Abstract

In this study, the impacts of temperature, nanoparticles mass fraction, and basefluid types were investigated on the dynamic viscosity of CuO-loaded nanofluids. The nanoparticles were dispersed in deionized water, ethanol, and ethylene glycol as basefluids separately and the measurements were performed on samples with nanoparticles loads ranging from 0.005 to 5 wt%, and the temperature range of 25 to 70 °C. TEM analysis were performed on dried nanoparticles and the results showed the average mean diameter of CuO nanoparticles ranged from 10 to 50 nm. The results of DLS analysis confirmed the results of nanoparticles size obtained by TEM analysis in mentioned basefluids and Zeta-Potential tests exhibited the high stability of the nanoparticles in the basefluids environment. The results indicate that by adding tiny amount of CuO nanoparticles to basefluids, relative viscosity of nanofluid increases. By the increase in nanoparticles load higher than 0.1 wt% the effect of both nanoparticles mass fraction and temperature would be more tangible, while for nanoparticles mass fraction lower than 0.1 wt% no significant change in viscosity was observed. In addition, the results declare that viscosity of nanofluid remains constant at various applied shear rates indicating Newtonian behavior of nanofluid at various nanoparticles load and temperature. According to experimental data, it is also evident that with the increase in temperature, the value of relative dynamic viscosity decreases significantly. Also it is concluded that for CuO/ethanol nanofluid, more interfacial interaction is resulted that causes higher relative dynamic viscosity while for CuO/water lower interfacial interaction between nanoparticles surface and water molecules are resulted which leads to the lower values for this parameter. The results of this study implied that with increase the temperature from 25 to 70 °C at the condition where nanoparticles mass fraction was chosen to be 5 wt%, the value of dynamic viscosity of CuO/ethanol, CuO/deionized water, CuO/ethylene glycol declined 69%, 66%, and 65% respectively. Finally, a correlation was proposed for the relative dynamic viscosity of nanofluid based on the CuO nanoparticles mass fraction and temperature of the basefluid and nanoparticles.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Due to the positive effects of nanoparticles on new technologies including preparation of highly-efficient nanoparticles-loaded materials, the application of these nano-sized materials has been noticed by many researchers [1,2,3,4,5,6,7,8,9,10,11,12]. The utilization and application of nanoparticles in various fields of science have been noticed due to their unique physical properties in different applications incorporating reinforced nanostructure-loaded polymer and ceramic composites, catalyzing agent used in chemical processes, novel and highly-efficient drugs in medical application, as well as thermal and hydrodynamic properties [13]. By adding solid nanoparticles to heat transfer working liquids new fluids, which are known as nanofluids, with considerable thermal and hydrodynamic properties are obtained. The term of nanofluid was proposed by Choi [14, 15] and he exhibited that the addition of tiny amount of nanoparticles to aqueous and non-aqueous basefluids, (ethylene glycol, glycerine, water and oil), produced homogenized mixture with appreciable thermophysical properties.

It is reported in previous researches that viscosity and thermal conductivity of nanofluid strongly depends on nanoparticles’ mass fraction and temperature. These two properties also directly affect the power needed for pumping nanofluid in various flow regimes as well as heat that can be transferred through a hot and cold source, respectively. According to the results reported by other scholars, the viscosity of nanofluid usually is higher than that of basefluids. Consequently, this leads to higher energy needed for pumping nanofluids through the heat exchangers devices. The viscosity and thermal conductivity of nanofluids strongly relays on temperature, nanoparticle size, nanoparticles load and type, and basefluid type [16,17,18].

