Abstract

While it is generally agreed that successful strategies to address the health and environmental impacts of engineered nanomaterials (NM) should consider the well-established frameworks for conducting life-cycle assessment (LCA) and risk assessment (RA), scientific research, and specific guidance on how to practically apply these methods are still very much under development. This paper evaluates how research efforts have applied LCA and RA together for NM, particularly reflecting on previous experiences with applying these methods to chemicals. Through a literature review and a separate analysis of research focused on applying LCA and RA together for NM, it appears that current research efforts have taken into account some key “lessons learned” from previous experience with chemicals while many key challenges remain for practically applying these methods to NM. We identified two main approaches for using these methods together for NM: “LC-based RA” (traditional RA applied in a life-cycle perspective) and “RA-complemented LCA” (conventional LCA supplemented by RA in specific life-cycle steps). Hence, the latter is the only identified approach which genuinely combines LC- and RA-based methods for NM-risk research efforts to date as the former is rather a continuation of normal RA according to standard assessment procedures (e.g., REACH). Both these approaches along with recommendations for using LCA and RA together for NM are similar to those made previously for chemicals, and thus, there does not appear to be much progress made specific for NM. We have identified one issue in particular that may be specific for NM when applying LCA and RA at this time: the need to establish proper dose metrics within both methods.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The general consensus among scientists, researchers, and regulatory agencies is that the potential health and environmental risks of engineered nanomaterials (NM) should be evaluated over their entire life-cycle (e.g., Davis 2007; DEFRA 2007; Seager and Linkov 2008). This is because a comprehensive approach to investigating these risks should consider the various life-cycle stages which span from extracting the raw materials for producing NM through their end-of-life stages to capture all potential risks to human health and the environment. Moreover, assessing the potential health and environmental risks of NM has in principle been based on previously developed frameworks to assess the risks of chemicals (SCHENIR 2007), and in Europe this is e.g., outlined in the REACH guidance documents for chemical safety assessment (ECHA 2010). In response, life-cycle assessment (LCA) and chemical risk assessment (RA) have been put forth as the two main approaches to address the health and environmental impacts of NM (see Box 1). Moreover, it has often been recommended that a combination of LCA and RA is needed to fully evaluate the potential health and environmental risks of NM (Sweet and Strohm 2006; Seager and Linkov 2008; US Army Environmental Policy Institute 2009; EC 2011b; Linkov et al. 2011). Thus, a number of organizations and scientists have called for improved methods for the complementary use of LCA and RA for NM (e.g., EC 2004, 2011a; Royal Society 2004; Davis 2007; Shatkin 2008a; US EPA 2008). A number of international research endeavors have been set forth in recent years to investigate the potential health and environmental risks of NM over their life-cycle in various formats and strategies, including attempts to use LCA and RA frameworks in their formal sense (i.e., ISO 14040 series, chemical RA: ISO 2006a, b; ECHA 2010) or in more general formats such as life-cycle (LC)- and RA-based methods (i.e., use of preliminary exposure data and/or toxicological data over various life-cycle stages) (e.g. Shatkin 2008a, b; US EPA 2008; EUMAT 2011).

In fact, this call for the use of both LCA and RA in the case of NM is not surprising given that they have been proposed and used previously, both separately as well as together for chemicals (e.g., Nishioka et al. 2002; Socolof and Geibig 2006). Formulating strategies to use LCA and RA together for chemicals has been pursued in a range of research efforts for more than a decade, and remains a topic of on-going work (e.g., Christensen and Olsen 2004; Bare 2006; Russel 2007; Kuczenski et al. 2010; Lim et al. 2011; Linkov and Seager 2011). Some proposed approaches to combining these tools together range from the use of the same data, the complementary use of the results as well as efforts to integrate these two tools into one. However, there have been a number of challenges to applying LCA and RA in combination for chemicals, as noted by several authors (e.g., Owens 1997). Some of these include different interpretations and perceptions of LCA and RA across disciplines (Christensen and Olsen 2004) as well as differing scopes, aims, and end results between the two methods (Olsen et al. 2001; Bare 2006). For example, as outlined in Fig. 1, LCA assesses a wide variety of environmental impacts of a product or system related to the functional unit (i.e., the function delivered), while RA assesses the health and environmental risks of a single substance at a particular point in the chemical’s life-cycle (or the total release of the substance from the chemical’s life-cycle). Another difference between the two methods and one which is an issue of common confusion is use of the term “life-cycle” (Christensen and Olsen 2004). In RA the life-cycle of a single chemical is considered, whereas the life-cycle related to the functional unit of a product/service system is considered in LCA (Fig. 1). In the case of NM, the challenges of using RA and LCA alone or in combination are further amplified given the extensive uncertainties in for instance understanding their toxicological potential and exposure profiles in many life-cycle stages which have hampered both LCA and RA evaluations (Seager and Linkov 2008; Som et al. 2010). Therefore, given the challenges of applying LCA and RA for chemicals, it may be worthwhile to investigate research efforts focused on applying these methods to NM, concentrating on if and how the lessons learned from applying LCA and RA to chemicals have been taken into account for NM.

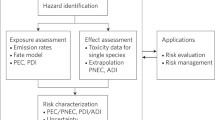

a Comparison and use of risk assessment (RA) and life-cycle assessment (LCA) in theory (based on Christensen and Olsen 2004) and b their complementary use in practice for a hypothetical nano-product, which illustrates that RA focuses on the life-cycle steps involving the chemical/material being assessed, whereas an LCA life-cycle also encompasses e.g. production of energy and other auxiliary materials. NM engineered nanomaterial

This paper therefore aims to evaluate how LCA and RA have been applied together for NM to date by first describing the main purposes and scope of these tools and then evaluating how research efforts have in fact applied these methods to NM in practice. With this background and particularly reflecting on previous findings and identified pitfalls in combining LCA and RA for chemicals, this paper aims to provide recommendations for their combined or separate use for NM, addressing the specific needs of risk assessors and decision-makers. The implications of potential misconceptions and ambiguities in present attempts for LCA and RA for NM will be analysed with the ultimate aim of strengthening research strategies geared toward investigating the health and environmental impacts of NM in comprehensive approaches, also considering the needs of decision-makers.

Methods

Approach used

This study is based on a literature review within the fields of LCA and RA for chemicals and engineered NM. In order to provide an overview of research efforts focused on LCA and RA for NM, both in terms of applying LCA and RA methods as prescribed by technical guidance notes or standards (e.g., EC 2003; ISO 2006a, b; ECHA 2010) as well as applying more general LC- and RA-based methods, the scientific literature was screened for past, current or planned research endeavors which focused on the combined or complementary use of these methods for NM. We found that research was presented primarily in the forms of published journal articles, RA or risk analysis frameworks, and international research projects. Published and peer-reviewed scientific journal articles were found using the ISI Web of Knowledge database within the search topics of “RA,” “LCA,” “risk,” and “life-cycle” of “NM.” The following frameworks were selected for evaluation: comprehensive environmental assessment (CEA) (Davis 2007; US EPA 2009, 2010a, b; Anastas and Davis 2010), CENARIOS® (TÜV 2008; Bühler Partec 2010; Swiss FOEN 2010), International Organization for Standards (ISO) risk evaluation process (ISO/TR 13121) (ISO 2011), nano risk framework (Environmental Defense and Dupont 2007a, b, c, d), nano screening level life-cycle risk assessment (LCRA) (Shatkin 2008a, b, 2009a, b), multi-criteria decision analysis (MCDA) (Linkov et al. 2007; Seager and Linkov 2008; Tervonen et al. 2009; Canis et al. 2010; Linkov and Seager 2011), precautionary matrix (Höck et al. 2008, 2010; Swiss Federal Office of Public Health 2010) and risk governance framework (IRGC 2005, 2007, 2009). These frameworks were selected since they have all aimed to use LC- and RA- based methods to evaluate the potential health and environmental risks of NM and have been frequently cited in the scientific literature (see Grieger et al. 2011). These frameworks were accessed on-line through publically available documents, many of which were produced by governmental institutions or other organizations (i.e., non-peer reviewed literature).

