Abstract

This work provides a new approach for the solution laser synthesis of magnetic Fe/Fe2O3 nanoparticles (15–25 nm average size), as well as core–shell nanoparticles consisting of crystalline Fe/Fe2O3 cores (5–15 nm average size), and amorphous carbon-shells. Laser irradiation of iron pentacarbonyl, Fe(CO)5, in different organic solvents (toluene, tetrahydrofuran, dimethyl sulphoxide, and acetonitrile) using the 532- and 355-nm wavelengths was investigated. The mechanism operating in the laser synthesis involves photodecomposition of Fe(CO)5 and the formation of iron and/or an iron oxide core surrounded by a carbon-shell depending on the nature of the solvent. In the case of toluene as a solvent, a magnetic Fe/Fe2O3 core surrounded by a carbon-shell was formed, while in the other solvents investigated (tetrahydrofuran, dimethyl sulphoxide, and acetonitrile), both Fe and Fe2O3 nanoparticles were formed without carbon-shells. Characterization techniques including X-ray photoelectron spectroscopy, transmission electron microscopy, X-ray diffraction, and Raman spectroscopy were used to determine the composition and morphology of the laser-synthesized magnetic Fe/Fe2O3 nanoparticles and the core–shell nanoparticles. In addition, the data revealed that the Fe/Fe2O3-nanoparticles produced in all the solvents used except tetrahydrofuran had good magnetic properties.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The development of nanotechnology depends on investigating new techniques that can be employed easily and efficiently for the synthesis of novel nanostructured materials with unique electronic, mechanical, and magnetic properties. Iron-based nanostructures (metal (Fe), carbide (Fe3C), and oxides (Fe3O4, magnetite, or γ-Fe2O3, maghemite) attract a great deal of interest in nanotechnology because of their widespread applications (Amendola et al. 2011; Gao et al. 2009; Figuerolaa et al. 2010; Katsoyiannis and Zouboulis 2002; Kay et al. 2006; Lu et al. 2007; McCarthy and Weissleder 2008; Xia et al. 2010), in addition to the biocompatibility of some iron-based materials which makes them especially promising for applications in nanomedicine such as magnetic resonance imaging, selective drug delivery, and magnetic hyperthermia (Gao et al. 2009; Figuerolaa et al. 2010; Xia et al. 2010). Other applications of nanostructured iron oxides include catalysis for water splitting, or for the removal of toxic metals from aqueous solutions (Katsoyiannis and Zouboulis 2002; Kay et al. 2006; McCarthy and Weissleder 2008).

In recent years, a number of methods have been developed for the synthesis of nanoscale iron-based materials with the choice of the method being dictated by the specific applications and materials of interest. The chemical approaches are particularly useful for obtaining colloidal solutions of metal and metal oxide nanoparticles with well-defined shapes and narrow size distributions (Haddad et al. 2009; Mandel et al. 2011; Laurent et al. 2011; Zeng and Sun 2008). While the physical methods such as spray or flame pyrolysis are useful for obtaining nanopowders of oxides and carbides (Buyukhatipoglu and Clyne 2010; Herrmann et al. 2009), most of the methods usually produce agglomerated nanoparticles. On the other hand, wet chemistry synthesis usually requires a controlled atmosphere and expensive and/or toxic chemicals and usually produces pollutant waste. To date there are relatively few studies on the laser assisted synthesis of iron-based nanostructures from solution, mostly based on laser ablation synthesis in solution (LASiS) which consists of the ablation of a bulk target placed at the bottom of a cell containing a selected solvent. LASiS has been successfully applied to metals, oxides, and semiconductor nanoparticles (Amendola et al. 2005, 2006, 2007, 2011; Boyer et al. 2010; Buyukhatipoglu and Clyne 2010; Chen et al. 2004; Dumitrache et al. 2005; Ishikawa et al. 2006; Jakobi et al. 2010 Kwong et al. 2010; Liu et al. 2008; Tsuji et al. 2005; Yang 2007).

