Abstract

A gene encoding extracellular lipase was cloned and characterized from metagenomic DNA extracted from hot spring soil. The recombinant gene was expressed in E. coli and expressed protein was purified to homogeneity using hydrophobic interactions chromatography. The mature polypeptide consists of 388 amino acids with apparent molecular weight of 43 kDa. The enzyme displayed maximum activity at 50°C and pH 9.0. It showed thermal stability up to 40°C without any loss of enzyme activity. Nearly 80% enzyme activity was retained at 50°C even after incubation for 75 min. However above 50°C the enzyme displayed thermal instability. The half life of the enzyme was determined to be 5 min at 60°C. Interestingly the CD spectroscopic study carried out in the temperature range of 25–95°C revealed distortion in solution structure above 35°C. However the intrinsic tryptophan fluorescence spectroscopic study revealed that even with the loss of secondary structure at 35°C and above the tertiary structure was retained. With p-nitrophenyl laurate as a substrate, the enzyme exhibited a K m , V max and K cat of 0.73 ± 0.18 μM, 239 ± 16 μmol/ml/min and 569 s−1 respectively. Enzyme activity was strongly inhibited by CuCl2, HgCl2 and DEPC but not by PMSF, eserine and SDS. The protein retained significant activity (~70%) with Triton X-100. The enzyme displayed 100% activity in presence of 30% n-Hexane and acetone.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Enzymes have major appeal as catalysts because of their high turnover number and refined level of selectivity, particularly in the synthesis of single-enantiomer compounds. One such enzyme, lipase exhibit remarkable broad substrate specificity which makes it highly versatile biocatalyst. Lipases are triacylglycerol hydrolases (EC 3.1.1.3) which hydrolyzes and synthesizes long chain acylglycerols and find immense applications in food, detergent, pharmaceutical and dairy industries [1]. The lipases showed heterogeneity both in the catalytic properties and in the amino acid sequence. The active site of most of the lipases contains a serine protease like catalytic triad consisting of three residues—Ser-His-(Asp/Glu) [1]. A variety of microbial lipases with different substrate specificities and biochemical properties have been reported [2, 3]. The structure elucidation had revealed that these are the members of α/β hydrolases superfamily [4, 5]. Most of the industrial processes in which lipases are employed, function at temperatures exceeding 45°C and in organic solvents. The enzymes thus are required to exhibit an optimum temperature of around 50°C and above. Fundamental reasons to choose thermostable enzymes in bioprocessing are of course the intrinsic thermostability, which implies possibilities for prolonged storage (at room temperature), increased tolerance to organic solvents etc. [6]. It is reported in many studies that thermostable lipases are more rigid than mesophilic enzyme and this rigidity is important for providing thermostability. Two types of protein thermostability are of interest that include thermodynamic stability and long term stability. Thermodynamic stability is the main issue when an enzyme is used under denaturing conditions i.e. high temperature and organic solvents [7]. The important factors that presumably contribute thermostability to the proteins include increase in ion-pairs-ion pairs interactions, disulphide bonds and hydrogen bonding [8]. The thermostable lipase can be produced from the thermophiles through either optimized fermentation of the microorganisms or cloning of fast-growing mesophiles by recombinant DNA technology. Few lipases and esterases have been cloned and characterized from various microorganism including Bacillus sp., Pseudomonas sp., Staphylococcus, C. cylandracia and Geotrichum candidum and Geobacillus [9–11]. The culture independent studies of various microbial communities however have demonstrated that portion of the viable but non-culturable bacteria in natural ecosystem is over 99% with only 1% culturable representatives [12–14]. Concerning biotechnological and pharmaceutical applications, the genomes of the non-culturable microbes represent an unlimited and very valuable resource for novel biocatalysts. Many novel genes and gene products were discovered using metagenomic approach that include the first bacteriorhodopsin gene from prokaryotic origin [15], many novel small molecules with anti microbial activity [16] and new members of unknown proteins, Na+(Li+)/H+ antiporter genes [17]. A few lipase and esterase genes have been cloned and characterized from uncultured microorganisms [18–26].

In the present investigation a gene encoding extracellular lipase was cloned from metagenomic DNA extracted from soil samples of hot spring from Himachal Pradesh (India). The recombinant lipase was expressed and purified to homogeneity using standard chromatographic techniques. We characterized the purified lipase biochemically in detail. During course of biochemical characterization it was interesting to note the thermostability behavior of this lipase compared to earlier reported identical lipases with which it shared more than 90% similarity at amino acids level. We probed the structural conformation of the lipase using sensitive tools like circular dichroism and intrinsic tryptophan fluorescence to address this question. Surprisingly we observed the distortion in its secondary structure above 35–45°C, however intrinsic fluorescence data showed that it has retained its tertiary structure. Further the kinetic parameter of the lipase was also determined.