A review of international research projects which aimed to combine LC- and RA-based methods for NM was made through reviewing the Organisation for Economic Co-operation and Development (OECD) database for either completed or on-going research projects involving in environmental, health, and safety aspects of NM (OECD 2011) as well as research projects involved in recent scientific conferences and meetings (EUMAT 2011; LEITAT 2011). Using the OECD database, a search for projects was made using the terms “life-cycle” and “RA” in the search fields. After an initial finding of over 30 projects using these search terms, only five research projects were in fact found to be focused on combining or integrating LC- and RA-based concepts for NM (as opposed to being either primarily LCA- or RA-based projects) after investigating these further. These research projects included: identifying and regulating environmental impacts of NM (NSF 2007), NEPHH (2011), NanoPolyTox (2011), Nanovalid (2010) and Prosuite (2011). Specific information and details pertaining to these research projects was obtained through websites and other documents which were publically available (most of which were non-peer reviewed). The authors of these research projects were also contacted (October 2011) and requested to confirm our findings regarding the depth and scope of their projects and to supply additional information if insufficient or minimal information was available in publicly accessed website and documents.

These identified research efforts focused on NM were evaluated against the scientific literature focused on improving applications of LCA and RA for chemicals to demonstrate if previous “lessons learned” for chemicals have been taken into consideration for NM. These research efforts were also screened to demonstrate their focus and content, and subsequently evaluated according to the following criteria: (1) Rationale, if the research effort presents rationale or justifications for using LC- and RA-based methods together for NM; (2) Approach, if research efforts present a specific approach for using LC- and RA-based methods for NM; (3) Guidance, if research efforts present guidance on how to use or apply the proposed approach for using LC- and RA-based methods for NM; (4) Recommendations, if research efforts provide recommendations for improving LC- and RA-based methods for NM; (5) Case studies, if research effort provides documented case studies of LC- and RA-based methods for NM (as opposed to only theoretical assessments). It was noted if the research efforts fulfilled these criteria to the full extent (•), only partially (∘) or was absent or no information was found regarding this (–). Finally, the authors of the analysis performed the evaluation of these research efforts.

Introduction to LCA and RA

Since this paper focuses on how LCA and RA have been applied together for NM, a brief introduction to these methods is provided below.

Life-cycle assessment

Life-cycle assessment is a systematic assessment of the potential environmental impacts of a defined good or service (commonly termed as “product”) throughout all life-cycle stages, contributing to the production of the product under investigation (including auxiliary materials), its use and disposal (Hauschild 2005) (Fig. 1; Box 1). The assessment typically covers a broad range of environmental impacts, such as climate change, resource depletion, and toxicity on human health exerted by releases of e.g., chemical agents. According to ISO Standards (ISO 2006a, b), LCA is conducted in four main phases: (i) defining the goal and scope of the study, (ii) establishing a life-cycle inventory which aggregates all inputs from and outputs to the environment within the system boundaries, (iii) performing a life-cycle impact assessment which translates the inventory into potential impacts of the system on the environment and (iv) interpreting the results from the assessment to provide consistent support to decision-makers in relation to the goal and scope of the study. The results of LCA are normally presented on a relative or comparative basis, such as the comparison of two alternative solutions for product development, to make informed decisions regarding the relative environmental sustainability of products (EC 2010). To insure a fair comparison, the basis for assessment is the so-called functional unit, i.e., the function delivered by the alternative solutions. This is for example a 10 m2 wall with a given quality of the painted surface for 10 years. This way e.g., different qualities or durability of two paints compared would be taken into account.

Life-cycle assessment can in principle be applied to all types of products and are sometimes applied for only part of the life-cycle e.g., cradle-to-gate. The LCA inventory is a mass-based (as opposed to e.g., concentration-based) accounting system that does not take into account spatial, temporal, dose–response, and threshold information (Owens 1997). Therefore, it does not predict actual impacts or risks (Owens 1997; Olsen et al. 2001). The assessment of (eco)toxicological impacts relies on general models (in common with RA) requiring a substantial amount of substance data that are not always available (see e.g., Rosenbaum et al. 2008).

Risk assessment

RA is an established procedure which assesses whether there is a risk or not associated with the use of an agent, such as a chemical or other substance (see Box 1). As mentioned previously, chemical RA has been the standard approach to assessing the potential health and environmental risks of bulk chemicals and subsequently been applied to NM in recent years (e.g., Rocks et al. 2008; SCENIHR 2009; Aschberger et al. 2010a, b; Christensen et al. 2010, 2011). In Europe this process is defined for chemicals by the EU chemicals policy REACH (European Communities 2007; ECHA 2010). Unlike LCA, RA focuses on a single agent (e.g., chemical or NM) rather than a product or system and the output of RA is on an absolute basis rather than a relative basis, indicating if further testing or risk reductions are needed (Fig. 1). RA is often performed throughout the life-cycle of the agent (from the production of the agent until the final disposal) to identify whether any life-cycle stages pose risks.

This assessment framework consists of four main steps: (i) hazard identification, (ii) dose–response assessment, (iii) exposure assessment, and (iv) risk characterization (e.g., EC 2003; ECHA 2010). The hazard identification step serves to map a chemical’s inherent physico-chemical and biological properties and provide a uniform basis to evaluate the hazard potential. One of the main purposes of the dose–response assessment is to obtain a quantitative estimate of the chemical concentration which can be expected not to have an effect on human health or the ecosystem’s species structure and function. In environmental RAs this predicted no-effect concentration is set using ecotoxicological data collected in the hazard identification step and taking uncertainties in extrapolation from known to expected effects into account. In exposure assessment, generic and/or specific scenarios are applied for realistic exposure pathways for a chemical. A key result of the exposure assessment for the environment is the so-called predicted environmental concentration (PEC) value for the specified scenario. The results of the previous steps are coupled together in the risk characterization, which provides a critical review of the data leading up to the risk quotient in which the predicted or measured exposure is compared to the predicted no-effect concentrations (PNEC). The outcome of the risk characterization may be that risk reduction measures need to be implemented, further information is needed to reach a conclusion or that no further action is needed. For human health assessment, a similar approach involving comparing exposure estimates with no effect levels in a risk characterization is followed. See e.g., ECHA (2010) on how this methodology is being implemented in the EU chemicals policy REACH.

Results and discussion

LCA and engineered NM

The general concept of using LCA for NM has received wide acceptance as an approach to quantify potential impacts of a NM or nano-product across different life-cycle stages (Seager and Linkov 2008). The ISO framework for LCA (ISO 2006b) was found to be suitable for NM-products, in which all stages should be included and assessed in a LCA study (Klöpffer et al. 2007). To date, there have been over a dozen studies which have been published on LCA for NM (e.g., Khanna et al. 2008a), products containing NM (e.g., Sengül and Theis 2011; Khanna et al. 2008b; Merugula et al. 2010; Meyer et al. 2010) or manufacturing/production processes involving NM (e.g., Krishnan et al. 2008; Moign et al. 2010; Grubb and Bakshi 2011); few of these studies have encompassed the full life-cycle, and most of them focused on a cradle-to-gate study or on a specific LC stage (e.g., two critical reviews by Gavankar et al. 2012 and Hischier and Walser 2012). Moreover, the majority of these have relied upon generic life-cycle impact databases or general literature in formulating the inventories and impact assessment criteria (i.e., excluding potential toxicological impacts of NMs). These short-comings are most likely due to a lack of data related to NM and their products (Klöpffer et al. 2007; US Army Environmental Policy Institute 2009).

As noted by several authors, there are indeed several challenges to conducting LCA for NM-products. For instance, there is a lack of robust data regarding emissions and exposures related to the production, use and disposal of NM and products containing NM and subsequently a need to establish a database which includes the most common production pathways (Klöpffer et al. 2007; Shatkin 2008a; Hendren et al. 2011). In addition, data regarding the environmental fate, behavior, and toxicological impacts of NM are generally limited (e.g., Seager and Linkov 2008; Som et al. 2010; Christensen 2010). There are also additional challenges related to unclear metrics used in these assessments (Shatkin 2008a), inconsistencies in viable data sources (Hendren et al. 2011), variability of NM resulting from different production methods, issues of purity and proper NM characterization (Seager and Linkov 2008). Due to these uncertainties particularly within the life-cycle inventory and environmental impact assessment stages, some have suggested that the results of LCA may be based on extensive uncertainties which may not be adequate for sound input to decision-making processes (Seager and Linkov 2008; Hendren et al. 2011). In response to these aforementioned challenges, it has been recommended that the background and information basis for conducting LCA should be further developed for instance by improving datasets regarding the most critical processes involved with NM which are accessible in well-known databases (Som et al. 2010); have thorough descriptions of NM releases (Bauer et al. 2008); identify functions of NM which are related to specific applications (Bauer et al. 2008); make disaggregated data available for future LCA studies (Klöpffer et al. 2007); use upper- and lower-bounds for expected impacts (Klöpffer et al. 2007) as well as involve toxicologists to review data and define boundaries in the study (Klöpffer et al. 2007). Also, in order to get a thorough description of NM releases, there is a need to know which physicochemical properties of NM should be characterized to be useful for impact assessment. On-going work within this field is currently underway by toxicologists as explained in subsequent sections of this paper.