The cooling and heating process is one of the most important issues in different industries and heat transfer devices. Higher thermal efficiency of nanofluid, the application of these fluids is affordable in heat transfer devices such as cooling system of car engines [19]. Based on the previous reports, the nanoparticles interface and polarity of basefluid components can be listed as important parameters that directly influence the thermo-physical properties of nanofluids [20]. Because of high polarity of conventional basefluids molecules such as water, ethanol, and ethylene glycol, stable nanofluid can be produced for the application of cooling processes. Therefore, the application of these nanofluids and the properties of the polarity of basefluid must be taken into consideration in heat transfer devices. Moreover, it is clear that the application of non-aqueous basefluid such as paraffin and conventional oil is limited in such devices because of their higher viscosity which needs higher energy for pumping through heat transfer device channels. On the other hand oil and liquid paraffin have nonpolar molecules which cause agglomeration of nanoparticles in such basefluids leading to blocking small channels [21,22,23,24]. Application of nanofluids as novel fluids and their various hydrodynamic properties have been noticed by expanding number of scholars. Following is a summary of the results obtained by other researchers regarding the effect of various parameters including temperature and nanoparticles’ load on viscosity and rheological properties of nanofluids.

Temperature effect

Hemmat Esfe et al. [25] studied the impacts of temperature and nanoparticles load on the viscosity of CuO-loaded nanofluid in ethylene glycol as the basefluid. Their findings showed that the maximum value for nanofluid relative viscosity was found to be 82.46% that obtained for those contains 1.5 vol% CuO nanoparticles at 50 °C. They also proposed a model for prediction of nanofluid’s viscosity and reported that the deviation of experimental data from those obtained by model, which was less than 4%.

Experimental results indicated that with the increase in nanofluid temperature, dynamic viscosity decreased significantly. Aberoumand et al. [26] studied the viscosity and thermal conductivity of Cu-loaded nanofluid in engine oil with various nanoparticles’ mass fractions. They reported that the viscosity of nanofluid was strongly depended on temperature at higher value of nanoparticles’ mass fraction and the value of this parameter declined from 235 to 35 cp with the increment of temperature.

Shima et al. [27] investigated the effect of temperature and volume fraction of monolyer surfactant-coated on Fe3O4 nanoparticles surface with average particle sizes of 8 nm on thermal conductivity and viscosity of aqueous and non-aqueous based nanofluids. They performed their experiments by using transient hot wire and a rotational rheometer in order to measure thermal conductivity and viscosity of nanofluids, respectively. The results exhibited that the value of relative dynamic viscosity of nanofluid remained constant at various temperature; although, dynamic viscosity of nanofluid declined significantly with the temperature enhancement.

Nanoparticles’ load effect

Duangthongsuk et al. [28] provided a research in order to investigate the effect of TiO2 nanoparticles on dynamic viscosity of water-based nanofluid. They reported that with the enhancement in nanoparticles volume fraction from 0.2 to 2.0 vol%, the value of relative viscosity (viscosity of TiO2/water nanofluid respect to pure water) increased from 4 to 15% at a fixed temperature. Murshed et al. [29] also measured dynamic viscosity and thermal conductivity of TiO2 and Al2O3-loaded nanofluids. They concluded that the thermal conductivity and viscosity of nanofluids were much higher than pure basefluids. Moreover, they observed the value of thermal conductivity and dynamic viscosity of nanofluid increased significantly with nanoparticles volume fraction variation from 0.01 to 0.05 vol%. Chandrasekar et al. [30] studied the impacts of nanoparticles volume load within the range of 0.33–5 vol% on Al2O3-loaded nanofluid, dispersed in water. It was seen that with the increase in nanoparticles’ load, the values of dynamic viscosity of the aforementioned nanofluid enhanced considerably.

Zadeh et al. [31] measured dynamic viscosity of nanosilver-loaded nanofluid dispersed in ethylene glycol at various temperatures and nanoparticles volume fractions. They observed that with the increase of nanoparticles volume fraction, dynamic viscosity of nanofluid increased significantly. They reported that relative viscosity of the nanofluid enhanced by 88.46, 90.44, 83.25, and 82.06% with the increase in the nanoparticles’ volume fraction from 0.25 to 2% at the temperature of 40, 45, 50, and 55 °C, respectively.

