Abstract

This study presents a new and simple method for the synthesis of hollow carbon spheres possessing nanocage sizes of 7.1, 14, and 20 nm in diameter. The core-shell (i.e., Cu@C) nanoparticles prepared by carbonization of the Cu2+–cyclodextrin (CD) complexes at 573 K for 2 h was etched with HCl (6N) to yield the hollow carbon spheres. The carbon-shell of the hollow carbon nanospheres, which consisted of mainly diamond-like and graphite carbons, is not perturbed during etching. In addition to the nanocages, the hollow carbon nanospheres also possess micropores with an opening of 0.45 nm, allowing small molecules to diffuse in and out through the carbon-shell. Many elements (such as Zn2+ or Cu2+) can therefore be filled into the nanocages of the hollow carbon nanospheres. With these unique properties, for instance, designable active species such as Cu and ZnO encapsulated in the carbon-shell can act as Cu–ZnO@C yolk-shell nanoreactors which are found very effective in the catalytic decomposition of methanol.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Hollow carbon nanospheres are getting increased attention because of the high stability in a wide range of environments regardless of temperature, acidity, or alkalinity. The nanocages in the hollow carbon spheres may be used to trap select elements to form inclusion compounds (Li et al. 2008). For instance, metal/metal oxide nanoparticles can be encapsulated in the spherical carbon nanocages to form yolk- or core-shell nanostructures. Note that the carbon-shell can prevent the core species from aggregation or oxidation. The hollow carbon spheres possessing the unique properties of durability and stability have promising applications in catalysts, sensors, microelectronics, biomaterials, semiconductors, and many other areas of nanotechnology (Battie et al. 2011; Kment et al. 2011; Tongay et al. 2011; Saito et al. 2011). It is also worth noting that the carbon-shell has the advantage of high electron transfer rates due to its abundant surface free electrons. Many applications in sensors (Feng et al. 2006), fuel cells electrodes (Han et al. 2003), solar cell electrolytes (Chen et al. 2010), and batteries (Zhou et al. 2009) have, therefore, been found.

The nanostructured carbon can be prepared in a variety of forms such as nanotubes, nanorods, and nanovesicles that may result in different functions (Deshmukh et al. 2010; Li et al. 2008). In order to achieve desired applications, the shape, size, and surface structure of the hollow carbon spheres need to be controlled carefully. Typical preparation methods of hollow carbon nanospheres include template etching (Yagi et al. 2010; Kim et al. 2003; Yoon et al. 2002), layer-by-layer chemical vapor deposition (Eswaramoorthi et al. 2006), and thermal treatments (Zhou et al. 2006). However, those approaches often involve complex procedures, toxic solvent or materials, and result in low yields or widely distributed size or shape of nanostructured carbon. Therefore, challenges to synthesize uniformly distributed and size-controlled hollow carbon spheres still remain.

In the separate experiments, we found that nanosize-controllable Cu@C core-shell nanoparticles ranged from 7–40 nm can be synthesized by carbonization of Cu2+-cyclodextrin (CD) complexes at 573–673 K (Huang et al. 2009). Notably, the carbon-shell has micropores to allow small molecules to diffuse in and out (Chiu et al. 2011; Hong et al. 2011; Gulino et al. 1996). Preparation of hollow carbon nanospheres possessing micropores and nanocages with selected sizes in the range of 7–40 nm by the etching of the core Cu from Cu@C was, therefore, studied. Furthermore, a feasibility study for designable catalytic active species refilled into the nanocages of the hollow carbon spheres to form nanoreactors was also carried out.

Experimental

Materials and preparation

The Cu@C core-shell nanoparticles were synthesized by chelation of Cu2+ (Cu(NO3)2 (Fluka)) with β-cyclodextrin (CD) (Wako) at the Cu/CD molar ratios of 3, 6, and 9. The Cu2+–CD complexes were dried at 333 K for 16 h and carbonized at 573 K in a flowing high-purity N2 (100 mL min−1) for 2 h to yield the metallic copper (Cu) encapsulated in the carbon-shell (Cu@C). The core Cu in the Cu@C was etched using a HCl (Fluka) (6 N) solution at 298 K for 6 h. After being dried at 378 K for 24 h and calcined at 573 K for 2 h in a flowing high-purity N2 (100 mL min−1), the hollow carbon nanospheres possessing the nanocages were obtained.

