Abstract

Underground Coal Gasification (UCG) produces less surface impact, atmospheric pollutants and greenhouse gas than traditional surface mining and combustion. Therefore, it may be useful in mitigating global change caused by anthropogenic activities. Careful monitoring of the UCG process is essential in minimizing environmental impact. Here we first summarize monitoring methods that have been used in previous UCG field trials. We then discuss in more detail a number of promising advanced geophysical techniques. These methods – seismic, electromagnetic, and remote sensing techniques – may provide improved and cost-effective ways to image both the subsurface cavity growth and surface subsidence effects. Active and passive seismic data have the promise to monitor the burn front, cavity growth, and observe cavity collapse events. Electrical resistance tomography (ERT) produces near real time tomographic images autonomously, monitors the burn front and images the cavity using low-cost sensors, typically running within boreholes. Interferometric synthetic aperture radar (InSAR) is a remote sensing technique that has the capability to monitor surface subsidence over the wide area of a commercial-scale UCG operation at a low cost. It may be possible to infer cavity geometry from InSAR (or other surface topography) data using geomechanical modeling. The expected signals from these monitoring methods are described along with interpretive modeling for typical UCG cavities. They are illustrated using field results from UCG trials and other relevant subsurface operations.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The transformation of the Earth’s biosphere by anthropogenic activities is a significant and ongoing problem. One of the major impacts is caused by the extraction of fossil fuels such as coal. A proposed method to reduce the environmental impact of coal mining is through the use of underground coal gasification (UCG). UCG is a method to gasify coal in-situ and produce product gas, a mixture of varying amounts of hydrogen (H2), carbon monoxide (CO), methane (CH4), and carbon dioxide (CO2). It is useful in extracting energy from inaccessible coal deposits and with less environmental impact than other methods such as strip mining. UCG produces less atmospheric pollutants than surface mining combined with combustion, and, with carbon capture, less greenhouse gas (Burton et al. 2007). It is therefore a useful technique in mitigating global change caused by greenhouse gases and in reducing the impact on the biosphere from large-scale surface mining. UCG is not without impact on the subsurface and in particular, can adversely affect local aquifers. A key element in reducing the impact is by properly monitoring the operations to ensure that byproducts do not migrate from the subsurface cavity. In the paper we present new methods to monitor UCG operations.

For a review of UCG history and uses, see Couch (2009) or Shafirovich and Varma (2009). As mentioned above, one difficulty with UCG is in monitoring the development of the underground cavity, which, due to uncertainties in the subsurface structure, may progress in unanticipated ways and may lead to poor efficiencies and unanticipated environmental impact. One example is roof collapse, which decreases the efficiency of the gasification and may allow UCG gases into shallower layers. Therefore, it is necessary to track the subsurface burn front carefully and in a cost effective way.

A strategic monitoring program for UCG is essential for risk mitigation and optimized process management. A UCG operation includes considerable risks and uncertainties because complicated chemical, thermal, geomechanical and hydrological processes take place in the deep subsurface and cannot be observed directly. A monitoring program enables us to “see” what is happening underground and this helps us make informed decisions on the process management. A strong monitoring plan will help improve syngas quality, provide better environmental performance, accelerate permitting and shield against liabilities.

This paper presents a brief review of historical developments in UCG monitoring, after which we introduce two new monitoring technologies: electrical resistance tomography (ERT) and interferometric synthetic aperture radar (InSAR) and provide examples of use in UCG.

A series of experiments were run in the United States in the 1970’s and 1980’s. Sites included: Hoe Creek, Wyoming, USA; Centralia, Washington, USA; and near Hanna, Wyoming, USA (Rocky Mountain I). Initially, the Hoe Creek tests were monitored by instrument wells equipped with thermocouples, which monitored the underground temperatures and the burn front. Air and gas flow along with product gas composition were also monitored (Stephens 1981). The second Hoe Creek test introduced the use of geomechanical sensors to measure subsidence and high-frequency (1 MHz to 100 MHz) electromagnetic radiation to monitor changes in subsurface resistivity caused by the thermal history (Duba et al. 1978). While these measurements were effective in tracking the burn front and associated sub-surface and surface collapse, they required instrument wells, which are costly. At Centralia, the UCG operations were both monitored and in some cases, excavated to validate models and measured data. Thermocouples, time-domain reflectometry, and controlled-source audio magneto-telluric measurements (CSAMT) were used for UCG monitoring. In general, cavity sizes measured during excavation were larger than estimated using instrumental data (Wilder et al. 1982). CSAMT was effective for shallow (<100 m) but lacked resolution for deeper sources.

