Abstract

Mo-doped WO3 nanowires were fabricated by a hydrothermal method in the presence of K2SO4. The physical properties of prepared nanowires were characterized by X-ray diffraction (XRD), energy-dispersive X-ray analysis (EDS), scanning electron microscopy (SEM), and transmission electron microscopy (TEM). The results show that the obtained products are nanowires with diameters ranging between 10 and 20 nm, and lengths of about 600 nm. Its photoactivity was evaluated through the photodegradation of methylene blue (MB) in aqueous solution. Effects of the molybdenum concentration on the photoactivity of the obtained samples were investigated detailedly. The experimental results indicated that the Mo-doping enhanced the photoactivity of WO3 nanowires.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Water is a prime source for all living organism including human beings. A number of industrial effluents, agricultural runoff, and chemical spills are directly released into the water systems. The removal of organic pollutants from water is very important for environmental protection and to fulfill the needs for drinking, irrigation, and industrial use (Qamar et al. 2009b). Many different oxide semiconductors have been used as photocatalysts for water decomposition to oxygen and hydrogen (Yu et al. 2009; Liu et al. 2009; Stengl et al. 2009; Zhang et al. 2004; Bamwenda and Arakawa 2001; Chen 2007). Among them, TiO2 has been dominantly used because of its high activity, long-term stability, low price, and availability. However, The TiO2 semiconductor has to mainly use ultraviolet irradiation (Yu et al. 2007) due to its wide band gap. The solar spectrum usually contains about 4% UV light. Therefore, many studies have been tried on the direction of utilizing narrower band gap semiconducting materials that undergo intrinsic photoexcitation, charge separation, and subsequently promote photoreactions using near ultraviolet and visible light, which is eventually beneficial for using solar energy as a source of irradiation.

Tungsten oxide and hydrated tungsten oxide are widely used in electrochromic windows, infrared switching devices, photocatalysis, writing-reading erasing optical devices, and gas sensors (Li et al. 2004; Yu et al. 2008b; Zhao et al. 2006; Lee et al. 2003). Tungsten oxide has drawn more attentions in the applications of photocatalysts because of its relative narrower band gap (between 2.2 and 2.8 eV) (Xin et al. 2009; Wang et al. 2008; Wang et al. 2002; Gondal et al. 2009; Qamar et al. 2009a; Gondal et al. 2007). Yu et al. have reported fabrication of WO3 hollow microspheres and their photocatalytic activity for the decolorization of rhodamine B aqueous solution (Yu et al. 2008a). Guo et al. have reported the high photocatalytic capability of self-assembled nanoporous WO3 (Guo et al. 2007). Yu et al. studied photocatalytic activity of flower-like tungsten trioxide assemblies prepared by a simple hydrothermal treatment of sodium tungstate in aqueous solution of nitric acid (Yu and Qi 2009). Metal-doped semiconducting oxides are potential materials for various photocatalyst and photoelectrochemical conversion applications because of its unique physico-chemical properties. Recently, Peng et al. have reported that Dy-doped WO3 nanoparticles exhibit much better photoactivity and photostability than that of the bare WO3 (Liu et al. 2007). It is well-known that nanometer-sized inorganic low-dimensional systems exhibit a wide range of optical and catalytic properties that rely sensitively on both size and morphology. However, the investigation on the photocatalytic activity of Mo-doped WO3 nanowire has never been reported before. The preparation of 1D nanostructured tungsten oxide in mass quantity has been accomplished by heating a tungsten foil, covered by SiO2 plate, in an argon atmosphere at 1,600 °C (Zhu et al. 1999) or recently by electrochemically etching a tungsten tip, followed by heating at 700 °C under argon (Gu et al. 2002). The 1D nanostructure synthesis using the inorganic salt instead of the surfactant and water-soluble high molecule has strong points in non-pollution, low-cost, easy-cleanout and recovery. In this work, we describe a facile inorganic route for the synthesis of Mo-doped nanowires in aqueous solution. The photocatalytic activities of the as-prepared samples for the methylene blue (MB) photodegradation were investigated.

