Abstract

A small- and wide-angle X-ray scattering (SWAXS) technique using a laboratory X-ray source is reported in this article. This non-destructive SWAXS technique allows simultaneous measurements of the primary particle or pore size, surface and mass-fractal dimensions, as well as quantitative determination of the crystallite properties, like phase identification, the co-existence of crystallite components, and their fractions. Some selected experimental results of the SWAXS study of the metallic and oxide nanostructured particles (such as pure Silver nanoparticles, commercial AEROXIDE® TiO2 P25, Nickel and Nickel oxide nanoparticles as well as Titanium nanoparticles generated by a laboratory electric discharge generator) are presented and discussed in detail, covering a size range of 1–50 nm. The results obtained by SWAXS are compared to those observed with the transmission electron microscope and scanning electron microscope, as well as the XRD reference patterns from the RRUFF database, showing good agreement. In addition, a comparison between powder and dispersion measurements was carried out for estimating the existence and accessibility of microporous structures inside the synthesized nanoparticles, as well as the fraction of open pores. Because of many advantages, such as the high intensity of the primary beam while using a conventional laboratory X-ray source equipped with unique X-ray focusing optics, a short measurement time can be realized. By noninvasive simultaneous measurement of SAXS and WAXS spectra using a single detector; this unique technique allows for fast and extensive in-situ characterizations of metal and metal oxide nanoparticles, respectively, as well as nanostructured materials in many other potential application fields.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nanostructured particles are of great industrial and scientific interest because of their special properties and numerous potential applications in optics, electronics, biomedicine, etc. Techniques for synthesizing nanoparticles are usually grouped into three main categories: mechanical processes, chemical synthesis in gas or liquid phases, and physical processes. Recently, a physical synthesis method for the fabrication of metallic nanoparticles called electric discharge in the inert gas phase has been considered as a green and sustainable synthesis process, which is suitable for scale-up due to the advantages reviewed by Kruis et al. (1998), since the spark discharge process was first described by Schwyn et al. (1988). This method allows for high-purity products, yields no liquid by-products, and requires no hazardous precursors, solvents, and stabilizers, leading to more economic particle separation from carrier gas than in liquid. Using spark discharge, it is possible to obtain high-temperature phases and even create alloys of normally immiscible metals (Tabrizi et al. 2010). A detailed presentation of the state-of-the-art on the synthesis of metallic nanoparticles by spark discharge can be found in (Tabrizi 2009; Tabrizi et al. 2009).

The product-related qualities like primary particle size, particle shape, surface, crystalline structure, and agglomeration state play a very important role in the properties of the synthesized nanoparticles. In order to establish better understanding of the influence of process parameters on the synthesized particle quality, it is necessary to monitor the particle properties online with proper measurement techniques. Characterization of nanoparticles can be done by means of a variety of different common techniques (Linsinger et al. 2012), such as atomic force microscopy (AFM), centrifugal liquid sedimentation (CLS), dynamic light scattering (DLS), scanning mobility particle sizer (SMPS), gas adsorption for determination of the specific surface area (BET), transmission or scanning electron microscopy (TEM, SEM), X-ray diffraction (XRD), small-angle neutron or X-ray scattering (SANS, SAXS), and so on. The latter X-ray methods show several advantages in comparison with the others, like determination of the information on the primary particles, agglomerates, and crystalline structure with higher statistical quality, capability of analyzing aerosols as well as dispersions and powders. These methods can be distinguished by their scattering angles. At small angles (SAXS), the primary particle size and the morphology can be determined, whereas at wide angles (WAXS), information on the crystallinity can be obtained. Using a synchrotron X-ray source, e.g., European Synchrotron Radiation Facility (ESRF, in Grenoble, France), it is possible to realize time-resolved in-situ measurement of particle size and crystallinity because of its extremely high intensity of the primary beam. However, utilizing external synchrotron radiation seems to be not practical for the in-situ and online characterization of the nanoparticles at the laboratory. By increasing the primary beam intensity of a laboratory SAXS camera by means of a focused two-dimensional (2D) beam geometry, a rapid determination of nanoparticle size distribution from the experimental SAXS data was shown to be possible (Goertz et al. 2009; Goertz 2011).

The main purpose of this study is to realize simultaneous analysis of primary particle size, surface morphology, and crystallinity in the nanometer regime by only a single measurement using a modified small- and wide-angle X-ray scattering (SWAXS) laboratory camera, which is deemed as promising technique for fast in-situ and online monitoring of nanostructured particles during a synthesis process. “Experiment” section gives an overview of the current SWAXS laboratory camera system, materials that have been used in this study, sample preparation procedure, and a brief description about the data analyses of SAXS and WAXS spectra measured with the SWAXS camera. Some experimental results are presented and discussed in detail in “Results and discussion” section. Finally, some conclusions are drawn.