The Rocky Mountain test had the most comprehensive set of instrumentation among the series of experiments with 31 site characterization boreholes that were fully logged (gamma, density, caliper, neutron, temperature, spontaneous potential, resistivity, cement bond, focused electric log) and with extensive measurements of the hydrological characteristics (water chemistry, transmissivity, hydraulic conductivity, storage, leakage, anisotropy and location of hydraulic boundaries). The monitoring consisted of 9 instrument wells, 114 temperature sensors (type K thermocouples), 24 flow meters, 23 pressure transducers, 15 analytical instruments and 5 level detectors (Metzger and Britten 1988). A time domain reflectometer (TDR) was used to monitor the cavity growth (Metzger 1988). In conjunction with the monitoring, numerical modeling was carried to predict cavity growth and gas production rate (Britten and Thorsness 1989). After the burn, a five-year monitoring phase continued while the cavern was vented and flushed.

Modern efforts in UCG have been accompanied by comprehensive monitoring. The Chinchilla, Australia tests include multiple boreholes (Blinderman and Fidler 2003) and included geomechanical instruments to measure earth motion, and electrical resistivity and acoustic measurements to measure cavity growth. Thermocouples were also employed.

A number of new technologies show great potential. These include fiber optic sensors, which can measure temperature, strain, and acoustic activity and 3D seismic reflection surveys. Unfortunately, cost is important and in the following section we examine two relatively low-cost methods: electrical resistivity tomography (ERT) and Interferometric Synthetic Aperture Radar (InSAR).

2 Electrical resistivity tomography

The success of electrical/electromagnetic geophysical techniques lies in the changes in resistivity due to the thermal alteration of coal resulting from the UCG process (Duba et al. 1978). Below 600 °C coal loses water and becomes less conductive than water saturated coal (Fig. 10). Above 600 °C coal can be 100,000 times more conductive than water-saturated coal, i.e., from 0.001 S/m to 100 S/m (Fig. 1). At temperatures above 300 °C, pyrolysis begins and the relative carbon content of the residue increases, enhancing its conductivity dramatically. As a UCG cavity is expected to reach temperatures between 300 – 1,000 °C, electrical resistivity is clearly an effective indicator of cavity conditions.

Coal conductivity versus temperature (adapted from Duba et al. 1978). Conductivity was measured at 1 kHz

Underground coal gasification consumes coal and develops a cavity in the coal seam. However, ash and partially burned coal fill up the cavity quickly and form a rubble zone inside a cavity. This leaves a very small portion air filled void. Thermally affected cavity wall zone and rubble zone are all very conductive due to their thermal history.

ERT is a proven tomographic technology for monitoring subsurface processes such as vadose zone water movement (Daily et al. 1992) and steam injection (LaBrecque and Yang 2001). ERT is well suited for UCG monitoring as it is very sensitive to gas/fluid saturation and temperature changes that are important variables of a UCG process. Compared with seismic surveys, ERT is considered a less expensive monitoring tool for near real-time tomographic monitoring. An ERT sensor or a metal stake is cheaper than a geophone. ERT electrodes may be collocated with other downhole monitoring sensors such as thermocouples and mandatory groundwater monitoring wells. Finally, an ERT system can provide tomographic images autonomously on a daily or even hourly basis for years with little additional cost. These advantages make near real-time monitoring of UCG with ERT feasible and relatively low-cost.

A synthetic data test was conducted to demonstrate effectiveness of ERT for UCG cavity location. The tests were run on a synthetic baseline resistivity model. Two coal seams (200 Ohm-m) are located at a depth approximately between 260 m and 285 m (Fig. 2). A 10 m-thick lower coal seam at a depth of 276 m to 286 m was targeted for this study.

