Abstract

In this paper, we reported a simple and efficient protocol for preparation of Cu2+-modified magnetic Fe3O4@SiO2 core/shell microspheres for immobilization of cellulase. The uniform magnetic Fe3O4@SiO2 core/shell microspheres with a thin shell of 20 nm were synthesized through a solvothermal method followed by a sol–gel process. An amino-terminated silane coupling agent of (3-aminopropyl)triethoxysilane (APTS) was then grafted on them for capturing Cu2+ ions. The reaction process is very simple, efficient, and economical. Noticeably, the content of Cu2+ ions on the magnetic core/shell microspheres can reach 4.6 Wt%, endowing them possess as high immobilization capacity as 225.5 mg/g for cellulase. And the immobilized cellulase can be retained over 90 % on the magnetic microspheres after six cycles. Meanwhile, the magnetic microspheres decorated with Cu2+ ions show a superparamagnetic character with a high magnetic saturation of 58.5 emu/g at room temperature, suggesting conveniently and rapidly recycle the enzyme from solution. This facile, recyclable, high immobilization capacity and activity strategy may find potential applications in enzyme catalytic reactions with low cost.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Magnetic core/shell silica microspheres have attracted increasing attention due to their unique magnetic responsivity, low cytotoxicity, and chemically liable surface, which have been extensively applied in the fields of biomolecular separation (Bae et al. 2008; Sen et al. 2006), drug delivery (El-Gamel et al. 2011; Kim et al. 2006), cell research (Yu et al. 2009), magnetic resonance imaging (Lee et al. 2010; Zhang et al. 2011), and immunoassays (Wacker et al. 2011). Silica coatings can not only protect the magnetic cores from erosion in acidic solutions, but also effectively screen the intersystem dipolar interactions, and provide a platform for easy surface modification by silanol groups that are useful for practical applications (Xu et al. 2006). Consequently, the silica-coated magnetic microspheres have received more and more focus as promising candidates for wide applications.

In most previous approaches, enzyme immobilization was usually achieved through covalent bonding between the enzymes and the supported substrate surface. This may result in a loss of biological activity because the active sites might be hidden or restricted from the conformation needed to initiate catalysis (Wang et al. 2009; Lee et al. 2009). To improve the activity of the immobilized enzyme, metal ions, which are readily bound to a protein’s histidine residues, are introduced to the support surface (Kim et al. 2009). When an oligopeptide of six or seven histidine residues is linked to the N- or C-terminus of a protein, the His-tagged protein can be strongly immobilized onto the support surface through metal chelates. Specifically, Cu2+ ions can strongly interact with amino chains of proteins due to the high affinity (Kim et al. 2009; Kadir et al. 2012). Some prominent works have been reported on the application of Cu2+ ions-modified magnetic supports in protein separation. Typically, Liu et al. (2010) synthesized magnetic mesoporous core/shell silica microspheres modified with IDA (a carboxy ligand), and subsequently used to chelate Cu2+ ions for separating the hydrophobic/hydrophilic peptides from protein digest solution. Woo et al. (2010) reported magnetic core/shell silica nanospheres anchored with different Cu complexes for immobilization of His-tagged Bacillus stearothermophilus L1 lipase. Gao et al. (2007) prepared carboxy magnetic nanoparticles through a two-step amidation reaction for immobilization of Cu2+ ions with the purpose of removing Microcystins from water. Zhang et al. (2010) synthesized Cu2+-charged IDA-silica-coated Fe3O4 microspheres for the removal of BHb from bovine blood. Although great success has been achieved in the synthesis of magnetic supports with functional ligands for immobilization of Cu2+ ions using in the separation of proteins, the process involves complex synthetic procedures, which are often carried out under harsh experimental conditions, and with use of toxic and expensive regents. Furthermore, none of these reports combined the capacity of effective enzyme immobilization for recycle use. Therefore, development of more facile and feasible routes for enzyme immobilization is important and highly desirable.

Cellulase is a valuable enzyme in practical fields, which can hydrolyze cellulose by cleaving the β-1,4-glucosidic linkages between glucosyl moieties to produce the materials such as dextrins, sirups, and sugar (Ho et al. 2008; Saville et al. 2004). The products are key intermediates for the production of a variety of useful chemicals and biofuels. However, high costs of cellulase used in the catalytic processes have limited its further application. Immobilization of cellulase on magnetic supports seems to perfectly solve the problems. As reported, cellulase has a jelly roll-like structure folded with two antiparallel β-sheets (outer A and inner B). The hydrophilic inner face of β-sheet B forms a long open cleft where the active sites are located, the hydrophilic outer face of β-sheet A is exposed to aqueous solution (Khademi et al. 2002). Large numbers of amino residues such as lysine, histidine, and arginine on the hydrophilic face of β-sheet A, which can interact with Cu2+ ions. It provides a chance for efficient immobilization of cellulase on solid supports.

