Abstract

A simple strategy for the one-step synthesis of polyaniline/AgCl nanocomposites at the water/magnetic ionic liquid interface was reported. By controlling the reactive conditions, highly dispersed polyaniline/AgCl nanocomposites with their size ranging around 50–80 nm were obtained with magnetic ionic liquid as the oxidant. Transmission electron microscopy was used to show the morphology of the nanocomposites. The nanocomposites were also characterized by Fourier transform infrared spectroscopy, X-ray diffraction, and thermogravimetric analysis. Moreover, polyaniline/AgCl nanocomposites on a glassy carbon electrode showed strong electrocatalytic activity for H2O2 and could be used to construct a H2O2 biosensor.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The nanocomposites with an organized structure usually provide a new functional hybrid, with synergetic or complementary properties over their single-component counterparts, which have attracted considerable attention for their potential applications (Lo et al. 2007; Rickert et al. 2007). Conducting polymers, such as polyaniline (PANi), polypyrrole, polythiophene, and their derivatives, have recently been subjected to numerous investigations because of their potential advantages with regard to mechanical flexibility, electrical, and optical properties (Pillalamarri et al. 2005a, b; Chen et al. 2008; Thanpitcha et al. 2009). PANi is one of the technologically most important materials because of its environmental stability in a conducting form, unique redox properties, and high conductivity with suitable dopants (McQuade et al. 2000). PANi composite materials possess the potential for a multitude of applications, such as in gas sensors and inductors (Li and Kaner 2007). Therefore, there has been increasing interest in the fabrication of nanomaterials based on PANi because of their novel physical properties and potential applications (Tseng et al. 2005; Kinyanjui et al. 2004). The preparation of PANI/titanium nitride nanocomposites with enhanced electrical properties was reported by Qiu and Gao (2005). Xia synthesized PANi/titanium oxide core–shell nanocomposites through ultrasonic irradiation (Xia and Wang 2002). PANi-capped silicon nanoparticles through the self-assembly method was presented by Ruckenstein (Li et al. 2004). PANi/AgCl composites were also synthesized in different reverse micelles (Sui et al. 2004; Yan et al. 2008). Yang and his coworkers have synthesized PANi/Au nanocomposites, which have significantly higher electrical conductivity than PANi alone, with the aid of ionic liquid (Yang et al. 2008).

Ionic liquids comprising entirely of ions are organic salts and a relatively new class of solvent. Ionic liquids are attracting significant attention in many fields of chemistry and industry because of their unique physicochemical properties, such as high thermal and electrochemical stability, and ionic conductivity (Welton 1999; Davis and Fox 2003; Lu and Mattes 2005). In addition, ionic liquids have been shown to dissolve a wide range of organic and inorganic materials, which allows access to a range of monomers and chemical oxidants at significant concentrations. Due to their merits as above mentioned, ionic liquids are ideal media for the synthesis and utilization of nanostructured materials, such as inorganic nanoparticles and conducting polymers by chemical or electrochemical methods (Ahmad et al. 2007; Dinda et al. 2008; Kubisa 2005; Pringle et al. 2007; Trewyn et al. 2004).

In this article, we report the results on the synthesis and characterization of PANi/AgCl nanocomposites at the interface of water and a magnetic ionic liquid (MIL), 1-butyl-3-methylimidazolium tetrachloroferrate (Bmim[FeCl4]). MIL is basically one of ionic liquids (IL). The only difference between IL and MIL is that the anion of MIL is FeCl4 −. MIL had been used as the solvent and oxidant to synthesize poly(3,4-ethylenedioxythiophene) nanospheres in our previous study (Li et al. 2009). When polymerization of π-conjugated polymer was carried out in Bmim[FeCl4], FeCl4 − moiety could play the roles as a synthetic catalyst as well as a dopant. On the other hand, interface polymerization has many advantages: for example, the purification is simple without template-removing steps; The process of synthesis is easily scalable and reproducible; and The interface polymerization could also suppress the agglomeration of conducting polymer (Huang et al. 2003). Fourier transform infrared (FTIR), X-ray diffraction (XRD), thermogravimetric analysis (TGA), and transmission electron microscopy (TEM) were used to characterize the PANi/AgCl nanocomposites prepared by interface polymerization. The obtained PANi/AgCl nanocomposites showed electrocatalytic activity for H2O2.