The spherical hollow carbon nanocages can be refilled with copper by impregnation with Cu2+ (3 N) (Cu(NO3)2·3H2O (Fluka)) for 6 h. After being dried in a flowing 5 % H2/N2 (100 mL min−1) at 378 K for 24 h and reduced at 573 K for 2 h, the Cu@C yolk-shell was formed. Zinc (Zn(NO3)6·3H2O (Fluka)) (3 N) was also refilled into the Cu@C yolk-shell nanoparticles in the similar way. The zinc-contained Cu@C yolk-shell sample was dried in a flowing high-purity N2 (100 mL min−1) at 378 K for 24 h, oxidized in a flowing 5 % O2/N2 (100 mL min−1) at 573 K for 2 h and then reduced in a flowing 5 % H2/N2 (100 mL min−1) at 573 K for 2 h.

Characterization

The nanoparticle samples were characterized by X-ray (powder) diffraction (XRD) (D8 Advance, Bruker) with Cu Kα (1.542 Å) radiation at a scanning rate of 1.5o min−1. The images of the Cu@C core-shell nanoparticles, hollow carbon nanocages, and Cu2+ and Zn2+-filled hollow carbon nanospheres were studied by transmission electron microscopy (TEM) (JEM-3010, JEOL) equipped with energy dispersive X-ray scattering (EDS) at an acceleration voltage of 200 kV. Specific surface area and pore sizes of the Cu@C core-shell nanoparticles and hollow carbon spheres were determined with the nitrogen adsorption–desorption isotherms on a BET (Brunauer–Emmett–Teller) analyzer (Coulter SA3100, Beckman). Samples of c.a. 0.2 g were pre-dried and surface cleaned up at 473 K for 1 h under the vacuum. Raman spectra of the Cu@C and hollow carbon spheres were determined by micro-Raman spectroscopy (Jobin–Yvon, Labram HR) using 532 nm laser (Nd:YAG) at 298 K.

Shape and size of the hollow carbon spheres were also analyzed using synchrotron in situ small angle X-ray scattering (SAXS) spectroscopy. The SAXS spectra were determined on the beamline 23A at the National Synchrotron Radiation Research Center (NSRRC). The storage ring was operated at 1.5 GeV and 300 mA. A double Mo/B4C-multilayer monochromator was used to select the beam with a modest energy resolution (ΔE/E = 1 × 10−2 eV eV−1) under the energy of 14 keV. The samples having a thickness of 1.2 mm were placed in the sample holder under a flowing high-purity nitrogen gas (Liu et al. 2009). The SXAS data were collected by the scattering intensity, I(q) versus the wave vector transfer, Q, at q < 1.0 nm−1, where q is the magnitude of the scattering wave vector (Feigin and Svergun 1987; Beaucage 1996, 1995). The particle sizes were analyzed by fitting SAXS spectra with the Schultz distribution function after removing the contributions of the background (Guinier and Fournet 1955; Aragon and Pecora 1976; Porod 1980).

Partial oxidation of methanol (POM)

Methanol was injected steadily into a microreactor using a syringe pump. The flow rate of the feed containing 21 % of methanol and 5 % of O2 in N2 was regulated at 20 mL min−1 using a mass flow controller (AALBORG). The composition of the product gas was determined by gas chromatography (GC) (Bruker GC-430) equipped with a TCD detector and on-line Fourier transform infrared (FT-IR) spectroscopy (Varian, FTS-40). A molecular sieve 5A column (353 K) was used for separation of H2 from other gases. A flowing N2 (30 mL min−1) was used as the carrier gas. CO and CO2 were analyzed by on-line FT-IR spectroscopy. A 32 scan accumulation was monitored at a resolution of 4 cm−1.

Results and discussion

To reveal the growths of Cu nanoparticle during temperature-programed carbonization (TPC) of the Cu2+–CD complexes at the heating rate of 2 K min−1, the in situ SAXS spectra were determined. Cu2+ was reduced and encapsulated in the carbon-shell as the CD was carbonized. Figure 1 shows the particle sizes of the repined Cu having the average of 7.1, 14, and 20 nm in diameter prepared at the Cu/CD molar ratios of 3, 6, and 9, respectively. It is also clear that at the high Cu/CD ratio (i.e., 9), the particle size of Cu is increased. As expected, more carbonization time is needed for large Cu, e.g., 20 nm Cu for 68 min versus 7.1 nm for 30 min.