In the present work, we report a convenient and efficient approach for immobilization of cellulase by Cu2+-modified magnetic Fe3O4@SiO2 core/shell microspheres. The Cu2+ ions are effectively immobilized on the magnetic supports by an amino-terminated silane coupling agent of APTS. And the resulting Fe3O4@SiO2–Cu2+ supports show a superparamagnetic property with high magnetic saturation (Ms) value of 58.5 emu/g at room temperature, meaning cellulase on the magnetic supports can be rapidly and efficiently collected with the help of a magnet. And the Fe3O4@SiO2 microspheres anchored with Cu2+ ions exhibit a high immobilization capacity of 225.5 mg/g for cellulase. Importantly, the enzyme on the magnetic supports shows high activity and stability, which can be retained over 90 % after six cycles. This facile, recyclable, high immobilization capacity and activity strategy promote the cellulase catalytic reactions with low cost. To the best of our knowledge, the use of Cu2+-modified magnetic Fe3O4@SiO2 core/shell microspheres for immobilization of cellulase has not been reported before. The Fe3O4@SiO2 microspheres decorated with Cu2+ ions may have wide applications in enrichment, separation, and purification of biomolecules.

Experimental sections

Materials

Cupric nitrate trihydrate (Cu(NO3)2·3H2O), sodium acetate (NaAc), iron (III) chloride hexahydrate (FeCl3·6H2O), hydrochloric acid (HCl), ammonia (NH3·H2O), ethylene glycol (EG), (3-aminopropyl)triethoxysilane (APTS), tetraethyl orthosilicate (TEOS), and ethanol were obtained from Shanghai Chemical Reagent Co. Ltd. (China). Cellulase was purchased from Aspergillus sp. All chemicals were A.R. grade and used without further purification. Doubled distilled water was used in our experiments.

Synthesis of Fe3O4 microspheres

The magnetic Fe3O4 microspheres were synthesized by a solvothermal reaction as previously described with slight modification (Deng et al. 2005): 2.70 g of FeCl3·6H2O was first dissolved in 100 mL of ethylene glycol under magnetic stirring. A yellow clear solution was obtained after stirring for 0.5 h. Then 7.20 g of NaAc was added to this solution. After being stirred for another 0.5 h, the resultant solution (80 mL) was transferred into a Teflon-lined stainless-steel autoclave with capacity of 100 mL. The autoclave was sealed and heated at 200 °C for 8 h and cooled to room temperature. The black magnetic microspheres were collected with the help of a magnet, followed by washing with recycle of ethanol and distilled water for six times. The product was then dried in vacuum at 60 °C for 12 h.

Synthesis of Fe3O4@SiO2 core/shell microspheres

For preparation of magnetic Fe3O4@SiO2 core/shell microspheres with narrow size distribution and uniform thin silica shell, 0.01 g magnetic Fe3O4 microspheres were first treated in 5.0 mL 2 M HCl aqueous solution under ultrasonic vibration for 5 min. Then, the treated Fe3O4 microspheres were thoroughly washed with distilled water and redispersed in a mixture containing of 70.0 g ethanol, 20.0 g distilled water, and 1.0 g, 28 wt% concentrated ammonia aqueous solution with the help of ultrasonication, and a stable dispersion was obtained. Subsequently, 50 μL TEOS was added to the above dispersion under mechanical stirring, and the reaction was allowed to proceed for 12 h. Finally, the product was separated and collected with a magnet, followed by washing with ethanol and water six times, and redispersed in absolute isopropyl alcohol to form a homogeneous dispersion.

For the surface modification of APTS, the as-prepared dispersion (40 mL) was further diluted in 100 mL isopropyl alcohol containing 0.2 mL APTS under ultrasonication in a water bath. The resultant dispersion was bubbled with nitrogen gas for 30 min, and then heated at 70 °C under mild mechanical stirring for 12 h. Finally, with the help of a magnet, the APTS-modified Fe3O4@SiO2 core/shell microspheres were harvested and repeatedly washed with ethanol and distilled water, and redispersed to form a homogeneous dispersion.