Materials and methods

Sample collection and DNA isolation

Soil samples were collected in autoclaved oakridge tube (15 ml) using the sterile forceps from hot springs area of Manikaran (Average water temperature 60–65°C) in Himachal Pradesh, India (32°1′40.34″N, 77°20′52.95″E). The soil was dried in oven where the temperature was maintained to 50°C. DNA from soil was extracted using method described by Zhou et al. [27], Sieved fine soil (0.5 g) was weighed in four micro-centrifuge tubes and DNA was extracted with 1.3 ml of extraction buffer (100 mM Tris–HCl, pH 8.0, 100 mM EDTA, pH 8.0, 1.5 M NaCl, 100 mM sodium phosphate, pH 8.0, 1% hexadecyltrimethylammonium bromide). After proper mixing, 13 μl of proteinase K (10 mg/ml) was added and incubated at 37°C with horizontally shaking for 45 min. After incubation 160 μl of 20% SDS was added and mixed for 30 s with further incubation at 60°C for 2 h. The sample in each micro-centrifuge tube was mixed thoroughly after every 15 min interval. The samples were centrifuged at 5000×g for 10 min. The supernatant was transferred into new micro-centrifuge tube. The remaining soil pellets were treated three times with 400 μl of extraction buffer, 60 μl of SDS (20%) and incubated at 60°C for 15 min with intermittent shaking after every 5 min. The supernatants collected from all four extractions were extracted three to four times with equal quantity of chloroform and isoamyl alcohol (24:1). Aqueous layer was separated and precipitated with 0.6 volume of isopropanol. After centrifugation at 12,000×g for 15 min, the brown pellet was washed with 70% ethanol, dried at room temperature and was dissolved in TE (10 mM Tris-Cl, 1 mM EDTA, pH 8.0). DNA was estimated spectrophotometrically at 230, 260 and 280 nm respectively to know its purity and concentration. The metagenomic DNA purification was carried out according to Sharma et al. [28].

Primer designing and molecular manipulations

Degenerate set of primers were designed using multiple sequence alignment (Clustal W) (http://www.ebi.ac.uk/clustalW/) of different lipase gene sequences reported from thermophilic bacterial species at NCBI site with accession number AF134840, AY260784, AY786185.1, U78785, FJ774007.1, DQ009618.1, AF237623, AY0952601, X95309. The Primers were checked carefully for their hairpin loop formation, GC contents and for primer dimer formation using IDT tools for oligo analysis available online. The purified DNA (0.1 μg) was used as template for amplification of lipase gene using degenerated primers. Primer sequences used for PCR amplification were 5′-ATGATGAA (A/G) GGNTG (T/C) AG (A/G) GTNCC-3′ (forward primer) and 5′-TTANGGNCGNA (A/G) N(C/G) (T/A) NGCNA (G/A) (T/C) TGNCC-3′ (reverse primer) and used in final concentration of 1 μM/25 μl reaction for amplification. The PCR (gradient) reaction was carried out in a Bio-Rad thermal cycler at 94°C for 4 min followed by 30 cycles at 94°C for 1 min, 55/59.5°C for 50 s, 72°C for 2 min followed by 10 min at 72°C. The amplified product was purified by gel extraction kit (Sigma) and ligated in the pGEM-T easy vector (Promega). The recombinant DNA molecules were transformed into E. coli DH5α cells using electroporation. The transformants were selected based on blue/white screening. The plasmid was extracted from white colonies using alkaline lysis method [29]. The presence of the insert was confirmed by colony PCR.

Nucleotide sequencing and analysis of gene and gene product

The nucleotide sequencing was carried out by commercial available service provided by Bangalore Genei Ltd. (India) using an automated AB1 3100 genetic analyzer that uses fluorescent label dye terminator, based on dideoxy chain termination method [30]. The sequence was analyzed and aligned using different tools available at European Bioinformatics Institute (EBI) and National center for Biotechnology Information (NCBI) for protein and nucleotide analysis. Blast was performed for similarity search of sequence at GeneBank database (http://www.ncbi.nlm.nih.gov/BLAST/) and multiple sequence alignment was carried out using Clustal W (http://www.ebi.ac.uk/clustalW/). The presence of signal peptide in amino acids sequence was determined using signalP 3.0 server (http://www.cbs.dtu.dk/services/SignalP/). The theoretical pI of the mature polypeptide was predicted using protparam while secondary structure predictions were carried out using SOMPA, both the software available online with expasy tools (expasy.org).

Cloning of the lipase gene in pQE-30UA vector

The open reading frame (ORF) of lipase gene was cloned in pQE-30UA expression vector (Qiagen, Germany) and expressed in E. coli M15 cells containing pREP4 plasmid as per manufacturer’s instructions. The recombinant colonies were initially screened on LB agar plates containing ampicillin (100 μg/ml) and Kanamycin 30 μg/ml. Clones were further screened for lipase production on LB agar plates containing 1% emulsified tributyrin, ampicillin (100 μg/ml), kanamycin (30 μg/ml) and IPTG (0.1 mM). The plates were incubated at 37°C overnight and the colonies showing zone of clearance on substrate plate were selected for further studies.