Experiment

SWAXS laboratory camera system

In this study, the simultaneous SWAXS study of some metallic and oxide nanostructured particles was performed by extending the detection angle 2θ up to 43° on the basis of a pre-existing SAXS laboratory camera (Goertz et al. 2009; Goertz 2011). In comparison with a conventional Kratky camera (Kratky and Glatter 1982; Dingenouts and Ballauff 1998; Dingenouts 1999; Bergmann et al. 2000), the SWAXS camera used herein, as shown in Fig. 1, mainly consists of a laboratory X-ray source (copper anode, X-ray tube KFLCu2K, λ = 0.154 nm, line focus 0.4 mm × 12 mm, Siemens, X-ray generator Kristalloflex 760, Bruker AXS), focusing X-ray optics (a multilayer Göbel mirror for converting the divergent incoming beam into a focusing monochromatic one), a slit collimation system in combination with the Göbel mirror, a measuring chamber, a primary beam stop, and a 2D imaging plate X-ray detector with a wide dynamic range and a high spatial resolution of 25 μm/pixel. Compared with the traditional autoradiographic film, the film-like radiation image sensor used in the current SWAXS system incorporates a much more photosensitive plate comprising a photostimulable phosphor layer which is located between a protective layer and a support film. The resulting digital image allows for quantitation of subtle signal intensity differences over a wide dynamic range of up to five orders of magnitude. Based on the current SWAXS system configuration, the angular resolution of the detector is about 0.0062°, and the resolution of the scattering vector q is about 4.4 × 10−3 nm−1. This special 2D imaging detector records the scattering signal continuously and simultaneously, covering a wide q-range, 0.07 nm−1 < q < 29.9 nm−1, i.e., a continuous detection angle 2θ up to 43°. Besides, an increase in the sample–detector distance can further extend the low q limit. Compared with other most regularly used SAXS/WAXS area detectors, such as ID2 CCD detectors (ESRF, France), VANTEC-2000 detector (NANOSTAR, Bruker AXS, Germany) and Pilatus detector (Rigaku, Japan), the imaging plate detector used in this study provides better spatial resolution. Besides, due to its favorable price and large flexible detection area with high spatial resolution, 2D imaging plate was chosen for our experiments in this study.

It is worth noting that the largest available scattering angle of the current SWAXS system can be further extended for various future applications, such as investigation on the behavior of additional crystalline materials. By simply changing the sample holder inside the measuring chamber, one can measure dry powder samples on a thin film holder, dispersions with a quartz capillary (1-mm internal diameter) as well as aerosols.

Measurements were carried out at a laboratory temperature of 19 °C. In order to minimize the influence of the scattering due to air molecules, the chamber inside the camera system was kept evacuated (P ≤ 1 mbar) during the measurement. The exposure time is adjustable (approx. 2 or 3 min in this study), depending on the sample concentration and electron density difference between the sample and its surrounding medium. The scattering intensity was recorded with a 2D flexible detector simultaneously in the whole range of the available detection angle. Subsequently, the measured pattern was digitized with a scanner (Fujifilm FLA-7000), and transmitted to a computer for further data analyses. This unique measuring system shows the advantage that the SAXS and WAXS spectra can be obtained simultaneously with a single measurement, providing information both on particle characters and crystallite properties. A typical SWAXS curve for an Au powder prepared on an adhesive tape (tesa SE) was plotted in Fig. 2. In the SAXS region (approx. 2θ < 5°), the scattering intensity varies with the scattering angle, whereas in the WAXS region, an obvious peak due to the gold crystal phase (111) was observed at the same time. Some other peaks resulting from the sample holder itself and low parasitical scattering can be removed by means of background subtraction during the data processing.

Materials and sample preparation

Several metallic and oxidic nanostructured particles were studied with the above-introduced SWAXS laboratory camera. Pure metallic nanoparticles, such as Ag and Au powders (purity: 99.99 %; particle morphology: spherical; average particle size: 50 nm; specific surface area: 3.3 m2/g), were obtained from IoLiTec Ionic Liquids Technologies GmbH, Germany. For metallic oxide nanostructured materials, titanium dioxide (AEROXIDE® TiO2 P25 from Evonik Industries AG, Germany) was used (purity: >99.5 %; average particle size: 21 nm; specific surface area: 50 ± 15 m2/g). Besides, Nickel and Nickel oxide nanoparticles (Ni–NiO), and Titanium (Ti) nanoparticles generated by an electric discharge setup were also investigated to assess the properties of the produced primary particles and agglomerates in the electric discharge synthesis process.