Synthesis of Cu2+-modified Fe3O4@SiO2 core/shell microspheres for cellulase immobilization

The as-prepared APTS-modified Fe3O4@SiO2 core/shell microspheres (10 mL) were then incubated with 20 mL 0.5 M Cu2+ aqueous solution and allowed to react at the temperature of 40 °C for 1 h. The Cu2+-chelated Fe3O4@SiO2 microspheres were then retained by a magnet and the supernatant was removed, followed by washing with distilled water.

For cellulase immobilization, the Cu2+-chelated Fe3O4@SiO2 core/shell microspheres (about 1 mg) were incubated with 10 mL 4 mg/mL cellulase HAc–NaAc buffer aqueous solution (pH 4.5) for 8 h under gentle rotation. After removal of the residual solution, the magnetic microspheres with immobilized cellulase were washed three times with distilled water.

Activity and stability analysis of the immobilized cellulase

The cellulase activity was determined by measuring the hydrolysis degree of sodium carboxymethyl cellulose (CMC, 4 mg/mL in HAc–NaAc buffer solution, pH 4.5). The reactions were initiated by adding the immobilized cellulose. Reaction pH and temperature were maintained at 4.5 and 37 °C, respectively. Glucose released from the CMC hydrolysis was measured with 2-nitrobenzenesulfonic acid reagent using a UV–Vis Spectrophotometer (Ghose 1987). One unit (U) of the cellulase activity was defined as the amount of enzyme required to liberate a 1 μmol of glucose from 4 mg/mL CMC solution in 1 min. After reaction, the support was collected by magnetic separation, washed twice with HAc–NaAc buffer solution, and reused.

The stability of immobilized cellulase on the magnetic support was evaluated by measuring the release amount in HAc–NaAc buffer solution. About 0.10 g above magnetic microspheres immobilized cellulase was dispersed in 10 mL HAc–NaAc buffer solution under gentle shaking. After the magnetic support was collected, the residual solution was detected by a UV–Vis Spectrophotometer. And the collected magnetic microspheres with cellulase were reused for next runs. The released amount in each run can be calculated from the linear equation, which was fitted by using different concentrations of cellulase solution against the absorption peak intensity at 279 nm.

Characterization

Scanning electron microscopy (SEM) with energy-dispersive X-ray (EDX) characterization was performed on Hitachi S-4800 at 10 kV. High-resolution transmission electron microscope (HRTEM) photos and selected area electron diffraction (SAED) patterns were performed on a JEOL-2010 transmission electron microscope. Powder X-ray diffraction (XRD) patterns were collected using a Philips X’Pert PRO SUPER X-ray diffractometer equipped with graphite monochromatized Cu-Kα radiation (λ= 1.54178Å). The magnetic properties were measured with a quantum design magnetic properties measurement system (MPMS) XL-7 superconducting quantum interference device (SQUID). Fourier transform infrared (FTIR) spectra were recorded with a Nicolet 870 instrument. An Ettan DALT twelve Gel Electrophoresis system (GE Instrument Limited, America), and a TU-1901 model UV–Vis double beam spectrophotometer (Beijing Purkinje General Instrument Co., Ltd, Beijing, China) was also used.

Results and discussion

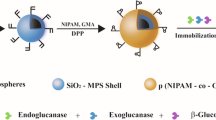

The procedure for the preparation of the Cu2+-modified magnetic Fe3O4@SiO2 core/shell microspheres and the immobilization of cellulase is illustrated in Scheme 1. First, magnetic Fe3O4 microspheres were prepared via a solvothermal reaction, and then the magnetic Fe3O4 microspheres were coated with a thin silica shell generated from the hydrolysis and condensation of TEOS. Subsequently, the obtained magnetic Fe3O4@SiO2 core/shell microspheres were then grafted with numerous amino groups by a silane coupling agent of APTS in isopropanol solution through the alcoholysis reaction, which provided chelate sites (amino groups) on their surface. In the next step, Cu2+ ions were chelated on the surface of the amine-functionalized magnetic Fe3O4@SiO2 microspheres by chelation. Finally, the resulting Cu2+-modified Fe3O4@SiO2 microspheres were applied to efficient immobilization of cellulase by the affinity interaction of the chelated Cu2+ ions with the carboxylic groups and amino groups of cellulase.