Experimental section

Fabrication of Mo-doped WO3 nanowires

All the chemicals were analytic grade reagents without the further purification. Experimental details were as follows: Na2WO4·2H2O (1 g) and (NH4)6Mo7O24·4H2O (the atomic ratios of Mo to W = 0, 0.01, 0.03, 0.07, 0.10) were dissolved in 30-mL deionized water to form a transparent solution. A (3 M) HCl solution was added dropwise into the above solution under continuous stirring until tungstenic acid was precipitated thoroughly. Next, the centrifuged precipitate was dissolved in 30 mL deionized water, 40 g K2SO4 was added to the system and agitated to form starchiness, and then transferred into Teflon-lined autoclave with a capacity of 50 mL. Hydrothermal treatments were carried out at 180 °C for 12 h. After that, the autoclave was allowed to cool down naturally. The final products were collected and washed with deionized water and ethanol several times and dried in air at 80 °C. The Mo-doped WO3 nanowires were finally obtained. For convenience of description, changing the atomic ratio of Mo to W, the 0.00, 001, 0.03, 0.07, and 0.10 doping of molybdenum ions in WO3 nanowires were marked as A, B, C, D, and E, respectively.

Characterization

The morphologies were characterized using scanning electron microscopy (SEM, Hitachi S-4700, 25 kV) and transmission electron microscopy (TEM, Tecnai G2 F30 S-Twin, 200 kV). The composition of the product was analyzed by energy-dispersive X-ray detector (EDS, Thermo Noran VANTAG-ESI). The X-ray diffraction (XRD, Thermo ARL SCINTAG X’TRA with CuKa irradiation, λ = 0.154056 nm.) was used to analysis the crystallinity.

Photocatalytic experiments

The photoactivity experiments on the prepared samples for the photodegradation of methylene blue (MB) were performed at ambient temperature. An 125 W high pressure mercury lamp (GYZ125) was used as a light source. In a typical process, aqueous suspensions of MB (200 mL, C 0 = 10 mg L−1) and 50 mg of Mo-doped WO3 nanowires were placed in a vessel. Prior to irradiation, the suspensions were magnetically stirred in the dark for ca. 30 min to ensure the equilibrium of the working solution. The suspensions were kept under constant air-equilibrated conditions before and during the irradiation. pH of the reaction suspension was not adjusted. Analytical samples (3 mL) were drawn from the reaction suspension every 10 min, and removal of Mo-doped WO3 nanowires by centrifugation. The changes of absorptions at 665 nm were applied to identify the concentrations of MB using a 721-type spectrophotometer. The percentage of degradation is reported as C/C 0. C is the maximum peak of the absorption spectra of MB for each irradiated time interval at wavelength 665 nm. C 0 is the absorption of the starting concentration when adsorption/desorption equilibrium was achieved. To test its photocatalytic lifetime, Mo-doped WO3 nanowires was recycled and reused five times in the decomposition of MB under the same conditions. After each photocatalytic reaction, the aqueous solution was centrifuged to recycle Mo-doped WO3 nanowires that were then dried at 80 °C for another test.

Results and discussion

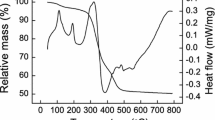

Figure 1 showed the XRD patterns of Mo-doped WO3 nanowires with different content of molybdenum ions. The main peaks can be indexed undisputedly to hexagonal WO3 (JCPDS card 35-1001). It is worth mentioning that the more the molybdenum ions doped, the narrower and lower was the diffraction spectrum as shown in Fig. 1b–e, which demonstrated that with the presence of molybdenum ions, the crystallization of the WO3 nanowires was inhibited. It is interesting to note that the typical MoO3 XRD peaks were not observed. There are two reasons responsible for this. One probable reason is that the concentration of Mo-doping is so low that it cannot be detected by XRD. The other is that the structure of Mo6+ and W6+ ions are very similar and the molybdenum ions maybe insert into the structure of WO3.

