Abstract

In the present work, we have investigated the effect of deposition time on the morphological, structural, and photoluminescence (PL) properties of β-Ga2O3 NWs grown by CVD technique. The diameter and length of the as-grown NWs varied for the deposition time of 1–4 h, from 50 to 100 nm and 5–15 μm, respectively. The crystalline quality of the NWs improved with increasing the deposition time. The detailed transmission electron microscopy (TEM) and fast Fourier Transformation (FFT) measurements revealed that the as-grown β-Ga2O3 NWs were single crystalline. Furthermore, we have studied the variation of PL spectra of the NWs with deposition time and provided an energy band diagram to give a plausible explanation of the origin of different emissions in the PL spectra. The PL spectra showed a broad strong UV-blue emission band and a weak red emission for 1 h deposited sample. We suggested that the UV and red emission from β-Ga2O3 NWs are related to oxygen vacancies and impurities such as nitrogen, respectively. It was observed that the intensity of UV emission decreased with deposition time and this reduction was attributed primarily to the reduction of oxygen vacancies in the NWs.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Monoclinic beta gallium oxide (β-Ga2O3) is a wide bandgap compound semiconductor with bandgap (Eg) of about 4.9 eV (Tippins 1965). The β-form of Ga2O3 has excellent thermal and chemical stability from room temperature (RT) up to melting point (1,800 °C). It shows conduction as well as luminescence properties (Lorenz et al. 1967; Binet and Gourier 1998). It is a transparent conducting oxide (TCO), and thus has potential applications in optoelectronic devices (Edwards et al. 1997; Kumar and Singh 2013). Due to stability at very high temperatures, β-Ga2O3 is useful for high temperature-stable gas sensor (Ogita et al. 1999). The conductivity of β-Ga2O3 depends on the deficiency of oxygen contents because oxygen behaves as shallow donor with ionization energy Ed ~ 30–40 meV (Lorenz et al. 1967). The luminescence of β-Ga2O3 has a very wide range of spectrum from ultraviolet (UV) to visible due to the presence of defect states inside the bandgap. The luminescence properties of β-Ga2O3 depend on the growth conditions such as temperature and impurity concentration. There are a number of reports related to the origin of different emissions from the Ga2O3 (Harwig and Kellendonk 1978; Blasse and Bril 1970; Binet and Gourier 1998). The UV emission is attributed to the recombination of self-trapped excitons. The blue and green emissions originate from transition between electron trapped by oxygen vacancy (VO) and holes captured by gallium-oxygen vacancies (VGa, VO) pair. Furthermore, the red emission originates from β-Ga2O3 NWs due to nitrogen doping (Song et al. 2004).

Recently, the PL properties of β-Ga2O3 nanostructures annealed in different environments (Jangir et al. 2012) were studied, and it was observed that UV-blue emission was affected by annealing in different environments such as oxygen, water vapor and ammonia. In the literature, it has been reported that the UV emission originates from intrinsic transition and thus independent of sample history and impurity concentration. But in one of the reports (Villora et al. 2002) it was mentioned that the UV luminescence did not have an intrinsic nature. According to this report, UV and blue emission depend on the concentration of oxygen vacancies. However, to the best of our knowledge, there are no reports that describe systematically the effect of the deposition time on the structural, morphological, and optical properties of β-Ga2O3 nanostructures.

In the literature, various methods have been employed for the synthesis of β-Ga2O3 nanostructures including arc-discharge method (Lee et al. 2000), physical deposition method (Zhang et al. 1999), carbothermal reduction technique (Liang et al. 2001), laser ablation (Hu et al. 2002),chemical vapor transport (Johnson et al. 2006, Kumar et al. 2014), microwave plasma reaction method (Zhu et al. 2006), and metal–organic chemical vapor deposition (MOCVD) (Chang and Wu 2004a, b). In our study, we have used chemical vapor deposition technique which is well-established and inexpensive.