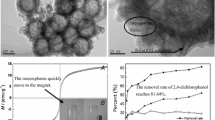

The morphology and structure of the as-synthesized magnetic particles were investigated by TEM and SEM images. From Fig. 1a, b, it can be clearly seen that the magnetic particles have a uniform spherical morphology with a relatively narrow size distribution, whose average diameter is about 250 nm. And the microspheres exhibit a rough surface composed of larger numbers of small primary crystals with a size of 10–15 nm as shown in Fig. 2a, b. The crystalline phase of the as-synthesized microspheres was characterized by XRD. The diffraction peaks such as (220), (311), (400), (511), and (440) planes shown in Figure S1 in the Supporting Information (ESI) could be indexed as inverse spinel structure Fe3O4 (JCPDS card No. 19-0629). When the spherical Fe3O4 particles were encapsulated by silica, the obtained magnetic microspheres with core/shell structure can be clearly seen from Fig. 1c, d. The core/shell microspheres also present a spherical morphology with a size in the range of 280–320 nm. It can be observed that the magnetic cores are fully encapsulated by a thin shell of about 20 nm. The thin fully silica shell can also be seen from Fig. 2c, d. Moreover, the energy-dispersive X-ray (EDX) spectrum shown in Fig. S2 in the ESI of the as-prepared core/shell microspheres present three strong peaks for the elements of O–Si and Fe, which further confirms that the coated thin shell is SiO2 layer. Notably, the introduction of a thin silica layer not only can effectively reduce the screening effects of shells on the magnetic saturation value of the magnetic composite materials, but also provide a silica-like surface for easy modification by silane coupling agent. Of course, the thin silica shell can also protect the magnetic Fe3O4 cores from being etched in practical applications. The most important is that the thin silica coating can make the magnetic particles stably dispersed in water, which is especially important for efficient immobilization of enzymes.

The surface modification of Fe3O4@SiO2 microspheres and further chelating Cu2+ ions with APTS were investigated by FTIR spectra and atomic absorption (AA) spectroscopy. Figure 3 shows FTIR spectra of the as-prepared magnetic particles and the pure APTS. The absorption band at 581 cm−1 in curve a is ascribed to Fe–O–Fe vibrations, which also confirms the magnetic particles are Fe3O4 (Li et al. 2011a; Xuan et al. 2007). In comparison with curve a, the absorption peaks at 1,085 cm−1 in curve b are assigned to the Si–O–Si vibrations, whereas the peaks around 1,630 and 3,400 cm−1 are attributed to the absorbed water and hydroxy groups (Shao et al. 2011). The vibration intensity of the Fe–O–Fe obviously weakened, possibly further confirming that the Fe3O4 particles are coated by silica shell. After modification with APTS (curve c), the peaks detected at 1,720 and 2,940 cm−1 can be assigned to the ester C=O and C–H bonds from the silane APTS (Deng et al. 2010; Li et al. 2011b). And most of the absorption peaks are similar to curve d (pure APTS). The results suggest that APTS is successfully grafted on the surface of the magnetic Fe3O4@SiO2 core/shell microspheres in the present conditions. The amine-functionalized magnetic Fe3O4@SiO2 core/shell microspheres can provide numerous chelate sites for capture of Cu2+ ions. The content of Cu2+ ions can be calculated from the standard curve of atomic absorption-spectrum analysis (shown in Fig. S3 in the ESI). The value is approximately 4.6 Wt%, suggesting a large number of Cu2+ ions are successfully immobilized on the surface of magnetic Fe3O4@SiO2 core/shell microspheres by chelation. Thus, the magnetic Fe3O4@SiO2–Cu2+ microspheres can be used as carrier for efficient immobilization of enzymes.

