused without significant losses of their initial properties in consecutive adsorption and elution operations.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In today’s world, one of the main risks is the presence of heavy metals in aquatic environment due to their extreme toxicity toward living beings (Bosch 2003). The conversion of heavy metal ions which have toxic properties to harmless products by biological decomposition is almost impossible. Therefore, they have to be removed from water for public health. Cadmium is a toxic heavy metal occurring in the environment naturally as well as a serious pollutant posing severe risks to human health emanating from industrial and agricultural sources (Järup and Åkesson 2009). Cadmium is an occupationally and environmentally important toxic element that is present in air, soil, sediment, and water with no known biological function. Its targets of toxicity include lung, liver, kidney, bone, the cardiovascular system, and the immune system, where cadmium-induced cell death leads to loss of function. The International Agency for Research on Cancer classified cadmium as a human carcinogen. Cadmium enters the organism primarily via the alimentary and/or respiratory tract. It gives damage to alimentary-respiratory tract and especially to kidneys in which it accumulates. Secondarily, hematopoiesis disorders occur. Approximately 5 % of cadmium, which enters via alimentary tract, is resorbed. For respiratory tract this ratio is 30 %. Only a little of cadmium which enters the organism can be eliminated, therefore it accumulates in the body (Templeton and Liu 2010; Nordberg et al. 1992; Goering et al. 1995; Bhattacharyya et al. 2000; Fowler 2009).

Consequently, in recent years, scientific researches dealing with direct determination of Cd2+ are increasing day by day due to insufficient sensitivity and matrix effects. Therefore, separation and preconcentration of trace metals prior to their analysis are often required. For this purpose, several methods have been developed, such as cloud point extraction (Durukan et al. 2011), coprecipitation (Prasad et al. 2006), and adsorption (Arpa et al. 2010), and so forth. Among all of the methods, adsorption has become increasingly popular because of its advantages of cost effectiveness, simple operation, and environmental friendliness. Up to now, a variety of adsorbents have been reported as materials for the adsorption of heavy metals such as modified silica gel (Thu et al. 2010), activated carbon (He et al. 2010), biomaterial (Munagapati et al. 2010), ion-imprinted polymer (Esen et al. 2009), inorganic material (Eren et al. 2010). In spite of this, the search of new materials to develop novel adsorbents is of continuing interest. In recent years, the use of nanostructures as supporting material for heavy metal removal has become a new interesting field (Türkmen et al. 2009; Uygun et al. 2013). Due to the high surface area per mass of nanoparticles, binding of heavy metal ions on nanoparticles can be achieved effectively.

Herein, a novel nano-sized supporting material to which heavy metal binds directly without any activation was synthesized for Cd2+ adsorption from aqueous solutions. For this goal, N-methacryloyl-(l)-glutamic acid (MAGA) and 2-hydroxyethyl methacrylate (HEMA) monomers were used in surfactant free emulsion polymerization and p(HEMA–MAGA) nanospheres with the size of 147.3 nm were synthesized. The p(HEMA–MAGA) nanospheres were characterized by surface area calculations, elemental analysis, zeta charge-zeta potential, SEM, and FTIR. Afterward, the p(HEMA–MAGA) nanospheres were used for adsorption of Cd2+ ions from aqueous solutions.

Experimental procedure

Apparatus

The metal ions were determined by inductively coupled plasma optical emission spectrometer (ICP-OES) (Teledyne Leemans Labs Prism model, Hudson, NH, USA). The instrumental parameters were those recommended by the manufacturer (listed in Table 1). The pH values of solutions were controlled with a digital pH-meter. All metals were measured under optimized operating conditions by ICP-OES with argon plasma.

Materials

Glutamic acid hydrochloride and methacryloyl chloride were supplied by Sigma (St. Louis, USA). Hydroxyethyl methacrylate (HEMA) and ethylene glycol dimethacrylate (EGDMA) were obtained from Fluka A.G. (Buchs, Switzerland), distilled under reduced pressure in the presence of hydroquinone inhibitor and stored at 4 °C until use. All other reagents used in this study were of analytical reagent grade and all solutions were prepared with deionised water. Stock solutions (1,000 mg L−1) of the elements were prepared by dissolving appropriate amounts of nitrate salts in 1.0 % HNO3. The working standard solutions were prepared daily by stepwise dilution of stock solutions. All containers were treated with 10 % (v/v) HNO3 for at least 24 h, rinsed with high purity deionized water, and dried at room temperature before usage.