In the investigation described in this paper, β-Ga2O3 NWs have been synthesized by the CVD technique at temperature 900 °C on gold (Au)-coated silicon (100) substrates using argon as a carrier gas. All the NWs were formed via VLS growth mechanism. We have studied the effect of deposition time on the morphological, structural and optical properties of the β-Ga2O3 NWs. The morphology and size of nanowires were measured using scanning electron microscopy (SEM), whereas the structural analyses were carried out using XRD and TEM. Furthermore, the optical properties of β-Ga2O3NWs were investigated using PL spectroscopy. A reduction in the PL intensity was observed with increasing the deposition time, and the potential reasons for that variation in the PL spectra are also discussed.

Experimental details

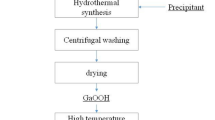

An ultra thin film of Au (2 nm) was deposited on the silicon (100) substrate in a vacuum of 10−5 Torr by thermal evaporation technique. For the formation of nanoparticles in the Au-layer, the samples were annealed at 600 °C for 1 h. Then, β-Ga2O3 NWs were grown using Ga metal with a purity of 99.999 % (Aldrich) as the precursor. About 0.5 g of Ga was placed in a quartz boat, and the Au-coated substrates were clipped over the boat. The whole system was positioned in the centre of a quartz tube, which was placed inside a tube-furnace, and was heat-treated at a temperature of 900 °C for 1, 2, and 4 h. During that process, a constant flow of argon (Ar) gas at the rate of 100–120 bubbles per minute was maintained in the quartz tube at atmospheric pressure. The ramp rate of furnace was 10 °C min−1. After the completion of process, the CVD system was cooled down naturally. During the heat-treatments white wool-like products were formed over the substrates, which later were identified to consist of β-Ga2O3 nanowires.

For the structural characterization of the NWs by XRD, a X-ray diffractometer (Philips Xpert Pro) using CuKα (λ = 1.5405 Å) radiation in 2θ range 20–80° was employed. SEM was performed using a Zeiss EVO-50 system which is dedicated to Energy dispersive X-ray spectroscopy (EDX) by an EDX-detector from Bruker-ASX (Model QuanTax 200). High-resolution transmission electron microscopy (HRTEM) was carried out using a probe Cs-corrected FEI- TITAN 80/300, which was also employed for EDX-measurements. PL measurements were performed at room temperature with an excitation wavelength of 266 nm by use of a luminescence spectrometer RPM 2000 of Accent Optics, USA.

Results and discussion

SEM analysis of β-Ga2O3 NWs

The SEM analysis was carried out to investigate the effect of deposition time on the morphology of β-Ga2O3NWs. Figure 1a shows a typical SEM image of the Au-nanoparticles, which were formed during annealing at 600 °C for 1 h. From the catalyst particles β-Ga2O3 NWs grow during the chemical vapor deposition (CVD). As can be seen on the SEM images in Fig. 1b–d, the NWs distribute uniformly over the Si (100) substrates. However, both the average diameters of the β-Ga2O3 NWs and their length increased with increasing the deposition time. The distributions of diameters are represented with histogram in inset Fig. 1b–d. The average diameters of the β-Ga2O3 NWs are 55 ± 4, 62 ± 3, and 81 ± 3 nm; and the length of the NWs are in the range of 3–5, 7–10, and 10–15 μm for deposition times of 1, 2, and 4 h, respectively. Recently, the similar behavior has also been observed in GaN NWs (Shi and Xue 2011). They studied the effect of reaction time on growth of GaN NWs prepared by CVD method. GaN NWs were grown for different reaction times of 10, 20, 40, and 60 min, and were observed to be highly crystalline after reaction at 1,100 °C for 60 min. The GaN NWs showed diameters from 50 to 100 nm and dozens of micrometers in length. The diameter, length, and crystalline quality of GaN NWs increased with the increase in the reaction time, which agrees with the results of our study.