This information suggests that these aforementioned challenges related to applying LCA to NM are not in fact specific to applying the LCA methodology to NM, rather related to increased uncertainty in the underlying data which could also exist for other substances such as chemicals. The most nano-specific issue seems to be related to the issue of the most proper metric which should be used, although we expect that it is likely that this can be resolved if data on emissions and hazard for the proper metric are available. This issue is discussed in more detail in subsequent sections.

RA and engineered NM

While there have been advances in developing various aspects of RA for NM in recent years (e.g., OECD 2010; Aitken et al. 2011; Hankin et al. 2011), the presence of serious and fundamental uncertainties throughout all four steps of the framework have seriously hampered evaluations (Grieger et al. 2009; SCENIHR 2009). To date, some studies have attempted to complete human and environmental RAs for NM according to standard protocols (e.g., Hanai et al. 2009; Kobayashi et al. 2009; Shinohara et al. 2009; Ashberger et al. 2010a, b; Christensen et al. 2010, 2011). However, all of these have concluded that due to limited data and extensive uncertainties, it is not possible based on readily available information to complete full RAs for regulatory decision-making for the NM investigated and their results are to be considered as preliminary. Among other challenges, there is a lack of measured exposure data for NM, lack of validated exposure estimation models, extensive uncertainties within characterizing NM, applicability of current test guidelines as well as a lack of (eco)toxicological studies in a variety of species (Baun et al. 2009; SCENIHR 2009; Stone et al. 2010). This means that meaningful hazard identification and hence dose–response, as well as exposure assessments are difficult to complete for most NM. Due to these challenges, many assessment efforts have been broadened to include other elements of risk analysis (which cover aspects of risk communication and management in addition to RA) rather than primarily chemical RA per se. There have been a number of attempts at providing preliminary risk evaluations using these framework for NM or production processes involving NM (Robichaud et al. 2005; Tervonen et al. 2009; Canis et al. 2010; O’Brien and Cummins 2011; Som et al. 2011; Valverde and Linkov 2011).

Overall the general consensus is that the basic RA framework is applicable to passive or first generation NM (SCENIHR 2009, 2010), although many methodological steps within the RA framework need to be refined or further developed for NM, often linked back to the basics of the hazard identification. Among others, one of the main recommendations made to improve RA is proper NM characterization (e.g., Warheit 2008; OECD 2009; Baer et al. 2010; Boverhof and David 2010; Pyell 2010; Clark et al. 2011). This is due to the importance of identifying the specific characteristics of NM which may cause e.g., adverse effects in organisms in (eco)toxicity testing which may differ from pre-test conditions or influence exposure conditions. Another main issue related to the NM characterization is the use of appropriate metric(s) for expressing exposure and hazards which can be compared in the risk characterization step of RA. The relevance of the traditional mass-based metric is questioned for many NM, and alternative/additional metrics based on number and surface area are being proposed (e.g., Aitken et al. 2011; Hankin et al. 2011). As NM (even of the same basic chemistry) exist in many different forms which may have different properties (e.g., due to different sizes, shapes, and coatings/functionalization) and as extensive (animal) testing of these different forms raise economical and ethical issues, there is a need to develop non-animal testing approaches such as read-across and quantitative structure activity relation(s) (QSARs). This would require research and development in understanding how different characteristics affect the properties and toxicity of a given form of a NM.

Using LCA and RA together

As highlighted in the preceding sections as well as by a number of other authors (Olsen et al. 2001; Flemström et al. 2004; Linkov and Seager 2011), LCA and RA are both tools to estimate the potential adverse impact of a given substance or product although they in fact have different aims, scopes, and desired outcomes, as well strengths and weaknesses (Fig. 1). The main strengths of LCA are that it is very comprehensive in its inclusion of impacts from all life-cycle stages involved in the production, use and disposal of products (Linkov and Seager 2011) and impact categories (Flemström et al. 2004), as well as assists in avoiding “problem shifting” (i.e., solving environmental challenges at one life-cycle stage and subsequently creating a different problem at another life-cycle stage) (Wrisberg and de Haes 2002). The main advantages of RA are the provision of an absolute assessment of whether there is a risk for specific settings and often the use of worst-case evaluations to help insure safety to a potential adverse effect (Flemström et al. 2004), often with regulatory significance.

Both LCA and RA include a structured format to evaluate information for environmental decision-making in a life-cycle perspective (Flemström et al. 2004) (keeping in mind that they are in fact two different tools intended for different purposes and the “life-cycle” is understood differently); estimate exposures and effects from emissions (Olsen et al. 2001); contain methods in theory to characterize uncertainty within the assessments; as well as provide guidance for decision support under uncertainty (Evans et al. 2002). On the other hand, both LCA and RA require substantial amounts of data, have been criticised for not being able to effectively handle uncertainties or lack of data well and require strong expert knowledge (Wrisberg and de Haes 2002; Linkov and Seager 2011). Some of the main differences between these methods include the fact that LCA focuses on a product or process while RA focuses on the emissions of a single substance or chemical (Olsen et al. 2001; Christensen and Olsen 2004) and consequently have different system boundaries and therefore address different life-cycles, which for methodological reasons are difficult to integrate (see e.g., Christensen and Olsen 2004). The output generated from the two methods also differ, in that LCA produces impact scores on a comparative basis while output from RA is based on risk quotients produced on an absolute basis (Olsen et al. 2001; Kuczenski et al. 2010). Furthermore, LCA covers a large number of environmental impact parameters while RA covers primarily (eco)toxicological data (Olsen et al. 2001; Christensen and Olsen 2004). It should also be noted that the term “characterization” within the LCA field generally refers to relative quantification of environmental fate and effects of substances, whereas this term usually denotes material physico-chemical properties in the hazard identification step of RA, particularly for RA of NM.

In part due to the limitations of both LCA and RA as used separately, a number of authors have argued that LCA and RA should be used as complementary tools. For instance, it has been argued that because RA may be too narrow in its scope and boundaries, e.g., investigating a single chemical substance or NM, the combined use with LCA may help broaden assessments to account for a wider range of adverse consequences (Olsen et al. 2001; Linkov and Seager 2011). Furthermore, by taking into account LCA in the risk analytical processes, it may also help avoid problem shifting. Others have suggested that combining or integrating LCA and RA may help promote the overall sustainable development of products and materials in a democratic way (Wrisberg and de Haes 2002), as well as help reduce overall chemical pressure (Flemström et al. 2004). However, it should be stated that while it may be beneficial to use these two tools together in a complementary manner for these aforementioned reasons, their full integration into one tool is considered neither desirable nor meaningful as the two tools answer different questions and have different system boundaries. In some cases, contradictory results have been found resulting from applying both methods (Flemström et al. 2004; Pant et al. 2004; Lim et al. 2011), which may only be logical given these differences. In such situations, the trade-off to be made between risks (identified in RA) and general environmental impacts (identified in LCA) would be kept transparent if full integration is avoided. Trade-offs could for instance be addressed by applying MCDA as suggested by Linkov and Seager (2011).

For chemicals, one common approach to combine or use LCA and RA together has been through the use of toxicological data generated from RA within the life-cycle impact assessment phase of LCA (Bare 2006; Kuczenski et al. 2010) as well as the use of industrial emissions data in both RA and life-cycle inventories (Flemström et al. 2004). Another common approach to use these tools together for chemicals has also been to perform RA at each or selected stages of a product’s life-cycle (Flemström et al. 2004). One main challenge has been the lack of a common object of study (i.e., functional unit in LCA and an amount of chemical in RA).