The XRD patterns of the Cu@C core-shell nanoparticles and hollow carbon spheres are shown in Fig. 2. The broadened diffraction peaks at (111), (200), and (220) for the Cu@C are suggestive of the existence of nanosize Cu. Note that copper oxides are not found, indicating that the Cu core is well coated with carbon shells. Diameters of Cu in the Cu@C core-shell nanoparticles estimated by the Scherrer equation (Ciupină et al. 2007) are 7.0, 14 and 20 nm. The characteristic diffraction peaks at the low 2θ region (1.4°–1.9°) (see Fig. 1b, d, f) are indicative of a long-term arrangement and the existence of mesopores is attributable to the nanocages in the hollow carbon spheres after etching of the core Cu from Cu@C and calcined in a flowing N2 at 573 K for 2 h.

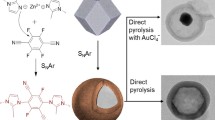

The TEM image of the Cu@C core-shell nanoparticles and hollow carbon spheres with Cu or nanocages of 7, 14, and 20 nm in diameter are shown in Fig. 3. A well-dispersed and uniform-size Cu encapsulated in the carbon-shell is observed. The carbon hollow spheres having corresponding nanocages can be formed by etching of Cu from the Cu@C core-shell nanoparticles with acid (6 N HCl). As shown in Fig. 3g, copper can be filled in the nanocages (20 nm) of the hollow carbon spheres. Nevertheless, the filled copper has an average diameter of 10 nm, forming Cu@C yolk-shell nanoparticles. The fact of the incomplete refilling may be associated with the repulsion between Cu2+ ions in the nanocages. By examining, the ratio of the effective size of Cu2+ (0.48 nm (ionic atmospheres thickness)) to Cu (0.30 nm), the experimental observations are consistently reasonable. Little interaction between the filled Cu and the carbon nanocage is found. As expected, other elements such as Zn2+ can also be filled into the nanocages of the hollow carbon spheres. For instance, Zn2+ can be filled into the Cu@C yolk-shell to form Cu–ZnO@C yolk-shell nanoparticles after oxidation with O2/N2 at 573 K and reduction with H2/N2 at 573 K for 2 h (see the TEM images in Fig. 3h). The EDS analysis clearly indicates that the refilled Cu–ZnO@C yolk-shell nanoparticles are composed of Cu surrounded with ZnO nanoparticles in the nanocages (points of 1 and 2 in Fig. 3h). The compositions of the Cu@C and Cu–ZnO@C yolk-shell nanoparticles are further confirmed by the XRD patterns (Fig. 4a, b). The featured peaks suggest that after oxidization and reduction treatments, Cu and ZnO coexist in the Cu2+- and Zn2+-refilled nanocages.

TEM images of the Cu@C core-shell nanoparticles having Cu diameters of a 20, b 14, and c 7.1 nm, hollow carbon spheres having nanocage diameters of d 20, e 14, and f 7.1 nm, g Cu and h Cu and ZnO refilled in the nanocages. The electron-dispersive scattering (EDS) analyses at the points 1 and 2 show Cu and ZnO nanoparticles, respectively

To reveal how Cu2+ or Zn2+ can be refilled into the nanocages of the hollow carbon spheres, their nitrogen adsorption/desorption isotherms are determined (shown in Fig. 5). The hollow carbon spheres have a sharp step on the desorption curve compared to Cu@C, attributable to the presence of nanocages after etching. At P/P o < 0.2, micropores (openings of 0.44–0.46 nm, see Table 1) in the carbon-shell are found. As the P/P o ratios are >0.4, a multilayer adsorption as well as capillary condensation is observed, ascribed to the nanocages of 7.1, 14, and 20 nm in diameter (Fig. 4a, b, c). Desorption from the spherical nanocages are delayed and emptying of nanocages occurs abruptly, suggesting existence of interconnection between nanocages and the micropores in the carbon-shell. In Table 1, the BET surface areas of the nanocages having the sizes of 7.1, 14, and 20 nm in diameters are 360, 469, and 507 m2 g−1 carbon, respectively. Note that the hollow carbon spheres have about 3 × 1017 nanocages per gram. The opening of micropores in the carbon-shell is about 0.45 nm that is accessible for metal ions such as Cu2+ and Zn2+ diffusing in or out of the hollow carbon spheres.