The magnetic properties of the as-prepared Cu2+-modified magnetic Fe3O4@SiO2 microspheres were investigated using a SQUID magnetometer at temperature range from 1.8 to 300 K under different applied magnetic fields. Figure 4a displays the temperature dependence of magnetization for Cu2+-modified Fe3O4@SiO2 microspheres. The zero-field cooling (ZFC) and field cooling (FC) measurements indicate a superparamagnetic behavior for the core/shell microspheres, and an estimated blocking temperature of 130 K can be obtained from the curves. The superparamagnetic property of the magnetic microspheres is due to the existence of Fe3O4 nanoparticles smaller than 30 nm in the microspheres (Hu and Yu 2006; Wang et al. 2011). The superparamagnetism is critical for their application in biological fields, which can prevent the magnetic particle aggregating and enable them to redisperse rapidly in solution once the magnetic field is removed. Figure 4b shows the magnetic hysteresis loop measured at 1.8 K cooled in the ZFC mode. It is clear that the Fe3O4@SiO2–Cu2+ microspheres are ferromagnetic at 1.8 K with a coercivity force of 130 Oe. When the hysteresis loop measured at 300 K, the curve indicates that Fe3O4@SiO2–Cu2+ microspheres possess a high magnetic saturation (Ms) value of about 58.5 emu·g−1 at room temperature, which implies strong responsivity of the composite microspheres. The high Ms value is possibly contributed by the high Fe3O4 content in the magnetic core/shell microspheres. By dissolving the silica shell with concentrated NaOH (10 M), it can be calculated that the magnetite content was about 92 wt%. It is in agreement with the TEM observation. The magnetic separability of such magnetic Fe3O4@SiO2–Cu2+ microspheres was tested in water by placing a magnet near the glass bottle (shown as an inset in Fig. 4c). The microspheres were attracted toward the magnet within 30 s, further clearly suggesting the strong magnetic responsivity of the Fe3O4@SiO2–Cu2+ microspheres. Nitrogen adsorption–desorption measurements were further used to characterize the surface structures of the magnetic products. As shown in Fig. S4 in the ESI, measurements of the Brunauer–Emmett–Teller specific surface area yield 32.6, 18.5, 16.2, and 13.4 m2/g for Fe3O4, Fe3O4@SiO2, Cu2+-modified Fe3O4@SiO2, and cellulose/Cu2+-modified Fe3O4@SiO2 microspheres, respectively. An obvious decrease in surface area was observed when SiO2 coating was introduced for enlarging the diameter in comparison with Fe3O4 microspheres. Further, as Cu2+ ions and cellulase were introduced onto the surface of the core/shell microspheres, their surface area slightly decreased as well. Although subsequent introduction of coating shell decreases the total surface area, there still remains sufficient interfacial area for adsorbing Cu2+ ions and immobilization of cellulase. Thus, the Cu2+- modified Fe3O4@SiO2 core/shell microspheres with high MS and large surface area can be used for fast and efficient separation and enrichment of biomacromolecules that specifically interact with the immobilized Cu2+ ions.

The large number of immobilized Cu2+ ions and superparamagnetism endows the Fe3O4@SiO2–Cu2+ microspheres to efficiently enrich cellulase by chelating with amino and carboxylic groups of the enzyme. Figure 5a shows FTIR spectrum of the immobilized cellulase by Fe3O4@SiO2–Cu2+ microspheres. Except for the peaks at 581 cm−1 (Fe–O–Fe vibrations) and 1,085 cm−1 (Si–O–Si vibrations) (Shao et al. 2011), the other peaks centered at 1,652, 1,542, and 1,241 cm−1 are assigned to be amide I, II, and III bands of cellulase and are owing to carbonyl stretching, and N–H and C–N stretching vibrations in the amide linkages of the enzyme, respectively (Li et al. 2007; Ma et al. 2005). The bands at 2,983 and 2,904 cm−1 are characteristic of stretching vibrations of methyl groups of cellulase. Notably, the activity of the immobilized enzyme is an important parameter for evaluating the immobilization method. Figure 5b displays the activity comparison of the immobilized with native cellulase. The relative activity of the immobilized cellulase is about 87.6 %, which is obvious higher than the immobilized cellulase by covalent method (Yu et al. 2008). The slight loss of cellulase activity after immobilized by Cu2+ ions may be caused by the bulk magnetic core/shell microspheres, which possibly decrease the enzyme dynamics, resulting in a lower reaction rate (Yu et al. 2008). It is worthy noting that the activity of the immobilized celluase can still maintain 37.5 % after reused ten times, suggesting that the celluase immobilized by the present method may have important application value. SDS-PAGE analysis (shown in Fig. 5c) further confirmed the cellulase immobilization. From the lane III in Fig. 5c, one can find that the molecular weight (MW) of the immobilized cellulase is 64.5 and 51.2 KD, which is similar to the native cellulase. The above results indicate that cellulase with relative high activity can be immobilized on the surface of Fe3O4@SiO2–Cu2+ microspheres by chelation effects.

a FTIR spectrum of cellulase immobilized by the magnetic Fe3O4@SiO2–Cu2+ microspheres. b The activity comparison of the immobilized with native cellulase. Curve I is the native cellulase, curve II is the cellulase immobilized by the magnetic microspheres, and curve III is the immobilized cellulase after reused ten times. c SDS-PAGE analysis of native cellulase and the enzymes released from the magnetic microspheres. Lane I is the molecular weight marker, lane II is the native cellulase without His-tag, lane III is the cellulase immobilized by the magnetic microspheres, and lane IV is the cellulase immobilized by conventional covalent method