Synthesis of 2-methacryloylamidoglutamic acid

The complexing monomer N-methacryloyl-(l)-glutamic acid (MAGA) was synthesized as reported previously (Denizli et al. 2004). The following experimental procedure was applied for the synthesis of MAGA monomer: 5.0 g of l-glutamic acid and 0.2 g of hydroquinone were dissolved in 100 mL of dichloromethane solution. This solution was cooled down to 0 °C. Then, 13.0 g triethylamine was added to the solution and 4.0 mL of methacryloyl chloride was poured slowly into this solution under nitrogen atmosphere. This solution was stirred magnetically at room temperature for 2 h. At the end of this chemical reaction period, unreacted methacryloyl chloride was extracted with 10 % NaOH. The aqueous phase was evaporated in a rotary evaporator and residue (i.e., MAGA) was dissolved in ethanol.

Preparation of p(HEMA–MAGA) nanospheres

HEMA and MAGA were polymerized in surfactant free emulsion polymerization using potassium persulphate (KPS) and poly(vinyl alcohol) as the initiator and the stabilizer, respectively (Uygun et al. 2012). Synthesis of p(HEMA–MAGA) nanospheres may be summarized as follows: The stabilizer, PVAL (0.5 g), was dissolved in 50 mL deionized water for the preparation of the continuous phase. Then, the monomer mixture was added to this dispersion, which was mixed in an ultrasonic bath for about half an hour. Before polymerization, initiator was added to the solution and nitrogen gas blown through the medium for about 1–2 min to remove dissolved oxygen. Polymerization was carried out in a constant temperature shaking bath at 70 °C, under nitrogen atmosphere for 24 h. After the polymerization, the polymeric nanospheres were cleaned by washing with methanol and water several times to remove the unreacted monomers. For this purpose, the nanospheres were precipitated at the rate of 18,000 g for 2 h in a centrifuge (Zentrifugen, Universal 32 R, Germany), the collected precipitate was resuspended in methanol and water several times. After that the p(HEMA–MAGA) nanospheres were further washed with deionized water. In this study the p(HEMA–MAGA) nanospheres having the size range of 147.3 nm were used as a solid matrix for the adsorption of Cd2+ ions from aqueous solutions. Figure 1 shows that the hypothetic structure of p(HEMA–MAGA) nanospheres (a) and binding regions of Cd2+ on the p(HEMA–MAGA) nanosheres (b).

Characterization of p(HEMA–MAGA) nanospheres

FTIR spectra of the nanospheres were obtained using FTIR spectrophotometer (Varian FTS 7000, USA). The dry nanospheres (about 0.1 g) were thoroughly mixed with KBr (0.1 g, IR Grade, Merck, Germany), and pressed into a tablet form, and the spectrum was then recorded.

The particle size, the size distribution, and the surface charge were determined by Zeta Sizer (Malvern Instruments, Model 3000 HSA, England).

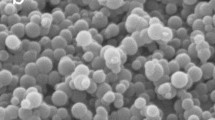

The surface morphology of the p(HEMA–MAGA) nanospheres was examined using SEM. The samples were initially dried in air at 25 °C for 7 days before being analyzed. A fragment of the dried sphere was mounted on a SEM sample mount and was sputter coated with gold for 2 min. The sample was then mounted in a scanning electron microscope (SEM, Phillips, XL-30S FEG, Germany). The surface of the sample was then scanned at the desired magnification to study the morphology of the nanospheres.

The degree of MAGA incorporation in the p(HEMA–MAGA) nanospheres was determined by elemental analyzer (Leco, CHNS–932, USA).

The surface area of p(HEMA–MAGA) nanospheres was calculated using the following expression (Eq. 1) (Bangs 1987; Kalburcu et al. 2014):

here, N is the number of nanospheres per milliliter, S is the % of solids, ρ s is the density of bulk polymer (g mL−1), d is the diameter (nm). From all these data, specific surface area of p(HEMA–MAGA) nanospheres was calculated by multiplying N and surface area of one nanosphere.