There have been a number of recommendations made on how to combine the use of LCA and RA for chemicals. For instance, it has been suggested that RA should be more aware of “life-cycle thinking” and that LCA should be more “toxics aware” e.g., by describing the toxic contents of intermediate flows (Kuczenski et al. 2010). Owens (1997) suggested that LCA identifies potential health issues on a system-wide and hypothetical basis and therefore cannot stand alone but that the identified potential (eco)toxicological impacts thereafter can be assessed in more detail by RA. On a methodological basis, it has been recommended that the functional unit of LCA should be defined in order that it provides a meaningful calculation of exposure concentrations which considers absolute mass of emissions (Flemström et al. 2004). More broadly, it has also been suggested that LCA is used as a strategic tool to prioritize data which is needed to complete RA (Socolof and Geibig 2006), as well as LCA and RA are used together in a common policy research agenda for decision-making (Cowell et al. 2002).

Using LCA and RA together for engineered NM

While there has been scientific consensus on the importance of using both LCA and RA together in strategies to assess the potential environmental and health impacts of NM, specific information or guidance on how to do this in practice is still in development. Moreover, many of the challenges for using LCA and RA together for NM are similar to those made previously for chemicals. For instance, one of the major obstacles which still persist is the use of different terminologies within the two tools. Som et al. (2010) documented that the terms “life-cycle concepts”, “life-cycle thinking”, “life-cycle considerations”, “life-cycle approach” and “life-cycle perspective” all generally referred to methods that were based on the life-cycles of NM/chemicals or products including a range of concepts (i.e., from ISO 14040 series to the organization of potential health and environmental impacts across different life-cycle stages). Linked to this, Seager and Linkov (2009) noted the challenge of using “life-cycle” specifically for NM, whereby they argued that this term was being used as a way to organize or identify potential sources of NM exposures rather than formal LCA procedures in many cases. Further obstacles have been noted to integrate LCA and RA for NM, namely the challenge of obtaining meaningful results for decision-making and a lack of specific guidance in these regards (Linkov and Seager 2011).

A number of scientists have suggested both conceptual and practical recommendations for applying LCA and RA for NM. Sweet and Strohm (2006) and Som et al. (2010) suggested that RA should take into account more life-cycle concepts and LCA should also be more risk-based for NM. Shatkin (2008a) also recommended that the risks of NM are evaluated at each life-cycle stage where there may be potential for exposure, and Wardak et al. (2008) recommended using LCA and RA methods based on scenario analyses with expert elicitation, specifically focusing on NM or nano-product use and disposal stages. Linkov and Seager (2011) also suggested using LCA and RA within a decision support frame (such as MCDA) for emerging materials including NM. In addition, Som et al. (2010) recommended using the same terminology, data and information flow between LCA and RA for NM, and Shatkin (2008a) suggested using alternative indicators when data are unavailable for life-cycle impact assessment models such as those parameters likely to influence potential adverse impacts. Hence, most if not all of these suggestions have been previously made for chemicals as outlined in this paper in the preceding section. Moreover, while these research recommendations have been very useful to help shape strategies to use LCA and RA for NM in theory, their practical demonstrations are extremely scarce, as exemplified through the handful of scientific research efforts as presented below. Overall, this information thus suggests that there are no conceptually new issues specifically for using LCA and RA for NM compared to previous investigations in relation to chemicals, and in particular strategies to use the two tools together (e.g., RA should be more life-cycle based, LCA be more risk-based, use of similar data and terminology, use of additional tools for decision-making).

Research progress for engineered NM

To date, we have identified six published and peer-reviewed journal articles, eight frameworks, and five international research projects which have specifically focused on the combined use of LC- and RA-based methods for NM (Tables 1, 2 Appendix). While it is recognized that there have been other research efforts which have focused on developing either LCA or RA separately, the research efforts summarized below are those efforts which have aimed at using both LC- and RA-based methods together for NM.

Looking across these research efforts, two main approaches have been proposed for combining or using these methods for NM. One approach, termed the “LC-based RA” approach, consists of a traditional RA applied in a life-cycle perspective to help concentrate efforts where it is the most needed, i.e., at each life-cycle stage. This is considered as a continuation of standard RA in a LC-perspective, as required by e.g., REACH. Another approach termed the “RA-complemented LCA” approach consists of a conventional LCA conducted to assess the environmental performances of the product and complemented by a qualitative, semi-quantitative or quantitative RA to assess risks related to specific life-cycle steps. Hence, the “RA-complemented LCA” approach is in fact the only identified approach which genuinely combines LC- and RA-based methods for NM-risk research efforts to date, as the “LC-based RA” approach is rather a continuation of normal RA according to standard assessment procedures.

These two approaches are similar to those previously proposed for chemicals (Flemström et al. 2004; Kuczenski et al. 2010). It is also found that several research articles and frameworks have developed guidance and recommendations on how to apply and improve these two approaches (Table 1). Apart from documented case studies involving the frameworks, very few peer-reviewed studies have shown the testing and validation of these strategies on concrete case studies (Wardak et al. 2008; Linkov and Seager 2011). Moreover, most of the identified international research projects are still in development phase and/or do not provide enough information to allow for conclusive evaluations.

Most of the selected published journal articles remain at a theoretical level and describe the use of the “RA-complemented LCA” approach (with exception of Wardak et al. 2008). The provision of rationales for combining or using LC- and RA-based methods together for assessing NM is common to all articles, i.e. the opportunity to assess potential environmental risks and impacts related to the production, use and disposal of NM with as much comprehensiveness and as early as possible in the product development. However, most of the studies (four of six) lack strong evidence of the workability of the proposed methodologies, with the exceptions being Wardak et al. (2008) and Linkov and Seager (2011). Som et al. (2010) was found to be the study providing the most concrete guidance on the possible intersections of LCA and RA in relation to the goals of the assessment. Sweet and Strohm (2006) also give a basic overview on how to apply a “RA-complemented LCA” approach across various product stages, although it lacked specific steps for application. Linkov and Seager (2011) proposed coupling LCA and RA together with the decision tool MCDA. Furthermore, all of the investigated journal articles provided guidance on how to use or apply the proposed approach and most (five out of six) provided recommendations on improving the proposed LC- and RA-based methods for NM.

Most of the identified frameworks presented methodologies and guidance to assess the potential health and environmental risks of NM across life-cycle stages. Most of the evaluated frameworks (five out of eight) used an “RA-complemented LCA”, where CEA, ISO Risk Evaluation framework, Nano Risk Framework, Nano LCRA, and proposed applications of MCDA are all based on evaluating potential risks of NM at separate life-cycle stages and then formulating decisions. CENARIOS®, precautionary matrix and to some extent the risk governance framework take a more “LC-based RA” approach. The former two frameworks rely on a structured approach to RA which takes into account life-cycle aspects and different evaluations are made at different life-cycle stages, while the latter framework considers life-cycle aspects only to some extent and very generally. While all of the frameworks provided guidance on how to use their proposed approach, only half of them provided detailed information such as concrete steps to complete the proposed frameworks. Most of the frameworks (six out of eight) provided recommendations on how to improve LC- and RA-based methods for NM, such as suggestions on how to use the proposed frameworks (i.e., through iterative processes or specific testing methods) or how to make management decisions resulting from the use of the frameworks.

Finally, it was difficult to assess the research progress made within the international research projects as most information was only presented on the project websites as opposed to within e.g., peer-reviewed articles or other publically-available literature, e.g. reports. With the exception of the project “identifying and regulating environmental impacts of NM”, most research projects are also still in development and therefore case studies are generally lacking but may be available in the future. For these reasons, information pertaining to these research projects is not presented in Table 1 alongside the results from the other research efforts (although included in Table 2 in Appendix as supporting information). Nonetheless based on limited information, it appears that most of the identified international research projects used a “RA-complemented LCA” approach (with the exception of NEPHH). Furthermore, only Nanovalid provided guidance on how to use or apply the proposed approach of LC- or RA-based methods for NM, and only Nanovalid and Prosuite provided recommendations for improving LC- and RA-based methods for NM as well as documented case studies.