The current paper discusses the laser-assisted synthesis and characterization of magnetic Fe/Fe2O3 nanoparticles as well as the core (Fe/Fe2O3)–shell (carbon) composite nanoparticles prepared in different organic solvent environments (from non-polar to highly polar solvents). The main advantage of using photochemical and photothermal methods is the ability to synthesize metal nanoparticles without the use of chemical reducing agents, thus providing a green approach for the synthesis and processing of a variety of nanomaterials and nanocomposites as demonstrated in our previous work (Abdelsayed et al. 2010; Moussa et al. 2011a, b, 2012).

Experimental section

In the experiments, iron/iron oxide nanoparticles were synthesized by laser irradiation of 100 μL of iron pentylcarbonyl (Fe(CO)5) dissolved in 10 mL of different organic solvents (toluene (Tol), tetrahydrofuran (THF), dimethyl sulphoxide (DMSO), and acetonotrile (AN). All chemicals used were of 99.99 % purity purchased from Sigma–Aldrich, USA. All Fe(CO)5 solutions were bubbled with Argon gas for 10 min before laser irradiation with a pulsed Nd:YAG laser (unfocused, second harmonic: = 532 nm, 2 W, hν = 2.32 eV, or third harmonic: = 355 nm, 1 W, hν = 3.49 eV, pulse width s = 7 ns, repetition rate = 30 Hz, Spectra Physics LAB-170-30) under continuous stirring. The iron/iron oxide nanoparticles were separated and dried overnight under vacuum before the X-ray diffraction (XRD) or the X-ray photoelectron spectroscopy (XPS) measurements. TEM images were obtained using a Joel JEM-1230 electron microscope operated at 120 kV equipped with a Gatan UltraScan 4000SP 4 × 4 K CCD camera. High resolution TEM (HRTEM) analysis was performed using a FEI Titan at 300 kV and having an energy dispersive X-ray spectroscopy (EDAX) detector. The preparation of the samples for HRTEM analysis involved depositing a drop (20 μL) of the relevant dispersion or suspension onto lacey carbon copper-coated TEM-grids. The XRD patterns were measured using an X’Pert Philips Materials Research Diffractometer using Cu Ka1 radiation. The XPS analysis was performed on a Thermo Fisher Scientific ESCALAB 250 using a monochromatic Al KR. The preparation of the samples for XPS involved placing 3 mg of each sample on Indium substrate, pressing them, followed by placing them in the preparation chamber over night under vacuum at pressure equal to 10−8 Torr before the XPS-measurements. Absorption spectra were recorded using a Hewlett-Packard HP-8453 diode array spectrophotometer. Raman spectra were carried out using Thermo DXR Raman, which has two laser excitation wavelengths of 532 and 780 nm, using a TE: cooled CCD detector. An excitation wavelength of 532 nm was used in our Raman measurements of the solid samples. Magnetic characterization was carried out using the Quantum Design VersaLab equipped with a Multifunctional platform for magnetic and electric measurements.

Results and discussion

Figure 1a illustrates a schematic representation of the laser-assisted (532 or 355 nm wavelength) synthesis of magnetic Fe/Fe2O3 nanoparticles starting from Fe(CO)5 in different organic solvents. Figure 1b displays digital images of the Fe(CO)5 solution before and after the laser irradiation which reveal the conversion of the yellow solution of Fe(CO)5 (before irradiation) to black (after irradiation) as a result of the formation of the Fe-based nanoparticles. The darkening of the Fe(CO)5 solution is attributed to the photodecomposition of Fe(CO)5 and the formation of iron/iron oxide nanoparticles depending on the solvent environment. Figure 1c, d display the temperature profiles of the laser-irradiated Fe(CO)5 solutions in different organic solvents as a function of time for the 355 nm (1 W, 30 Hz) and 532 nm (2 W, 30 Hz) laser irradiation experiments. The temperature changes are caused by the photothermal energy conversion during the laser photodecomposition of Fe(CO)5. The comparison with pure solvent experiments under identical laser irradiation conditions clearly demonstrates the high photothermal effect accompanied by the photodissociation of Fe(CO)5. Owing to the higher absorption of the 355 nm radiation by the organic solvents, the temperature rise of the pure solvents is more with the 355 nm than with the 532-nm laser irradiation. In both cases (the 532- or the 355-nm laser irradiation), pure solvent samples did not display significant temperature increase within 5 min of laser irradiation (Fig. 1c, d), unlike the temperatures of the Fe(CO)5 solutions which rose above 60 °C under the same laser irradiation conditions. The observed temperature rise reflects the steady state net heat transfer from the photodissociated Fe(CO)5 products to the solvent. The increase absorption by the solvent leads to less efficient photodissociation of Fe(CO)5, and hence lower yield of the iron/iron oxide nanoparticles.