Adsorption experiments

The efficiency of the Cd2+ ions adsorption from aqueous solutions using p(HEMA–MAGA) nanospheres is studied in a batch mode by mixing 10 mL of aqueous solutions of Cd(NO3)2 at different concentrations with 20 mg of p(HEMA–MAGA) nanospheres. The effect of the pH was studied in the range of 2.0–8.0 adjusted with universal buffer solutions. The effect of the initial concentration of Cd2+ on the adsorption rate and adsorption capacity was also studied. For this purpose, 10 mL volumes of aqueous solutions containing different amounts of Cd2+ ions (in the range of 5–100 mg L−1) were treated with the p(HEMA–MAGA) nanospheres in suspension at room temperature and magnetically stirred at a speed of 200 rpm. Further experiments were proceeded to investigate the effect of contact time, during which samples were harvested at 15, 30, 45, 60, 75, 90, 105, and 120 min. After the desired treatment periods, the concentration of the Cd2+ ions in the aqueous phase was measured by using ICP-OES. The instrument response was periodically checked with known Cd2+ solution standards. The experiments were performed in replicates of three. For each set of data present, standard statistical methods were used to determine the mean values and standard deviations. Confidence intervals of 95 % were calculated for each set of samples in order to determine the margin of error. The amount of Cd2+ adsorption per unit mass of the nanospheres was evaluated by using the mass balance. The adsorption capacity of the p(HEMA–MAGA) nanospheres for Cd2+ was calculated according to the following equation (Eq. 2):

where C 0 and C e represent the initial and equilibrium metal ion concentrations (mg L−1), respectively, V is the volume of the metal ion solution (mL), and m is the amount of nanospheres (mg).

Competitive adsorption

Competitive heavy metal adsorption from aqueous solutions containing Cd2+, Cu2+, Zn2+, Ni2+ was also investigated in a batch experimental system. A solution (10 mL) containing 30 mg L−1 of each metal ion was treated with 20 mg of nanospheres in suspension at a pH of 4.0, in the flasks stirred magnetically at 200 rpm for 60 min. The temperature was maintained at 25 °C. After a sufficient amount of time for equilibration, the solution was centrifuged, and the supernatant was removed and analyzed for remaining metal ions. The amounts of adsorbed heavy metal ions were then determined by difference.

Desorption and reusability of p(HEMA–MAGA) nanospheres

Desorption of Cd2+ ions were carried out in 10 mL of 0.1 M HNO3 solution. The p(HEMA–MAGA) nanospheres which adsorbed Cd2+ ions were placed in this desorption medium and stirred continuously at a stirring rate of 200 rpm for 30 min at room temperature. The desorption ratio was calculated from the amount of Cd2+ ions adsorbed on the nanospheres and the final Cd2+ ions concentration in the desorption medium using the following equation (Eq. 3):

In order to test the reusability of the nanospheres, the adsorption–desorption procedure of Cd2+ ions was repeated fifteen times using the same nanospheres.

Results and discussion

Nanospheres can produce larger specific surface area and therefore may result in high ligand loading. Therefore, it may be useful to synthesize nanospheres with large surface area and utilize them as suitable carriers for the removal of heavy metal ions. The specific surface area was calculated as 1,779 m2/g. The p(HEMA–MAGA) nanospheres with an average size of 147.3 nm in diameter were produced by surfactant free emulsion polymerization. The p(HEMA–MAGA) nanospheres are spherical and very narrowly size distributed as shown by the SEM microscopy images (Fig. 2). It is also evident that the nanospheres are monodisperse (polydispersity index: 0.200). The small polydispersity index suggests that nucleation is fast compared to particle growth, and also the absence of a secondary nucleation step (Silva et al. 2013; Wu et al. 2013). In addition, the total monomer conversion was determined as 98.5 % (w/w) for the p(HEMA–MAGA) nanospheres.