Figure 6 shows the Raman spectra of the carbon in the Cu@C and hollow carbon spheres. The broadening and downshifting at 1,332 cm−1 for the Cu@C nanoparticles indicate that the carbon-shell is in the state of nanoscale. The Raman spectra also suggest that the carbon-shell is amorphous having the sp3/sp2 ratio of 0.7. The feature at 1,590 cm−1 can be assigned to the vibration of graphite (sp2), while the broadened feature centered at 1,350 cm−1 is associated with diamond-like carbon (sp3). A very low intensity feature at 1,230 cm−1 can be attributed to the fourfold coordinated microcrystalline diamond. It is worth to note that chemical structure of carbon in the Cu@C core-shell nanoparticles or hollow carbon spheres with different sizes of Cu or nanocage is little perturbed in the etching or refilling process.

The etching and refilling processes are shown in the Scheme 1. The core Cu is etched and dissolved to Cu2+ which diffuses out through the micropores of the carbon-shell in the Cu@C to form hollow carbon spheres. As expected, Cu2+ can be refilled into the nanocages of the hollow carbon spheres through the microporous carbon-shell, and then reduced to Cu forming Cu@C yolk-shell nanoparticles. Similarly, Zn2+ can be trapped in the Cu@C yolk-shell nanoparticles. After oxidization and reduction, the Cu–ZnO@C yolk-shell nanoparticles can be obtained.

Catalytic active species can be designed in the hollow carbon spheres. For instance, as shown in Fig. 2h, the Cu–ZnO@C yolk-shell particles can be used as nanoreactors in catalytic partial oxidation of methanol (POM) to yield H2. In Fig. 7, it is clear that H2 yielded from the catalytic POM reaction in the Cu@C yolk-shell nanoreactors is much more effective than that in the hollow carbon spheres. In the presence of ZnO, the H2 yields from POM are enhanced. ZnO seems to promote the POM reactions. In addition, in the confined nanocages, the collision frequency between reactants and catalytic active species is also remarkably increased.

Conclusions

This work presents a new and simple method for the preparation of hollow carbon spheres having the nanocages of 7.1, 14, and 20 nm in diameter. In additions to the nanocages, the hollow carbon spheres also possess micropores with an opening of 0.45 nm, allowing small molecules to diffuse in and out, which can be used in the preparation of designable active species in nanoreactors. Copper and zinc can be filled into the nanocages of the hollow carbon spheres to form Cu–ZnO@C yolk-shell nanoreactors. The Cu–ZnO@C nanoreactors are found very effective in the catalytic POM reaction for H2 generation, which may be associated with the high collision frequency between methanol, O2, and catalytic active species in the confined nanocages.

References

Aragon SR, Pecora R (1976) Theory of dynamic light-scattering from polydisperse systems. J Chem Phys 64(6):2395–2404

Battie Y, Ducloux O, Thobois P, Dorval N, Lauret JS, Attal-Tretout B, Loiseau A (2011) Gas sensors based on thick films of semi-conducting single walled carbon nanotubes. Carbon 49(11):3544–3552

Beaucage G (1995) Approximations leading to a unified exponential power-law approach to small-angle scattering. J Appl Crystallogr 28:717–728

Beaucage G (1996) Small-angle scattering from polymeric mass fractals of arbitrary mass-fractal dimension. J Appl Crystallogr 29:134–146

Chen FL, Letortu A, Liao CY, Tsai CK, Huang HL, Sun IW, Wei YL, Paul Wang H (2010) Cu@C nanoparticles dispersed RTILs used in the DSSC electrolyte. Nucl Instrum Methods Phys Res A 619(1–3):112–114

Chiu YM, Huang CH, Chang FC, Kang HY, Wang HP (2011) Recovery of copper from a wastewater for preparation of Cu@C nanoparticles. Sustain Environ Res 21(4):279–282

Ciupină V, Zamfirescu S, Prodan G (2007) Evaluation of mean diameter values using Scherrer equation applied to electron diffraction images. In: Simeonova PP et al (eds) Nanotechnology—toxicological issues and environmental safety. Springer, New York, pp 231–237

Deshmukh AA, Mhlanga SD, Coville NJ (2010) Carbon spheres. Mat Sci Eng R 70(1–2):1–28

Eswaramoorthi I, Sundaramurthy V, Dalai AK (2006) Partial oxidation of methanol for hydrogen production over carbon nanotubes supported Cu–Zn catalysts. Appl Catal A 313(1):22–34

Feigin LA, Svergun DI (1987) Structure analysis by small-angle X-ray and neutron scattering. Plenum, New York and London