Experimental

Materials

Silver nitrate (AgNO3), polyvinylpyrrolidone (PVP), hydrochloric acid (HCl), hydrogen peroxide (H2O2), ammonium persulfate ((NH4)2S2O8), and the anhydrous iron chloride (FeCl3) were all purchased from Aldrich and used without further purification. Aniline was distilled twice under atmospheric pressure and stored in dark at low temperature before use. Crystalline 1-butyl-3-methylimidazolium chloride ([Bmim]Cl) was prepared according to the standard procedure followed by repeated recrystallization from dry acetonitrile. The synthesis of Bmim[FeCl4] has already been reported in the literature (Sitze et al. 2001) and was dried and degassed before use.

Preparation of PANi/AgCl nanocomposites at the interface of water and MIL

In a typical procedure for the synthesis of PANi/AgCl nanocomposites, AgNO3 (0.02 M) and aniline (0.02 M) were added to 0.5 or 4% PVP aqueous solution. 6 mL of Bmim[FeCl4] and the above solution were then carefully transferred to a beaker, and an interface was generated between two layers. After 10 min, green polyaniline formed at the interface. The reaction was allowed to proceed for 24 h. After the reaction, the solution was centrifuged, and the precipitate was washed with both distilled water and ethanol for several times. The final product was dried in vacuum at 40 °C for 24 h. With the same molar ratio of oxidant to monomer, conventional solution polymerization by using FeCl3 as the oxidant was also carried out.

Preparation of PANi/AgCl modified glassy carbon electrodes

The glassy carbon electrodes (GCE, 3 mm in diameter) were polished with alumina slurry, followed by a rinse with doubly distilled water and then allowed to dry at room temperature. PANi/AgCl nanocomposites were dispersed in distilled water to obtain a 1.0 mg/mL solution and ultrasonically treated for 30 min, and then 10 μL of colloidal solution was coated onto the pre-treated GCE surface and allowed to dry under ambient conditions.

Characterization

FTIR spectra of the nanocomposites dispersed in KBr disks were recorded on Bruker Fourier transform spectrometer model VECTOR22. TEM images were acquired with JEM-200CX transmission electron microscope. TGA was conducted on a Du Pont Thermal Analyst 2100 system, equipped with a TGA 2050 thermogravimetric thermal analyzer with a heating rate of 10 °C/min in air atmosphere. XRD patterns were taken on a shimadzu XD-3A instrument using Cu Kα radiation (λ = 0.154 nm). Electrochemical experiments were conducted using a CHI660B workstation (Chenhua, Shanghai) in a three-electrode system. All electrochemical experiments were performed in a cell containing 25 mL of phosphate buffer solution (PBS, 0.1 M) at room temperature, using a coiled platinum wire as the auxiliary, a saturated calomel electrode (SCE) as reference, and the PANi/AgCl modified glassy carbon electrode (GCE) as a working electrode. All the experimental solutions were deaerated by bubbling high purity nitrogen for 20 min. A nitrogen environment was kept over the solutions in the cell to keep them oxygen free during measurements.