As mentioned before, MAGA was selected as the metal complexing ligand. In the first step, MAGA was synthesized from l-glutamic acid hydrochloride and methacryloyl chloride. Then, synthesized MAGA was co-polymerized with HEMA in order to form p(HEMA–MAGA) nanospheres by surfactant free emulsion polymerization.

FTIR spectrum given in Fig. 3, shows the incorporation of MAGA into the structure of p(HEMA–MAGA) nanospheres. MAGA has the characteristic stretching vibration bands amide I and amide II absorption bands at 1,655 and 1,548 cm−1, a carbonyl band at 1,732 cm−1 as shown in Fig. 3.

To evaluate the degree of MAGA incorporation, elemental analysis of the p(HEMA–MAGA) nanospheres was performed. The incorporation of the MAGA was found to be 3.5 mmol MAGA/g from the nitrogen stoichiometry.

As seen in Fig. 4, average particle size and size distribution of the p(HEMA–MAGA) nanospheres were measured by Zeta Sizer and about 147.3 nm with 0.200 polydispersity. The average particle size was an average of minimum 30 measurements, and the size distribution was recorded automatically by the software of these repeated measurements.

Cd2+ Adsorption studies

Effect of contact time

The results in Fig. 5 make clear that the adsorption rate was fast initially. Thereafter, the adsorption capacity increased with the contact time before reaching a plateau value after the contact time of 60 min. Therefore, equilibration time was considered as 60 min. Consequently in the following experiments, the contact time was set to 60 min to insure adsorption equilibrium. The amount of adsorbed Cd2+ ions by p(HEMA–MAGA) nanospheres (q e) from an initial concentration of 20 mg L−1 after a 60 min equilibration time was 44.2 mg g−1.

Adsorption capacity

Figure 6 shows the equilibrium concentration of Cd2+ dependence of the adsorbed amount of the Cd2+ on the p(HEMA–MAGA) nanospheres. The adsorption values increased with increasing equilibrium concentration of Cd2+, and a saturation value was achieved at ion concentration of 20 mg L−1, which represents saturation of the active binding sites on the p(HEMA–MAGA) nanospheres.

The maximum Cd2+ adsorption capacity achieved in the studied range is around 395 μ mol per gram of the nanospheres. A wide variety of adsorbents used to adsorb Cd2+ ions have been reported. Table 2 presents a brief list of the published maximum adsorption capacity of various cadmium adsorbents, including the present studied. Comparing these data, we may conclude that the p(HEMA–MAGA) is a promising reusable adsorbent for the removal of Cd2+ ions.

Effect of pH

pH is one of the most critical parameters for metal adsorption as it influences both the polymer surface chemistry as well as the solution chemistry of soluble metal ions. In order to show the effect of pH on the adsorption of Cd2+ onto p(HEMA–MAGA) nanospheres, the batch adsorption equilibrium studies were carried out at different pHs in the range of 2.0–8.0 and the results which show the pH dependence of adsorption values of Cd2+ are presented in Fig. 7.

In this group of experiments, the equilibrium concentration of Cd2+ and the adsorption equilibrium time were 20 mg L−1 and 60 min, respectively. It is indicated that the adsorption of Cd2+ on the p(HEMA–MAGA) nanospheres was pH dependent. It was observed that the adsorption capacity increased with increasing pH, reaching a value around 4.0. –COOH groups in side chain (pKa value is about 4.2) and α–COOH (pKa value is about 2.2) of glutamic acid parts of MAGA monomer which is in polymer structure is protonated at that pH values (Murray et al. 2003). So it’s expected that ionic interactions between Cd2+ and nanospheres due to negatively charged –COO− groups are weak at pH 2.2 and lower pH values. Therefore, Cd2+ adsorption values decrease. At over pH 4.0, decreasing of adsorption values may be due to metal precipitation at high pH values (Say et al. 2002).

Competitive adsorption

Competitive adsorption of heavy metal ions was carried out in batch experiment with Cu2+, Zn2+, Ni2+, and Cd2+. According to the obtained results, Cd2+ adsorption capacity of p(HEMA–MAGA) nanospheres is higher than those obtained for Cu2+, Zn2+, and Ni2+. The adsorption capacities are 12.6, 14.1 and 19.3 mg g−1 for Cu2+, Zn2+, and Ni2+, respectively. It can be concluded from these results that the order of affinity is Cd2+ > Ni2+ > Zn2+ > Cu2+. This trend is given on the basis of mass (mg) metal adsorption per gram adsorbent and this unit is important in quantifying respective metal capacities in real terms.