Overall these findings regarding how research activities have in fact applied these methods to NM in practice indicate that while most of these provide support for using these two tools for NM, there have been no significant developments in their approach for applying LCA and RA together for NM compared to previous experiences with chemicals. This is exemplified by the fact that two of the main proposed approaches were based on previous experience with chemicals. Finally, most research efforts provided guidance and recommendations for using the proposed approaches although documented case studies in the peer-reviewed literature were lacking but present in association with most of the risk analysis frameworks. In light of these findings, we have identified one particular issue that may be specific in the case of NM when applying LCA and RA at this current stage of research: the need for proper dose metrics for describing meaningful scenarios for hazard and exposure assessments and for combining the two in risk quotients (in RA) or toxicity characterization factors (in LCA). It is likely that research which addresses this will need to be first addressed within each methodology in terms of developing the conceptual approaches, although subsequent research is needed to develop a common use of e.g., toxicological data which should first be solved in RA and then later adapted within LCA.

Conclusions and recommendations

In light of previous experiences with applying LCA and RA together for chemicals, current research efforts focused on using these methods together for NM appear to have taken into account some key “lessons learned” while most key challenges remain for practically applying these methods. For instance, many recommendations made for applying LCA and RA together in the case of NM are very similar to those made for chemicals on both a conceptual level (e.g., RA should be more “life-cycle aware” and LCA more “toxics aware”) as well as practical level (e.g., use of same database on inherent properties for use and exposure). Moreover, there have also been similar challenges in terms of applying these methods to NM (e.g., use of different terminologies, different interpretations or perceptions of the terms and approaches). Through the analysis of research efforts in the form of published and peer-reviewed journal articles, risk analysis frameworks and international research projects which specifically focused on the combined use of LC- and RA-based methods for NM, two main approaches have been proposed for NM: “LC-based RA” (traditional RA applied in a life-cycle perspective) and “RA-complemented LCA” (conventional LCA conducted to assess environmental performances of the product and complemented by RA), where only the latter in fact genuinely combines LC- and RA-based methods for NM-risk research efforts to date. These approaches are similar to strategies previously developed for RA in a life-cycle perspective and for combing LCA and RA for chemicals. It was also found that most of the identified journal articles present theoretical work and most do not provide strong evidence of the workability of the proposed methodologies, while the frameworks presented specific methodologies and guidance for applying the proposed approaches and all but one were demonstrated in documented case studies. Most of the identified international research projects are still in development phase and/or do not provide enough information to allow for conclusive evaluations.

This information suggests that there does not appear to be much progress made specifically in respect to applying LCA and RA to NM, as many of the proposed approaches and recommendations for combining or using these methods together for NM are similar to those made previously for chemicals. We have identified one issue in particular that may be specific in the case of NM when applying LCA and RA: the need to establish proper metrics develop hazard and exposure assessments and to combine these in risk quotients or toxicity characterization factors, in RA and LCA, respectively.

In light of these findings, we first recommend that those working with applying or integrating LCA and RA together for NM should avoid “reinventing the wheel” by taking into account previous experiences and findings related to combined use of RA and LCA for chemicals. This would insure that on-going and future research efforts address the presently existing challenges of applying these methods, also acknowledging the respective strengths and weaknesses of both methods. Second, it is recommended that the decision of whether to use LCA, RA or a combination of them will likely depend on the overall goal to be achieved (see Fig. 1). For instance, if the overall environmental impacts should be evaluated over the life-cycle of a product or process, then LCA should be used as this is essentially what LCA is designed for. In other instances such as if risks should be evaluated/controlled for a single NM in a particular use or at a particular location along the material’s life-cycle, RA should then be used. This may be beneficial in cases in which it is needed to know whether a risk related to exposure of a particular NM exists or not in a particular circumstance. The use of RA may also be directly required by regulation. Third, given the confusion around the term “life-cycle”, it is recommended that whenever the term “life-cycle” is used (even in a non-NM context), it is clarified whether it refers to a chemical or NM’s life-cycle, to an LCA product life-cycle, to part of any of those life-cycles or to another entity (see Box 1). Finally, in order to improve decision support based on findings from either tool it is also recommended that research is needed in the short-term to develop an agreed-upon best metric(s) to be used in both LCA and RA-both separately as well as used in combination with each other. This is needed to establish meaningful scenarios for hazard and exposure assessments and for combining risk quotients or toxicity characterisation factors in RA and LCA, respectively.

References

Aitken RA, Bassan A, Friedrichs S et al. (2011) Specific advice on exposure assessment and hazard/risk characterisation for nanomaterials under REACH (RIP-oN 3). Final Project Report, RNC/RIP-oN3/FPR/1/FINAL. http://ec.europa.eu/environment/chemicals/nanotech/pdf/report_ripon3.pdf. Accessed 9 Nov 2011

Anastas P, Davis M (2010) August 2010 BOSC nanomaterial case studies workshop review letter report. US Environmental Protection Agency Office of Research and Development, Board of Scientific Counselors (BOSC). http://www.epa.gov/osp/bosc/pdf/nano1008rpt.pdf. Accessed 9 Nov 2011

Aschberger K, Johnston HJ, Stone V, Aitken RJ, Tran CL, Hankin SM, Peters SAK, Christensen FM (2010a) Review of carbon nanotubes toxicity and exposure—appraisal of human health risk assessment based on open literature. Crit Rev Toxicol 40:759–790

Aschberger K, Johnston HJ, Stone V, Aitken RJ, Tran CL, Hankin SM, Peters SAK, Christensen FM (2010b) Review of fullerene toxicity and exposure—a human health risk assessment appraisal based on open literature. Regul Toxicol Pharmacol 58:455–473

Baer DR, Gaspar DJ, Nachimuthu P, Techane SD, Castner DG (2010) Application of surface chemical analysis tools for characterization of nanoparticles. Anal Bioanal Chem 396:100–983

Bare J (2006) Risk assessment and life-cycle impact assessment (LCIA) for human health cancerous and noncancerous emissions: integrated and complementary with consistency within the USEPA. Hum Ecol Risk Assess 12:493–509

Bauer C, Buchgeister J, Hischier R, Poganietz WR, Schebek L, Warsen J (2008) Towards a framework for life-cycle thinking in the assessment of nanotechnology. J Clean Prod 16:910–926

Baun A, Hartmann NB, Grieger K, Hansen SF (2009) Setting the limits for engineered nanoparticles in European surface waters. J Environ Monit 11:1774–1781

Biomedtalk (2009) Public discussion on the FP7 project 228536 – NEPHH. http://www.biomedtalk.com/forumdisplay.php?f=631. Accessed 17 June 2012

Boverhof DR, David RM (2010) Nanomaterial characterization: considerations and needs for hazard assessment and safety evaluation. Anal Bioanal Chem 396:953–961

Bühler P (2010) Media releases: Bühler Partec’s risk management system certified. http://www.buhlergroup.com/global/en/about-buhler/media/media-releases.htm. Accessed 9 Nov 2011

Canis L, Seager T, Linkov I (2010) Selecting nanomanufacturing technology using integrated risk, life-cycle assessment and decision-analytical framework. Environ Sci Technol 44:8704–8711

Christensen FM (2010) Reflections from an OECD workshop on environmental benefits of nanotechnology. Int J Life Cycle Assess 15:137–138

Christensen F, Olsen S (2004) The potential role of life-cycle assessment in regulation of chemicals in the European Union. Int J Life Cycle Assess 9:327–332

Christensen FM, Johnston HJ, Stone V, Aitken RJ, Hankin S, Peters S, Aschberger K (2010) Nano-silver—feasibility and challenges for human health risk assessment based on open literature. Nanotoxicol 4:284–295

Christensen FM, Johnston HJ, Stone V, Aitken RJ, Hankin S, Peters S, Aschberger K (2011) Nano-TiO2—feasibility and challenges for human health risk assessment based on open literature. Nanotoxicol 5:110–124

Clark K, White RH, Wilbergeld EK (2011) Predictive models for nanotoxicology: current challenges and future opportunities. Regul Toxicol Pharm 59:361–363

Cowell SJ, Fairman R, Lofstedt RE (2002) Use of risk assessment and life-cycle assessment in decision making: a common policy research agenda. Risk Anal 22:879–894

Davis JM (2007) How to assess the risks of nanotechnology: learning from past experience. J Nanosci Nanotechnol 7:402–409