Results and discussion

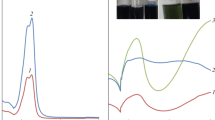

Interface polymerization is an effective approach to prepare conducting polymer nanostructures using an organic/aqueous biphasic system. Conducting polymers with fibrillar morphology have been synthesized in the biphasic ionic liquid/water system (Pringle et al. 2007). The electrochemical synthesis of conducting polymer in ionic liquids has also been reported by several groups (Ahmad et al. 2007; Randriamahazaka et al. 2005). Therefore, IL is an ideal media for the synthesis of conducting polymer. The only difference between IL and MIL is that the anion of MIL is FeCl4 −. In this study, the two phases of Bmim[FeCl4] and aqueous solution containing aniline, AgNO3, and PVP acted as the reactive biphasic system to prepare PANi/AgCl nanocomposites. For the preparation of the PANi/AgCl nanocomposites, Bmim[FeCl4] ionic liquid containing no additional oxidants was used. FeCl4 − moiety could play roles as a synthetic oxidant as well as a dopant. TEM analysis of the PAN/AgCl nanocomposites synthesized in the biphasic MIL/water system, revealed a product with almost core–shell morphology (Fig. 1). The dark spots inside the nanoparticles corresponded to AgCl that was surrounded by PANi matrix. The effect of PVP concentration on the resultant core–shell composite had been studied. When the content of PVP was 0.5%, the diameter of the PANi/AgCl composite nanoparticles was in the range of 40–70 nm. Further, it was observed that there are many PANi nanoparticles without AgCl core (Fig. 1a). When the content of PVP was increased to 4%, the particles with a shell thickness of 10–20 nm and a core diameter of 30–50 nm were prepared. Moreover, the degree of dispersion and the uniformity of resultant composite nanoparticles were obviously improved, as shown in Fig. 1b. Therefore, PVP as an anchor agent played an important role in the synthesis process of PANi/AgCl nanocomposites. Shin et al. synthesized silver nanoparticles stabilized with amphiphilic PVP and suggested that PVP promotes the nucleation of metallic silver (Shin et al. 2004). The amphiphilic PVP would be beneficial for the adherence between the polymer shell and the inorganic core. Ag–O coordination could be formed through the pyrrolidone ring which was tilted on the surface of the silver (Gao et al. 2004). PVP with its dipolar imide group carried a fractional negative charge on carbonyl oxygen (Murugesan et al. 2004). In this study, aniline could be oxidized by MIL and polymerized to form polycationic PANi, which may react with PVP through an electrostatic effect. The adsorbed PVP might provide active sites on AgCl so as to induce the growing polycationic PANi chains to complete the coating of PANi. In addition, PVP could prevent the aggregation of PANi/AgCl nanocomposites efficiently (Ghosh et al. 1999). Therefore, in the experiment, when aniline solution containing PVP and AgNO3 was mixed with MIL, the formation of AgCl and oxidation of aniline by FeCl4 − of MIL occurred simultaneously, leading to the formation of the polyaniline/AgCl nanocomposites.

The PANi/AgCl nanocomposite was characterized by FTIR spectroscopy as shown in Fig. 2. The spectra exhibited the clear presence of quinoid and benzenoid ring stretching near around 1,570 and 1,491 cm−1, respectively (Quillard et al. 1994). The peaks around 1,293 and 1,246 cm−1 were related to the C–N and C=N stretching modes (Ghosh et al. 1999). The peaks around 1,146 and 801 cm−1 may be assigned to the in-plane bending of C–H (Pillalamarri et al. 2005a, b) and the out-of-plane bending of C–H (Sarma et al. 2002), respectively. The absorption band assignable to C=O is observed at 1,651 cm−1, which indicated the presence of PVP.

The powder XRD pattern confirmed further the presence of AgCl in the nanocomposites. As shown in Fig. 3a and b, the broad band appearing at 2θ value of 25o was ascribed to the periodicity parallel to the polymer chains of PANi (Pillalamarri et al. 2005a, b). However in Fig. 3a, another diffraction peaks above 25o corresponding to Bragg’s reflections from (111), (200), (220), (311), (222), and (400) planes of AgCl showed the existence of AgCl nanoparticles in the products. Crystallite sizes were calculated from the AgCl (111) diffraction line using Scherrer’s equation, L = Kλ/β cos θ, where L is the mean dimension of the crystallites, β is the full width at half maximum of the diffraction peak, θ is the diffraction angle, λ is the wavelength of the Cu Kα radiation (0.154 nm), and K is equal to 0.89 (Sarma et al. 2002). The calculated average size of AgCl in the composite was about 40 nm, which was in agreement with the result from TEM (Fig. 1b).