Protein expression and purification

The M I5 E. coli cells harboring pQE-UA-lipase were grown overnight at 37°C in 5 ml liquid LB media containing ampicillin (100 μg/ml) and kanamycin (30 μg/ml) overnight. Next day 1% of overnight grown cells were inoculated in 500 ml LB media and the culture was grown at 37°C. The lipase expression was induced with a final concentration of 0.1 mM Isopropyl-beta-thio galactopyranoside (IPTG) when A600 ~0.5. Cells were harvested after 3 h of the induction and the clear supernatant was collected. All the steps for purification were carried out at 4°C. The clear supernatant was saturated to 80% with ammonium sulphate and the precipitated protein was collected by centrifugation at 10,000×g for 30 min. The pellet was dissolved in 40 ml of 0.05 M sodium phosphate buffer (pH 8.0). The dissolved ammonium sulphate fraction (33 ml) was layered on a Phenyl Sepharose column (5.3 × 4.5 cm) pre equilibrated with equilibration buffer (0.5 M NaCl in 0.05 M phosphate buffer pH 8.0). The column was first washed with 5 column volumes of equilibration buffer, followed by 2 volumes each of 0.05 and 0.001 M phosphate buffer (pH 8.0). The bound enzyme was eluted first with 20 ml of 40% ethylene glycol followed by 15 ml of 80% ethylene glycol in 0.001 M phosphate buffer (pH 8.0). The fractions (1.5 ml) were collected and analyzed for lipase activity. The fractions showing high lipase activity were pooled and desalted by dialyzing against 0.01 M phosphate buffer over night in cold room. The dialyzed sample was concentrated using 10 kDa cut off membrane filter (Millipore USA).

Protein concentration was determined using the commercially available BCA (Bicinchoninic acid method) kit (Banglore Genei, India). Bovine serum albumin was used as standard. Protein samples were analyzed on SDS-PAGE (sodium dodecyl sulphate-polyacrylamide gel electrophoresis) according to Laemmli [31] for purity and molecular mass determination. Molecular weight of the purified protein sample was determined by running SDS PAGE marker reconstituted by mixing the different known protein samples purchased from Sigma (USA) that corresponds to mixed protein samples of (Phosphorylase b 97.4 kDa, Bovine Serum Albumin 66 kDa, Ovalbumin (chicken egg) 45 kDa, Carbonic Anhydrase 29 kDa, Lactoglobulin 18.4 kDa, Lysozyme 14.3 kDa). The exact molecular weight of the protein was determined by semi-log plot (distance migrated on X axis and log molecular weight on Y axis).

Enzyme assay

The enzyme activity was determined according to the modified method of Sigurgisladottir et al. [32]. To 0.8 ml of 0.05 M phosphate buffer (pH 8.0), 0.1 ml enzyme and 0.1 ml of 0.001 M p-nitrophenyl laurate was added. The reaction was carried out at 50°C for 10 min, after which 0.25 ml, 0.1 M Na2CO3 was added. The mixture was centrifuged and the activity was determined by measuring absorbance at 420 nm in UV/Vis spectrophotometer (JENWAY 6505 UK). One unit of enzyme activity is defined as the amount of enzyme, which liberates 1 μmol of p-nitrophenol from pNP-laurate as substrate per min under standard assay conditions. The total enzyme activity was expressed in Unit/ml and specific activity was expressed as Unit/mg of protein.

Effect of temperature and pH on enzyme activity and stability

The pH optima was determined by assaying the purified lipase in buffer of different pH at 50°C (sodium acetate— pH 5.0, sodium phosphate—pH 6.0–8.0, Tris-HCl—pH 9.0, Glycine NaOH—pH 10.0–11.0). The pH stability of the lipase was determined by incubating the enzyme with 0.05 M buffer of different pH (5.0–11.0) for 1 h at room temperature.

The temperature optimum of the purified lipase was determined by assaying the enzyme activity at different temperature (20–80°C). Enzyme stability assay was carried out at these temperatures by incubating the enzyme for 30 min followed by cooling on ice for 15 min. The enzyme assay was carried out at 50°C. Thermostability assay was carried out at 50 and 55°C by preincubating the purified enzyme for 15, 30, 45, 60, and 75 min respectively at given temperature. The samples were cooled on ice for 15 min followed by enzyme assay at 50°C. The enzyme without incubation was taken as control (100%). The residual lipase activity after each incubation was determined. Reaction mix without enzyme served as blank.

Substrate specificity

The substrate specificity of lipase was carried out using pNP ester (final concentration of 0.3 mM) of following chain length: pNP-acetate (C3), pNP-butyrate (C4), pNP-caprylate (C8), pNP-deconate (C10), pNP-laurate (C12), pNP-myristate (C14), pNP-palmitate (C16), pNP-stearate (C18) (Sigma USA), dissolved in absolute alcohol. Assay was performed according to the standard enzyme assay method at 50°C and pH 8.0.

Effect of additives and chemical modifiers on lipase activity

The effect of various additives such as metal ions (0.1 and 1 mM each), detergents (1% w/v) and solvents (10, 20 and 30% v/v) were studied by addition of these additives separately into the reaction mix. The activity was measured according to standard assay conditions.

The effect of chemical modifiers such as PMSF (phenylmethylsulphonyl fluoride), eserine, DEPC (Diethyl pyrocarobnate) and β-ME (0.1 and 1 mM each), on enzyme activity was studied. The enzyme assay was carried out in presence and absence of chemical modifiers. The reaction mix with respective additives/chemical modifiers but without enzyme served as blank. The sample without any additive/modifier was taken as control (100%).

Kinetic parameter

Enzyme activity of the lipase as function of substrate concentration (0.01–5 mM) was carried out using standard assay method. With pNP laurate as substrate the Michaelis–Menten constant (K m) and maximum velocity for the reaction (V max ) were calculated by Lineweaver-Burk plot, k cat and k cat /K m were also calculated.