Department for Environment, Food and Rural Affairs (DEFRA) (2007) Characterising the potential risks posed by engineered nanoparticles: second UK Government research report. UK Department for Environment, Food and Rural Affairs, London. http://files.nanobio-raise.org/Downloads/nanoriskrep07.pdf. Accessed 9 Nov 2011

Environmental Defense (ED) and Dupont (2007a) Nano risk framework. Environmental Defense–Dupont Nano Partnership, Washington, DC. http://apps.edf.org/documents/6496_nano%20risk%20framework.pdf. Accessed 9 Nov 2011

Environmental Defense (ED) and Dupont (2007b) Nanomaterial risk assessment worksheet: DuPont™ light stabilizer for use as a polymer additive. Environmental Defense–Dupont Nano Partnership, Washington, DC. http://epa.gov/oppt/nano/dupont1.pdf. Accessed 9 Nov 2011

Environmental Defense (ED) and Dupont (2007c) Nanomaterial risk assessment worksheet: incorporation of single and multi walled carbon nano tubes (CNTs) into polymer nanocomposites by melt processing. Environmental Defense–Dupont Nano Partnership, Washington, DC. http://www.nanoriskframework.com/files/2011/11/6914_CNTs_Worksheet.pdf. Accessed 9 Nov 2011

Environmental Defense (ED) and Dupont (2007d) Nanomaterial risk Assessment worksheet: zero valent nano sized iron nanoparticles (nZVI) for environmental remediation. Environmental Defense–Dupont Nano Partnership, Washington, DC. http://www2.dupont.com/Media_Center/en_US/assets/downloads/pdf/NRAW_nZVI.pdf. Accessed 9 Nov 2011

European Chemicals Agency (ECHA) (2010) Guidance on information requirements and chemical safety assessment. http://guidance.echa.europa.eu/docs/guidance_document/information_requirements_en.htm?time=1289468158. Accessed 9 Nov 2011

European Commission (EC) (2003) Technical guidance document in support of commission directive 93/67/EEC on risk assessment for new notified substances and commission regulation (EC) 1488/94 on risk assessment for existing substances. European Commission, Brussels. http://ihcp.jrc.ec.europa.eu/our_activities/public-health/risk_assessment_of_Biocides/doc/tgd/tgdpart2_2ed.pdf. Accessed 9 Nov 2011

European Commission (EC) (2004) Towards a European strategy for nanotechnology. http://cordis.europa.eu/nanotechnology/actionplan.htm. Accessed 9 Nov 2011

European Commission (EC) (2010) International reference life-cycle data system (ILCD). In: Handbook of general guide for life-cycle assessment. Joint Research Centre, Institute for Environment and Sustainability, Luxembourg. http://lct.jrc.ec.europa.eu/pdf-directory/ILCD-Handbook-General-guide-for-LCA-DETAIL-online-12March2010.pdf. Accessed 9 Nov 2011

European Commission (EC) (2011a) Commission recommendation of 18 October 2011 on the definition of nanomaterial. Off J Eur Union L 275:38–40. http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2011:275:0038:0040:EN:PDF. Accessed 9 Nov 2011

European Commission (EC) (2011b) Europe-wide life-cycle thinking essential for sustainable nanotechnology applications. http://ec.europa.eu/environment/etap/inaction/policynews/702_en.html. Accessed 9 Nov 2011

European Communities (2007) Corrigendum to regulation (EC) No. 1907/2006 of the European Parliament and of the Council of 18 December 2006 concerning the registration, evaluation, authorisation and restriction of chemicals (REACH), establishing a European Chemicals Agency, amending directive 1999/45/EC and repealing council regulation (EEC) No. 793/93 and commission regulation (EC) No. 1488/94 as well as Council Directive 76/769/EEC and commission directives 91/155/EEC, 93/67/EEC, 93/105/EC and 2000/21/EC (OJ L 396, 30.12.2006). Off J Eur Union L 136:3–280. http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2007:136:0003:0280:en:PDF. Accessed 9 Nov 2011

European Technology Platform for Advanced Engineering Materials and Technologies (EUMAT) (2011). Specialist brainstorming and coordination meeting on “life-cycle assessment (LCA) and risk analysis in nanomaterials-related NMP projects”, Brussels. http://eumat.eu/Events/default.aspx?EventID=2912. Accessed 9 Nov 2011

Evans JS, Hofstetter P, McKone TE, Hammitt JK, Lofstedt R (2002) Introduction to special issue on life-cycle assessment and risk analysis. Risk Anal 22:819–820

Flemström K, Carlson R, Erixon M (2004) Relationships between life-cycle assessment and risk assessment—potentials and obstacles. Report 5379, industrial environmental informatics (IMI). Chalmers University of Technology. http://www.naturvardsverket.se/Documents/publikationer/620-5379-5.pdf. Accessed 9 Nov 2011

Gavankar S, Suh S, Keller AF (2012) Life-cycle assessment at nanoscale: review and recommendations. Int J Life Cycle Assess 17:295–303

Grieger K, Hansen SF, Baun A (2009) The known unknowns of nanomaterials: describing and characterizing uncertainty within environmental, health and safety risks. Nanotoxicol 3:1–12

Grieger K, Linkov I, Hansen SF, Baun A (2011) Environmental risk analysis for nanomaterials: review and evaluation of frameworks. Nanotoxicology. doi:10.3109/17435390.2011.569095

Grubb FG, Bakshi RB (2011) Life-cycle of titanium dioxide nanoparticle production. J Ind Ecol 15:81–95

Hanai S, Kobayashi N, Ema M, Ogura I, Gamo M, Nakanishi J (2009) Risk assessment of manufactured nanomaterials—titanium dioxide (TiO2). NEDO project research and development of nanoparticle characterization methods, Report No. P06041. http://goodnanoguide.org/tiki-download_wiki_attachment.php?attId=32. Accessed 9 Nov 2011

Hankin SM, Peters SAK, Poland CA et al. (2011) Specific advice on fulfilling information requirements for nanomaterials under REACH (RIP-No. 2). Final project report, RNC/RIP-oN2/FPR/1/FINAL. http://ec.europa.eu/environment/chemicals/nanotech/pdf/report_ripon2.pdf. Accessed 9 Nov 2011

Hauschild MZ (2005) Assessing environmental impacts in a life-cycle perspective. Environ Sci Technol 39:81A–88A

Hendren CO, Mesnard X, Dröge J, Wiesner MR (2011) Estimating production data for five engineered nanomaterials as a basis for exposure assessment. Environ Sci Technol 45:2562–2569

Hischier R, Walser T (2012) Life-cycle assessment of engineered nanomaterials: state of the art and strategies to overcome existing gaps. Sci Total Environ 425:271–282

Höck J, Hofmann H, Krug H, Lorenz C, Limbach L, Nowack B, Riediker M, Schischke K, Som C, Stark W et al. (2008) Guidelines on the precautionary matrix for synthetic nanomaterials, Version 1. Swiss Federal Office for Public Health and Federal Office for the Environment, Berne. http://www.temas.ch/wwwtemas/temas_homepage.nsf/vwRes/Spiegel_051/$FILE/Raster_021208_EN.pdf. Accessed 9 Nov 2011

Höck J, Epprecht T, Hofmann H, Höhner K, Krug H, Lorenz C, Limbach L, Gehr P, Nowack B, Riediker M et al. (2010) Guidelines on the precautionary matrix for synthetic nanomaterials, Version 2.1. Swiss Federal Office for Public Health and Federal Office for the Environment, Berne. http://www.temas.ch/wwwtemas/temas_homepage.nsf/vwRes/NanoSR26/$FILE/Wegleitung_e.pdf. Accessed 9 Nov 2011

International Organization for Standardization (ISO) (2006a) Environmental management—life-cycle assessment—requirements and guidelines (ISO 14044:2006). http://www.iso.org/iso/catalogue_detail?csnumber=38498. Accessed 9 Nov 2011

International Organization for Standardization (ISO) (2006b) Environmental management—life-cycle assessment—principles and framework (ISO 14040:2006). http://www.iso.org/iso/catalogue_detail?csnumber=37456. Accessed 9 Nov 2011

International Organization for Standardization (ISO) (2008) Spécification technique international nanotechnologies—terminology and definitions for nano-objects—nanoparticle, nanofibre and nanoplate. http://www.iso.org/iso/iso_catalogue/catalogue_tc/catalogue_detail.htm?csnumber=44278. Accessed 17 June 2012