For the measurement of powders, the samples under investigation were prepared by carefully placing them on an adhesive tape (tesa SE) and then positioning it in a sample holder inside the measurement chamber. Liquid dispersions of the powders were examined as well. TiO2 nanopowders were dispersed in distilled water. Silver nanoparticles were also dispersed in distilled water, but a small amount of citric acid was added to the silver dispersion so as to minimize the agglomeration of Ag nanoparticles and hence to improve the dispersion stability. The dispersion of Nickel and Nickel oxide nanoparticles was prepared in isopropanol, and it was observed that such a dispersion showed high stability. Before the measurement, all dispersions were pretreated with ultrasonication for about 5 min. The liquid samples were filled into a thin-walled quartz capillary with an internal diameter of 1 mm using a syringe.

For further comparison and observation of the sample’s surface property, a scanning electron microscope (Hitachi, S-4500) was used. Transmission electron microscopy investigations were also performed using a Philips CM12 instrument operating at 120 kV. Samples were prepared by dipping the carbon-coated grids into the diluted dispersions, respectively. Subsequently, these TEM grids were dried in air.

Data analyses

The intensity scattered by the particles inside the X-ray beam was simultaneously recorded within the whole available scattering angle 2θ of the current SWAXS camera (2θ < 90°). Afterward, the scattering intensity recorded on the detector was digitized by means of a scanner (Fujifilm FLA-7000) for further data processing and representation of the scattering intensity curve. A detailed description of the data evaluations, such as data desmearing, normalization, and background subtraction, can be found in the literature (Dingenouts and Ballauff 1998).

At small angles, the SAXS intensity spectra are measured as a function of the scattering vector:

where λ is the wavelength of the incident X-ray beam.

In the low q region, the scattering intensity I(q) decays, following Guinier’s law (Guinier and Fournet 1955; Kratky and Glatter 1982):

where R g is the radius of gyration of the particles, which is defined as the root-mean-square of the distances of all the electrons in the particle from their center of gravity. For a spherical particle with a geometric diameter d p, the relationship between R g and d p is given by \( d_{\text{p}} = 2\sqrt {5/3} R_{\text{g}}, \) and G is the Guinier prefactor:

with r 2e being the electron cross section, C N the particle number concentration, Δρ e the excess electron density defined as the difference between the electron density of the particles and that of the surrounding medium, and V P the particle volume.

In the high q region, the scattering intensity decays with a power law (Schmidt 1991; Beaucage 1996, 2004):

where B is the power-law prefactor, and P is the power-law exponent. The values of the exponent P can be determined from the slopes of linear parts of log I(q) versus log q plots. In general, for surface fractals, 3 < P < 4, the surface-fractal dimension d s is given by d s = 6 − P, and especially for the ideal two-phase structure with sharp boundaries and smooth surfaces; P is equal to 4. For mass fractals, 1 < P < 3, the mass-fractal dimension d m is equal to P, which describes the mass-fractal scaling inside the aggregate.

Recently, the so-called Beaucage-model, global unified approximation equation, has been used to fit the entire scattering curve for different structural levels like primary particles and aggregates, respectively (Beaucage 1995, 1996)

where erf( ) is the error function, and i refers to the differently sized structures.

Equations (2), (4), and (5) can be used to determine the surface morphology, surface- and mass-fractal dimensions as well as the sizes of the primary particles and aggregates.

In contrast to the SAXS spectra, wide-angle X-ray scattering (WAXS) contains useful information on the fine structure, typically crystalline structures. As mentioned above, the scattering intensity at wide angles was simultaneously recorded in a single run, without the need to change the diffraction angle step by step like conventional XRD instruments. Different phases, the so-called fingerprints resulting from the specific crystalline structures, are identified by comparing the peaks in the scattering pattern with the reference database. The mean crystalline size D can be estimated by means of the Scherrer equation (Klug and Alexander 1954):

where λ is the wavelength of the incident X-ray beam, K is the Scherrer constant (0.9), β is the full width at half maximum (FWHM) of the X-ray diffraction peak, and θ is half of the scattering angle.

The experimental data corresponding to the crystal phase peaks at wide angles were fitted with a Gaussian profile, and the fit parameters like position, intensity, and FWHM were obtained for crystal phase identification, determination of the mass fraction of crystal phases, and crystalline size.