Empirical correlations

According to the results presented in previous researches, temperature, nanoparticle volume fraction, and basefluid and nanoparticle type influenced the hydrodynamic properties of nanfluids significantly [32]. In addition, temperature mainly affected the attraction forces between nanoparticle surface and basefluid components, leading to higher viscosity. Based on theoretical and experimental efforts, numerous studies have been carried out in order to find a correlation that estimated the nanofluids’ relative viscosity by using nanoparticle volume fraction and temperature. Hosseini et al. [33] presented a new relation, (Eq. 1), in order to estimate the viscosity of Al2O3/water nanofluid. The correlation was obtained dimensionless and was applicable for viscosity prediction including nanoparticles load, size, temperature and physical properties of the capping layer. In their equation \(T\), T0 are temperature and reference temperature (K), φh is hydrodynamic volume fraction of nanoparticles, β and γ are empirical constant, d and r are nanoparticles diameter and thickness of capping layer, respectively.

Chen et al. [34] proposed a new relation, (Eq. 2), as function of nanoparticles volume fraction for estimation the viscosity of TiO2-loaded nanofluid in ethylene glycol within the temperature range of 20–60 °C. In this equation φ is volume fraction of nanoparticles in the basefluid.

Nielsen et al. [35] also proposed a new correlation, (Eq. 3), in order to estimate the viscosity of nanofluid by using the volume fraction of nanoparticle based on theory presented model by Einstein. In their equation φm is the maximum volumetric packing fraction of nanoparticles in the basefluid.

Considering the previous researches proposing an empirical correlation for nanofluid viscosity, there is not fully agreement among those studies that investigate impacts of basefluid types on nanofluids’ viscosity and their proposed correlations. Therefore, it is needed to find a new correlation for estimating the nanofluid viscosity independent to the basefluid type and its physical properties. The aim of this study is to measure the viscosity of CuO-loaded nanofluid dispersed in water, ethanol and ethylene glycol as well as find a comprehensive correlation for prediction of nanofluid relative viscosity. For this purpose, the viscosity of nanofluid is measured at different nanoparticle loads and temperatures. Finally an empirical relation incorporating temperature, nanoparticles mass fraction, and physical properties of nanoparticles and basefluid is proposed to predict the relative viscosity of nanofluid.

2 Experimentation

2.1 Materials

To synthesis the CuO nanoparticles, Cu(NO3)2·3H2O with high purity of 99.9% was purchased from Merck Co. Germany and dissolved in deionized water to produce Cu2+ [19]. Then, for precipitation of Cu2+, sodium hydroxide with purity of 99.99% was purchased from Merck Co. Germany and used during nanoparticles synthesis. In addition, nanofluids were prepared by dispersing synthesized CuO nanoparticles in deionized water, ethanol, and ethylene glycol. The laboratory glass wares also washed by using deionized water.

2.2 Instrument

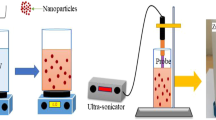

Transmission Electron Microscopy, (TEM), (Hitachi, 9000 NA, Japan), was used for characterization of the morphology and size of synthesized CuO nanoparticles. Also the stability of CuO nanoparticles within the basefluids, (water, ethanol, and ethylene glycol), was assessed by using Zeta Potential analysis, (ZetaSizer, Malvern, ZetaSizer Nano ZS, United Kingdom), which was performed on diluted nanofluids. Consequently, the repulsive forces between nanoparticles’ surface were analyzed by using the plot of total counts versus total electrostatic voltage. Moreover, the sizes of CuO nanoparticles within the basefluids were measured by using Dynamic Light Scattering, (DLS), (Malvern, ZetaSizer Nano ZS, United Kingdom). In addition, poly dispersity index, (PDI), of CuO nanoparticles was obtained on low-concentration nanofluids by using DLS test. For preparation of nanofluids with different nanoparticles mass fraction, a certain amount of synthesized CuO nanoparticles were weighted by means of a precise electric balance, (HT series, Che Scientific Co., Hong Kong). During viscosity measurement, the temperature of nanofluids was kept at constant value by using an isothermal circulator bath, (− 40, 7 L Ref. Circulator, PolyScience Co., U.S.A). Also during the synthesis of CuO nanoparticles, NaOH solution was added into the Cu2+ solution at fixed flow rate by using a syringe pump during, (Viltechmeda Plus SEP21S) [19]. In order to prepare nanofluid with different nanoparticles mass fraction an ultrasonic processor (Hielscher, UP100St, Germany) was used for prevention of nanoparticles agglomeration. The dynamic viscosity of prepared nanofluid was measured by using a cylindrical viscometer of Brookfield model DV2T, U.S.A which its specifications were presented in Table 1.