a Schematic representation of the laser-assisted synthesis of Fe/Fe2O3 nanoparticles from the photodecomposition of Fe(CO)5 in different organic solvents. b Digital photographic images of Fe(CO)5 solution in an organic solvent before (yellow colour) and after laser irradiation (black colour). c and d Temperature profiles of the laser-irradiated Fe(CO)5 solutions in different organic solvents as a function of time using the 355 nm (blue lines, 1 W, 30 Hz) and 532 nm (green lines, 2 W, 30 Hz) wavelengths. The temperature profiles of pure solvents in the absence of Fe(CO)5 are shown as dashed lines. (Color figure online)

It has been reported by Dumitrache et al. 2005 that the primary photochemical event of the Fe(CO)5 photodecomposition involves the ejection of CO to form Fe(CO)4, which can participate in further reactions such as cluster formation followed by Fe–CO bond breaking and ultimately a metallic iron will form and CO gas will evolve out of the solution as described below

Indeed this finding was confirmed by both the XRD and XPS data shown in Fig. 2 which displays the XRD patterns (Fig. 2a) and the XPS spectra (Fig. 2b–d) of the nanoparticles formed by the 532 nm (2 W, 30 Hz, dotted lines) and the 355 nm (1 W, 30 Hz, solid lines) laser irradiation of the Fe(CO)5 solutions in different organic solvents using the 355 nm (1 W, 30 Hz) (solid-lines) and the 532 nm (2 W, 30 Hz) (dotted-line) (Fig. 2b–d). The XRD patterns displayed in Fig. 2a revealed that the broad peaks corresponding to α-Fe (reference code: ICCD-03-065-4899) crystalline phase were present when Tol was used as a solvent, while in the case of DMSO and AN solvents, the γ-Fe-crystalline phase (reference code: ICCD-01-089-4185) as well as the Fe2O3 phase (reference code: ICCD-00-39-1346) were present. The broad XRD peaks of the α-Fe formed in the presence of Tol as a solvent indicate that the Fe nanoparticles have very small crystalline sizes in the range of 5–7 nm. In contrast, the use of THF as a solvent resulted in the formation of amorphous Fe-based nanoparticles. Similar results were reported by Zhao et al. 1994 who studied the synthesis of γ-Fe2O3 nanoparticles by laser-induced decomposition of Fe(CO)5. In this study, Fe nanoparticles (20–40 nm) containing 70.6 wt% γ-Fe were prepared by the CW CO2 laser-induced decomposition of Fe(CO)5 (Zhao et al. 1994).

a XRD-patterns of laser-irradiated Fe(CO)5 in organic solvents using the 532-nm wavelength (2 W, 30 Hz), (asterisk) denotes Fe2O3 diffraction pattern. b XPS C 1s, c XPS O 1s, and d XPS Fe2p spectra of laser-irradiated Fe(CO)5 in organic solvents using the 355 nm (1 W, 30 Hz) (solid-lines) and the 532 nm (2 W, 30 Hz) (dotted-line) wavelengths