Biophysical characterization of the purified recombinant protein

The effect of temperature on enzyme conformation (secondary and tertiary) was monitored by CD and fluorescence spectroscopic techniques. The protein was exposed to temperatures ranging from 25 to 95°C. Circular dichroism measurements were made with a JASCO J-715 spectropolarimeter fitted with a Jasco Peltier-type temperature controller (PTC-348WI). The instrument was calibrated with D-10 camphor sulfonic acid. The temperature of the protein solution was controlled employing cell holder attached to a Neslab’s RTE-110 water bath, with an accuracy of ±0.1°C. Spectra were collected with a scan speed of 20 nm/min and with a response time of one second. Each spectrum was the average of 2 scans. Far UV CD spectra were taken in the wavelength region of 200–250 nm at a protein concentration of 12 μM with a 2 mm path length cell. The protein concentration used was 0.05 mg/ml in 50 mM sodium phosphate buffer (pH 8.0) with path length of 1 cm. Temperature dependent unfolding profiles were obtained by heating protein from 25 to 95°C and Far-UV CD spectra were recorded in the 200–250 nm range.

Intrinsic tryptophan fluorescence measurements were carried out on a Shimadzu spectrofluorometer (model RF-540) equipped with a data recorder DR-3. The fluorescence spectra were measured at a protein concentration of 9.8 μM with a 1-cm path length cuvette. The excitation wavelength was set at 280 nm and emission spectra were recorded in the range of 300–400 nm or at a fixed wavelength of 340 nm with 5 and 10 nm slit width for excitation and emission respectively.

Nucleotide sequence accession number

The complete nucleotide sequence of JkP01 reported in this study has been assigned GeneBank accession number FJ392756.

Results

Cloning and sequence analysis of the lipase gene

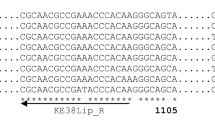

The degenerate primers set amplified three fragments of 650, 900 and 1260 bp. All three fragments were cloned in pGEM-T easy vector separately. Out of the three, only the clone with 1260 bp fragment resulted in expression of lipase when screened on LB agar tributyrin plate, while no zone of clearance was observed with clones carrying 650 and 900 bp fragment. The sequencing of the clone (JkP01) confirmed the fragment having complete open reading frame of 1254 bp coding for 417 amino acids with a predicted molecular mass of 43 kDa. The lipase gene displayed high identity with the earlier reported thermostable lipases [33–36]. The active site of the JkP01 lipase was also predicted based upon the conserved sites observed after multiple sequence alignment with the other lipases i.e. TW1, L1 and P1 lipase with accession number AY786185, U78785, AF237623 respectively, having serine (142), aspartate (346) and histidine (387) as catalytic member of this lipase. A conserve pentapeptide AHSQG sequence, which has been suggested to contain the active-site serine residue, is fully conserved in JkP01 sequence. Furthermore, another consensus peptide, His-Gly, present in the N-terminal part of all known lipases except for the fungal lipases, was also present in JkP01 at position 43 and 44 (Supplementary Material 1). The most probable cleavage site for the signal peptide of JkP01 lipase would be between Ala-29 and Ala-30 in the prolipase sequence as also predicted using the signalP 3.0 server.

Expression of the lipase gene and protein purification

The enzyme expression was achieved by inducing the lipase expression with 0.1 mM IPTG. The enzyme was eluted from Phenyl Sepharose column as a single peak with 80% ethylene glycol. The purified enzyme resulted in 61 fold of purification with 6% yield. The specific activity of purified lipase was calculated to be 2022 ± 31 U/mg of protein (Table 1). The purified recombinant lipase showed a single band ~43 kDa on SDS-PAGE (Supplementary Material 2) which is consistent with the predicted molecular weight of the lipase. It was observed that the high concentration of protein always resulted in aggregation.

Biochemical and biophysical characterization

The temperature optimum for the enzyme was observed at 50°C with pNP-laurate as substrate. Enzyme was stable from 20 to 50°C for 30 min, however enzyme activity was reduced drastically at 60°C temperature (Fig. 1a). The enzyme was almost completely stable at 50°C for 60 min, while the activity was reduced to 70% after 75 min incubation. At 55°C the enzyme retained 100% activity for 30 min and almost reduced to 50, 44 and 32% after incubation for 45, 60 and 75 min respectively (Fig. 1b).

a Effect of temperature on enzyme activity and stability. Activity of the lipase (filled triangle) Stability of the lipase (filled square) after incubation at respective temperature for 30 min b Effect of temperature on lipase activity. The enzyme was incubated at 50°C (filled square) and 55°C (filled triangle). Aliquots of enzyme were taken out after every 15 min

Figure 2a shows the far UV CD spectra of recombinant lipase upon its exposure to elevated temperature. Native structure of the protein displays strong negative bands in the region of 200–250 nm and the signal intensity is greater at 208 nm than at 222 nm, which is a characteristic of α + β protein [37]. On increasing the temperature from 25 to 35°C and further, there was complete distortion in secondary structure.

As also revealed by intrinsic fluorescence studies, exposure of JkP01 lipase to higher temperature brings about conformational changes in the protein structure. Increase in temperature from 35 to 45°C resulted in substantial increase in intrinsic fluorescence with red shift. Further elevation of temperature caused gradual increase in fluorescence intensity with red shift presumably because of exposure of tryptophan residues to the polar solvent that may resulted in quenching of the tryptophan (Fig. 2b). Increase in temperature from 85°C onward ensued in abrupt increase in fluorescence intensity of the protein.