To investigate the thermal stability of PANi/AgCl nanocomposites obtained at the interface of water and MIL, PANi/AgCl nanocomposites were characterized by TGA. As shown in Fig. 4, in the TGA curve of PANi, the step starting at about 250 °C corresponded to the loss of acid dopant. Then, a very significant weight loss occurred at about 360 °C due to thermal oxidative decomposition of polymer chain (Yu et al. 2005). In the case of PANi/AgCl nanocomposites, three evident decomposition processes occurred during the thermal degradation. The first weight loss ranging from 200 to 300 °C was believed to be due to the departure of acid dopant, and the second weight loss step was ascribed to the decomposition of PANi chains and the departure of residual acid dopant. When the temperature was increased to about 800 °C, the decomposition of AgCl in the nanocomposites began, which was consistent with pure AgCl.

The catalytic reduction and oxidation of H2O2 were investigated using the glassy carbon electrode modified by PANi/AgCl nanocomposites. Figure 5 showed cyclic voltammograms of the glassy carbon electrode modified by PANi/AgCl nanocomposites in 0.1 M PBS (pH 7.0) in the absence and the presence of H2O2 at a scan rate of 50 mV/s. After the addition of H2O2, a large reduction current for the reduction of H2O2 appeared while the oxidation peak current decreased, which was similar to that in the PANi/Au nanocomposites (Yang et al. 2008). However, no electrocatalytic current can be obtained at bare GCE in the potential range, indicating that the PANi/AgCl nanocomposites may act as a catalyst for the reduction of H2O2. Figure 6 showed the steady-state response of the PANi/AgCl modified GCE on successive injection of H2O2 into stirring PBS. When an aliquot of H2O2 was added into 10 mL PBS, the reduction current rose steeply to reach a stable value. The time to reach 95% of the maximum current was within 8 s, which indicated a fast response process. The PANi/AgCl modified GCE had the increasing amperometric responses to H2O2 with linear ranges from 7 × 10−4 to 1 × 10−2 M, and a detection limit of 3 × 10−4 M at a signal-to-noise ratio of 3. In addition, the stability of the modified GCE was studied. When the modified electrode was stored at 4 °C and measured intermittently, no obvious change in the response to 1 mM H2O2 was found. Moreover, it was found that the peak current retained 99% of its initial response for the modified GCE after 100 cycles at a H2O2 concentration of 1 mM at a scan rate of 50 mV/s. Based on the above results, the as-prepared PANi/AgCl nanoparticles would be particularly attractive as a promising candidate to develop a H2O2 biosensor.

Conclusions

In summary, we have presented a simple and practical route for preparing PANi/AgCl nanocomposites employing MIL as the oxidant at the interface of water and MIL. When the content of PVP was 4%, the obtained nanocomposites were uniform in size and well dispersed. The formation of the nanocomposites was confirmed by TEM, TGA, FTIR, and XRD analyses. Our preliminary results demonstrate that the GCE modified with the as-prepared PANi/AgCl nanocomposites could be applied to construct a H2O2 biosensor. Moreover, this synthetic strategy may be extended to the preparation of hierarchical nanocomposites of other conducting polymers and inorganic nanoparticles.