Desorption and reuse

The desorption of Cd2+ from the p(HEMA–MAGA) nanospheres was carried out in a batch experimental setup. Different eluents were tested in order to evaluate and compare the desorption ratios. The use of organic solvents was not possible since they generate instability in the ICP, which can eventually lead to its extinction. 0.1 M solutions of nitric, hydrochloric, and sulfuric acids were tested for 30 min and the results that have been obtained as percentage of desorption were as 98.9, 96.4, and 89.3 % respectively. Nitric acid turned out to be a good eluent for Cd2+ ions adsorbed. Consequently, 0.1 M solution of HNO3 was used for further desorption experiments.

In order to indicate the reusability study of p(HEMA–MAGA) nanospheres, the adsorption–desorption procedure of Cd2+ ions was repeated fifteen times using the same nanospheres. Desorption ratios were quantitative as up to 99 %. The adsorption capacity of nanospheres did not change significantly, though at the end of fifteen adsorption–desorption cycle the adsorption percentage was approximately 98 %. This is the proof of perfect reusability of p(HEMA–MAGA) nanospheres.

Adsorption isotherms

The p(HEMA–MAGA) nanospheres interacted with 10 mL of metal ion (i.e. Cd2+) solution with various concentrations of 5.0–100.0 mg L−1. The adsorption was performed in a batch system using a shaker with pH 4.0 and optimum interaction time. Then, the solution was centrifuged and filtrate was taken to analyze the metal ion concentration left by ICP-OES. The interaction between Cd2+ ions and the p(HEMA–MAGA) nanospheres is characterized via adsorption isotherms. It shows the relation between the amount of adsorbed Cd2+ ions per unit mass of nanospheres (q e) and the Cd2+ concentration in solution (C e) at equilibrium. Langmuir and Freundlich isotherms obtained at pH 4.0 in the range of initial Cd2+ concentrations (5.0–100.0 mg L−1) are shown in Figs. 8 and 9. The equilibrium amount of adsorbed Cd2+ first increases by increasing the Cd2+ concentration of the solution. It then reaches a constant value equal to 44.2 mg g−1.

The non-linear equation of the Langmuir adsorption model is given as (Eq. 4) (Langmuir 1918):

and this equation can be converted to (Eq. 5):

where q e is the equilibrium Cd2+ ion concentration on the p(HEMA–MAGA) nanospheres (mg g−1), C e is the equilibrium Cd2+ ion concentration in the solution (mg L−1), q max is the monolayer adsorption capacity of the adsorbent (mg g−1) and K L is the Langmuir constant (L/g) and related to the free energy of adsorption. Therefore, a plot of log 1/q e versus C e gives a straight line of slope 1/q max K L and intercept. The Langmuir equation is applicable to the homogeneous sorption where each metal ion-adsorbent sorption process has equal sorption activation energy.

The non-linear equation of the Freundlich equation is given by (Eq. 6) (Freundlich 1906):

where K F [(mg g−1)(L/g)n] and 1/n are the Freundlich adsorption isotherm constants. K F is Freundlich capacity factor and n is the Freundlich’s intensity factor. The value of n in the range of 1–10 denotes favorable adsorption. The linear form of Freundlich’s equation is given by (Eq. 7):

Therefore, a plot of log q e versus log C e enables the constant K F and exponent n. The graph obtained for Freundlich isotherm is shown in Fig. 9.

The Langmuir and Freundlich constants along with the correlation coefficients (R 2) were calculated from the corresponding plots for adsorption of the Cd2+ ions on the p(HEMA–MAGA) nanospheres and the results are presented in Table 3.