Results and discussion

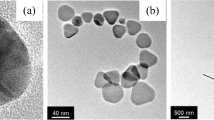

Pure metallic nanoparticles were studied with the current SWAXS camera in two forms (powder and dispersion). This was done to imitate the SWAXS monitoring of the properties of metallic aerosol nanoparticles collected in different ways, such as particles deposited from aerosols on filters, substrates, or in liquids, during the nanoparticle synthesis process. Different amounts of silver powders were placed on the sample supporter, corresponding to three respective measurements at different concentrations, as seen in Fig. 3a. Among these scattering curves, a higher X-ray scattering intensity corresponds to a higher sample concentration. Similarly, the prepared silver dispersion was also measured at two different dilutions, as illustrated in Fig. 3b. The mass ratios of silver particles to water were 0.13 and 1.78 %, corresponding to the measurements 1 and 2 in Fig. 3b, respectively. In the SAXS region, the scattering curves show a similar trend varying with the scattering angle. As described in “Data Analyses” section, a unified model, i.e., Guinier’s law combined with a power law, as expressed in terms of Eqs. (2), (4), and (5), was employed to analyze the SAXS spectra. Guinier fit yields the radius of gyration R g of the silver nanoparticles of 17.9 nm, which corresponds to a geometric particle diameter d p of 46.2 nm. For further comparison and quantitative evidence, a TEM measurement of these silver nanoparticles was conducted. TEM micrographs reveal information on the mean equivalent particle size, e.g., the Feret diameter obtained using software ImageJ, particle shape, and surface morphology. Although SAXS and TEM are two different methods of analysis, the particle sizes from TEM images agree well with those obtained from the SAXS spectra, as seen in the inset of Fig. 3c. As can also be seen from the TEM micrographs, the silver nanoparticles under investigation have a very smooth surface. The particle surface morphology was determined by applying a power law to the SAXS spectra. The surface-fractal dimension is 2.02, corresponding to a power-law decay of q −3.98, very close to q −4 in Porod’s law, as shown in Fig. 3c. With three unified fit parameters B, G, and R g, a dimensionless polydispersity index (PDI) for polydisperse spheres can be determined with the ratio B · R 4g /(1.62G) = 3, corresponding to the condition where the Porod’s power-law decay intercepts the Guinier scattering regime (Beaucage et al. 2004). For monodisperse spheres, the PDI is equal to 1. Besides, with the assumption of a log-normal particle distribution of nearly spherical primary particles, the geometric standard deviation σ g can be expressed with the determined PDI as \( \sigma_{\text{g}} = { \exp }(\sqrt {({ \ln }\;{\text{PDI}})/12} ) = 1. 3 6 { } \).

SWAXS spectra of silver nanoparticles. a Silver powders placed on a sample supporter of a tesa adhesive tape; b silver dispersions; c spectra at small angles (SAXS). Inset is a TEM micrograph; d spectra at wide angles (WAXS), compared with the reference spectra from the RRUFF database (Downs 2006)

In the wide angle range of 2θ > 5°, several peaks were observed, as shown in the insets of Fig. 3a, b. The peak in the powder measurement appears somewhat smoother than that in the dispersion measurement. This is due to a relatively higher particle concentration and electron density contrast in the powder measurement. The peak position 2θ at a value of 38.5° corresponds to the microstructure of the silver crystalline phase (111). The spectrum for this phase (111) was compared with the reference spectrum from the RRUFF database (Downs 2006) as fingerprint verification, as shown in Fig. 3d. Both are consistent with each other. In order to determine the FWHM of the peak, the measured data of this crystalline phase (111) have been fitted with Gaussian profiles. The calculated details of the crystal size are listed in Table 1. The measured crystal size is 29.3 nm.

It is well known that metallic oxide nanoparticles sometimes exhibit different crystalline phases under different conditions, such as at different heating temperatures resulting from inhomogeneous process conditions. These different crystalline phases will have their effects on the particle properties, for instance, the anatase titanium dioxide has a higher photocatalytic activity due to its crystalline structure and is commonly used for photocatalysis (Hashimoto et al. 2005). Therefore, a better understanding of the characteristics will help us control and optimize the synthesis process, improve the product quality, and hence fulfill end-user requirements. Some studies of metallic oxide nanoparticles have been carried out with the current SWAXS laboratory camera, which should prove very useful for the future in-situ online application of this SWAXS system to the nanoparticle synthesis process. A commercial sample, titanium dioxide (AEROXIDE® TiO2 P25 from Evonik, Germany), was used, and the corresponding SWAXS results are displayed in Fig. 4.

SWAXS spectra of metallic oxide nanoparticles TiO2. a Spectra at small angles (SAXS). Inset is a TEM micrograph; b spectra at wide angles (WAXS), compared with the reference from the RRUFF database (Downs 2006); c anatase and rutile phases of TiO2 measured with the SWAXS camera and their corresponding fits with Gaussian profiles

Figure 4a illustrates the measured scattering intensity at small angles. It can be seen that the scattering intensity at relatively high scattering vector q is proportional to q −4, indicating a surface-fractal dimension of 2. This implies that the sample has a smooth surface, which was also observed in the TEM micrograph in the inset of Fig. 4a. Using Guinier’s law in the low q range, the radius of gyration R g determined by fitting was 11.3 nm, corresponding to a primary particle size d p of 29.2 nm. This value was consistent with the TEM measurement. With the unified fit parameters, a dimensionless PDI for polydisperse spheres is 2.8 (σ g = 1.34). Furthermore, in the smaller scattering vector range q < 0.15 nm−1, a power-law fit leads to a fractal dimension of the agglomerates of 2.16.