In addition to the morphology, the chemical composition of the β-Ga2O3 NWs was investigated by EDX. The EDX results showed that the nanowire consist of Ga and O with an atomic ratio of about 2:3, which indicates the formation of β-Ga2O3 NWs. The particles at the tips of the NWs contain a mixture of Ga, O, and Au.

XRD analysis of β-Ga2O3 NWs

A structure and phase purity analysis of the grown β-Ga2O3NWs was performed by XRD. Figure 2 shows typical XRD patterns of the β-Ga2O3 NWs deposited on the Si substrate at 900 °C for different deposition times of 1, 2, and 4 h, respectively. All diffraction peaks in the patterns can be attributed to β-Ga2O3 with monoclinic structure (being in good agreement with the reported β-Ga2O3with the lattice constants a = 12.23 Å, b = 3.04 Å, c = 5.80 Å, and β = 103.7° (JCPDS Card no. 43-1012). Miller indices of β-Ga2O3 were marked in the pattern, and no other crystalline phases were noticed within the detection limit. The XRD results indicate that the as-synthesized NWs are highly pure, single-phase β-Ga2O3. As can be seen in Fig. 2, there are many reflection peaks such as (110), (002), \(\left( {\bar{1}11} \right)\), (111), \(\left( {\bar{3}11} \right)\), \(\left( {\bar{6}11} \right)\), (112), (510), \(\left( {\bar{3}13} \right)\), (113), (020), (512), and (420), the intensities of which increased with the dwell times. That corresponds to an enhancement of the crystalline quality of β-Ga2O3NWs and thus the sample grown for 4 h has the best crystalline quality. Similar results were observed (Sinha et al. 2009), they have grown Ga2O3NWs via self catalytic vapor–liquid–solid method using sol–gel prepared Ga2O3 thin films as substrates for different deposition times of 10, 20, and 45 min. In agreement with our observations the crystalline nature of grown NWs improved with the increasing deposition time and the intensity of peaks was highest for the deposition time of 45 min.

TEM analysis of the β-Ga2O3NWs

For the further structural, morphological, and chemical phenomena of the β-Ga2O3 NWs were investigated using TEM. The low-magnification TEM images in Fig. 3a and b show the general morphology of as-synthesized β-Ga2O3 NWs. The diameter of NWs varies from 50 to 100 nm; and the lengths of NWs are up to several micrometers. Some ripples are also observed inside the NWs which correspond to the bent contours and indicate a bending of the wires under the electron beam (cf Fig. 3b). The TEM image of a single nanowire in Fig. 3c reveals a peel off of the Au catalyst particle from the nanowire by a layer which was proven to contain Ga, O, and Au by EDXS. That clearly indicates the nanowire growth via the VLS mechanism. Figure 3d shows a high resolution TEM image of an individual nanowire. The lattice fringes in the image demonstrate a single crystalline structure of the β-Ga2O3 nanowire which is also verified by the fast Fourier Transform (FFT) image of the wire in Fig. 3e. The white arrow in Fig. 3d indicates the growth direction \(\left[ {\bar{3}92} \right]\) of the nanowire. Lattice fringes of \(\left( {\bar{3}\bar{1}0} \right)\), \(\left( {3\bar{1}\bar{1}} \right)\), and \(\left( {60\bar{1}} \right)\) planes are marked in the image with their distances of 0.241, 0.234, and 0.204 nm, respectively. The measured angles between the indicated planes of \(\left( {3\bar{1}\bar{1}} \right)\) and \(\left( {60\bar{1}} \right)\), \(\left( {60\bar{1}} \right)\)and \(\left( {\bar{3}\bar{1}0} \right)\), \(\left( {\bar{3}\bar{1}0} \right)\) and \(\left( {3\bar{1}\bar{1}} \right)\)planes are ~52.9°, ~124.8°, and ~71.9°, respectively, and correspond to those of the identified β-Ga2O3 structure.