As seen in Table 3, the R 2 value for adsorption of Cd2+ ions using Freundlich model was not as good as the Langmuir model. In contrast, the R 2 value obtained from Langmuir model was unity. The higher R 2 value showed that the Langmuir isotherm exhibited a better fit to the adsorption data than the Freundlich isotherm which leads to a monolayer adsorption. Moreover, there was a good agreement between q max calculated (44.6 mg g−1) and q e experimental (44.2 mg g−1) values from the Langmuir equation.

Kinetics of adsorption

In order to analyze the adsorption rate of heavy metal ions onto the p(HEMA–MAGA) nanospheres, pseudo-first-order, and pseudo-second-order rate equations were employed to interpret the experimental data.

The Lagergren’s first-order rate equation is represented by (Eq. 8) (Lagergren 1898):

where q t is the amount of Cd2+ ion adsorbed onto the p(HEMA–MAGA) nanospheres at time t (mg/g), k 1 is the pseudo-first-order rate constant (min−1), and q 1 is the final equilibrium adsorption amount. The k 1 can be determined by the linear plot of ln (q 1 − q t) versus t. The plot obtained for Cd2+ adsorption onto the p(HEMA–MAGA) nanospheres according to pseudo-first-order rate equation is given in Fig. 10.

The Ho’s second-order rate equation (Ho and McKay 1998) can be expressed as (Eq. 9):

where q t is the amount of Cd2+ ion adsorbed onto the p(HEMA–MAGA) nanospheres at time t (mg g−1), k 2 is the pseudo-second-order adsorption rate constant (g mg−1 min−1) and q 2 is the final equilibrium adsorption amount. Values of k 2 and q 2 can be calculated from the plot of t/q t against t. The plot obtained for Cd2+ adsorption on the p(HEMA–MAGA) nanospheres according to pseudo-second-order rate equation is given in Fig. 11.

Much higher R 2 value (0.96 > 0.73) was obtained from pseudo-second-order model than pseudo-first-order model which indicates that the adsorption process best followed the pseudo-second-order model, i.e. chemical sorption being the rate-controlling step in contrast to the pseudo-first-order model.

Conclusions

In this work, p(HEMA–MAGA) nanospheres were successfully synthesized. Accordingly, a new nano-sized sorbent was proposed for Cd2+ adsorption from aqueous solutions. The adsorption characteristics have been examined at different contact times, pH values, initial Cd2+ ion concentrations. The optimum pH for the efficient adsorption of Cd2+ from aqueous solutions by p(HEMA–MAGA) nanospheres is 4.0. Due to well fit of isotherm data with Langmuir model (R 2 = 1.0), homogeneous adsorption sites on the p(HEMA–MAGA) nanospheres have been recognized. Kinetics of the adsorption reactions of Cd2+ from aqueous solutions by the p(HEMA–MAGA) nanospheres take place according to the pseudo-second-order mechanism due to higher R 2 value. The p(HEMA–MAGA) nanospheres could be utilized 15 times without obviously deterioration in their adsorption capacities. On the other hand the desorption values are also quantitative. To sum up, the p(HEMA–MAGA) nanospheres seem to be a promising material for adsorption of Cd2+ ions from aqueous solutions due to performing satisfactory results.

References

Arpa Ç, Bereli N, Özdil E, Bektaş S, Denizli A (2010) Reactive green HE-4BD functionalized supermacroporous poly(hydroxyethyl methacrylate) cryogel for heavy metal removal. J Appl Polym Sci 118:2208–2215

Badruddoza AZM, Shawon ZBZ, Daniel TWJ, Hidajat K, Uddin MS (2013) Fe3O4/cyclodextrin polymer nanocomposites for selective heavy metals removal from industrial wastewater. Carbohydr Polym 91:322–332

Bangs LB (1987) Uniform latex particles. Seradyn Inc. Seragen diagnostics, Indianapolis

Bhattacharyya MH, Wilson AK, Rajan SS, Jonah M (2000) Biochemical pathways in cadmium toxicity. In: Zalups RK, Koropatnick J (eds) Molecular biology and toxicology of metals. Taylor and Francis, London, pp 34–74

Bosch X (2003) Cadmium cuts two ways: the heavy metal mutates DNA, and then prevents cells from repairing the damage. Science 609:1–11