To simulate 3D UCG monitoring with ERT, we introduced four boreholes with 17 electrodes per borehole for a total of 68 electrodes in the computational model (Fig. 3). Four boreholes are laid out at the corners of a 30 m by 30 m square. Electrode spacing is 3 m. Any pair of electrodes can be used to inject electric current and one or more pairs of electrodes measure the voltages simultaneously. We chose a dipole-dipole electrode array configuration and produced about 2000 synthetic measurements. We created two synthetic data sets with and without the embedded cavity (Fig. 4) using an ERT modeling code. The forward solution is obtained by solving a boundary value problem using a finite difference method. The governing equation is a diffusive Maxwell equation under steady-state and direct current (very low frequency) conditions.

The objective of ERT monitoring is to detect subsurface resistivity changes induced by UCG processes. Once the synthetic ERT data were created, we used a least squares inverse approach (LaBrecque and Yang 2001) to invert for resistivity changes caused by temperature variations. Instead of inverting baseline and monitor data sets separately, we inverted a difference data set between monitor and baseline data. The difference inversion method enhances temporal changes in the model while canceling the inversion artifacts caused by systematic measurement errors.

The results reveal resistivity changes relative to the baseline model. Figure 5 shows inverted resistivity models with and without a cavity. It is clear that a cavity caused a significant resistivity decrease compared with the baseline resistivity model while surrounding rock had little or no resistivity changes. ERT resolved the cavity size and shape quite accurately (dark red color in cross-section image of Fig. 6). There is a clear indication of thermal impact (light red and yellow colors in cross-section image of Fig. 6). It appears that ERT is an effective means to resolve cavity geometry and temperature. However, we have not seen any case histories in the literature about UCG monitoring using cross-well ERT.

Our simulation above is based on an assumption of a resistive coal seam. In a deeper saline condition, a coal seam and surrounding formations are very conductive with a resistivity lower than a few Ohm-meters. According to Fig. 1, thermally altered coal can be more conductive than saline fluids. Saline conductivity also increases at higher temperature. ERT method is very sensitive to these changes, though conductive environment poses challenge to ERT data acquisition system and reduces signal to noise ratio.

3 Interferometric synthetic aperture radar

Subsidence can be monitored using ground-based or space-based methods. Ground-based methods may be survey-based or require emplacement of instrumentation. Surveys include optical leveling, Global Positioning System (GPS) measurements, or LiDAR. Ground-based instrumentation usually consists of tiltmeters or strainmeters. Space-based interferometric synthetic aperture radar (InSAR) has proven effective in measuring subsidence over wide areas. In this work the effectiveness of InSAR for resolving subsidence due to UCG operations is assessed. In general, the pattern of subsidence from UCG operations is expected to resemble subsidence caused by coal mining. In this work, the term ‘subsidence’ is reserved for surface deformation and refers to primarily downward vertical deformation but may include some horizontal displacement as well. The primary factors influencing subsidence are the width, thickness and depth of the excavation. Other factors, such as type of overburden, void geometry, subsurface heterogeneities, surface topography, and the stress field will influence the pattern and amplitude of deformation as well.

The underlying cause of surface subsidence is subsurface roof and chamber failure, either by collapse or bending. This displacement propagates upward and creates surface subsidence. The resulting surface displacements typically appear as either steep-sided collapse features (sinkholes) or as a downward bending of the surface (troughs). Surface subsidence due to collapse may be concurrent with mining or delayed in time and occur years after the initial excavation. Delays of a year or more are more common with deeper (>250 m) mines (Whittaker and Reddish 1989). If sub-surface roof collapse does not occur, very little surface subsidence will be observed. Therefore, if the UCG operation end-result is a series of chambers separated by thick walls, as occurs in room-and-pillar coal mining, little surface subsidence is expected. If the chambers merge over time then the surface subsidence may resemble the effects of longwall coal mining except that the roof collapse may occur more gradually.