2.3 Nanoparticle preparation

In this part of research, CuO nanoparticles were synthesized by means of precipitation method in which 2.416 gr of Cu(NO3)2·3H2O was dissolved in 100 ml pure water to obtain solution containing Cu2+. Afterward, the precipitation was performed by adding 250 ml 0.1 M NaOH solution using a syringe pump with flow rate of 250 ml/hr. The basic solution was added to solution that contains Cu2+ ions under stirring condition of 1200 rpm. Addition NaOH solution was continued until no precipitation reaction occurred as the pH of solution reached to 14. Then, in order to separate precipitates, the solution was introduced to centrifugal-separator with 5000 rpm for 7 min. Moreover, for neutralization of obtained precipitates and removing remained NaOH, the particles were washed 6 times by means of ethanol. Also for evaporation of remained liquid i.e. ethanol and to dry the particles, they were introduced to an oven and kept under temperature of 70 °C for 24 h. Addition NaOH solution to a solution containing Cu2+ led to the formation of both CuO and Cu(OH)2; moreover, the hydroxyl groups (–OH) was removed by keeping the synthesized particles at temperature of 500 °C [36]. Accordingly, the precipitates were kept in oven with temperature of 500 °C for 4 h in order to convert Cu(OH)2 to CuO.

2.4 Nanofluid preparation

The stock nanofluids, (5 wt% CuO-loaded nanofluid), were prepared by dispersing 5 g of synthesized CuO nanoparticles in 95 g of basefluids, (deionized water, ethanol, ethylene glycol). Then in order to separate the agglomerates of nanoparticles in the basefluids, the main nanofluids were subjected to the three step of sonication for 1 h with amplitude and step time of 60% and 0.5 s, respectively. In addition, other nanofluids with various nanoparticles mass fractions were obtained by dilution of certain amount of stock suspension. Mass fraction of CuO was chosen as 5, 1, 0.5, 0.1, 0.05, 0.01 and 0.005 wt% in different basefluids.

2.5 Measuring nanofluid’s viscosity

The viscosity of CuO-loaded nanofluid dispersed in deionized water, ethanol, and ethylene glycol was measured at different mass fractions of CuO nanoparticles ranging from 0.005 to 5 wt% and various temperatures of 25, 40, 55, and 70 °C. The measurement of nanofluids dynamic viscosity was done 5 times in order to verify the repeatability of experimentation and the standard deviation was obtained by using to Eq. 4.

where μi represents the dynamic viscosity of CuO-loaded nanofliuds for each measurement, \(\bar{\mu }\) is average dynamic viscosity of nanofluid at constant condition, and n shows the numbers of measurements, (n = 5).

2.6 Uncertainty analysis

The uncertainty of viscosity measurement was calculated by using the accuracy of viscometer, (± 1%), precise electric balance, (± 0.0003 gr), and thermal circulator bath, (± 0.005 °C). The uncertainty of measurement was obtained according to Eq. 5 [37]:

According to this equation the maximum uncertainty of measurement was found to be ± 5.8%.

3 Results and discussion

3.1 Nanofluid characterization

TEM analysis

TEM analysis was performed on dried CuO nanoparticles to determine the morphology and mean diameters of nanoparticles. For this purpose, a very small amount of dried CuO nanoparticles were dispersed in pure ethanol. After full evaporation of remained ethanol, the samples were introduced to TEM. Figure 1 exhibits the images of TEM analysis for synthesized CuO nanoparticles. The results of this figure showed that CuO nanoparticles were synthesized with mean diameter less than 100 nm. It was found that nanoparticles mean diameter was ranged from 10 to 50 nm. Moreover, it was concluded that the nanoparticles morphology was semi-spherical.