a TEM image showing the general morphology of β-Ga2O3 NWs grown using Au catalyst at 900 °C for 4 h, b–c TEM images of β-Ga2O3 NWs at low and higher magnifications showing VLS growth mechanism and absence of amorphous shells around the NWs, d HRTEM image of a single β-Ga2O3 nanowire. The image was recorded along \(\left[ {1\bar{3}6} \right]\) zone axis.The direction of the wire axis \(\left[ {\bar{3}92} \right]\) is indicated by a white arrow. The d-spacings between the fringes are marked in the image which is overlaid with the model of the β-Ga2O3 structure, e Fast Fourier-Transform (FFT) of the single β-Ga2O3 nanowire in (d) specifying the orientation of the wire axis by the streaks

Energy dispersive X-ray spectroscopy-measurements taken via a line from the nanowire to the catalyst particle are shown in Fig. 4. Corresponding to the STEM image in Fig. 4a, b demonstrates the concentration profiles of Ga and Au across the interfacial region between the nanowire and the catalyst. Only Ga and Au were included into the calculation, which thus yields 100 wt% Ga in the wire. The Ga-concentration (represented by -filled square- in the figure) drops sharply at about 30 nm (demonstrating the interface between wire and catalyst), and the Au-concentration (represented by -filled circle- in the Fig.) starts to increase abruptly at about 30 nm. However, there are shoulders in both steep profiles at a distance of about 32 nm which correspond to the interfacial layer between the wire and the catalyst already shown in Fig. 3c (Wang et al. 2009). This indicates a certain concentration of Ga at the interface to the Au-particle being consistent with the VLS growth mechanism. The Au-particle itself contains several wt% Ga in a distance of about 15 nm from the interface to the wire, whereas there is no mixing of Au into the nanowire.

The growth mechanism of β-Ga2O3 NWs

We may now discuss growth mechanism involve in our results. There are mainly two growth mechanisms of β-Ga2O3 nanostructures; these are vapor–solid (VS) and vapor–liquid–solid (VLS) mechanism. In case of VLS mechanism, a droplet of catalyst is situated at the tip of the growing nanowire, whereas, in case of VS mechanism, there is no catalytic particle at the tip of the nanowire. In the presented experiments TEM and SEM clearly show Au nanoparticles at the tip of the nanowires, which confirms VLS growth mechanism (Wagner and Ellis 1964; Wacaser et al. 2009). The formation of β-Ga2O3 NWs can be explained by following chemical reaction:

(In the above equation, (s) means solid state and (g) means gaseous state.) The VLS mechanism of β-Ga2O3 NWs can be explained in accordance with the growth of semiconductor GaN NWs (Zhang and Zhang 2003). In analogy to ref. (Zhang and Zhang 2003) three steps of NW generation might be distinguished: (I) metal alloy formation, (II) nucleation of NWs, and (III) growth of β-Ga2O3 NWs.

-

(I)

Metal alloy formation: The thermal reaction in the CVD system vaporizes Ga which will be oxidized due to the presence of oxygen in the CVD atmosphere. An Au–Ga–O alloy is formed between Au and oxidized Ga vapor at about 450 °C.

-

(II)

Nucleation of NWs: The surface of the liquid Au catalyst alloy acts as favorable site for absorption of oxidized Ga vapor. As the concentration of Ga2O3 increases in the Au–Ga–O alloy, the Au–Ga–O alloy enters into a biphasic region of Au–Ga–O alloy and Ga2O3 crystal. The nucleation of nanowires will start at this point. The volume of the Au–Ga–O alloy droplet increases gradually, and the Au–Ga–O alloy becomes supersaturated, which supports the growth of Ga2O3 NWs at the liquid–solid interface.