References

Ahmad S, Deepa M, Singh S (2007) Electrochemical synthesis and surface characterization of poly(3, 4-ethylenedioxythiophene) films grown in an ionic liquid. Langmuir 23:11430–11433

Chen SJ, Chen W, Xue G (2008) Electrogeneration of polypyrrole/alginate films for immobilization of glucose oxidase. Macromol Biosci 8:478–483

Davis JH, Fox PA (2003) From curiosities to commodities: ionic liquids begin the transition. Chem Commun 11:1209–1212

Dinda E, Si S, Kotal A, Mandal TK (2008) Novel ascorbic acid based ionic liquids for the in situ synthesis of quasi-spherical and anisotropic gold nanostructures in aqueous medium. Chem Eur J 14:5528–5537

Gao Y, Jiang P, Liu DF, Yuan HJ, Yan XQ, Zhou ZP, Wang JX, Song L, Liu LF, Zhou WY, Wang G, Wang CY, Xie SS, Zhang JM, Shen AY (2004) Evidence for the monolayer assembly of poly(vinylpyrrolidone) on the surfaces of silver nanowires. J Phys Chem B 108:12877–12881

Ghosh P, Siddhanta SK, Chakrabarti A (1999) Characterization of poly(vinyl pyrrolidone) modified polyaniline prepared in stable aqueous medium. Eur Polym J 35:699–710

Huang JX, Virji S, Weiller BH, Kaner RB (2003) Polyaniline nanofibers: facile synthesis and chemical sensors. J Am Chem Soc 125:314–315

Kinyanjui JM, Harris-Burr R, Wagner JG, Wijeratne NR, Hatchett DW (2004) Hexachloroplatinate-initiated synthesis of polyaniline/platinum composite. Macromolecules 37:8745–8753

Kubisa P (2005) Ionic liquids in the synthesis and modification of polymers. J Polym Sci Polym Chem 43:4675–4683

Li D, Kaner RB (2007) How nucleation affects the aggregation of nanoparticles. J Mater Chem 17:2279–2282

Li L, Huang Y, Yan G, Liu F, Huang Z, Ma Z (2009) Poly(3, 4-ethylenedioxythiophene) nanospheres synthesized in magnetic ionic liquid. Mater Lett 63:8–10

Li ZF, Swihart MT, Ruckenstein E (2004) Luminescent silicon nanoparticles capped by conductive polyaniline through the self-assembly method. Langmuir 20:1963–1971

Lo MY, Zhen C, Lauters M, Jabbour GE, Sellinger A (2007) Organic-inorganic hybrids based on pyrene functionalized octavinylsilsesquioxane cores for application in OLEDs. J Am Chem Soc 129:5808–5809

Lu W, Mattes BR (2005) Factors influencing electrochemical actuation of polyaniline fibers in ionic liquids. Synth Met 152:53–56

McQuade DT, Pullen AE, Swager TM (2000) Conjugated polymer-based chemical sensors. Chem Rev 100:2537–2574

Murugesan R, Anitha G, Subramanian E (2004) Multi-faceted role of blended poly(vinyl pyrrolidone) leading to remarkable improvement in characteristics of polyaniline emeraldine salt. Mater Chem Phys 85:184–194

Pillalamarri SK, Blum FD, Tokuhiro AT, Bertino MF (2005a) One-pot synthesis of polyaniline—metal nanocomposites. Chem Mater 17:5941–5944

Pillalamarri SK, Blum FD, Tokuhiro AT, Story JG, Bertino MF (2005b) Radiolytic synthesis of polyaniline nanofibers: a new templateless pathway. Chem Mater 17:227–229

Pringle JM, Ngamna O, Lynam C, Wallace GG, Forsyth M, MacFarlane DR (2007) Conducting polymers with fibrillar morphology synthesized in a biphasic ionic liquid/water system. Macromolecules 40:2702–2711

Qiu Y, Gao L (2005) Novel polyaniline/titanium nitride nanocomposite: controllable structures and electrical/electrochemical properties. J Phys Chem B 109:19732–19740

Quillard S, Louarn G, Lefrant S, Macdiarmid AG (1994) Vibrational analysis of polyaniline—a comparative-study of leucoemeraldine, emeraldine, and pernigraniline bases. Phys Rev B 50:12496–12508