Deng JH, Zhang XR, Zeng GM, Gong JL, Niu QY, Liang J (2013) Simultaneous removal of Cd(II) and ionic dyes from aqueous solution using magnetic graphene oxide nanocomposite as an adsorbent. Chem Eng J 226:189–200

Denizli A, Sanli N, Garipcan B, Patir S, Alsancak G (2004) Methacryloylamidoglutamic acid incorporated porous poly(methylmethacrylate) beads for heavy-metal removal. Ind Eng Chem Res 43:6095–6101

Durukan İ, Şahin ÇA, Şatıroğlu N, Bektaş S (2011) Determination of iron and copper in food samples by flow injection cloud point extraction flame atomic absorption spectrometry. Microchem J 99:159–163

Eren E, Gümüş H, Özbay N (2010) Equilibrium and thermodynamic studies of Cu(II) removal by iron oxide modified sepiolite. Desalination 262:43–49

Esen C, Andaç M, Bereli N, Say R, Henden E, Denizli A (2009) Highly selective ion-imprinted particles for solid-phase extraction of Pb2+ ions. Mater Sci Eng C 29:2464–2470

Fowler BA (2009) Monitoring of human populations for early markers of cadmium toxicity: a review. Toxicol Appl Pharm 238:294–300

Freundlich HMF (1906) über die adsorption in lösungen. Zeitschrift für Physikalische Chemie (leipzig) 57A:385–470

Goering PL, Waalkes MP, Klaassen CD (1995) Toxicology of cadmium. In: Goyer RA, Cherian MG (eds) Handbook of experimental pharmacology, vol 115. Toxicology of metals-biochemical aspects. Springer, Berlin, pp 189–214

Gupta VK, Nayak A (2012) Cadmium removal and recovery from aqueous solutions by novel adsorbents prepared from orange peel and Fe2O3 nanoparticles. Chem Eng J 180:81–90

He Q, Hu Z, Jiang Y, Chang X, Tu Z, Zhang L (2010) Preconcentration of Cu(II), Fe(III) and Pb(II) with 2-(2-aminoethylamino)-methyl)phenol-functionalized activated carbon followed by ICP-OES determination. J Hazard Mater 175:710–714

Ho YS, McKay G (1998) Sorption of dye from aqueous solution by peat. Chem Eng J 70:115–124

Huang Z, Wu Q, Liu S, Liu T, Zhang B (2013) A novel biodegradable β-cyclodextrin-based hydrogel for the removal of heavy metal ions. Carbohydr Polym 97:496–501

Järup L, Åkesson A (2009) Current status of cadmium as an environmental health problem: a review. Toxicol Appl Pharm 238:201–208

Kalburcu T, Öztürk N, Tüzmen N, Akgöl S, Denizli A (2014) Cholesterol removal onto the different hydrophobic nanospheres: a comparison study. J Ind Eng Chem 20:153–159

Lagergren S (1898) Zur theorie der sogenannten adsorption geloster Stoffe. Kungliga Svenska Vetenskapsakademiens, Handlingar 24:1–39

Langmuir I (1918) The adsorption of gases on plane surfaces of glass, mica and platinum. J Am Chem Soc 40:1361–1403

Li YH, Wang S, Luan Z, Ding J, Xu C, Wu D (2003) Adsorption of cadmium(II) from aqueous solution by surface oxidized carbon nanotubes. Carbon 41:1057–1062

Li ZC, Fan HT, Zhang Y, Chen MX, Yu ZY, Cao XQ, Sun T (2011) Cd(II)-imprinted polymer sorbents prepared by combination of surface imprinting technique with hydrothermal assisted sol–gel process for selective removal of cadmium(II) from aqueous solution. Chem Eng J 171:703–710

Madhava Rao M, Ramesh A, Purna Chandra Rao G, Seshaiah K (2006) Removal of copper and cadmium from the aqueous solutions by activated carbon derived from Ceiba pentandra hulls. J Hazard Mater 129:123–129

Min SH, Han JS, Shin EW, Park JK (2004) Improvement of cadmium ion removal by base treatment of juniper fiber. Water Res 38:1289–1295

Mohan D, Singh KP (2002) Single- and multi-component adsorption of cadmium and zinc using activated carbon derived from bagasse-an agricultural waste. Water Res 36:2304–2318