The enzyme displayed maximum activity at pH 9.0. It was completely stable at pH 8.0 and 9.0 when incubated at room temperature for 1 h, while nearly 50% enzyme activity was retained at pH 7, 10 and 11 (Fig. 3). Effect of various solvents in aqueous solution was studied on enzyme stability. The enzyme retained 100% activity in 10, 20 and 30% of acetone and n-Hexane, while 70–80% activity was observed each with 10% of dimethyl formamide, dimethyl sulphoxide, propanol, methanol, glycerol and ethylene glycol. Significant loss (~90%) in enzyme activity was observed when 20 and 30% each of these solvents were used. The detergents like Tween (20, 40, 60, 80) inhibited the lipase activity significantly, however enzyme displayed 100% activity each with SDS and Sodium deoxycholate while 74% activity was observed with Triton X-100.

The metal ions HgCl2 and CuCl2 at concentration of 0.1 mM strongly inhibited the enzyme activity. However the enzyme activity was increased in the presence of ZnCl2, CoCl2, CaCl2 and LiCl2 (162, 124, 163 and 112% respectively at 0.1 mM concentration), while at 1 mM all of these inhibited the enzyme activity (Table 2). The enzyme displayed 100% activity each with PMSF and eserine at 0.1 and 1 mM concentration respectively. In contrary to this DEPC strongly inhibited the enzyme activity at 0.1 mM concentration. β-ME, a reducing agent did not affect the enzyme activity (Table 2). The substrate specificity of the enzyme towards the pNP ester was observed in the order C12 > C14 > C10 > C16 > C18 > C8. No activity was observed with lower chain fatty acids i.e. C3 and C4 (Fig. 4). The K m and V max were calculated to be 0.73 ± 0.18 μM and 239 ± 16 μmol/ml/min respectively, the k cat and k cat /K m values for the purified lipase were calculated to be 569 s−1 and 779 μM−1 s−1 respectively.

Discussion

A gene encoding a lipase was cloned and expressed from a metagenomic DNA extracted from hot spring environmental sample from India. After induction of lipase production with IPTG, the mature lipase protein was secreted out of the cell in active form. The enzyme was purified using Phenyl Sepharose chromatography as a single step process that yielded a highly active and pure lipase. The elution of lipase with 80% ethylene glycol suggested that the enzyme was strongly adsorbed to Phenyl Sepharose column for a water-soluble protein. Low yield of the lipase might be attributed to incomplete desorption from the HIC column. A reasonable explanation for this strong adsorption might be explained via interfacial activation. [38]. Low yield of purified enzyme can also be attributed to loss during ammonium sulphate precipitation. Like most of the Bacillus lipases, this lipase also forms aggregates at high protein concentration which resulted in further lowering the yield of the protein. Our observation of low yield of lipase during protein purification is consistent with the studies carried out previously [39–42]. The consistency of the calculated molecular mass of the denatured lipase and predicted molecular weight from gene sequence suggested that enzyme existed as a monomer.

Sequence analysis of cloned lipase depicted that this gene was closely identical to the lipases of the Bacillus species especially the Geobacillus . A comparison of the nucleotides and its deduced amino acid sequence of JkP01 lipase with other lipase and esterase sequences in the EMBL and SwissProt database showed significant sequence identity to the Bacillus stearothermophilus L1 (96%), Geobacillus thermocatenulatus (94%) and Geobacillus species SF1(93%). They all belonged to lipolytic enzymes of Family 1.5.

Bioinformatics analysis of the cloned lipase gene revealed the presence of terminal signal sequence of 29 amino acids present at the N terminus site of the polypeptide. Like many of α/β hydrolase family members, in addition to conserved penta-peptide AXSXG, a conserved HG-dipeptide was also observed in the N-terminus region of the JkP01 protein. This dipeptide flanked the catalytic pocket playing a role in stabilizing the oxyanion intermediate of the hydrolysis reaction. Since the lipase belongs to family 1.5 of the lipases, the active site residues are reported to be protected by lid helix region which is a unique domain in this family [43]. Although this lipase demonstrated optimum enzyme activity at 50°C, Far-UV CD spectra indicated significant distortion in its secondary structure at 35°C and above. This observation was interesting if the protein shows optimum temperature at 50°C. The intrinsic fluorescence data also showed conformational changes in lipase solution structure above 35°C. The data indicates that at lower temperature (25°C) native structure is maintained and the lipase protein either has solvent exposed tryptophan or these are quenched (by aromatic amino acids or histidine, Asp or Glu). However as the temperature was increased there is increase in the tryptophan fluorescence intensity which indicates that tryptophan residues are buried in hydrophobic pockets that gave characteristically increased fluorescence. Though CD spectra showed change in the secondary structure, intrinsic fluorescence spectroscopy demonstrated that it has retained its tertiary structure. Unfortunately no such biophysical study is available for comparison of our data to the earlier reported identical lipases (L1, TW1, P1). Therefore at the moment, it can not be pointed out if this structural pattern is a common phenomenon for all thermostable lipases used for comparision in this study or it is because of the changes in few amino acids observed in JkP01 lipase. The amino acids of JkP01 lipase were compared with other lipases showing high identity at amino acid level (Supplementary Material 3). The comparison demonstrated that an amino acid at position 310 for the lipase showing highest thermostability (>5 h at 60°C) was completely different when compared with other similar lipases (including JkP01 lipase) demonstrating low thermostability (<30 min at 60°C). While 6 other amino acids at C-terminus end were completely different in JkP01 lipase when compared with other similar lipases showing higher thermostability than JkP01. If the changes observed in biochemical and biophysical properties of JkP01 were because of the changed amino acid composition, it will be interesting to study the role of these different amino acids for maintenance of secondary structure at higher temperature. To further compare the secondary structure contents among all the four lipases compared in (Supplementary Material 1) we predicted the secondary structure of the mature polypeptide using SOMPA [44]. Secondary structure prediction has shown major difference at the random coil and β turn in all four lipases. The least β turns 8.76% were observed in JkP01 lipase while TW1, L1 and P1 has β turn % age of 9.02, 9.79 and 9.28% respectively. The highest random coil i.e. 46.91% was observed in case of P1 lipase however the JkP01and L1 has 45.88% each, while TW1 has 45.76% of random coil.