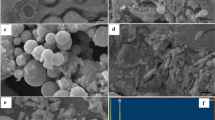

Morphology and particle sizes of the samples were investigated by SEM and TEM. Figure 2a shows the TEM image of pure WO3 nanowires prepared via K2SO4-assisted hydrothermal route at 180 °C. It can be seen that pure WO3 products are nanowires with diameters ranging between 10 and 20 nm, and lengths of about 600 nm. Interestingly, when samples prepared at different Mo-doping concentrations, Mo-doped WO3 nanowires can be obtained in the whole concentrations range under the investigation (Mo/W: 0.01–0.10). It was found that the Mo-doping concentration had little effect on the crystal shapes of products during this range. For example, TEM image of the Mo-doped WO3 nanowires (D) are shown in Fig. 2b. As shown in Fig. 2c, the SEM image further demonstrated that the Mo-doped WO3 nanowires (D) have a uniform wire-like morphology. Diameters and lengths of nanowires were consistent with TEM results (Fig. 2b). Energy-dispersive spectrometry (EDS) analysis was employed to determine the composition of the Mo-doped WO3 nanowires. For example, the EDS patterns of the Mo-doped WO3 nanowires (D) are shown in Fig. 2d. The EDS results confirm that the obtained products are composed of the WO3 doped with molybdenum ions. The three major peaks corresponded to tungsten, oxygen, and molybdenum, respectively.

To understand the detailed structural of the WO3 nanowires doped with different contents of molybdenum ions, the high resolution TEM (HRTEM) technique was employed. Figure 3a is a typical HRTEM image of pure WO3 nanowires and shows clear lattice fringes. Figure 3b and c are HRTEM images of the Mo-doped WO3 nanowires (D) and nanowires (E), respectively. It can be seen that with Mo-doping concentration increasing, the lattice fringes slightly blurred. Therefore, it is reasonable to deduce that the larger the amount of Mo-doping, the poorer the crystallization of the WO3 nanowires.

Figure 4 showed the photocatalytic degradation rates of MB on the Mo-doped WO3 nanowires with different molybdenum contents. Among the five samples, sample D has much higher photocatalytic degradation rates. For sample D, the MB was removed 94% within 90 min. The blank experiment with catalyst absence was also performed. It can be found that MB is almost not decomposed under the same irradiation time. This result clearly indicates that molybdenum ions dopant can effectively improve the photocatalytic degradation activities of WO3 nanowires. When the Mo-doping concentration was lower than 0.07, it is seen from Fig. 4 that as increasing the content of the molybdenum ions, the degradation rate increases. With further increasing Mo-doping concentration, the phtotcatalytic activity of WO3 nanowires decreases obviously. The high phtotcatalytic activity of the sample D is due to the following factor. The molybdenum ions can serve as a mediator of the transfer of interfacial charge at an appropriate doping concentration. The activity evaluation shows that the presence of a small amount of molybdenum ions can enhance the activity, but excessive molybdenum ions are detrimental. This may be due to the fact that a small amount of molybdenum ions can act as a photo-generated hole and a photo-generated electron trap and inhibit the hole-electron recombination.