Figure 4b illustrates the WAXS spectra of TiO2 under investigation. For comparing the peaks, the XRD patterns of pure crystalline anatase and rutile phases of TiO2 from the RRUFF database (Downs 2006) were also plotted, respectively. It is evident that the peaks from both the anatase and rutile phases appear at 25.4° and 27.6° in the WAXS spectra, respectively, agreeing well with the reference patterns. For quantitative estimation of the crystallite size of TiO2, both the anatase (101) peak and rutile (110) peak were fitted with a Gaussian function, as shown in Fig. 4c, yielding the values of the FWHM. The corresponding crystallite sizes were determined with Eq. (6), as given in Table 2.

Furthermore, for mixtures of allotropes, the scattering intensity for each component is substantially proportional to its weight fraction, and so the mass fraction of anatase f a in the anatase–rutile mixture can be estimated from the detected intensities scattered from the strongest anatase peak (101) and the strongest rutile peak (110), expressed as (Spurr and Myers 1957):

where I A and I R are the peak intensities of the anatase phase (101) and rutile phase (110), respectively.

With Eq. (7), the mass fraction of anatase phase is 80.65 %, and rutile phase is 19.35 % on the basis of the integrated intensity ratio (I R/I A) of the rutile and anatase peaks in the observed WAXS spectra. Obviously, this method can be further used to study the crystalline phase transformation by determining the mass fractions of different phases, such as phase transformation due to temperature variation. In addition to WAXS spectra, simultaneously obtained SAXS curves allow for a study of possible correlation between the crystallite-related and particle-characterizing parameters, such as particle size distribution and morphology.

Figure 5 depicts the SWAXS results of nanoparticles synthesized by a laboratory electric discharge generator with nickel electrodes in the carrier gas N2. The generation parameters are as follows: spark discharge with a loading current of 4 mA, a capacitance of 15 nF, a breakdown voltage of 12 kV, both Ni 99.99 % electrodes with a diameter of 3 mm, and carrier gas N2 with a percentage purity of 99.99 % at a flow rate of 0.42 slpm. The scattering curve in the small-angle range indicates a size of 50.60 nm (PDI = 11.3, σ g = 1.57) seen in Fig. 5a, which matches the TEM micrograph in Fig. 5b. At high q region, the scattering intensity decays with a power law, proportional to q −3.49, giving the information on the surface roughness and suggesting that these nanoparticles have a surface-fractal dimension d s of 2.51, which is greater than 2. When the particle surface is very smooth, the surface-fractal dimension d s is equal to 2, i.e., the power-law exponent P in Eq. (4) equals 4. Thus, the measured surface-fractal dimension implies that the particle surface or inner interfaces are to some extent rough, as seen in the TEM micrograph in Fig. 5b. Besides, to observe the particle morphology and microstructure, Fig. 5c shows a SEM micrograph of the nanoparticles synthesized using a laboratory electric discharge generator with nickel electrodes in the carrier gas N2. It can be seen that the individual particles in the agglomerates appear to have been connected with each other and form a porous structure to some extent. The SEM observation also indicates that these particles have rough surfaces.

SWAXS spectra of nanoparticles synthesized by a laboratory discharge generator with nickel electrodes in the carrier gas N2. a Spectra at small angles (SAXS); b TEM micrograph; c SEM micrograph; d comparison of the scattering curves between the dispersion (solid line) and the powder (dots). The shifted curve for the dispersion is plotted with a dashed line; e spectra at wide angles (WAXS)

More interestingly, this study also found that there appears a hump in the scattering curve at 1 nm−1 < q < 5 nm−1, which indicates a dimension related to the formed fine structures characteristic of microporosity. One plausible explanation is that particles were created by agglomeration and sintering of much smaller subunits during the synthesis process. The structures stemming from these much smaller subunits are partly visible as bright interstices on the TEM micrograph in Fig. 5b. These interstices created in between the subunits lead to the fine porous structure. The other plausible explanation for this hump occurring at 1 nm−1 < q < 5 nm−1 is that a porous oxidic structure might be formed on the particle surface during the synthesis process. The unified fit parameters allow for quantitative determination of the pore size, their size distribution, or a dimensionless PDI for the polydisperse spherical model. The measured pore size is 1.85 nm, and the PDI is 4.81 (σ g = 1.44).