The surface composition of the nanoparticles was studied by XPS spectra as shown in Fig. 2b, c, d for the C 1s, O 1s, and Fe 2p-electron binding energies, respectively. The results indicate that the Fe is present on the surface of the nanoparticles mainly as Fe2O3 with the observed binding energy of 710.8 for the 2p3/2 and 724 eV for the 2p1/2 photoelectrons consistent with the NIST database (NIST 2012). The formation of Fe2O3 is consistent with the higher tendency of Fe nanoparticles for oxidation (Gangopadhyay et al. 1991; Zhao et al. 1994; Jonsson et al. 1996). Also, the O 1s-electron binding energy (Fig. 1c) revealed two peaks around 530 and 532 eV which could be assigned, respectively, to iron oxide Fe2O3 and undissociated Fe(CO)n (n < 5) resulting from the incomplete decomposition of Fe(CO)5. This later assignment is consistent with the C 1s-electron binding energy spectrum (Fig. 2b) which exhibits two peaks at 284.5 eV corresponding to a graphitic carbon bond (C–C), and a small peak at 288.5 eV which could be assigned to C≡O. It also interesting to note that the peak intensity assigned to CO at 288.5 eV is relatively high in the case of using THF as a solvent indicating the presence of more adsorbed CO species within the carbon matrix in addition to the incomplete decomposition of Fe(CO)5 to iron oxide nanoparticles consistent with the amorphous nature of the sample prepared in THF as shown by the XRD data in Fig. 2a. Similar finding was reported by Ouyang and Hiraoka 1995 who studied the XPS spectra of the films deposited by excimer laser ablation of poly(ferric methacrylate) under different experimental conditions.

Figure 3a illustrates the absorption spectra of the of the laser-irradiated Fe(CO)5 solutions in different organic solvents. All solvents show an absorption shoulder or edge between 300 and 375 nm. It is known that iron-based nanoparticles cannot be easily identified by absorption spectroscopy because they lack sharp absorption bands in this spectral region (Amendola et al. 2011). However, an absorption peak was reported for solutions of iron nanoparticles and was confirmed by calculations performed on iron nanoparticles using the Mie scattering model (Amendola et al. 2011). It should be noticed that the experimental observation of the absorption peak of iron nanoparticles is infrequent in the literature because the particles are usually covered by strongly absorbing organic stabilizers that are not present in the current work. Also, the absorption edge observed at shorter wavelength is compatible with the optical spectra of most iron oxide phases as well as with the presence of amorphous or graphitic carbon. Similar findings were reported by Amendola et al. 2011 and Kwong et al. 2010 who studied the formation of Fe-nanoparticles (Amendola et al. 2011) and the synthesis of noble metal nanoparticles (Kwong et al. 2010) in organic solvents by LASiS.

To confirm the above experimental findings in Figs. 2 and 3a, Raman spectra of the laser-irradiated Fe(CO)5 solutions in different organic solvents were measured. The data shown in Fig. 3b revealed the presence of two broad bands typical of amorphous graphitic carbon at 1,360 (D-band) and 1,595 cm−1 (G-band). In addition, a well-defined Raman feature at 713 cm−1 corresponding to γ-Fe2O3 was identified in the case of DMSO as a solvent, while in the case of Tol and THF both showed weak Raman spectra in the low frequency range of 200–800 cm−1 corresponding to Fe–O bond vibrational stretching, which confirm the presence of small amount of γ-Fe2O3 and α-Fe2O3 on the surface. Similar finding was obtained for the Raman shift study of Fe-encapsulated nanocomposites undergoing passivation in air, which revealed the dominant presence of α-Fe2O3 and γ-Fe2O3 at 350, 478, 503, 570, 623, 650, and 713 cm−1 and as a minor phase Fe3O4 at 663 cm−1 (Dumitrache et al. 2005).