It is well-known that the preparation condition has relation with crystallization and morphology for the sample. To substantially understand the effect of K2SO4 on the Mo-doped WO3 nanowires, the experiments of the hydrothermal process with different concentration of K2SO4 were carried out. The morphologies of the synthesized Mo-doped WO3 (Mo/W = 0.07) with different amounts of K2SO4 were shown in Fig. 5a–c. Figure 5a is the SEM image of the sample obtained without K2SO4. The result showed that the products synthesized were only nanoparticles. With the addition of 20 g K2SO4, the morphologies of the synthesized Mo-doped WO3 shown in Fig. 5b are the nanorods with diameters ranging between 10 and 20 nm, and lengths of about 100 nm. With the addition of 40 g K2SO4, Mo-doped WO3 nanowires are the major product (Fig. 2c). As the content of K2SO4 reaches 50 g, Fig. 5c is SEM image of products and shows similar morphology as observed in Fig. 2c image. Figure 6 shows the effects of the concentration of K2SO4 on phase structures of Mo-doped WO3 nanocrystals. The hexagonal phase of WO3 (JCPDS card 33-1387) was obtained without K2SO4 (Fig. 6a). With the addition of 20 g K2SO4, Fig. 6b exhibited the hexagonal reflections (JCPDS card 35-1001). The XRD results in Fig. 6 also reveal changes in the peak intensities of the obtained Mo-doped WO3 nanocrystals with different concentration of K2SO4. A distinct sharpening resolution of peaks can be observed in the presence of 40 g K2SO4. The morphologies and dimensions of synthesized nanocrystals were controlled not only by the inner structure, but also affected by the surrounding conditions such as temperature, pressure, and composition of the solution. In our experiments, the presence of K2SO4 is important factor influencing the crystallization process and the growth of the Mo-doped WO3 nanowires. With the addition of different concentration of K2SO4, the corresponding properties of the solution are different in the hydrothermal conditions. The changes in the surrounding conditions would affect the crystal phase, and further affect the morphologies and crystallization of the WO3 nanocrystals. Figure 7 shows the effects of K2SO4 on the photocatalytic activity of the samples. It can be seen that concentration of K2SO4 has a significant effect on the photocatalytic activity of the as-prepared samples. This indicates that the crystal phase and crystallinity are the vital factor that affects the photocatalytic activity of the materials in this work.

The stability of a photocatalyst is important for its application. Herein, the stability of Mo-doped WO3 nanowires (D) was investigated. After five recycles for the photodegradation of MB, the catalyst did not exhibit any significant loss of activity, as shown in Fig. 8, confirming Mo-doped WO3 nanowires (D) is not photocorroded during the photocatalytic oxidation of the pollutant molecules.

Conclusion

A hydrothermal method was developed to the preparation of the Mo-doped WO3 nanowires. The Mo-doped WO3 nanowires exhibited the high photocatalytic activity for the decomposition of the aqueous MB. A small amount of Mo-doping could obviously enhance the photocatalytic activity of WO3 nanowires. At an optimal atomic ratio of Mo to W of 0.07, sample has the highest photocatlytic activity, and after 90 min of irradiation, the MB was removed 94%. The high activities of the Mo-doped WO3 nanowires could be attributed to the synergetic effects of Mo-doping and crystallinity structure.

References

Bamwenda GR, Arakawa H (2001) The visible light induced photocatalytic activity of tungsten trioxide powders. Appl Catal A 210:181–191

Chen CC (2007) Degradation pathways of ethyl violet by photocatalytic reaction with ZnO dispersions. J Mol Catal A 264:82–89

Gondal MA, Sayeed MN, Arfaj A (2007) Activity comparison of Fe2O3, NiO, WO3 and TiO2 semiconductor catalysts in phenol degradation by laser enhanced photo-catalytic process. Chem Phys Lett 445:325–330

Gondal MA, Dastageer A, Khalil A (2009) Synthesis of nano-WO3 and its catalytic activity for enhanced antimicrobial process for water purification using laser induced photo-catalysis. Catal Comm 11:214–219

Gu G, Zheng B, Han WQ, Roth S, Liu J (2002) Tungsten oxide nanowires on tungsten substrates. Nano Lett 2:849–851

Guo Y, Quan X, Lu N, Zhao H, Chen S (2007) High photocatalytic capability of selfassembled nanoporous WO3 with preferential orientation of (002) planes. Environ Sci Technol 41:4422–4427

Lee K, Seo WS, Park JT (2003) Synthesis and optical properties of colloidal tungsten oxide nanorods. J Am Ceram Soc 125:3408–3409

