Results from a study of CG5 gravity meters are presented and ways of using these for reducing the error in field gravimetric surveys are discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

High precision gravimetric surveys are currently needed for the development of gas and oil deposits, in geodesy, geodynamics, construction, studies of landslides, mud flows, and karsts, and in other applications. Their accuracy depends directly on the quality of the gravity meters (gravimeters) that are used and the techniques for working with them. At present, the best instruments in the world for field surveys are the CG5 relative gravity meters manufactured by the Canadian firm Scintrex. Here we describe some approaches to working with these gravimeters at the company NIIMorgeofizika-Servis.com since 2007 which have made it possible to improve the accuracy of surveys.

Setting Up a Gravimeter for Measurements. According to the recommendations from Scintrex in the Operating manual for the CG5 gravimeter [1], it must be set up before the start of work and all the operational checks must be performed. This includes, in particular, determining its drift coefficient in order to compensate the linear drift of the gravimeter.

To minimize the correction for drift of the “zero point,” the drift coefficient is determined automatically with the gravimeter in a fixed position. As a result, linear drift of the readout is automatically eliminated. However, in a field survey the instrument is not in a fixed position, as transport is accompanied by vibrations which affect the detector element. When the gravimeter is positioned at observation points, the system sensitivity is affected by bumping. As a rule, the temperatures in the transport medium and at the observation point are different, and this also affects the detector element. These three factors lead to an additional drift in the readout, which shows up only with changes in the acceleration g of gravity between different points, especially during gravimetric field surveys, and can be very substantial. Drift does not affect the convergence of the results, but when it is smaller during a survey, it is easier for the operator to monitor the behavior of the instrument during the measurements. Thus, it is easier to work if the drift is minimal. In the automatic mode, it is not possible to compensate the drift; it has to be compensated manually in the SETUP PARAMETERS window of the gravimeter by entering the drift coefficient. This simple operation is permitted by the operating manual and is carried out after some “conditioning” transport (15–20 min) during the first (conditioning) measurements for 15–20 min at the first reference point. This coefficient usually has to be corrected 1–2 times per month when the gravimeter is used a lot.

It has been noted that, depending on the outside temperature and the quality of the stands, inclinations of the gravimeter by 20–30″ may be observed. According to the operating manual, the X, Y OFFSET coefficients can be found automatically within a range of ±150″. A site with low seismic noise levels must be chosen for these tests. When there is a high level of this noise, the X, Y OFFSET coefficients are found with a large scatter, so after the completion of a study it is useful to check these coefficients. To do this, one sets the gravimeter with an incline of ± (20–30)″ and wait for a steady readout. The readouts within this range should not vary. If this happens, then it is necessarily to correct these coefficients manually or to determine them repeatedly in the automatic mode and then feed in the average coefficients.

Adjustment of the Readouts. One of the most important characteristics of the gravimeter described on the Scintrex website is the repeatability (convergence) of the readouts from repeated measurements. Of course, the repeatability is determined after the drift has been eliminated (or the zero creep of the gravimeter has been accounted for).

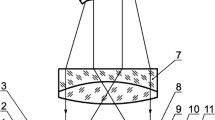

In order to obtain a minimal measurement error Δg, it is necessary to study the process of adjusting the readouts from the gravimeter after it is placed at a point. These studies are necessary to obtain the best convergence of the results over a minimum observation time at the points and they must be carried out after all the adjustments prescribed in the instructions have been completed. As an example, the figure illustrates the process of establishing the readouts from a CG5 189 gravimeter at points 11 and 12, along with the corresponding drifts (curves 1 and 2). The graphs were plotted using the Graview program developed at NIIMorgeofizika-Servis.com. The total observation time at the points is 40 min. The readouts for the first 20 min are ignored, since it is assumed that they are affected by transient processes after transport of the instrument. The readouts from 20 to 40 min are averaged and Δg is determined from that. The sampling time from 20 to 40 min corresponds to the vertical bands II–VIII. Measurement I was a conditioning run and does not form part of the drift correction. The figure shows that the way the readouts are established varies, and that a readout can lie above or below the established value.

The process of establishing the readouts is best studied under the conditions to be used in a gravitational survey with the same outside temperatures and on the same means of transport. The test must be repeated before each field run, since the parameters of the transient process vary with time. The test should be done at gravimetric field points with stable stands, and that are far from roads, and protected from wind and rain. The place where the gravimeter is mounted should be cleaned of loose concrete, ice, dirt, and dust, and should be marked at all the field points.

Since the duration of the observations at a point can be up to 40 min, in order to avoid creating additional seismic noise during the measurements, the operator and the transporter should be at a distance of at least 10–15 m from the instrument. To protect the gravimeter from wind, rain, and sunlight at the measurement points, it is best to use a portable, rigid box with a removable lid and without a bottom.

The test is conducted with an unlimited number of readouts (#of Cycles = 88888 in the DEFINE THE OPTIONS window). The duration of the data collection for a single reading (Read Time) can be chosen arbitrarily, but the optimum is 55 sec. To save time, it is convenient to set the delay before the next readout (Start Delay) at 1 sec. Then the readouts will appear after exactly 1 min.

In order to determine the repeatibility of the readings (or their minimum spread), the test can be carried out at one or two field points. If two points are used, then the conditions for carrying out the measurements be more restrictive, since not only the acceleration of gravity, but also the conditions, can vary at these two points. Unfortunately, the number of repeated measurements will be smaller owing to the large amount of time spent on each measurement.