The most common type of roof failure is spalling of rock from the roof into the chamber (Gregg 1977). Spalling is expected to be more prevalent for UCG operations than in coal mining due to the drying out and thermal cracking caused by the heat of the combustion. For single chambers, spalling will continue until a stable arched roof forms (Gregg 1977). For larger chambers formed by the possible merging of closely-spaced UCG chambers, spalling may progress into complete roof collapse, in which the failure continues until the chamber fills with rubble. The height of the chamber formed by spalling is generally 2 to 10 times the original cavity height. Unless the spalling breaks through to the surface, the surface expression will appear as a trough (Gregg 1977) due to bending and fracturing of the overburden above the collapse. The amplitude of the trough depends on the depth and type of overburden as well as the height of the chamber. A less common, but more unpredictable type of roof failure is chimneying, which is progressive failure by spalling confined to a small area and which may occur at a high rate (10’s of meters per day). Chimneying was observed in Soviet era UCG operations and was especially prevalent in steeply dipping beds (Gregg 1977).

Subsidence presents multiple hazards to UCG operations. From an operational view, roof collapse during burns will likely adversely impact process efficiency by plugging the chamber. Roof collapse or severe upward fracturing may also allow hot gases to permeate into shallower layers resulting in gas loss, which reduces efficiency. The shallow layers may contain aquifers and result in environmental impact. Finally, excessive subsidence or sinkhole formation at the surface may damage nearby infrastructure. Careful monitoring of subsidence may allow mitigation of effects by allowing the operator to respond or an understanding of likely fracture patterns. It may be possible to predict where tensile fractures occur, which tend to be more permeable, may occur.

Historically, the primary approach in modeling subsidence has been to match the observed subsidence using empirically or semi-empirically derived equations. More recently, direct numerical modeling of the subsurface has been applied. Profile functions predict subsidence by using a defined equation combined with empirically determined constants. Numerical modeling can be effective but requires exact material properties for accurate estimation. As rocks may behave in a non-linear fashion, even small inaccuracies may have a significant influence on the accuracy of the results. Localized subsidence can be difficult to predict.

The majority of industrial-scale UCG production efforts were undertaken in the Soviet Union. Here we summarize the work of Gregg (1977). In horizontal seams, the gasification was conducted on a grid with series of boreholes for air injection and gas withdrawal spaced 25 m apart. At one UCG site, Podmoskovnaya, the coal seam (lignite) averaged 2.7 m thick at a depth of 48 m. The overburden primarily consisted of clays and sands. As the gasification was conducted, subsidence occurred immediately after the gasification in a relatively slow manner (<60 mm/day). The total amount approached ~ 1.2 m at the surface but increased with depth. The total subsidence at depth was slightly less than the original seam thickness. The subsidence rate appeared to track the gasification rate and was used to track the burn front. Later excavation showed that no cavities larger than 1 m existed in the subsurface and the rapid subsidence was inferred to be due to the weak overburden.

At the Lisichansk and the Yuzhno-Abinsk sites, the coal layers were steeply inclined but differed in thickness at the two sites. Lisichansk was less than 1.5 m thick and Yuzhno-Abinsk was up to 9 m thick. Overburden consisted of shales, sandstone, and limestone. At Lisichansk little subsidence was observed and appeared to correlate to that expected by bending subsidence. Bending subsidence also occurred at Yuzhno-Abinsk but was accompanied by intermittent chimneying and sinkhole formation up the steeply dipping coal beds and overburden. The collapse caused considerable gas leakage.

As many modern operations have operated only at the test-bed and pilot scale level, significant subsidence was not expected or measured (Burton et al. 2007). A subsidence event occurred at Hoe Creek but the hole was relatively small (meters in diameter) with steep sides (Burton et al. 2007).

Synthetic Aperture Radar (SAR) is an active imaging technique that uses microwave length electromagnetic energy to create back-scatter images of the earth’s surface from a moving antenna (Curlander and McDonough 1991). Interferometric SAR (InSAR) refers to using phase differences between pairs of images to image displacement of the ground surface and surface motion from a wide variety of causes, both natural (e.g. earthquakes, glaciers) and anthropogenic (e.g. groundwater, hydrocarbon extraction, or mining), have been imaged (e.g. Massonnet and Feigl 1998). In this work we examine the use of using satellite SAR data to image ground displacement from underground coal gasification.