In order to investigate the immobilization capacity of cellulase on the magnetic Fe3O4@SiO2–Cu2+ microspheres, some reaction parameters such as reaction time, pH value, and the concentration of cellulase were considered. UV–Vis spectra of different concentrations of cellulase solution are shown in Fig. S5 in the ESI. It demonstrates that the intensity of the absorption peak progressively increased with the concentration of the cellulase in the range of 0.01 ~ 1.0 mg/mL. The relative linear equation of cellulase concentration versus absorbance at 279 nm can be expressed as A = 0.5415C + 0.00531 (R = 0.99996). The immobilization capacity of cellulase on the magnetic Fe3O4@SiO2–Cu2+ microspheres can be calculated by the following equation (Zhou et al. 2009):

where Q is the immobilization capacity (mg/g), A 0 is the absorbance of the initial cellulase solution, A is the absorbance of the cellulase solution after immobilization, C 0 is the concentration of initial cellulase solution, V 0 is the volume of cellulase solution before immobilization, and m is the mass of the magnetic Fe3O4@SiO2–Cu2+ microspheres.

The effect of reaction time on the immobilization capacity of cellulase by the Cu2+-modified Fe3O4@SiO2 core/shell microspheres is shown in Fig. 6a. As can be seen, the immobilization capacity of cellulase gradually increased with time in the period of 8 h. Then the immobilization capacity arrives to the platform region after time of 8 h. The saturation immobilization capacity of the magnetic core/shell microspheres to cellulase can reach as high as 225.5 mg/g at reaction time of 8 h. Figure 6b exhibits the effect of cellulase concentration on the immobilization capacity by the composite magnetic microspheres. It can be observed that the immobilization capacity progressively improved within the cellulase concentration of 4 mg/ml, and the saturation immobilization capacity of the magnetic microspheres to cellulase is calculated of about 224.0 mg/g at the present condition. Figure 6c displays the effect of pH on the immobilization capacity by the composite magnetic microspheres. It demonstrates that the immobilization capacity of cellulase locates at high level at pH between 4.0 and 5.0, whereas the capacity sharply dropped when pH is higher than 4.5. This may be due to the positive charge of cellulase at higher pH. The saturation immobilization capacity of the magnetic microspheres to cellulase is about 216.0 mg/g with pH value of 4.5.

The effects of reaction time a with initial cellulase concentration of 4 mg/mL, pH 4.5; b cellulase concentration with initial pH of 4.5, reaction time of 10 h; and c pH value with initial cellulase concentration of 4 mg/mL, reaction time of 10 h on the immobilization capacity of cellulase on the magnetic microspheres. The content of the magnetic microspheres: 1 mg; the total volume of cellulase solution: 10 mL

Although the as-prepared magnetic Cu2+-modified Fe3O4@SiO2 microspheres exhibit higher immobilization capacity for cellulase, the stability during enzymic catalytic reactions is also important in view of its applications. To evaluate the stability and efficiency of immobilized cellulase by the Cu2+-modified magnetic microspheres, the circulating runs in the buffer solution (pH 4.5) were investigated. As shown in Fig. 7a, it can be seen that the absorption peak slowly weakened with increasing circulating runs. The loss weight of the immobilized enzyme after each run in the buffer solution can be calculated by the linear equation (A = 0.5415C + 0.00531), and the results are shown in Table S1 in the ESI and Fig. 7b. As expected, the enzyme is retained on the magnetic support over 90 % after six cycles, this very slight drop after each cycle (<1.5 %) was likely caused by the slight loss of magnetic support during separation and transfer between cycles. The release cellulase is much smaller than that immobilized on the magnetic supports. It means that the enzyme is strongly immobilized on the composite magnetic support. The results suggest that the cellulase immobilized by the Cu2+-modified magnetic microspheres present high stability and activity, which is very important for its practical applications. Furthermore, the high Ms value of the as-prepared Cu2+-modified magnetic microspheres is also favorable for the separation and recycling of such catalysts by simple magnetic separation.

Conclusions

In this study, we successfully prepared Cu2+-modified magnetic Fe3O4@SiO2 core/shell microspheres for immobilization of cellulase by a facile approach. The as-prepared Cu2+-modified magnetic microspheres possess high immobilization capacity for cellulase, and the immobilization process is very facile, efficient, and economical. The cellulase immobilized by the Cu2+-modified magnetic microspheres display high activity and stability. It is worth noting that the immobilized cellulase can be easily collected from solution with the help of a magnet. This recyclable, high immobilization capacity and activity strategy make the cellulase catalytic reactions low cost. It means that this technical can be widely used in practical applications such as immobilization of enzymes, enrichment, separation or purification of proteins, etc.