Munagapati VS, Yarramuthi V, Nadavala SK, Alla SR, Abburi K (2010) Biosorption of Cu(II), Cd(II) and Pb(II) by acacia leucocephala bark powder: kinetics, equilibrium and thermodynamics. Chem Eng J 157:357–365

Murray RK, Granner DK, Mayes PA, Rodwell VW (2003) Harper’s illustrated biochemistry, 28th edn. Lange Medical Books/McGraw-Hill Companies, New York

Nabid MR, Sedghi R, Bagheri A, Behbahani M, Taghizadeh M, Oskooie HA, Heravi MM (2012) Preparation and application of poly(2-amino thiophenol)/MWCNTs nanocomposite for adsorption and separation of cadmium and lead ions via solid phase extraction. J Hazard Mater 204:93–100

Nordberg GF, Herber RFM, Alessio L (Eds) (1992) Cadmium in the human environment: toxicity and carcinogenicity. International Agency for Research on Cancer, Lyon

Ossman ME, Mansour MS (2013) Removal of Cd(II) ion from wastewater by adsorption onto treated old newspaper: kinetic modeling and isotherm studies. Int J Ind Chem 4:13

Prasad K, Gopikrishna P, Kala R, Prasada Rao T, Naidu GRK (2006) Solid phase extraction vis-`a-vis coprecipitation preconcentration of cadmium and lead from soils onto 5,7-dibromoquinoline-8-ol embedded benzophenone and determination by FAAS. Talanta 69:938–945

Saeed A, Iqbal M, Holl WH (2009) Kinetics, equilibrium and mechanism of Cd2+ removal from aqueous solution by mungbean husk. J Hazard Mater 168:1467–1475

Say R, Garipcan B, Emir S, Patır S, Denizli A (2002) Preparation and characterization of the newly synthesized metal-complexing-ligand N-methacryloylhistidine having PHEMA beads for heavy metal removal from aqueous solutions. Macromol Mater Eng 287:539–545

Silva MF, Hechenleitner AAW, de Fernandes Oliviera DM, Agüeros M, Penalva R, Irache JM, Pineda EAG (2013) Optimization of maghemite-loaded PLGA nanospheres for biomedical applications. Eur J Pharm Sci 49:343–351

Templeton DM, Liu Y (2010) Multiple roles of cadmium in cell death and survival: a mini review. Chem Biol Interact 188:267–275

Terashima M, Oka N, Sei T, Yoshida H (2002) Adsorption of cadmium ion and gallium ion to immobilized metallothionein fusion protein. Biotechnol Progr 18:1318–1323

Thu PTT, Thanh TT, Phi HN, Kim SJ, Vo V (2010) Adsorption of lead from water by thiol-functionalized SBA-15 silicas. J Mater Sci 45:2952–2957

Türkmen D, Yilmaz E, Öztürk N, Akgöl S, Denizli A (2009) Poly(hydroxyethyl methacrylate) nanobeads containing imidazole groups for removal of Cu(II) ions. Mater Sci Eng C 29:2072–2078

Uygun DA, Şenay RH, Türkcan C, Akgöl S, Denizli A (2012) Metal-chelating nanopolymers for antibody purification from human plasma. Appl Biochem Biotechnol 168:1528–1539

Uygun M, Feyzioğlu E, Özçalışkan E, Caka M, Ergen A, Akgöl S, Denizli A (2013) New generation ion-imprinted nanocarrier for removal of Cr(VI) from wastewater. J Nanopart Res 15(1833):1–11

Wu S, Zhang W, Jia S, Liu Y, Ran J, Ren H, Hou J (2013) Novel pathway for the synthesis of monodisperse MCM-41 nanospheres with different particle size distributions. Mater Lett 98:138–141

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Esen, C., Şenay, R.H., Feyzioğlu, E. et al. Poly(hydroxyethyl methacrylate-co-methacryloylglutamic acid) nanospheres for adsorption of Cd2+ ions from aqueous solutions. J Nanopart Res 16, 2255 (2014). https://doi.org/10.1007/s11051-014-2255-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-014-2255-z