Randriamahazaka H, Plesse C, Teyssie D, Chevrot C (2005) Charging/discharging kinetics of poly(3,4-ethylenedioxythiophene) in 1-ethyl-3-methylimidazolium bis-(trifluoromethylsulfonyl)imide ionic liquid under galvanostatic conditions. Electrochim Acta 50:4222–4229

Rickert PG, Antonio MR, Firestone MA, Kubatko KA, Szreder T, Wishart JF, Dietz ML (2007) Tetraalkylphosphonium polyoxometalate ionic liquids: novel, organic-inorganic hybrid materials. J Phys Chem B 111:4685–4692

Sarma TK, Chowdhury D, Paul AJ (2002) Synthesis of Au nanoparticle-conductive polyaniline composite using H2O2 as oxidising as well as reducing agent. Chem Commun 10:1048–1049

Shin HS, Yang HJ, Kim SB (2004) Mechanism of growth of colloidal silver nanoparticles stabilized by polyvinyl pyrrolidone in gamma-irradiated silver nitrate solution. J Colloid Interface Sci 274:89–94

Sitze MS, Schreiter ER, Patterson EV, Freeman RG (2001) Ionic liquids based on FeCl3 and FeCl2. Raman scattering and ab initio calculations. Inorg Chem 40:2298–2304

Sui XM, Chu Y, Xing SX, Liu CZ (2004) Synthesis of PANI/AgCl, PANI/BaSO4 and PANI/TiO2 nanocomposites in CTAB/hexanol/water reverse micelle. Mater Lett 58:1255–1259

Thanpitcha T, Sirivat A, Jamieson AM, Rujiravanit R (2009) Polyaniline nanoparticles with controlled sizes using a cross-linked carboxymethyl chitin template. J Nanopart Res 11:1167–1177

Trewyn BG, Whitman CM, Lin VSY (2004) Morphological control of room-temperature ionic liquid templated mesoporous silica nanoparticles for controlled release of antibacterial agents. Nano Lett 4:2139–2143

Tseng RJ, Huang JX, Ouyang J, Kaner RB, Yang Y (2005) Polyaniline nanofiber/gold nanoparticle nonvolatile memory. Nano Lett 5:1077–1080

Welton T (1999) Room-temperature ionic liquids. Solvents for synthesis and catalysis. Chem Rev 99:2071–2083

Xia HS, Wang Q (2002) Ultrasonic irradiation: a novel approach to prepare conductive polyaniline/nanocrystalline titanium oxide composites. Chem Mater 14:2158–2165

Yan W, Feng X, Chen X, Li X, Zhu JJ (2008) A selective dopamine biosensor based on AgCl@polyaniline core-shell nanocomposites. Bioelectrochemistry 72:21–27

Yang W, Liu J, Zheng R, Liu Z, Dai Y, Chen G, Ringer S, Braet F (2008) Ionic liquid-assisted synthesis of polyaniline/gold nanocomposite and its biocatalytic application. Nanoscale Res Lett 3:468–472

Yu Y, Che B, Si Z, Li L, Chen W, Xue G (2005) Carbon nanotube/polyaniline core-shell nanowires prepared by in situ inverse microemulsion. Synth Met 150:271–277

Acknowledgments

The study is supported by the Educational Bureau of Hubei Province (Q20091508), the Scientific Research Key Project of Ministry of Education of China (209081), the State Key Laboratory of Coordination Chemistry (Nanjing University), and the National Natural Science Foundation of China (20904044).

Author information

Authors and Affiliations

Corresponding author

Additional information

An erratum to this article can be found at http://dx.doi.org/10.1007/s11051-010-0126-9

Rights and permissions

About this article

Cite this article

Zhang, Q., Liu, F., Li, L. et al. Magnetic ionic liquid-assisted synthesis of polyaniline/AgCl nanocomposites by interface polymerization. J Nanopart Res 13, 415–421 (2011). https://doi.org/10.1007/s11051-010-0070-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11051-010-0070-8