References

Bae DR, Lee SJ, Han SW, Lim JM, Kang D, Jung JH (2008) Au-doped magnetic silica nanotube for binding of cysteine-containing proteins. Chem Mater 20:3809–3813

Deng H, Li X, Peng Q, Wang X, Chen J, Li Y (2005) Monodisperse magnetic single-crystal ferrite microspheres. Angew Chem Int Ed 44:2782–2785

Deng Y, Cai Y, Sun Z, Liu J, Liu C, Wei J, Li W, Liu C, Wang Y, Zhao D (2010) Multifunctional mesoporous composite microspheres with well-designed nanostructure: a highly integrated catalyst system. J Am Chem Soc 132:8466–8473

El-Gamel NEA, Wortmann L, Arroub K, Mathur S (2011) SiO2@Fe2O3 core-shell nanoparticles for covalent immobilization and release of sparfloxacin drug. Chem Commun 47:10076–10078

Gao M, Deng C, Fan Z, Yao N, Xu X, Yang P, Zhang X (2007) A simple pathway to the synthesis of magnetic nanoparticles with immobilized metal ions for the fast removal of microcystins in water. Small 3:1714–1717

Ghose TK (1987) Measurement of cellulase activities. Pure Appl Chem 59:257–268

Ho KM, Mao X, Gu L, Li P (2008) Facile route to enzyme immobilization: core–shell nanoenzyme particles consisting of well-defined Poly(methyl methacrylate) cores and cellulase shells. Langmuir 24:11036–11042

Hu X, Yu JC (2006) Microwave-assisted synthesis of a superparamagnetic surface-functionalized porous Fe3O4/C nanocomposite. Chem Asian J 1:605–610

Kadir MA, Kim SJ, Ha E-J, Cho HY, Kim B-S, Choi D, Lee S-G, Kim BG, Kim S-W, Paik H-J (2012) Encapsulation of nanoparticles using nitrilotriacetic acid end-functionalized polystyrenes and their application for the separation of proteins. Adv Funct Mater 22:4032–4037

Khademi S, Zhang D, Swanson SM, Wartenberg A, Witte K, Meyer EF (2002) Determination of the structure of an endoglucanase from Aspergillus niger and its mode of inhibition by palladium chloride. Acta Crystallogr D 58:660–667

Kim J, Lee JE, Lee J, Yu JH, Kim BC, An K, Hwang Y, Shin C-H, Park J-G, Kim J, Hyeon T (2006) Magnetic fluorescent delivery vehicle using uniform mesoporous silica spheres embedded with monodisperse magnetic and semiconductor nanocrystals. J Am Chem Soc 128:688–689

Kim H, Kwon H-S, Ahn J, Lee C-H, Ahn I-S (2009) Evaluation of a silica-coated magnetic nanoparticle for the immobilization of a His-tagged lipase. Biocatal Biotransformation 27:246–253

Lee KS, Woo MH, Kim HS, Lee EY, Lee IS (2009) Synthesis of hybrid Fe3O4-silica-NiO superstructures and their application as magnetically separable high-performance biocatalysts. Chem Commun 3780–3782

Lee JE, Lee N, Kim H, Kim J, Choi SH, Kim JH, Kim T, Song IC, Park SP, Moon WK, Hyeon T (2010) Uniform mesoporous dye-doped silica nanoparticles decorated with multiple magnetite nanocrystals for simultaneous enhanced magnetic resonance imaging, fluorescence imaging, and drug delivery. J Am Chem Soc 132:552–557

Li S, Shen Y, Xie A, Yu X, Qiu L, Zhang L, Zhang Q (2007) Green synthesis of silver nanoparticles using Capsicum annuum L. extract. Green Chem 9:852–858

Li S-K, Huang F-Z, Wang Y, Shen Y-H, Qiu L-G, Xie A-J, Xu S-J (2011a) Magnetic Fe3O4@C@Cu2O composites with bean-like core/shell nanostructures: synthesis, properties and application in recyclable photocatalytic degradation of dye pollutants. J Mater Chem 21:7459–7466

Li S-K, Guo X, Wang Y, Huang F-Z, Shen Y-H, Wang X-M, Xie A-J (2011b) Rapid synthesis of flower-like Cu2O architectures in ionic liquids by the assistance of microwave irradiation with high photochemical activity. Dalton Trans 40:6745–6750

Liu S, Chen H, Lu X, Deng C, Zhang X, Yang P (2010) Facile synthesis of Copper(II) immobilized on magnetic mesoporous silica microspheres for selective enrichment of peptides for mass spectrometry analysis. Angew Chem Int Ed 49:7557–7561