Given the expected signals from UCG associated subsidence and known InSAR capabilities, a rough assessment of the use of InSAR for UCG can be conducted. The minimum signal size (spatial) that can be reliably measured should span several pixels and hence the signal should exceed 50 m spatially. If the target area happens to include a point scatterer either by accident or intent (e.g. corner reflector) it would be possible to measure the displacement of the point scatterer directly. The range change resolution also depends on the signal quality and wavelength but in general, at least 5 mm of line-of-sight displacement is required to produce an unambiguous signal. For most satellite geometries, this infers roughly 1 cm of vertical displacement. If a time series approach is applied, which requires a series of repeat measurements over the same area, it is expected that line-of-sight resolution might approach 1–2 mm.

Signals of this magnitude are easily caused by coal mining operations and have been reported for commercial scale UCG operations, as noted above. Small (tens of m) pilot plant type UCG tests at depths greater than 100 m are unlikely to create measurable signals unless accompanied by collapse. In this work, we report on InSAR surveys of three active (or formerly active) UCG areas and one coal mining area. Processing was done using both a commercial package (GAMMA) and an open source package (GMTSAR), (Sandwell et al. 2011).

As the number of active UCG areas is limited, it is useful to first review the use of INSAR over coal mining areas and then selected UCG sites. A number of studies have used InSAR to examine subsidence from coal mines (e.g. Cao et al. 2008; Ng et al. 2011; Perski 2000; Stow and Wright 1997). Ng et al. (2011) examined subsidence over the West Cliff colliery in the Sydney basin of Australia. It is a mine at a depth of 470–540 m that extracted a 2.2–2.8 m thick coal seam using longwall mining with panels approximately 305 m wide. Typical surface subsidence after roof collapse was ~ 1 m. Using multiple Advanced Land Observing Satellite (ALOS) synthetic aperture radar (SAR) (L-band) images from the including ascending and descending, the 3D vector deformation was resolved using different look angles with an estimated error level of less than 1 cm. Measurements were validated using GPS. Atmospheric errors were assumed minimal and less resolution was achieved in the north–south direction. Similar results should be possible for large-scale UCG operations. In a related area, a coal collapse at Crandall Canyon was imaged using InSAR (Lu and Wicks 2010; Plattner et al. 2010). The collapse occurred during room and pillar operations at a depth of about 600 m in a seam with a thickness of about 2.4 m. Plattner et al. (2010) conducted modeling of the signal using a variety of methods and concluded that elasto-plastic collapse of an elliptic cavity provided the best fit to the data.

For our InSAR test areas, we examine three areas of UCG operations in China, South Africa, and Uzbekistan. For the site in China we used both Envisat C band and ALOS L band. Perpendicular baselines were generally good (<100 for C band and < 600 for L band) and topography was not severe. No obvious signals at this site or at the site in South Africa were observed.

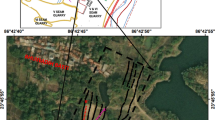

The next test was over a commercial UCG program in Uzbekistan. The site has been in operation since 1961. The source is brown coal at a depth of ~ 150 m. The production is sent via pipeline to a power plant approximately 5 km from the production fields (http://www.lincenergy.com/acquisitions_yerostigaz.php). For a review of geology and operations at this site during the Soviet era see Olness (1982).

ALOS L-band SAR data was acquired via the Alaska SAR facility. All images were aligned using 070825 as a master and elevation corrections applied using a 30 m ASTER digital elevation model (DEM). Secondary atmospheric corrections were applied as a linear phase ramp that correlated with elevation was evident on most interferograms. On the best interferograms (high coherence) several signals were evident (Fig. 7). These included subsidence near the open pit coal mine likely due to slumping of the pit sides. Signal was also associated with tailings piles along the side of the valley that may also be due to slow slumping. Isolated signals occurred near areas of slumping and the area of likely UCG extraction showed some minor (~5 cm) anomalies that may be related to UCG operations (Fig. 8) although this has not been confirmed (Fig. 9).