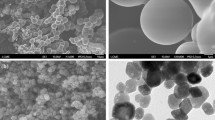

The TEM images of the nanoparticles formed after the 355 nm (1 W, 30 Hz) and the 532 nm (2 W, 30 Hz) laser irradiation of Fe(CO)5 in different organic solvents are displayed in Figs. 4 and 5, respectively. In addition, a HRTEM image and EDS-analysis of the nanoparticles formed by the 355-nm laser irradiation of Fe(CO)5 in Tol are shown in Fig. 4d, e, respectively. The core–shell morphology is clearly observed when Tol is used as a solvent as shown in Fig. 4d. The EDS analysis performed on a single nanoparticle of the core–shell morphology, shown in Fig. 4e, indicates the presence of a graphitic shell with a thickness of 4–6 nm surrounding the Fe-based nanoparticle core. On the other hand, using THF or AN as a solvent during the 355-nm laser irradiation of Fe(CO)5 results in the formation of Fe/Fe2O3 nanoparticles embedded in an amorphous carbon matrix as shown in Fig. 4b, c, respectively. Similar results are obtained using THF or DMSO as a solvent under the 532 nm laser irradiation as shown in Fig. 5b, c, respectively. These results are consistent with the finding of Amendola et al. who reported the formation of a passivating oxide layer of about 4-nm thickness during the LASiS of an iron plate in THF (Amendola et al. 2011). Also, the synthesis of similar nanoparticles has been recently reported where an amorphous cobalt core surrounded by a graphitic shell was obtained by laser ablation of a cobalt target in Tol (Amendola et al. 2011; Kwong et al. 2010). This was explained as a result of the rapid cooling provided by the organic medium (Yang 2007). It is likely that metal atoms were free to interact with atmospheric oxygen dissolved in the solvents to yield iron oxide nanoparticles. The importance of oxygen dissolved in the organic solvents is evidenced from the studies of the LASiS of metals in hexane, cyclopentanone, or acetone, which showed that the chemical interaction between the solvent molecules and the metal atoms does not play an important role in the final composition of the nanoparticles [Boyer et al. 2010; Ishikawa et al. 2006; Sajti et al. 2010; Tsuji et al. 2005). The degree of oxidation was found to decrease with the formation of partially nonoxidized nanostructures as a result of desecrating the solvents. Moreover, the presence of an iron oxide layer surrounding the iron core nanoparticle helps to prevent the oxidation of the core when exposed to atmospheric oxygen at room temperature as discussed elsewhere (Amendola et al. 2011).

The key differences between our laser synthesis methodology and the LASiS process are the starting materials and the different nature of the laser photodecomposition of organometallic compounds operating in our method and the laser ablation of metal targets operating in the LASiS method. In our study, Fe(CO)5 is laser irradiated by an unfocused beam in different organic solvents, while in the LASiS process, a focused laser beam is used for the ablation of a bulk metal target placed in a cell containing the selected solvent (Amendola et al. 2005, 2006, 2007, 2011; Boyer et al. 2010; Buyukhatipoglu and Clyne 2010; Chen et al. 2004; Dumitrache et al. 2005; Ishikawa et al. 2006; Jakobi et al. 2010; Kwong et al. 2010; Liu et al. 2008; Tsuji et al. 2005; Yang 2007).

Figure 6 illustrates qualitatively the magnetic properties of the laser-irradiated Fe(CO)5 in organic solvents using the 532-nm laser (2 W, 30 Hz). The figures display the digital photographs of the irradiated solutions in the absence (left) and the presence of a magnet (right). The photographs revealed that the Fe/Fe2O3 nanoparticles produced in all solvents except THF have good magnetic properties as they are collectively aggregated and attracted to the magnet as shown in Fig. 6a, c, and d. However, in the case of THF as a solvent (Fig. 6b), only few particles seem to be attracted to the magnet and more time is required to see this effect. Indeed this result in the case of Fe-THF can be explained based on the presence of non-magnetic thick graphitic layer covering the iron–iron oxide nanoparticles resulting from the partial decomposition of Fe(CO)5 as discussed earlier. Similar findings were reported elsewhere (Amendola et al. 2011). The data shown in Fig. 6 was confirmed by the quantitative room temperature magnetization measurements shown in Fig. 7, which revealed the magnetic properties of the as-prepared iron–iron oxide core/carbon-shell nanoparticles prepared by the laser photodecomposition of Fe(CO)5 in Tol. According to the data shown in Fig. 7, the bulk saturation magnetization (Ms) and coercivity (Hc) are found to be 66.5 emu g−1 and 40.4 Oe, respectively. A similar value of Hc has been reported by Tang et al. for the Fe/SiO2 coated with nonmagnetic carbon (Tang et al. 2006). Also, according to the literature, the saturation magnetization of bulk magnetite or maghemite is 90 emu/g and for metallic iron is 220 emu g−1 (Amendola et al. 2011). Although these values are higher than measured value for the Fe/Fe2O3-core/carbon-shell nanoparticles reported here, the Fe/Fe2O3-core/carbon-shell nanoparticles offer interesting structure and morphology which could provide better thermal and chemical stability due to the presence of the carbon-shell (Amendola et al. 2011; Tang et al. 2006).