International Organization for Standardization (ISO) (2011) Nanotechnologies-nanomaterial risk evaluation (ISO/TR 13121). http://www.iso.org/iso/catalogue_detail.htm?csnumber=52976. Accessed 9 Nov 2011

International Risk Governance Council (IRGC) (2005) Risk governance: towards an integrative approach. IRGC, Geneva. http://www.irgc.org/IMG/pdf/IRGC_WP_No_1_Risk_Governance__reprinted_version_.pdf. Accessed 9 Nov 2011

International Risk Governance Council (IRGC) (2007) Nanotechnology risk governance: recommendations for a global, coordinated approach to the governance of potential risks. IRGC, Geneva. http://www.irgc.org/IMG/pdf/PB_nanoFINAL2_2_.pdf. Accessed 9 Nov 2011

International Risk Governance Council (IRGC) (2009) Appropriate risk governance strategies for nanotechnology applications in food and cosmetics. IRGC, Geneva. http://www.irgc.org/IMG/pdf/irgc_nanotechnologies_food_and_cosmetics_policy_brief.pdf. Accessed 9 Nov 2011

Khanna V, Bakshi BR, Lee LJ (2008a) Carbon nanofiber production. J Ind Ecol 12:394–410

Khanna V, Bakshi BR, Lee LJ (2008b) Assessing life-cycle environmental implications of polymer nanocomposites. IEEE Int Symp Electron Environ 1–6

Klöpffer W, Curran MA, Frankl P et al. (2007) Nanotechnology and life-cycle assessment: a systems approach to nanotechnology and the environment. Woodrow Wilson International Center for Scholars, Project on Emerging Nanotechnologies, Washington, DC. http://www.nanotechproject.org/file_download/files/NanoLCA_3.07.pdf. Accessed 9 Nov 2011

Kobayashi N, Ogura I, Gamo M, Kishimoto A, Nakanishi J (2009) Risk assessment of manufactured nanomaterials—carbon nanotbues (CNTs). Report No. P06041, NEDO project research and development of nanoparticle characterization methods. http://goodnanoguide.org/tiki-download_wiki_attachment.php?attId=31. Accessed on 9 Nov 2011

Krishnan N, Boyd S, Somani A, Raoux S, Clark D, Dornfeld D (2008) A hybrid life-cycle inventory of nano-scale semiconductor manufacturing. Environ Sci Technol 42:3069–3075

Kuczenski B, Geyer R, Boughton B (2010) Tracking toxicants: towards a life-cycle aware risk assessment. Environ Sci Technol 45:45–50

LEITAT (2011) Safety issues of nanomaterials along their life-cycle. LEITAT Technological Center, Symposium 4–5 May 2011, Barcelona. http://www.leitat.org/nanoLCA/index.htm. Accessed 9 Nov 2011

Lim SR, Lam CW, Schoenung JM (2011) Priority screening of toxic chemicals and industry sectors in the US toxics release inventory: a comparison of the life-cycle impact-based and risk-based assessment tools developed by US EPA. J Environ Manag 92:2235–2240

Linkov I, Seager T (2011) Coupling multi-criteria decision analysis, life-cycle assessment, and risk assessment for emerging threats. Environ Sci Technol 45:5068–5074

Linkov I, Satterstrom FK, Steevens J, Ferguson E, Pleus RC (2007) Multi-criteria decision analysis and environmental risk assessment for nanomaterials. J Nanoparticle Res 9:543–554

Linkov I, Bates ME, Canis LJ, Seager TP, Keisler JM (2011) A decision-directed approach for prioritizing research into the impact of nanomaterials on the environment and human health. Nat Nanotechnol 6:784–787

Merugula AL, Khanna V, Bakshi RB (2010) Comparative life-cycle assessment: reinforcing wind turbine blades with carbon nanofibers. In: Proceedings of the 2010 IEEE international symposium on sustainable systems and technology, p 5507724

Meyer ED, Curran MA, Gonzalez MA (2010) An examination of silver nanoparticles in socks using screening-level life-cycle assessment. J Nanoparticle Res 13:147–156

Moign A, Vardelle A, Themelis NJ, Legoux JG (2010) Life-cycle assessment of using powder and liquid precursors in plasma spraying: the case of yttria-stabilized zirconia. Surf Coat Technol 205:668–673

Nanopolytox (2011) Toxicological impact of nanomaterials derived from processing, weathering and recycling from polymer nanocomposites used in various industrial applications. European Union F7 project. http://www.nanopolytox.eu/. Accessed 9 Nov 2011

Nanovalid (2010) NANOVALID—Seventh Framework Programme (FP7). http://www.venetonanotech.it/it/news-eventi/news-dal-distretto/nanovalid-seventh-framework-programme-fp7,3,9959. Accessed 9 Nov 2011

National Science Foundation (NSF) (2007) NER: identifying and regulating environmental impacts of nanomaterials. www.nsf.gov/awardsearch/showAward.do?AwardNumber=0508347&version=noscript. Accessed 9 Nov 2011

NEPHH (2011) Nanomaterials related environmental pollution and health hazards throughout their life-cycle. http://www.nephh-fp7.eu/. Accessed 9 Nov 2011

Nishioka Y, Levy JI, Norris GA, Wilson A, Hofstetter P, Spengler JD (2002) Integrating risk assessment and life-cycle assessment: a case study of insulation. Risk Anal 5:1003–1017

O’Brien NJ, Cummins EJ (2011) A risk assessment framework for assessing metallic nanomaterials of environmental concern: aquatic exposure and behaviour. Risk Anal 5:706–726

Olsen SI, Christensen FM, Hauschild M, Pedersen F, Larsen HF, Tørsløv J (2001) Life-cycle impact assessment and risk assessment of chemicals—a methodological comparison. Environ Impact Assess Rev 21:385–404

Organisation for Economic Co-operation and Development (OECD) (2009) Preliminary review of OECD test guidelines for their applicability to manufactured nanomaterials. Report No. ENV/JM/MONO(2009)21, Environment Directorate, Joint Meeting of the Chemicals Committee and the Working Party on chemicals, pesticides and biotechnology, Paris. http://www.oecd.org/document/53/0,3746,en_2649_37015404_37760309_1_1_1_1,00&&en-USS_01DBC.html. Accessed 9 Nov 2011

Organisation for Economic Co-operation and Development (OECD) (2010) Current developments/activities on the safety of manufactured nanomaterials: Tour de Table at the 6th meeting of the working party on manufactured nanomaterials. Report No. ENV/JM/MONO(2010)4, Paris. http://www.oecd.org/document/53/0,3746,en_2649_37015404_37760309_1_1_1_1,00&&en-USS_01DBC.html. Accessed 9 Nov 2011

Organisation for Economic Co-operation and Development (OECD) (2011) OECD database on research into the safety of manufactured nanomaterials. http://webnet.oecd.org/NanoMaterials/Pagelet/Front/Default.aspx. Accessed 9 Nov 2011

Owens JW (1997) Life-cycle assessment in relation to risk assessment: an evolving perspective. Risk Anal 17:359–365

Pant R, Van Hoof G, Schowanek D, Feijtel TCJ, de Koning A, Hauschild M, Pennington DW, Olsen SI, Rosenbaum R (2004) Comparison between three different LCIA methods for aquatic ecotoxicity and a product environmental risk assessment. Int J Life Cycle Assess 9:295–306

Prosuite (2011) Development and application of standardized methodology for the prospective sustainability assessment of technologies. European Union FP7. http://www.prosuite.org. Accessed 9 Nov 2011

Pyell U (2010) Characterization of nanoparticles by capillary electromigration separation techniques. Electrophoresis 31:814–831

Renn O (2008) Risk governance: coping with uncertainty in a complex world, Earthscan, London

Robichaud CO, Tanzil D, Weilenmann U, Wiesner MR (2005) Relative risk analysis of several manufactured nanomaterials: an insurance industry context. Environ Sci Technol 39:8985–8994

Rocks S, Pollard S, Dorey R, Levy L, Harrison P, Handy R (2008) Comparison of risk assessment approaches for manufactured nanomaterials. Defra project (CB403). Cranfield University. http://www.cranfield.ac.uk/health/researchareas/environmenthealth/ieh/page26480.html. Accessed 9 Nov 2011