Feng XM, Mao CJ, Yang G, Hou WH, Zhu JJ (2006) Polyaniline/Au composite hollow spheres: synthesis, characterization, and application to the detection of dopamine. Langmuir 22(9):4384–4389

Guinier A, Fournet G (1955) Small-angle scattering of X-rays. Wiley, New York

Gulino A, LaDelfa S, Fragala I, Egdell RG (1996) Low-temperature stabilization of tetragonal zirconia by bismuth. Chem Mat 8(6):1287–1291

Han S, Yun Y, Park K-W, Sung Y-E, Hyeon T (2003) Simple solid-phase synthesis of hollow graphitic nanoparticles and their application to direct methanol fuel cell electrodes. Adv Mater 15(22):1922–1925

Hong C-I, Kang H-Y, Wang HP, Lin W-K, Jeng US, Su C-H (2011) Cu–ZnO@C nanoreactors studied by in situ synchrotron SAXS spectroscopy. J Electron Spectrosc Relat Phenom 184(3–6):301–303

Huang CH, Wang HP, Chang JE, Eyring EM (2009) Synthesis of nanosize-controllable copper and its alloys in carbon shells. Chem Commun 31:4663–4665

Kim M, Yoon SB, Sohn K, Kim JY, Shin CH, Hyeon T, Yu JS (2003) Synthesis and characterization of spherical carbon and polymer capsules with hollow macroporous core and mesoporous shell structures. Microporous Mesoporous Mat 63(1–3):1–9

Kment S, Hubicka Z, Kmentova H, Kluson P, Krysa J, Gregora I, Morozova M, Cada M, Petras D, Dytrych P, Slater M, Jastrabik L (2011) Photoelectrochemical properties of hierarchical nanocomposite structure: carbon nanofibers/TiO2/ZnO thin films. Catal Today 161(1):8–14

Li HB, Liang YY, Yin G, Wei XW, Xu Z (2008) Template-free fabrication of fullerene(C-60, C-70) nanometer-sized hollow spheres under solvothermal conditions. Carbon 46(13):1736–1740

Liu DG, Chang CH, Liu CY, Chang SH, Juang JM, Song YF, Yu KL, Liao KF, Hwang CS, Fung HS, Tseng PC, Huang CY, Huang LJ, Chung SC, Tang MT, Tsang KL, Huang YS, Kuan CK, Liu YC, Liang KS, Jeng US (2009) A dedicated small-angle X-ray scattering beamline with a superconducting wiggler source at the NSRRC. J Synchrot Radiat 16:97–104

Porod G (1980) Small angle X-ray scattering. Academic Press, New York

Saito N, Aoki K, Usui Y, Shimizu M, Hara K, Narita N, Ogihara N, Nakamura K, Ishigaki N, Kato H, Haniu H, Taruta S, Kim YA, Endo M (2011) Application of carbon fibers to biomaterials: a new era of nano-level control of carbon fibers after 30-years of development. Chem Soc Rev 40(7):3824–3834

Tongay S, Schumann T, Miao X, Appleton BR, Hebard AF (2011) Tuning Schottky diodes at the many-layer-graphene/semiconductor interface by doping. Carbon 49(6):2033–2038

Yagi I, Hayashi A, Kimijima K, Notsu H, Ohta N, Yamaguchi A (2010) Mesoporous materials toward nanofabricator and nanoreactor. Electrochemistry 78(2):105–113

Yoon SB, Sohn K, Kim JY, Shin CH, Yu JS, Hyeon T (2002) Fabrication of carbon capsules with hollow macroporous core/mesoporous shell structures. Adv Mater 14(1):19–21

Zhou GJ, Lu MK, Yang ZS (2006) Aqueous synthesis of copper nanocubes and bimetallic copper/palladium core-shell nanostructures. Langmuir 22(13):5900–5903

Zhou JS, Song HH, Chen XH, Zhi LJ, Yang SY, Huo JP, Yang WT (2009) Carbon-encapsulated metal oxide hollow nanoparticles and metal oxide hollow nanoparticles: a general synthesis strategy and its application to lithium-ion batteries. Chem Mater 21(13):2935–2940

Acknowledgments

The financial supports of the Taiwan National Science Council and Bureau of Energy are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tsai, CK., Kang, H.Y., Hong, CI. et al. Preparation of hollow spherical carbon nanocages. J Nanopart Res 14, 1315 (2012). https://doi.org/10.1007/s11051-012-1315-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-012-1315-5