Conclusions

In summary, we presented here a facile method for the laser-assisted synthesis of a variety of magnetic nanostructures in organic liquids by varying the nature of the solvent during the laser photodecomposition of Fe(CO)5 at room temperature and under simple experimental conditions. It was found that the solvent plays an important role in the final composition of the nanostructures formed by the photodecomposition of Fe(CO)5. Nanoparticles containing metallic iron embedded in a dense amorphous organic matrix were obtained in DMSO and acetonitrile. Magnetic nanoparticles with low coercivity and soft magnetic properties comprised of an iron/iron oxide core surrounded by a carbon-shell were obtained in Tol. These nanoparticles could have promising applications in various fields ranging from nanomedicine to the fabrication of soft magnetic devices.

References

Abdelsayed V, Moussa S, Hassan, Aluri H, Collinson M, El-Shall M (2010) Photothermal deoxygenation of graphite oxide with laser excitation in solution and graphene-aided increase in water temperature. J Phys Chem Lett 1:2804–2809

Amendola V, Rizzi G, Polizzi S, Meneghetti M (2005) Synthesis of gold nanoparticles by laser ablation in toluene: quenching and recovery of the surface plasmon absorption. J Phys Chem B 109:23125–23128

Amendola V, Polizzi S, Meneghetti M (2006) Laser ablation synthesis of gold nanoparticles in organic solvents. J Phys Chem B 110:7232–7237

Amendola V, Polizzi S, Meneghetti M (2007) Free silver nanoparticles synthesized by laser ablation in organic solvents and their easy functionalization. Langmuir 23:6766–6770

Amendola V, Riello P, Meneghetti M (2011) Magnetic nanoparticles of iron carbide, iron oxide, iron–iron oxide, and metal iron synthesized by laser ablation in organic solvents. J Phys Chem C 115:5140–5146

Boyer P, Menard D, Meunier M (2010) Nanoclustered Co–Au particles fabricated by femtosecond laser fragmentation in liquids. J Phys Chem C 114:13497–13500

Buyukhatipoglu K, Clyne A (2010) Controlled flame synthesis of α-Fe2O3 and Fe3O4 nanoparticles: effect of flame configuration, flame temperature, and additive loading. J Nanopart Res 12:1495–1508

Chen G, Hong M, Lana B, Wang Z, Lu Y, Chong T (2004) A convenient way to prepare magnetic colloids by direct Nd:YAG laser ablation. Appl Surf Sci 228:169–175

Dumitrache et al (2005) Iron–iron oxide core–shell nanoparticles synthesized by laser pyrolysis followed by superficial oxidation. Appl Surf Sci 247:25–31

Figuerolaa A, Coratob R, Mannaa L, Pellegrinoa T (2010) From iron oxide nanoparticles towards advanced iron-based inorganic materials designed for biomedical applications. Pharm Res 62:126–143

Gangopadhyay et al (1991) Effect of oxide layer on the hysteresis behavior of fine Fe particles. J Appl Phys 70:5888

Gao J, Gu H, Xu B (2009) Multifunctional magnetic nanoparticles: design, synthesis, and biomedical applications. Acc Chem Res 42:1097–1107

Haddad et al (2009) Interplay between crystallization and particle growth during the isothermal annealing of colloidal iron oxide nanoparticles. J. Colloid Interf Sci 339:344–350

Herrmann I, Grass R, Mazunin D, Stark W (2009) Synthesis and covalent surface functionalization of nonoxidic iron core–shell nanomagnets. Chem Mater 21:3275–3281

Ishikawa Y, Kawaguchi K, Shimizu Y, Sasaki T, Koshizaki N (2006) Preparation of Fe–Pt alloy particles by pulsed laser ablation in liquid medium. Chem Phys Lett 428:426–429

Jakobi et al (2010) Magnetic alloy nanoparticles from laser ablation in cyclopentanone and their embedding into a photoresist. Langmuir 26:6892–6897

Jonsson et al (1996) Oxidation states and magnetism of fe-nanoparticles prepared by a laser vaporization technique. J Appl Phys 79:5063–5065