At a single point, the test is carried out as follows: the instrument is mounted at the point and data acquisition is started, e.g., for at least 30 min (during which 30 readouts will be taken). Then the instrument is removed, transported for 15–20 min and again mounted at the same point. This is done for 8–10 times and then the instrument readings are recorded. After the drift is taken into account, the convergence of the averaged readouts over different, e.g., five minute, intervals is studied, i.e., from 5 to 10, from 10 to 15, from 15 to 20, from 20 to 25, and from 25 to 30 min. The averaging intervals can have any length. The convergence (repeatability) of the readouts are used to determine the error for each interval. The required time interval for averaging and the number of measurement times at the points are chosen on the basis of the resulting errors and as functions of the specified error for the survey.

During the test, it is desirable simultaneously to determine the voltage jump when the supply is switched from one internal battery to another. In some gravimeters, this jump can be seen in the signal as a change in g. Thus, during testing of a gravimeter it is necessary to trace the supply voltage and record the times when the batteries are switched. Since the test is not done just once, the change in g is clearly recorded.

It should be noted that, in order to obtain the required accuracy, a 30 min relaxation time may not be sufficient for the detector element of some gravimeters, so the observation time at a point can be increased.

The test of the operational quality of the thermostat for the gravimeter can be done at two points with different temperatures. Reference points are fairly often located in buildings. During winter, the temperature in heated buildings differs greatly from the outside temperature. With a normally functioning thermostat, the error in the multiply measured variation Δg between points inside and outside a building should be essentially the same as for testing at a single point.

Power Supplies for Gravimeters at Low Temperatures. In many regions of Russia, the outside temperature is below 0°C for more than half the year, so there is a problem of ensuring reliable power supply to gravimeters at low temperatures. At temperatures near 0°C, the charge in the lithium ion batteries used in the gravimeter dissipates over a very short time owing to internal resistance and the gravimeter thermostat shuts down. In addition, on cooling to below 0°C the capacity of the batteries is lost and there is a significant and unacceptable reduction in their service life. On the back of the gravimeter there is a label indicating that the supply voltage must never exceed 18 V. The terminal voltage of a fully charged automobile oxide battery never exceeds 15 V. Thus, it is convenient to use 12 V car or motorcycle (snowmobile) oxide batteries as power supplies for gravimeters in the field. We note also that it is difficult to work with 20-min observations at field points by temperatures below −25°C, since the heater is not strong enough to warm the display (the liquid crystal display begins to operate very slowly at low temperatures).

In practice there are frequent cases where the batteries are charged by an internal charger in the gravimeter mounted on the power supply chassis; this ultimately leads to failure of the charger. Thus, an external charger must be used for charging the batteries. If a battery is defective, then the charger reports its failure. A defective battery cannot be used, since the internal charger will than break down. Charged batteries have to be inserted into the gravimeter no later than 2 h before the start of work, because this produces a temperature shift in the gravimeter that shows up as a change in g. Replacing a battery often leads to a nonlinear drift for two hours (depending on the difference in temperature between the switched batteries), which may cause an increase in the error in measuring g over this time. Discharged batteries should be replaced with charged batteries and recharged. But this means that two batteries must be available for each instrument. These problems vanish if external oxide batteries are used.

There is yet another case in which the internal charger can break down. A gravimeter is usually connected to the grid between measurements. It usually contains a pair of charged batteries. Sometimes as bad contact in a socket (or in the grid plug and socket for the gravimeter power supply) will cut the instrument supply off. If the instrument is cut off for 15–20 h, then the internal batteries will discharge fully during that time and the instrument will go cold. If the connection is resumed afterward, and the discharged batteries are not removed from the gravimeter, then there is a high probability that the internal charger will fail.

Transport. During long, intensive surveys, after some time “fatigue” begins to show up in the detector element, the gravimeter drift becomes nonlinear, and the readout error increases. The causes of this behavior of the detector element are vibrations and bumps during transport, carrying, and installation of the gravimeter. Thus, in order to prolong the time when the gravimeter operates well, it is necessary to pay constant attention to creating suitable conditions in all the involved transportation media. For example, in caterpillar transportation systems it is best to carry the gravimeter by hand in a strictly vertical position. As much as possible, the gravimeter should always be oriented in a single direction relative to the direction of motion. Practical use of standard transportable containers has shown that prolonged caterpillar transport leads to rapid “fatigue” of the detector elements. Thus, “soft” transportable containers must be used for transport in roadless regions. Three containers of this type have been developed at NIIMorgeofizika-Servis.com.

Conclusion. These studies of CG5 gravimeters show that the errors in gravimetric field surveys can be reduced substantially. This depends on the quality with which the instruments and measurement points are prepared, the characteristics of the survey region, the skill and competence of the gravimeter operators, the transport media used, and the external conditions. As an example, we consider the error in surveys conducted during winter and summer in boggy tundra. The mean square error in the increment between reference points over 5 years of work never exceeded ±1.2 μGal (1.2·10−8 m/sec2) with four measurements at 5 reference points. For the series points, this error was less than ±2.0 μGal in two measurements at (each of) 150 points over an area of 2500 km2. All the measurements were made with respect to a selected central point.

Reference

Operating Manual for the CG5 Gravity Meter (electronic resource), www.scintrexltd.com, accessed Feb. 3, 2011.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Izmeritel’naya Tekhnika, No. 5, pp. 10–12, May, 2011.

Rights and permissions

About this article

Cite this article

Yushkin, V.D. Operating experience with CG5 gravimeters. Meas Tech 54, 486–489 (2011). https://doi.org/10.1007/s11018-011-9753-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11018-011-9753-5