-

(III)

Growth of NWs: Once the nanocrystal of Ga2O3 nucleates at the liquid–solid interface, further dissolution of oxidized Ga vapor into the system will increase the precipitation of Ga2O3 crystal from the Au–Ga–O alloy. The wire like morphology is formed due to the low amount of surface energy which has to be contributed during wire growth. Moreover, the supersaturation of Au–Ga–O alloy continues and the favorable unidirectional growth of Ga2O3 nanowire occurs, as long as, oxidized Ga vapor is supplied and the catalyst remains in liquid form. The nanowire growth stops if the CVD system is cooled down and the alloy droplet solidifies on the tip of the NW.

PL analysis of the β-Ga2O3NWs

The β-Ga2O3 is a wide bandgap compound semiconductor, which shows conduction, as well as luminescence properties. Here, we have studied the variation of PL spectra of β-Ga2O3 NWs with increasing the deposition time. Figure 5a–d shows the PL spectra of the β-Ga2O3 NWs grown for different growth times, and measurements were carried out at RT. In all the samples a broad strong UV-blue emission peak was observed. In addition, a weak red peak also observed in our PL spectra. We deconvoluted the broad emission band, and it was found to consist of four distinct emission peaks with their positions at 345 nm (3.59 eV), 390 nm (3.18 eV), 470 nm (2.64 eV), and 720 nm (1.72 eV), respectively. The first two peaks correspond to UV emission while the third and fourth peaks are related to blue and red emission, respectively. The origin of these emission peaks has been reported in earlier studies also (Harwig et al. 1978; Zhou et al. 2007). In these investigations, the UV emission has been attributed to the recombination of self-trapped excitons. Self-trapped excitons are created when an electron at the donor level (being formed by oxygen vacancies) is captured by a hole at the acceptor level (being formed by gallium (VGa), or pair of gallium and oxygen vacancy (VO, VGa) (Harwig and Kellendonk 1978; Blasse and Bril 1970). The origin of blue emission has been attributed to the recombination of a donor–acceptor pair (DAP) through a tunneling process (Binet and Gourier 1998). In one of the reports (Zhou et al. 2007), the Ga2O3 nanostructures showed a crystalline β-Ga2O3 core and an amorphous shell, consisting of another phase of Ga2O3 such as α-Ga2O3. They suggested that UV and red emissions came from the amorphous shell, whereas the blue and yellow emissions were generated from the crystalline β-Ga2O3 core. It is clearly seen from Fig. 3b that there is no core–shell structure or other amorphous phase of Ga2O3 in our NWs, and hence, the above model cannot be applied for explaining the PL spectra in the present work. Moreover, in one of the reports Villora et al. (Villora et al. 2002) reported that UV emission does not have intrinsic nature as reported previously. They suggested that UV and blue emission depend on the concentration of oxygen (O−2) vacancies. In our work, we have synthesized NWs at very high temperature (900 °C) and thus a large concentration of oxygen vacancies (VO) and gallium-oxygen vacancies (VGa, VO) pairs can be assumed to exist in our NWs. According to our PL results, the intensity of UV-blue emission decreased with increasing the deposition time, which (in accordance with the interpretation of Villora et al. 2002) might be yielded by a decrease in the number of oxygen (O−2) vacancies. For the dwell time of 1 h, there may be enough oxygen vacancies in the Ga2O3 lattice thereby inducing UV emission. As the deposition time increases, the crystallinity improves leading to a reduction in oxygen vacancy concentration and decrease in UV intensity (cf Fig. 5c, d). For the first time, red emission was observed along with a broad blue-green emission in nitrogen doped β-Ga2O3 nanowires (Song et al. 2004). They suggested that the red emission was generated by the recombination of an electron, being trapped on a donor due to oxygen vacancies, and a hole, being trapped on an acceptor due to nitrogen doping (Wang et al. 2011). It is worth mentioning here that our tube-furnace experiments were performed under atmospheric pressure with flowing Ar gas and trace amount of nitrogen was also present in the environment (Vanithakumari and Nanda 2009). Thus, in our experimental results red emission might be attributed to nitrogen impurity from the atmosphere. The nitrogen impurity creates deep acceptor level inside the band gap and this level lies near the middle of the band gap (Song et al. 2004; Vanithakumari and Nanda 2009). We have provided an energy band diagram to give a plausible explanation of the origin of different emissions such as UV, blue, and red in our PL spectra of β-Ga2O3 NWs as shown in Fig. 6.