The biochemical properties, displayed by the purified JkP01 lipase were also quite different when correlated to the earlier reported lipases (Table 3). In addition to the properties discussed in Table 3 the JkP01 lipase has also shown different substrate specificity when compared to the identical lipases. This enzyme displayed maximum lipase activity towards the pNP-laurate when compared to the lipase from Bacillus stearothermophilus L1 that displayed maximum activity with pNP-caprylate. Similarly the lipase from TW1 a thermophillic Bacillus sp. displays maximum activity with pNP-deconate [9, 34]. To further study the effect of detergents on the enzyme activity we tested the enzyme activity in the presence of the different detergents. Interestingly it was observed that this enzyme displays 100% activity each with SDS, sodium deoxychoalate and β-Mercaptoethanol, while 74% activity with Triton X-100. In contrast the lipase from Bacillus stearothermophilus L1 displayed only 2% activity with SDS and 80–90% activity each with sodium deoxycholate, β-Mercaptoethanol and Triton X-100 [34]. The thermophilic TW1 lipase however showed similar observation with SDS, Triton X-100 and β-Mercaptoethanol respectively when compared with JkP01 lipase [9]. The thermostable lipase from Bacillus staerothermophillus P1 showed 50% reduction in enzyme activity with SDS and 80–95% activity each with sodium deoxycholate, β-Mercaptoethanol and Triton X-100 respectively [36]. These studies implied that lipase activity in these detergents might be due to the change in the interfacial properties or because of change in the conformation of the enzyme. We further tested the effect of different inhibitors molecules on lipase enzyme activity that included PMSF and DEPC. According to our observation the PMSF which is a well known serine inhibitor does not inhibit the JkP01 lipase activity. This observation was consistent with other studies where lipases reported to be remained active in presence of PMSF [34, 45, 46]. It might be hypothesized that the serine residue was buried in the hydrophobic core and could not be accessed by the PMSF easily. On contrary to this DEPC, a histidine modifier loss in enzyme activity was observed at very low concentration suggesting the easy accessibility of the catalytic histidine residue to DEPC. The eserine, an esterase’s inhibitor did not affected the enzyme activity which suggested that the JkP01 is a true lipase. Generally lipase activity is not affected by the presence of metal ions, however the metal ion Hg 2+ and Cu2+ completely inhibited the enzyme activity of this lipase which indicated binding of these ions to the active center. In contrast to this Ca2+ and Zn2+ has stimulated the enzyme activity. The Ca2+ ion generally also found to stimulate the lipase activity by facilitating the removal of free fatty acids formed in the reaction at the water–oil interface which may be another reason for enhanced activity in the presence of this ion [47, 48]. Generally lipase catalyzed transesterification reactions and synthesis of esters is being carried out in water immiscible organic solvents and small amount of water [49]. Since, the lipase displayed 100% activity even in presence of 30% n-Hexane the enzyme might be useful for transesterification and ester synthesis.

Conclusion

In conclusion this study reported cloning of a lipase gene which is closely related with the lipases of other thermophilic Bacillus sp., It displayed different biochemical properties when compared with other reported thermostable lipases. Attempt was made to probe the structural behavior of this lipase at higher temperature. Though the CD spectrum was quite distorted at 35°C and above, the tertiary structure of lipase was retained as demonstrated by fluorescence spectroscopy as well as enzyme activity. Further the stability of lipase in detergents and solvents especially in n-Hexane supports its candidature for industrial application where the reactions are carried out in presence of the solvent.

References

Jaeger KE, Dijkstra BW, Reetz MT (1999) Bacterial biocatalysts; molecular biology, three dimensional structures, and biotechnological applications of lipases. Annu Rev Microbiol 53:315–351

Kim S, Lee SB (2004) Thermostable estrase from thermoacidophilic archeon: Purification and characterization of enzymatic resolution of chiral compound. Biosci Biotechnol Biochem 68:2289–2298

Rubin B, Dennis EA (eds) (1997) Lipases part B. Enzyme characterization and utilization. In: Methods in enzymology, vol 286. Academic Press, San Diego, pp 1–563

Pouderoyen V, Eggert T, Jaeger KE, Dijkstra BW (2001) The crystal structure of Bacillus Subtili lipase; a minimal α/β hydrolase fold enzyme. J Mol Biol 309:215–226

Jeong ST, Kim HK, Jun KS, Chi SW, Pan JG, Oh TK, Ryu ES (2002) Novel Zinc-binding center and a temperature switch in the Bacillus stearothermophilus L1 lipase. J Biol Chem 277:17041–17047

Kristjansson JK (1989) Thermophilic organisms as sources of thermostable enzymes. Trends Biotechnol 7:349–353