Katsoyiannis I, Zouboulis A (2002) Removal of arsenic from contaminated water sources by sorption onto iron-oxide-coated polymeric materials. Water Res 36:5141–5155

Kay A, Cesar I, Graetzel M (2006) New benchmark for water photooxidation by nanostructured α-Fe2O3 films. J Am Chem Soc 128:15714–15721

Kwong H, Wong M, Leung C, Wong Y, Wong K (2010) Formation of core/shell structured cobalt/carbon nanoparticles by pulsed laser ablation in toluene. J Appl Phys 108:034304

Laurent et al (2011) Magnetic fluid hyperthermia: focus on superparamagnetic iron oxide nanoparticles. Adv Collo Interf Sci 166:8–23

Liu P, Cai W, Zeng H (2008) Fabrication and size-dependent optical properties of FeO nanoparticles induced by laser ablation in a liquid medium. J Phys Chem C 112:3261–3266

Lu A, Salabas EL, Schuth F (2007) Magnetic Nanoparticles: synthesis, protection, functionalization, and application. Angew Chem Int Ed 46:1222–1244

Mandel K, Hutter F, Gellermann C, Sextl G (2011) Synthesis and stabilization of superparamagnetic iron oxide nanoparticle dispersions. Colloid Surf A Physicochem Eng Asp 390:173–178

McCarthy J, Weissleder R (2008) Multifunctional magnetic nanoparticles for targeted imaging and therapy. Adv Drug Deliv Rev 60:1241–1251

Moussa S et al (2011a) Laser assisted photocatalytic reduction of metal ions by graphene oxide. J Mater Chem 21:9608–9619

Moussa S, Abdelsayed V, El-Shall M (2011b) Laser synthesis of Pt, Pd, CoO and Pd–CoO nanoparticle catalysts supported on graphene. Chem Phys Lett 510:179–184

Moussa S, Siamaki A, Gupton F, El-Shall M (2012) Pd-partially reduced graphene oxide catalysts (Pd/PRGO): laser synthesis of Pd nanoparticles supported on PRGO nanosheets for carbon–carbon cross coupling reactions. ACS Catal 2:145–154

NIST (2012) XPS-database. http://srdata.nist.gov/xps/. Accessed 9 Dec 2011

Ouyang M, Hiraoka H (1995) Preparation and characterization of iron oxide films by the excimer laser ablation of poly(ferric methacrylate). Mater Sci Eng B 34:188–191

Sajti C, Sattari R, Chichkov N, Barcikowski S (2010) Gram scale synthesis of pure ceramic nanoparticles by laser ablation in liquid. J Phys Chem C 114:2421–2427

Tang et al (2006) Highly stable carbon-coated Fe/SiO2 composites: synthesis, structure and magnetic properties. Carbon 44:423–427

Tsuji T, Hamagami T, Kawamura T, Yamakia J, Tsujia M (2005) Laser ablation of cobalt and cobalt oxides in liquids: influence of solvent on composition of prepared nanoparticles. Appl Surf Sci 243:214–219

Xia et al (2010) Ferrofluids for fabrication of remotely controllable micro-nanomachines by two-photon polymerization. Adv Mater 22:3204–3207

Yang G (2007) Laser ablation in liquids: applications in the synthesis of nanocrystals. Prog Mater Sci 52:648–698

Zeng H, Sun S (2008) Syntheses, properties, and potential applications of multicomponent magnetic nanoparticles. Adv Funct Mater 18:391–400

Zhao et al (1994) γ-Fe2O3 nanoparticle preparation from oxidation of iron powder synthesized by laser-induced decomposition of Fe(CO)5. Nanostruct Mater 4:397

Acknowledgments

We thank the National Science Foundation CHE-0911146 and the NASA NNX08AI46G (Origin of Solar Systems Program) Grants for the partial support of this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is part of the topical collection on nanomaterials in energy, health and environment

Rights and permissions

About this article

Cite this article

Moussa, S., Atkinson, G. & El-Shall, M.S. Laser-assisted synthesis of magnetic Fe/Fe2O3 core: carbon-shell nanoparticles in organic solvents. J Nanopart Res 15, 1470 (2013). https://doi.org/10.1007/s11051-013-1470-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-013-1470-3