Image of the extraction area overlaid with colors representing the subsidence anomaly. Blue represents the area of subsidence using the same color scheme shown in Fig. 8. The maximum subsidence is approximately 8 cm

This work suggests that InSAR is capable of observing UCG operations in some cases. A possible signal was observed that coincided with known UCG operations although we do not have any specific information on the timing of the UCG operations. No signals were observed at other active areas. This is likely due to the increased depth and limited (pilot plant) type operations in China and South Africa, as opposed to the relatively shallow and industrial scale UCG work in Uzbekistan. Differences in geology (e.g. strength of overburden) may have played a role as well.

It is also possible to infer cavity geometry from the InSAR measurements. Using a linear, deterministic inversion that assumes a given influence function for the extraction of an infinitesimal volume (e.g. Ren et al. 1987), we can calculate the expected change in subsurface volume at a specific depth. Here we assume a depth of 150 m and we can solve for the cavity height and geometry and match the observed signal (Fig. 10). A trade-off exists between cavity height and geometry, which we are unable to resolve at this time due to lack of specific knowledge of the site. In general, monitoring operations would have sufficient knowledge to constrain these parameters.

This study did not specifically task acquisition of the data and was relied on data already collected. This caused relatively poor data coverage (in terms of timing and geometry) for the sites. Most operational use of InSAR acquires data periodically (once a month, for example) which provides much better control. Newer satellites and newer satellite constellations such as the Italian SkyMed 4 satellite constellation can provide repeat times as short as 4 days. Newer techniques, which use time series analysis, are capable of much higher resolution of deformation signals.

For use in monitoring ongoing UCG operations, it is likely that a much shorter temporal resolution is required (on the order of hours), which is unlikely with current and near-future InSAR satellites. In this case, instruments such as tiltmeters would be required. A combination of tiltmeters, with high temporal resolution, and InSAR, with excellent spatial coverage, would be ideal.

This may be the first successful detection of UCG operations using InSAR and suggests that the method has some potential in monitoring subsidence related to UCG. An advantage is the relatively low-cost of the technique, as well as the capability to conduct the monitoring without deploying instrumentation at the site itself. SAR scenes typically cost on the order of several thousand US dollars per scene, with some variation according to the mode of operation. A minimum of two scenes are required but additional images will enhance results. In addition to the data cost, processing is required.

4 Conclusions

New developments in geophysics have the potential to allow cost-effective UCG monitoring. Both ERT and InSAR have the capability to monitor cavity growth and surface subsidence effectively and at relatively low cost. While InSAR did not work for two of the cases tested here, both were relatively small pilot operations at the time of data acquisition. We have demonstrated that it is possible to measure and monitor production-scale operations using InSAR.

The key strategy for implementing UCG in a manner consistent with reduced anthropogenic impact would include monitoring to reduce sub-surface impact. UCG inherently has lower impact than surface mining and combined with low sub-surface effect, would make it an attractive technology for fossil fuel use during a transition to alternate energy sources.

This improved monitoring, especially at low-cost, using the methods illustrated in this article, may lead to increased UCG efficiencies and wider use of this intriguing technology. In turn, wider use would lead to reduced greenhouse gas emissions (as compared with traditional methods) and less atmospheric pollutants than surface mining. This would allow continued use of coal and allow more time to transition to other energy sources but reduce the overall impact on the atmosphere in an economically feasible manner.

References

Blinderman MS, Fidler S (2003) Groundwater at the underground coal gasification site at Chinchilla, Australia. Water in Mining Conference, Brisbane

Britten JA, Thorsness CB (1989) A model for cavity growth and resource recovery during underground coal gasification. In Situ 13:1–53

Burton E, Friedmann J, Upadhye R (2007) Best practices in underground coal gasification. Lawrence Livermore National Laboratory, Livermore

Cao L, Zhang Y, He J, Liu G, Yue H, Wang R, Ge L (2008) Coal mine land subsidence Monitoring by using Spaceborne INSAR data - a case study in Fengfeng, Hebei Province, China, The International Archives of the Photogrammetry, Remote Sensing and Spatial Information Sciences. Vol. XXXVII. Part B8. Beijing 2008