Conclusions

In summary, we have synthesized the β-Ga2O3 NWs using Au as a catalyst on Si (100) at 900 °C via CVD technique. The structural, morphological, and PL properties of β-Ga2O3 NWs were investigated using XRD, SEM, TEM, and PL. The XRD results suggested that the as-grown NWs have monoclinic crystal structure and the crystalline quality of NWs improved with the deposition time. It has been clearly observed from SEM images that the diameter and length of the NWs increased with the increasing deposition time. The TEM and SEM analysis showed that the growth of NWs was dominated by the VLS process. Furthermore, HRTEM and FFT revealed single crystalline nature of the NWs and these NWs were oriented along \(\left[ {\bar{3}92} \right]\) direction. According to the PL spectra the as-synthesized NWs, which were deposited for 1 h, possess strong UV-blue and weak red emission. The UV emission is related to oxygen vacancies, while red emission may be caused by impurity of nitrogen. The intensity of UV emission of β-Ga2O3 NWs was observed to be reduced with the deposition time which is attributed to the reduction of oxygen vacancies in the NWs.

References

Binet L, Gourier D (1998) Origin of the blue luminescence of β-Ga2O3. J Phys Chem Solids 59:1241–1249

Blasse G, Bril A (1970) Some observations on luminescence of β-Ga2O3. J Phys Chem Solids 31:707–711

Chang K-W, Wu J–J (2004a) Low-temperature growth well-aligned β-Ga2O3 nanowires from a single-source organometallic precursor. Adv Mater 16(6):545–549

Chang K-W, Wu J–J (2004b) Low-temperature catalytic growth of β-Ga2O3 nanowires using single organometallic precursor. J Phys Chem B 108(6):1838–1843

Edwards DD, Mason TO, Goutenoir F, Poeppelmeier KR (1997) A new transparent conducting oxide in the Ga2O3–In2O3–SnO2 system. Appl Phys Lett 70:1706–1708

Harwig T, Kellendonk F (1978) Some observations on photoluminescence of doped beta-gallium sesquioxide. J Solid State Chem 24:255–263

Harwig T, Kellendonk F, Slappendel S (1978) Ultraviolet luminescence of beta-gallium sesquioxide. J Phys Chem Solids 39(6):675–680

Hu JQ, Li Q, Meng XM, Lee CS, Lee ST (2002) Synthesis of β-Ga2O3 nanowires by laser ablation. J Phys Chem B 106:9536–9539

Jangir R, Porwal S, Tiwari P, Mondal P, Rai SK, Ganguli T, Oak SM, Deb SK (2012) Photoluminescence study of β-Ga2O3 nanostructures annealed in different environments. J Appl Phys 112:034307–1–034307-6

Johnson MC, Aloni S, McCready DE, Bourret-Courchesne ED (2006) Controlled vapor–liquid–solid growth of indium, gallium, and tin oxide nanowires via chemical vapor transport. Cryst Growth Des 6(8):1936–1941

Kumar S, Singh R (2013) Nanofunctional gallium oxide (Ga2O3) nanowires/nanostructures and their applications in nanodevices. Phys Status Solidi RRL 7:781–792

Kumar S, Tessarek C, Christiansen S, Singh R (2014) A comparative study of β-Ga2O3 nanowires grown on different substrates using CVD technique. J Alloys Compd 587:812–818. doi:10.1016/j.jallcom.2013.10.165

Lee YH, Choi YC, Kim WS, Park YS, Lee SM, Bae DJ (2000) Catalytic growth of β-Ga2O3 nanowires by arc discharge. Adv Mater 12:746–750

Liang CH, Meng GW, Wang GZ, Wang YW, Zhang LD (2001) Catalytic synthesis and photoluminescence of β-Ga2O3 nanowires. Appl Phys Lett 78:3202–3204