Rosenbaum RK, Bachmann TM, Gold LS et al (2008) USEtox, the UNEP-SETAC toxicity model: recommended characterisation factors for human toxicity and freshwater ecotoxicity in life-cycle impact assessment. Int J Life Cycle Assess 13:532–546

Royal Society and Royal Academy of Engineering (2004) Nanoscience and nanotechnologies: opportunities and uncertainties. The UK Royal Society, London. http://www.nanotec.org.uk/finalReport.htm. Accessed 9 Nov 2011

Russel AJ (2007) Human and ecological risk assessment and life-cycle assessment: intersections, collisions, and future directions. Hum Ecol Risk Asess 12:427–430

Scientific Committee on Emerging and Newly Identified Health Risks (SCENIHR) (2009) Risk assessment of products of nanotechnologies. European Commission Health and Consumer Protection Directorate-General, Directorate C—public health and risk assessment, C7—risk assessment, Brussels. http://ec.europa.eu/health/ph_risk/committees/04_scenihr/docs/scenihr_o_023.pdf. Accessed 9 Nov 2011

Scientific Committee on Emerging and Newly Identified Health Risks (SCENIHR) (2010) Scientific basis for the definition of the term “nanomaterial.” European Commission Health and Consumer Protection Directorate-General, Directorate C—public health and risk assessment, C7—risk assessment, Brussels. http://ec.europa.eu/health/scientific_committees/emerging/docs/scenihr_o_032.pdf. Accessed 9 Nov 2011

Seager TP, Linkov I (2008) Coupling multicriteria decision analysis and life-cycle assessment for nanomaterials. J Ind Ecol 12:282–285

Seager TP, Linkov I (2009) Uncertainty in life-cycle assessment of nanomaterials: multi-criteria decision analysis framework for single wall carbon nanotubes in power applications. In: Steevens J (ed) Linkov I. Nanomaterials: risks and benefits, Springer, pp 423–436

Sengül H, Theis LT (2011) An environmental impact assessment of quantum dot photovoltaics (QDPV) from raw material acquisition through use. J Clean Prod 19:21–31

Shatkin JA (2008a) Informing environmental decision making by combining life-cycle assessment and risk analysis. J Ind Ecol 12:278–281

Shatkin JA (2008b) Nanotechnology: health and environmental risks. CRC Press, Boca Raton. http://www.uotechnology.edu.iq/NTRC/PDF/nano/Nanotechnology%20Health%20And%20Enviroment.pdf. Accessed 9 Nov 2011

Shatkin JA (2009a) Investigating the life-cycle risks of a nanomaterial in a coating using nano LCRA. Society for risk analysis annual meeting. Symposium M4-I, Baltimore

Shatkin JA (2009b) Risk analysis for nanotechnology: state of the science and implications. US Department of Agriculture, Washington, DC. http://www.usda.gov/oce/risk_assessment/risk_forums/Shatkin100709.pdf. Accessed 9 Nov 2011

Shinohara N, Gamo M, Nakanishi J (2009) Risk assessment of manufactured nanomaterials—Fullerene (C60). Report No. P06041, NEDO project research and development of nanoparticle characterization methods. http://goodnanoguide.org/tiki-download_wiki_attachment.php?attId=29. Accessed 9 Nov 2011

Socolof ML, Geibig JR (2006) Evaluating human and ecological impacts of a product life-cycle: the complementary roles of life-cycle assessment and risk assessment. Hum Ecol Risk Assess 12:510–527

Som C, Berges M, Chaudhry Q, Dusinska M, Fernandes T, Olsen S, Nowack B (2010) The importance of life-cycle concepts for the development of safe nanoproducts. Toxicol 269:160–169

Som C, Wick P, Krug H, Nowack B (2011) Environmental and health effects of nanomaterials in nanotextiles and facade coatings. Environ Int 37:1131–1142

Stone V, Aitken R, Aschberger K, Baun A, Christensen FM, Fernandes TF, Hansen SF, Hartmann NB, Hutchison G, Johnston H et al. (2010) Engineered nanoparticles: review of health and environmental safety (ENRHES). Final report, ENRHES FP 7 project. http://ihcp.jrc.ec.europa.eu/whats-new/enhres-final-report. Accessed 9 Nov 2011

Sweet L, Strohm B (2006) Nanotechnology—life-cycle risk management. Hum Ecol Risk Assess 12:528–551

Swiss Federal Office for the Environment (FOEN) (2010) Workplace safety is first priority. http://www.bafu.admin.ch/dokumentation/umwelt/10649/10660/index.html?lang=en. Accessed 4 Nov 2010

Swiss Federal Office of Public Health (2010) Application of precautionary matrix on life-cycle of anti-fingerprint product. 2nd NanoImpactNet conference, Lausanne

Tervonen T, Linkov I, Figueira JR, Steevens J, Chappell M, Merad M (2009) Risk-based classification system of nanomaterials. J Nanoparticle Res 11:757–766

TÜV SÜD (2008) Certification standard CENARIOS®.TÜV SÜD Industrie Service GmbH, Munich, DE. http://www.tuev-sued.de/uploads/images/1219824286015340810363/CENARIOS_Zertifiziergrundlage_e.pdf. Accessed 9 Nov 2011

US Army Environmental Policy Institute (2009) Army Environmental Policy Institute (AEPI) report: managing the life-cycle risks of nanomaterials. Army Environmental Policy Institute, Arlington. http://www.aepi.army.mil/docs/whatsnew/Managing_the_Life_Cycle_Risks_of_Nanomaterials_Final_July_2009.pdf. Accessed 9 Nov 2011

US Environmental Protection Agency (US EPA) (2008) Draft nanomaterial research strategy. Report No. EPA/600/S-08/002, Office of Research and Development. http://epa.gov/ncer/nano/publications/nano_strategy_012408.pdf. Accessed 9 Nov 2011

US Environmental Protection Agency (US EPA) (2009) External review draft nanomaterial case studies: nanoscale titanium dioxide in water treatment and in topical sunscreen. Report No. EPA/600/R-09/057, National Center for Environmental Assessment, Office of Research and Development, Research Triangle Park. http://cfpub.epa.gov/ncea/cfm/recordisplay.cfm?deid=210206. Accessed 9 Nov 2011

US Environmental Protection Agency (US EPA) (2010a) Nanomaterial case study: Nanoscale silver in disinfectant spray (external review draft). Report No. EPA/600/R-10/081, Washington, DC. http://cfpub.epa.gov/ncea/cfm/recordisplay.cfm?deid=226723. Accessed 9 Nov 2011

US Environmental Protection Agency (US EPA) (2010b) Nanomaterial case studies workshop: Developing a comprehensive environmental assessment research strategy for nanoscale titanium dioxide. Report No. EPA/600/R-10/042, National Center for Environmental Assessment-RTP Division Office of Research and Development, Research Triangle Park. ofmpub.epa.gov/eims/eimscomm.getfile?p_download_id=505179. Accessed 9 Nov 2011

Valverde LJ, Linkov I (2011) Nanotechnology: risk assessment and risk management perspective. Nanotechnol Law Bus 8:25–47

Wardak A, Gorman ME, Swami N, Deshpande S (2008) Identification of risks in the life-cycle of nanotechnology-based products. J Ind Ecol 12:435–448

Warheit DB (2008) How meaningful are the results of nanotoxicity studies in the absence of adequate material characterization? Toxicol Sci 101:183–185

Wrisberg N, de Haes U (2002) Analytical tools for environmental design and management in a systems perspective. Kluwer Academic Publishers, The Netherlands

Acknowledgments

Funding for this analysis has been partially provided by the European FP7 project, PlasmaNice (Atmospheric Plasmas for Nanoscale Industrial Surface Processing), as well as the graduate school 3R Residual Resources Research at the Technical University of Denmark.

Author information

Authors and Affiliations

Corresponding author

Additional information

The opinions expressed in the paper are those of the authors and not necessarily those of the European Commission.

Appendix

Appendix

See Table 2.

Rights and permissions

About this article

Cite this article

Grieger, K.D., Laurent, A., Miseljic, M. et al. Analysis of current research addressing complementary use of life-cycle assessment and risk assessment for engineered nanomaterials: have lessons been learned from previous experience with chemicals?. J Nanopart Res 14, 958 (2012). https://doi.org/10.1007/s11051-012-0958-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-012-0958-6