Couch G (2009) Underground coal gasification. International Energy Agency Coal Research, London

Curlander J, McDonough R (1991) Synthetic aperture radar systems and signal processing. John Wiley & Sons, New York

Daily W, Ramirez A, LaBrecque D, Nitao J (1992) Electrical resistivity tomography of vadose water movement. Water Resour Res 28(5):1429–1442

Duba A, Davis DT, Laine EF, Lytle RJ (1978) Geotomography and coal gasification, LLNL UCRL- 81923

Gregg DR (1977) Ground subsidence resulting from underground coal gasification, LLNL Report UCRL-52255

LaBrecque DJ, Yang X (2001) Difference inversion of electrical resistivity tomography (ERT) data - a fast inversion method for 3-D in-situ monitoring. J Environ Eng Geophys 6(2):83–89

Lu Z, Wicks C (2010) Characterizing 6 August 2007 Crandall Canyon mine collapse from ALOS PALSAR InSAR. Geom Hazards Risk 1(1):85–93. doi:10.1080/19475701003648077

Massonnet D, Feigl K (1998) Radar interferometry and its application to changes in the Earth’s surface. Rev Geophys 36:441–500

Metzger GA (1988) Preliminary time domain reflectometer results of the Rocky Mountain 1 coal gasification, LLNL Report, 1988

Metzger GA, Britten, J A (1988) Data acquisition system and instrumentation for the Rocky Mountain 1 Coal Gasification Test, LLNL Report UCRL-98640

Ng HN, Hsing-Chung AC, Zhang K, Ge L, Rizos C, Omura M (2011) Deformation mapping in three dimensions for underground mining using InSAR - Southern highland coal field in New South Wales, Australia. Int J Remote Sens 32(22):7227–7256

Olness D (1982) The Angrenskaya underground coal gasification station, LLNL UCRL-53300

Perski Z (2000) The interpretation of ERS-1 and ERS-2 InSAR data for the mining subsidence monitoring in Upper Silesian Coal Basin, Poland. Int Arch Photogramm Remote Sens 33(7):1137–1141

Plattner C, Wdowinski S, Dixon TH, Biggs J (2010) Surface subsidence induced by the Crandall Canyon Mine (Utah) collapse: InSAR observations and elasto-plastic modeling. Geophys J Int 183:1089–1096

Ren G, Reddish DJ, Whittaker BN (1987) Mining subsidence and displacement prediction using influence function methods. Min Sci Technol 5:89–104

Sandwell D, Mellors RJ, Tong X, Wei M, Wessel P (2011) Open radar interferometry software for mapping surface deformation. Eos Trans. AGU 92:(28) doi:10.1029/2011EO280002

Shafirovich E, Varma A (2009) Underground coal gasification: a brief review of current status. Ind Eng Chem Res 48:7865–7875

Stephens DR (1981) The Hoe Creek experiments: LLNL’s underground coal gasification project in Wyoming, LLNL UCRL-53211

Stow R, Wright P (1997) Mining subsidence land surveying by SAR Interferometry. 3rd ERS Symposium, Florence, Italy

Whittaker BN, Reddish DJ (1989) Subsidence: occurrence, prediction and control. Elsivier, Amsterdam

Wilder DG, Ramirez A, Hill RW (1982) Overview of the cavity mapping exercise, large block test, Centralia, Washington, LLNL Report UCRL-87529

Acknowledgements

S. Hunter and W. Foxall provided useful input and the results benefitted greatly from discussions of the LLNL UCG group. We also appreciate the guidance and comments from two reviewers that greatly improved the paper. ALOS SAR data copyright JAXA [2007]. This work performed under the auspices of the U.S. Department of Energy by Lawrence Livermore National Laboratory under Contract DE-AC52-07NA27344. Submission LLNL-JRNL-641052.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mellors, R., Yang, X., White, J.A. et al. Advanced geophysical underground coal gasification monitoring. Mitig Adapt Strateg Glob Change 21, 487–500 (2016). https://doi.org/10.1007/s11027-014-9584-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11027-014-9584-1