Lorenz MR, Woods JF, Gambino RJ (1967) Some electrical properties of the semiconductor β-Ga2O3. J Phys Chem Solids 28:403–404

Ogita M, Saika N, Nakanishi Y, Hatanaka Y (1999) Ga2O3 thin films for high-temperature gas sensors. Appl Surf Sci 142:188–191

Shi F, Xue C (2011) Influence of reaction time on growth of GaN nanowires fabricated by CVD method. J Mater Sci 22:1835–1840

Sinha G, Dutta A, Panda SK, Chavan PG, More MA, Joag DS, Patra A (2009) Self-catalytic growth and field-emission properties of Ga2O3 nanowires. J Phys D Appl Phys 42:185409–185415

Song YP, Zhang HZ, Lin C, Zhu YW, Li GH, Yang FH, Yu DP (2004) Luminescence emission originating from nitrogen doping of β-Ga2O3 nanowires. Phys Rev B 69:075304–075311

Tippins HH (1965) Optical absorption and photoconductivity in the band edge of β-Ga2O3. Phys Rev 140:A316–A319

Vanithakumari SC, Nanda KK (2009) A one-step method for the growth of Ga2O3-nanorod-based white-light-emitting phosphors. Adv Mater 21:3581–3584

Villora EG, Yamaga M, Inoue T, Yabasi S, Mausi Y, Sugawara T, Fukuda T (2002) Optical spectroscopy study on β-Ga2O3. Jpn J Appl Phys 41:L622–L625

Wacaser BA, Dick KA, Johansson J, Borgstrom MT, Deppert K, Samuelson L (2009) Preferential interface nucleation: an expansion of the VLS growth mechanism for nanowires. Adv Mater 21:153–165

Wagner RS, Ellis WC (1964) Vapor–liquid–solid mechanism of single crystal growth. Appl Phys Lett 4:89–90

Wang GH, Brewer JR, Chan JY, Diercks D, Cheung CL (2009) Morphological evolution of neodymium boride nanostructure growth by chemical vapor deposition. J Phys Chem C 113:10446–10451

Wang GH, Luo G, Soo YL, Sabirianov RF, Lin HJ, Mei WN, Namavar F, Cheung CL (2011) Phase stabilization in nitrogen-implanted nanocrystalline cubic zirconia. Phys Chem Chem Phys 13:19517–19525

Zhang J, Zhang L (2003) Growth of semiconductor gallium nitride nanowires. J Vac Sci Technol B 25:2415–2419

Zhang HZ, Kong YC, Wang YZ, Due X, Bai ZG, Wang J–J, Yu DP, Ding Y, Hang QL, Feng SQ (1999) Ga2O3 nanowires prepared by physical evaporation. Solid State Comm 109:677–682

Zhou XT, Heigl F, Ko JYP, Murphy MW, Zhou JG, Regier T, Blyth RIR, Sham TK (2007) Origin of luminescence from Ga2O3 nanostructures studied using x-ray absorption and luminescence spectroscopy. Phys Rev B 75:125303–125308

Zhu F, Yang ZX, Zhou WM, Zhang YF (2006) Direct synthesis of beta gallium oxide nanowires, nanobelts, nanosheets and nano-grasses by microwave plasma. Solid State Comm 137:177–181

Acknowledgments

The authors gratefully thank the XRD and SEM measurement facilities of IIT Delhi. The authors acknowledge the Nanoscale Research Facility (NRF), IIT Delhi for providing partial financial support for this work. One of the authors (Sudheer Kumar) also acknowledges IIT Delhi for providing research fellowship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, S., Kumar, V., Singh, T. et al. The effect of deposition time on the structural and optical properties of β-Ga2O3 nanowires grown using CVD technique. J Nanopart Res 16, 2189 (2014). https://doi.org/10.1007/s11051-013-2189-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-013-2189-x