Ma Z, Guan Y, Liu X, Liu H (2005) Covalent immobilization of albumin on micron-sized magnetic poly(methyl methacrylate-divinylbenzene-glycidyl methacrylate) microspheres prepared by modified suspension polymerization. Polym Adv Technol 16:554–558

Saville B, Khavkine M, Seetharam G, Marandi B, Zuo Y-L (2004) Characterization and performance of immobilized amylase and cellulase. Appl Biochem Biotechnol 113:251–259

Sen T, Sebastianelli A, Bruce IJ (2006) Mesoporous silica–magnetite nanocomposite: fabrication and applications in magnetic bioseparations. J Am Chem Soc 128:7130–7131

Shao M, Ning F, Zhao J, Wei M, Evans DG, Duan X (2011) Preparation of Fe3O4@SiO2@Layered double hydroxide core–shell microspheres for magnetic separation of proteins. J Am Chem Soc 134:1071–1077

Wacker JB, Parashar VK, Gijs MAM (2011) Anisotropic magnetic porous assemblies of oxide nanoparticles interconnected via silica bridges for catalytic application. Langmuir 27:4380–4385

Wang W, Xu Y, Wang DIC, Li Z (2009) Recyclable nanobiocatalyst for enantioselective sulfoxidation: facile fabrication and high performance of chloroperoxidase-coated magnetic nanoparticles with iron oxide core and polymer shell. J Am Chem Soc 131:12892–12893

Wang Y, Li S, Xing X, Huang F, Shen Y, Xie A, Wang X, Zhang J (2011) Self-Assembled 3D flowerlike hierarchical Fe3O4@Bi2O3 core–shell architectures and their enhanced photocatalytic activity under visible light. Chem 17:4802–4808

Woo E, Ponvel KM, Ahn I-S, Lee C-H (2010) Synthesis of magnetic/silica nanoparticles with a core of magnetic clusters and their application for the immobilization of His-tagged enzymes. J Am Chem Soc 20:1511–1515

Xu X, Deng C, Gao M, Yu W, Yang P, Zhang X (2006) Synthesis of magnetic microspheres with immobilized metal ions for enrichment and direct determination of phosphopeptides by MALDI-TOF-MS/MS. Adv Mater 18:3289–3293

Xuan S, Hao L, Jiang W, Gong X, Hu Y, Chen Z (2007) Preparation of water-soluble magnetite nanocrystals through hydrothermal approach. J Magn Magn Mater 308:210–213

Yu C-C, Lin P-C, Lin C-C (2008) Site-specific immobilization of CMP-sialic acid synthetase on magnetic nanoparticles and its use in the synthesis of CMP-sialic acid. Chem Commun 1308–1310

Yu J, Zhao H, Ye L, Yang H, Ku S, Yang N, Xiao N (2009) Effect of surface functionality of magnetic silica nanoparticles on the cellular uptake by glioma cells in vitro. J Mater Chem 19:1265–1270

Zhang M, Cheng D, He X, Chen L, Zhang Y (2010) Magnetic silica-coated sub-microspheres with immobilized metal ions for the selective removal of bovine hemoglobin from bovine blood. Chem Asian J 5:1332–1340

Zhang L, Zhang F, Dong W-F, Song J-F, Huo Q-S, Sun H-B (2011) Magnetic-mesoporous Janus nanoparticles. Chem Commun 47:1225–1227

Zhou J, Meng L, Lu Q, Fu J, Huang X (2009) Superparamagnetic submicro-megranates: Fe3O4 nanoparticles coated with highly cross-linked organic/inorganic hybrids. Chem Commun 6370–6372

Acknowledgments

This work is supported by the National Science Foundation of China (Grants 50973001, 21301001, 21303002), the Key Project of Anhui Provincial Education Department (KJ2011A021), Anhui Provincial Natural Science Foundation (1208085QB43, 1208085QB35, 11040606Q01), the Science Foundation for Excellent Youth Scholars of Higher Education of Anhui Province (2011SQRL016ZD), the Research Fund for the Doctoral Program of Higher Education of China (Ref. No.: 20123401120004), the Foundation of Key Laboratory of Environment-friendly Polymer Materials of Anhui Province (KF2012010).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Li, SK., Hou, XC., Huang, FZ. et al. Simple and efficient synthesis of copper(II)-modified uniform magnetic Fe3O4@SiO2 core/shell microspheres for immobilization of cellulase. J Nanopart Res 15, 2013 (2013). https://doi.org/10.1007/s11051-013-2013-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-013-2013-7