Li XL, Lou TJ, Sun XM, Li YD (2004) Highly sensitive WO3 hollow-sphere gas sensors. Inorg Chem 43:5442–5449

Liu H, Peng T, Ke D, Peng Z, Yan C (2007) Preparation and photocatalytic activity of dysprosium doped tungsten trioxide nanoparticles. Mater Chem Phys 104:377–383

Liu Y, Zhang YC, Xu XF (2009) Hydrothermal synthesis and photocatalytic activity of CdO2 nanocrystals. J Hazard Mater 163:1310–1314

Qamar M, Gondal MA, Hayat K, Yamani ZH, Al-Hooshani K (2009a) Laser-induced removal of a dye C.I. Acid Red 87 using n-type WO3 semiconductor catalyst. J Hazard Mater 170:584–589

Qamar M, Gondal MA, Yamani ZH (2009b) Synthesis of highly active nanocrystalline WO3 and its application in laser-induced photocatalytic removal of a dye from water. Catal Comm 10:1980–1984

Stengl V, Bakardjieva S, Murafa N (2009) Preparation and photocatalytic activity of rare earth doped TiO2 nanoparticles. Mater Chem Phys 114:217–226

Wang HY, Xu P, Wang TM (2002) The preparation and properties study of photocatalytic nanocrystalline/nanoporous WO3 thin films. Mater Des 23:331–336

Wang S, Shi X, Shao G, Duan X, Yang H, Wang T (2008) Preparation, characterization and photocatalytic activity of multi-walled carbon nanotube-supported tungsten trioxide composites. J Phys Chem Solids 69:2396–2400

Xin G, Guo W, Ma T (2009) Effect of annealing temperature on the photocatalytic activity of WO3 for O2 evolution. Appl Surf Sci 256:165–169

Yu J, Qi L (2009) Template-free fabrication of hierarchically flower-like tungsten trioxide assemblies with enhanced visible-light-driven photocatalytic activity. J Hazard Mater 169:221–227

Yu JG, Su YR, Cheng B (2007) Template-free fabrication and enhanced photocatalytic activity of hierarchical macro-/mesoporous titania. Adv Funct Mater 17:1984–1990

Yu J, Qi L, Cheng B, Zhao X (2008a) Effect of calcination temperatures on microstructures and photocatalytic activity of tungsten trioxide hollow microspheres. J Hazard Mater 160:621–628

Yu JG, Yu HG, Guo HT, Li M, Mann S (2008b) Spontaneous formation of a tungsten trioxide sphere-in-shell superstructure by chemically induced selftransformation. Small 4:87–91

Yu J, Yu X, Huang B, Zhang X, Dai Y (2009) Hydrothermal synthesis and visible-light photocatalytic activity of novel cage-like ferric oxide hollow spheres. Cryst Growth Des 9:1474–1480

Zhang M, An T, Hu X, Wang C, Sheng G, Fu J (2004) Preparation and photocatalytic properties of a nanometer ZnO-SnO2 coupled oxide. Appl Catal A 260:215–222

Zhao X, TL Cheung Y, Zhang X, Ng DHL, Yu J (2006) Facile preparation of strontium tungstate and tungsten trioxide hollow spheres. J Am Ceram Soc 89:2960–2963

Zhu YQ, Hu W, Hsu WK, Terrones M, Grobert N, Hare JP, Kroto HW, Walton DRM, Terrones H (1999) Tungsten oxide tree-like structures. Chem Phys Lett 309:327–334

Acknowledgment

We wish to acknowledge the financial support from the National Natural Science Foundation of China (no. 20873020).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Song, X.C., Yang, E., Liu, G. et al. Preparation and photocatalytic activity of Mo-doped WO3 nanowires. J Nanopart Res 12, 2813–2819 (2010). https://doi.org/10.1007/s11051-010-9859-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11051-010-9859-8