To assess the existence and accessibility of the inner fine porous structure, i.e., to check if the pores are of open or closed nature, as suggested by Fairen-Jimenez et al. (2006), a comparison between the powder and dispersion measurements was made. To this end, the nickel nanopowder was dispersed in isopropanol and then measured with SWAXS. The scattering intensity changes with the variation of electron density difference Δρ e between the particle and the surrounding medium (air or isopropanol). For the measurement of the powder, the scattering intensity is proportional to (Δρ e,powder)2 ≈ (ρ e,particle)2. For the measurement of the dispersion, the scattering intensity is proportional to (Δρ e,dispersion)2 ≈ (ρ e,particle − ρ e,isopropanol)2. Scattering curves for the powder and the dispersion, both showing a hump shape, were plotted indicated by dots and a solid line in Fig. 5d, respectively. For further comparison of the shapes of these two scattering curves, the curve for the dispersion was arbitrarily shifted to the profile of the powder. It appears that both curves overlap very well in the range of q < 0.7 nm−1. However, a difference between these two curves was observed in the range of 1 nm−1 < q < 5 nm−1. If there were no closed pores in the particle or the pores were accessible to the surrounding material, then both curves would nearly overlap in the range of 1 nm−1 < q < 5 nm−1 after the shift of the dispersion curve to the powder curve. On the contrary, if there exist some micropores in the particle and if they are closed or too small to be filled with the surrounding liquid, then a relative increase in the excess electron density in the dispersion measurement occurs, resulting in an increased value of the scattering curve in the range of 1 nm−1 < q < 5 nm−1, as shown in Fig. 5d. This indicates that some closed smaller pores or a microporous structure were created within the nickel particles of this synthesized sample. In addition, the fraction of open pores, f o , in this synthesized sample was estimated via analyzing the scattering curves obtained in the powder and dispersion measurements. The hump-shaped scattering curve at 1 nm−1 < q < 5 nm−1 in the dispersion measurement resulted from the contribution of the open pores filled with liquid and the closed pores inaccessible to liquid, i.e., the scattering intensity is proportional to f o·(Δρ e,dispersion)2 + (1 − f o)·(Δρ e,powder)2. Further application of Guinier fit to these two hump-shaped curves led to the radii of gyration of the pores and Guinier prefactors in Eqs. (2) and (3), and thus the fraction of open pores in this synthesized sample f o was determined to be 52 %.

Furthermore, a peak corresponding to the NiO phase (111) in comparison with the reference spectrum (2θ = 37.41°) in the RRUFF database (Downs 2006) was observed at the scattering angle 2θ of 37.38° in the WAXS measurement, as shown in Fig. 5e. The experimental data of the NiO phase (111) peak were fitted with a Gaussian profile, yielding the FWHM and hence a mean crystallite size of 6.72 nm. This implies that although pure nickel electrodes were used to generate aerosol nanoparticles during this electric discharge synthesis process, trace oxygen in the carrier gas led to the formation of nickel oxide. The oxidation of the nickel nanoparticles in this synthesis process may result from the insufficient nitrogen purity (N2 grade 4, percentage purity 99.99 %) and from the possible system leakage due to the loose connection of the setup. As reported by Vons et al. (2011a, b), nanoparticles of pure materials like Si and Mg are known to oxidize even when small amounts of oxygen are present during the spark discharge synthesis process. These small quantities of oxygen were enough to at least partially oxidize such a sensitive metal as nickel used in this study. Therefore, through phase identification and quantification, one can get important feedback information, which helps us further improve and optimize the synthesis process so as to obtain the expected product quality.

In addition, Titanium (Ti) nanoparticles synthesized by a laboratory electric discharge generator were also studied using current SWAXS camera. These nanoparticles were generated using following synthesis process parameters (spark discharge with a loading current of 2 mA, a capacitance of 50 nF, a breakdown voltage of 10 kV, both Ti 99.7 % electrodes with a diameter of 3 mm, and carrier gas N2 with a high percentage purity of 99.999 % at a flow rate of 3 slpm). The experimental scattering spectra are plotted in Fig. 6. The scattering profile shows two structural levels. A power-law regime with a weak slope, corresponding to the mass-fractal scattering (mass-fractal dimension d m = 2.6), was observed for smaller q. These fractal aggregates are composed of nanoscale primary particles. For large q, the scattering from primary particles follows a continuous transition from the primary particle Guinier regime to Porod’s power-law decay (\( I \propto q^{ - 4} \)), implying that the primary particles possess a smooth surface. Combining Guinier fit with Porod’s power law, the unified fit parameters yield a radius of gyration R g of 2.95 nm, and therefore a primary particle size d p of 7.62 nm (PDI = 3.40, σ g = 1.38). TEM observation reveals that these fractal aggregates consist of smooth primary particles (6.3 ± 0.7 nm), as shown in the inset of Fig. 6. The SWAXS observation is consistent with the TEM observation. Due to the high purity (99.999 %) of the carrier gas N2 used in this synthesis process, the detected WAXS spectra did not show the peaks related to the oxides of titanium in this measurement. This implies that the influence of the trace oxygen in this highly purified carrier gas on the oxidation of these prepared titanium nanoparticles was negligible.