Mozhaev VV (1993) Mechanisms-based strategies for protein thermostabilization. Trends Biotechnol 11:88–95

Ladenstein R, Ren B (2006) Protein disulfides and protein disulfide oxidoreductases in hyperthermophiles. FEBS Journal. 273:4170–4185

Li H, Zhang X (2005) Characterization of thermostable lipase from thermophilllic Geobacillus sp. TW1. Prot Exp Puri 42:153–159

Zhang A, Ranjun G, Diao N, Xie G, Gao G, Cao S (2009) Cloning, expression and characterization of an organic solvent tolerant lipase from Pseudomonas fluorescens. J Mol Catal B 56:78–84

Kampen MDV, Rosenstein R, Gotz F, Engmond MR (2001) Cloning, purification and characterisation of Staphylococcus warneri lipase 2. Biochim Biophys acta 1544:229–241

Amann RI, Ludwig W, Schleifer KH (1995) Phylogenetic identification and In situ detection of individual microbial cells without cultivation. Microbiol Rev 59:143–169

Hugenholtz P, Pace NR (1996) A molecular phylogenetic approach to the natural microbial world: the biotechnological potential. Trends Biotechnol 14:190–197

Pace NR, Stahl DA, Lane DJ, Olsen GJ (1985) Analyzing natural microbial populations by rRNA sequences. ASM News 51:4–12

Beja O, Aravind L, Koonin EV, Suzuki MT, Hadd A, Nguyen LP, Jovanovich SB, Gates CM, Feldman RA, Spudich JL, Spudich EN, DeLong EF (2000) Bacterial rhodopsin; evidence for a new type of phototrophy in the sea. Science 289:1902–1906

MacNeil IA, Tiong CL, Minor C, August PR, Grossman TH, Loiacono KA, Lynch BA, Phillips T, Narula S, Sundaramoorthi R, Tyler A, Aldredge T, Long H, Gilman M, Holt D, Osburne MS (2001) Expression and isolation of antimicrobial small molecules from soil DNA libraries. J Mol Microbiol Biotechnol 3:301–308

Majernik A, Gottschalk G, Daniel R (2001) Screening of Environmental DNA Libraries for the presence of genes conferring Na+ (Li+)/H+ antiporter activity on Escherichia coli; characterization of the recovered genes and the corresponding gene products. J Bacteriol 183:6645–6653

Rees HC, Grant S, Brian J, Grant WD, Heaphy S (2003) Detecting cellulose and esterase enzyme activities encoded by novel genes present in environmental DNA libraries. Extremophiles 7:415–421

Kourist R, Hari Krishna S, Patel JS, Bertnek F, Hitchman TS, Weiner DP, Bornscheuer UT (2007) Identification of a metagenome-derived esterase with high enantioselectivity in the kinetic resolution of arylaliphatic tertiary alcohols. Org Biomol Chem 5:3310–3313

Lammle K, Zipper H, Breuer M, Hauer B, Buta C, Brunner H, Rupp S (2007) Identification of novel enzymes with different hydrolytic activities by metagenome expression cloning. J Biotechnol 127:59–575

Elend C, Schmeisser C, Leggewie C, Babiak P, Carballeira JD, Steele HL, Reymond JL, Jaeger KE, Streit WR (2006) Isolation and biochemical characterization of two novel metagenome-derived esterases. Appl Environ Microbiol 72:3637–3645

Lee M, Lee C, Oh T, Song JK, Yoon J (2006) Isolation and characterization of a novel lipase from a metagenomic library of tidal flat sediments: evidence for a new family of bacterial lipases. Appl Environ Microbiol 72:7406–7409

Bertram M, Hildebrandt P, Weiner DP, Patel JS, Bartnek F, Timothy S, Hitchman TS, Bornscheuer UT (2008) Characterization of lipases and esterases from metagenomes for lipid modification. J Am Oil Chem Soc 85:47–53

Bell PJL, Sunna A, Gibbs MD, Curach NC, Nevalainen H, Bergquist PL (2002) Prospecting for novel lipase using PCR. Microbiology 148:2283–2291

Tirawongsaroj P, Sriprang R, Harnpicharnchai P, Thongaram T, Champreda V, Tanapongpipat S, Pootanakit K, Eurwilaichitr L (2008) Novel thermophilic and thermostable lipolytic enzymes from a Thailand hot spring metagenomic library. J Biotechnol 133:42–49

Fan Z, Yue C, Tang Y, Zhang Y (2009) Cloning, sequence analysis and expression of bacterial lipase-coding DNA fragments from environment in Escherichia coli. Mol Biol Rep 36:1515–1519

Zhou J, Bruns MA, Tiedje JM (1996) DNA recovery from soils of diverse composition. App Env Microbiol 62:316–322

Sharma PK, Capalsh N, Kaur J (2007) An improved method for single step purification of metagenomic DNA. Mol Biotechnol 36:61–63

Sambrook J, Fritsch E, Maniatis T (1989) Molecular cloning: a laboratory manual, 2nd edn. Cold spring Harbor Laboratory, New York

Sanger F, Nicklen S, Coulsion AR (1977) DNA sequencing with chain terminating inhibitors. Proc Nat Acad of Sci USA 74:5463–5467

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 15:680–685

Sigurgisladottir S, Konraosdottir M, Jonsson A, Kristjansson JK, Matthiasson E (1993) Lipase activity of thermophilic bacteria from icelandic hot springs. Biotechnol Lett 15:361–366