Compared with the nickel nanoparticles discussed above, the morphologies of the titanium nanoparticles prepared by spark discharge with different process parameters were nanoscale mass fractals with a fractal dimension d m of 2.6. Beside the material dependence, the flow rate of the carrier gas has influence on the mean primary particle size and the size distribution of the nanoparticles synthesized by spark discharge. Both the cooling and dilution rates are usually expected to be enhanced by increasing the flow rate of the carrier gas, leading to a narrower particle size distribution with a smaller mean diameter. During the synthesis of nickel nanoparticles at a very small flow rate, porous-structured nanoparticles were observed (flow rate = 0.42 slpm, d p = 50.60 nm, PDI = 11.3, and σ g = 1.57). However, with a highly purified carrier gas at a higher flow rate, this synthesis method enables one to produce particles, such as titanium nanoparticles (flow rate = 3 slpm, d p = 7.62 nm, PDI = 3.40, and σ g = 1.38), surfaces of which were so clean that the metal–metal contact had no or negligible diffusion barrier. This helped one form the sintered agglomerates (mass-fractal aggregates), as seen on the TEM micrograph in the inset of Fig. 6.

Conclusions

A simultaneous SWAXS measurement technique realized by means of a laboratory X-ray source was presented, and the properties of some metallic and oxide nanostructured particles have been investigated using this system. Some selected experimental results of metallic and oxide nanoparticles (Ag, AEROXIDE® TiO2 P25, as well as the nickel, and titanium nanoparticles synthesized by a laboratory electric discharge generator) have been discussed in detail. A variety of useful quantitative information on nanostructured particles was obtained with a single measurement per sample simultaneously, including primary particle or pore size, surface roughness, and fractal dimensions from the SAXS spectra, as well as the identification and quantitative determination of the crystallite properties, co-existing crystallite components, and their fractions from the WAXS fingerprints. At small scattering angles, the determined primary particle, surface morphology, and roughness have been compared with the TEM measurements, showing good agreement. At wide scattering angles, the identified phases were consistent with the reference XRD patterns from the RRUFF database. Further combination with the quantitatively determined crystallite properties, such as crystallite size and fractions, provides the possibility to identify and distinguish the co-existing crystallite components, such as in the mixed crystals or in the course of the crystalline phase transformation. Besides, in order to estimate the existence and accessibility of the micropores detected in the synthesized nickel nanoparticles, comparative measurements between powder and dispersion samples were performed. SAXS results indicated that some small closed pores or microporous structures were formed within the nickel nanoparticles of this synthesized sample. The pore size and their size distribution were measured. Meanwhile, the fraction of open pores was determined. Furthermore, to study the dependence of the particle properties on the synthesis procedure, measurement on titanium nanoparticles prepared by an electric discharge with different parameters was performed, showing that besides the material dependence, an increase in the flow rate led to a narrower particle size distribution with a smaller mean diameter. At a very small flow rate, porous-structured nanoparticles were observed during the synthesis of nickel nanoparticles, whereas with a highly purified carrier gas at a higher flow rate, the synthesized titanium nanoparticles had clean surfaces so that the metal–metal contact had no or negligible diffusion barrier. In this case, the sintered agglomerates (mass-fractal aggregates) were formed and observed from the TEM micrograph. The morphologic features of aggregates have been described with the fractal concept and determined from the scattering experiment.

In the current study, our SWAXS measurements have been carried out within a scattering angle 2θ of 43°. However, in some cases, the peaks related to the corresponding crystalline phases of certain materials occur at relatively larger angles and a wider range of the detection angle will be necessary to resolve these. The described methodology is very interesting for analyzing the nanoparticles generated by physical nanoparticle synthesis method under different conditions. The influence of spark characteristics, e.g., energy consumption, duration, and electrode material, etc. on the primary particle size distribution, aggregate morphology and mass production rate remains to be investigated in the future. Due to the advantages of the current laboratory measuring system, e.g., short exposure time and noninvasive simultaneous SAXS and WAXS measurement, this technique will find many other potential applications in the fields of nanostructured materials, such as study of particle formation and growth mechanisms in synthesis process, core–shell particles, and magnetic nanoparticles.

References

Beaucage G (1995) Approximations leading to a unified exponential/power-law approach to small-angle scattering. J Appl Crystallogr 28:717–728

Beaucage G (1996) Small-angle scattering from polymeric mass fractals of arbitrary mass-fractal dimension. J Appl Crystallogr 29:134–146

Beaucage G (2004) Determination of branch fraction and minimum dimension of mass-fractal aggregates. Phys Rev E 70:031401

Beaucage G, Kammler HK, Pratsinis SE (2004) Particle size distributions from small-angle scattering using global scattering functions. J Appl Crystallogr 37:523–535

Bergmann A, Orthaber D, Scherf G, Glatter O (2000) Improvement of SAXS measurements on Kratky slit systems by Göbel mirrors and imaging-plate detectors. J Appl Crystallogr 33:869–875

Dingenouts N (1999) Röntgenkleinwinkelstreuung als Methodik der Strukturanalyse teilgeordneter kolloidaler Systeme. Dissertation, Universität Karlsruhe, Germany

Dingenouts N, Ballauff M (1998) Structural investigation of latexes by small-angle X ray scattering in slit-collimation: measurements and evaluation of data. Acta Polym 49:178–183

Downs R T (2006) The RRUFF project: an integrated study of the chemistry, crystallography, Raman and infrared spectroscopy of minerals. Program and abstracts of the 19th general meeting of the international mineralogical association in Kobe, Japan, O03-13. http://rruff.info/index.php

Fairen-Jimenez D, Carrasco-Marin F, Djurado D, Bley F, Ehrburger-Dolle F, Moreno-Castilla C (2006) Surface area and microporosity of carbon aerogels from gas adsorption and small- and wide-angle X-ray scattering measurements. J Phys Chem B 110:8681–8688

Goertz V (2011) Untersuchungen zur Synthese und zum Wachstum von anorganischen Nanopartikeln in der Flüssig- und Gasphase mit Hilfe der Röntgenkleinwinkelstreuung. Dissertation, Karlsruhe Institute of Technology, Germany

Goertz V, Dingenouts N, Nirschl H (2009) Comparison of nanometric particle size distributions as determined by SAXS, TEM and analytical ultracentrifuge. Part Part Syst Charact 26:17–24

Guinier A, Fournet G (1955) Small angle scattering of X rays. Wiley, New York

Hashimoto K, Irie H, Fujishima A (2005) TiO2 photocatalysis: a historical overview and future prospects. Jpn J Appl Phys 44(12):8269–8285

Klug HP, Alexander LE (1954) X-ray diffraction procedures for polycrystalline and amorphous materials. Wiley, London

Kratky O, Glatter O (1982) Small angle X-ray scattering. Academic Press, London

Kruis FE, Fissan H, Peled A (1998) Synthesis of nanoparticles in the gas phase for electronic, optical and magnetic applications—a review. J Aerosol Sci 29(5/6):511–535

Linsinger T, Roebben G, Gilliland D, Calzolai L, Rossi F, Gibson N, Klein C (2012) Requirements on measurements for the implementation of the European Commission definition of the term “nanomaterial”. JRC Reference Reports 2012, European Commission EUR25404-Joint Research Centre-Institute for Reference Materials and Measurements, ISSN 1831-9424 (online). doi:10.2787/63490

Schmidt PW (1991) Small-angle scattering studies of disordered, porous and fractal systems. J Appl Crystallogr 24:414–435

Schwyn S, Garwin E, Schmidt-Ott A (1988) Aerosol generation by spark discharge. J Aerosol Sci 19(5):639–642

Spurr RA, Myers H (1957) Quantitative analysis of anatase–rutile mixtures with an X-ray diffractometer. Anal Chem 29(5):760–762

Tabrizi NS (2009) Generation of nanoparticles by spark discharge. Dissertation, Delft University of Technology, the Netherlands

Tabrizi NS, Xu Q, Van der Pers M, Lafont U, Schmidt-Ott A (2009) Synthesis of mixed metallic nanoparticles by spark discharge. J Nanopart Res 11(5):1209–1218

Tabrizi NS, Xu Q, Van der Pers N, Schmidt-Ott A (2010) Generation of mixed metallic nanoparticles from immiscible metals by spark discharge. J Nanopart Res 12(1):247–259

Vons VA, Smet LCPM, Munao D, Evirgen A, Kelder EM, Schmidt-Ott A (2011a) Silicon nanoparticles produced by spark discharge. J Nanopart Res 13:4867–4879

Vons VA, Anastasopol A, Legerstee WJ, Mulder FM, Eijt SWH, Schmidt-Ott A (2011b) Low-temperature hydrogen desorption and the structural properties of spark discharge generated Mg nanoparticles. Acta Mater 59:3070–3080

Acknowledgments

The research leading to these results has received funding from the European Union’s Seventh Framework Programme under Grant Agreement No. 280765 (BUONAPART-E). We also acknowledge the support from the German Research Foundation (DFG Ni 414/13-1). We express our immense thanks to Mr. Thomas Lebe for the experimental assistance with TEM and SEM.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, X., Gutsche, A., Wagner, M. et al. Simultaneous SWAXS study of metallic and oxide nanostructured particles. J Nanopart Res 15, 1559 (2013). https://doi.org/10.1007/s11051-013-1559-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-013-1559-8