Castro RQ, Diaz P, Alfaro GV, Gracia HS, Ros RO (2009) Gene cloning, expression and characterization of the Geobacillus thermoleovorans CCR11 thermoalkaliphilic Lipase. Mol Biotechnol 42:75–83

Kim HK, Park SY, Lee JK, Oh TK (1998) Gene cloning and characterization of thermostable lipase from Bacillus stearothermophilus L1. Biosci Biotechnol Biochem 62:66–71

Sinchaikul S, Sookkheo B, Phutrakul S, Pan FM, Chen ST (2001) Optimization of a thermostable lipase from Bacillus stearothermophilus P1; overexpression, purification, and characterization. Prot Exp Puri 22:388–398

Soliman NA, Knoll M, Fattah YRA, Schmid RD, Lange S (2007) Molecular cloning and characterization of thermostable esterase and lipase from Geobacillus thermoleovorans YN isolated from desert soil in Egypt. Process Biochem 42:1090–1100

Chandrayan KS, Dhaunta N, Guptasarma P (2008) Expression, purification, refolding and characterization of a putative lysophospholipase from Pyrococcus furiosus: retention of structure and lipase/esterase activity in the presence of water-miscible organic solvents at high temperatures. Prot Exp Puri 59:327–333

Palomo JM, Muñoz G, Fernández-Lorente G, Mateo C, Fernández-Lafuente R, Guisán JM (2002) Interfacial adsorption of lipases on very hydrophobic support (octadecyl-Sepabeads): immobilization, hyperactivation and stabilization of the open form of lipases. J Mol Catal B 19(20):279–286

Nawani N, Kaur J (2000) Purification, characterization and thermostability of lipase from a thermophilic Bacillus sp. Mol Cell Biochem 206:91–96

Saxena RK, Sheoran A, Giri B, Davidson WS (2003) Purification strategies for microbial lipases. J Microbiol Methods 52:1–18

Pastore GM, Costa VSR, Koblitz MGB (2003) Partial purification and biochemistry characterization of an extracellular lipase obtained from new Rhizopus sp stream. Ciência e Tecnologia de Alimentos 23(2):135–140

Pencreac’h G, Barrati JC (1996) Hydrolysis of p-nitrophenyl palmitate in n-heptane by the Pseudomonas cepacia lipase: a simple test for the determination of lipase activity in organic media. Enz Microbial Tech 18:417–422

Choi WC, Kim MH, Ro HS, Sang RR, Oh TK, Lee JK (2005) Zinc in lipase L1 from Geobacillus stearothermophilus L1 and structural implications on thermal stability. FEBS Lett 579:3461–3466

Geourjon C, Deleage G (1995) SOPMA: Significant improvements in protein secondary structure prediction by consensus prediction from multiple alignments. Comput Appl Biosci 11:681–684

Nakatani T, Hiratake J, Yoshikawa K, Nishioka T, Oda J (1992) Chemical inactivation of lipase in organic solvent: a lipase from Pseudomonas aeruginosa TE3285 is more like a typical serine enzyme in an organic solvent than in aqueous media. Biosci Biotechnol Biochem 56:1118–1123

Dannert CS, Sztajer H, Stocklein W, Menge U, Schmid RD (1994) Screening, purification and properties of a thermophilic lipase from Bacillus thermocatenulatus. Biochim Biophy Acta 1214:43–53

Jiang Y, Zhou X, Chen Z (2009). Cloning, expression and biochemical characterization of a thermostable lipase from Geobacillus stearothermophilus JC. World J Microbiol Biotechnol. doi:10.1007/s11274-009-0213-1

Sabri S, Zaliha NR, Rahman R, Leow CT, Basri M, Salleh B (2005) Secretory expression and characterization of a highly Ca2 + activated thermostable L2 lipase. Prot Exp Puri 68:161–166

Nawani N, Dosanjh NS, Kaur J (1998) A novel thermostable lipase from a thermophilic Bacillus sp.: characterization and esterification studies. Biotechnol Lett 20:997–1000

Acknowledgments

The Senior research fellowship to PKS by CSIR and financial support to Dr. Jagdeep Kaur by Department of Science and Technology, India and CSIR, New Delhi is duly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

11033_2011_1038_MOESM1_ESM.tif

Supplementary Material 1. Multiple sequence alignment of JkP01, accession number FJ 392756 [lipase, uncultured bacterium] at protein level with some of the closely related lipases at Gene Database. U78785 [lipase, Bacillus stearothermophilus L1], AY786185 [TW1 lipase Geobacillus sp. TW1], AF237623 [P1 lipase Bacillus stearothermophilus P1.The catalytic triad of the lipase is text as red color, the conserve dipeptide is text as blue and the conserve pentapeptide having catalytic serine residue text as green. (TIFF 162 kb)

11033_2011_1038_MOESM2_ESM.tif

Supplementary Material 2: SDS PAGE analysis of recombinant protein Lane1. Protein molecular weight marker, Lane2. Purified lipase protein (4.8 μg) (TIFF 96 kb)

Rights and permissions

About this article

Cite this article

Sharma, P.K., Singh, K., Singh, R. et al. Characterization of a thermostable lipase showing loss of secondary structure at ambient temperature. Mol Biol Rep 39, 2795–2804 (2012). https://doi.org/10.1007/s11033-011-1038-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11033-011-1038-1