DLS analysis

Dynamic Light Scattering, (DLS), was used for determining the mean diameter of CuO nanoparticles and distribution of nanoparticles’ diameter within the basefluids, (deionized water, ethanol, and ethylene glycol). Figure 2 represents the results of DLS analysis for each nanofluids with different basefluids. These indicate that for CuO-loaded nanofluids dispersed in water, ethanol, and ethylene glycol, the average diameter of the nanoparticles is about 30–40 nm, (Fig. 2a–c), with Poly Dispersity Index, (P.D.I.), ranging from 0.142 to 0.242.

Zeta potential analysis

According to previous researches, zeta potential analysis represents the repulsive forces between dispersed particles within the basefluid [9]. Thus, by comparing the maximum value of zeta potential, the maximum intensity of distributed electrostatic charges which covers nanoparticles’ surface can be easily estimated. Consequently, if the value of zeta potential exceeds higher than + 40 mV or declines less than − 40 mV, stability of nanoparticles would be resulted within the basefluids. In the other words, it represents large magnitude of the zeta potential showing high repulsive electrostatic forces between nanoparticles that ceases them to agglomerate [38, 39]. The results of zeta potential test for CuO-loaded nanofluids dispersed in deionized water, ethanol, and ethylene glycol/water are presented in Fig. 3. These results represent the most of CuO nanoparticles have maximum zeta potential at electrical potential less than − 40 mV declaring high stability of CuO nanoparticles within the deionized water, ethanol and ethylene glycol [40].

3.2 Nanofluid viscosity

After synthesis of CuO nanoparticles and preparation of nanofluids with various basefluids, (deionized water, ethanol, and ethylene glycol), the viscosity of nanofluids were measured at different temperatures and CuO nanoparticles loads. The effects of nanoparticles mass fraction and temperature were investigated within the range of 0.005–5 wt% and 25, 40, 55 and 70 °C, respectively. In addition, the rheological behavior of nanofluids was studied based on the measurement of nanofluids dynamic viscosity at various shear rates. Figure 4 exhibits the value of nanofluid dynamic viscosity versus various shear rates of 3, 6, 11, 15, 20, 36, 54, and 65 1/s for water-based nanofluid at different temperatures and CuO nanoparticles mass fractions of 5 wt%. It is evident from the results of this figure that the value of dynamic viscosity of water-based nanofluids does not change at various shear rates indicating Newtonian behavior of CuO/deionized water nanofluids at various temperatures and maximum nanoparticles load.

Figure 5 shows the value of nanofluid dynamic viscosity versus shear rate for ethanol-based nanofluid at various temperatures and CuO nanoparticles load of 5 wt%. It is concluded from the results of this figure that the value of dynamic viscosity of ethanol-based nanofluids does not change at various shear rates, (similar to the results obtained for water-based nanofluids), indicating Newtonian behavior of CuO/ethanol nanofluids at various temperatures and maximum CuO nanoparticles load.

The results presented in Fig. 6, imply the value of dynamic viscosity versus shear rate for ethylene glycol-based nanofluid at various temperatures of 25, 40, 55, and 70 °C and CuO nanoparticles mass fraction of 5 wt%. With the increase of temperature from 25 to 70 °C a significant reduction in nanofluid viscosity is observed due to the higher random motion of nanoparticles which leads to intense declination in intra-molecular forces between basefluids components. It is also concluded from the results of this figure that the value of dynamic viscosity for ethylene glycol-based nanofluids does not change at various shear rates, (similar to the results obtained for water-based and ethanol-based nanofluids), indicating Newtonian behavior of CuO/ethylene glycol nanofluids at various temperatures of 25, 40, 55, and 70 °C and maximum CuO nanoparticles load, (5 wt%).

Data presented in Fig. 7 exhibit the dynamic viscosity of CuO/deionized water nanofluid at various temperatures of 25, 40, 55, and 70 °C and nanoparticles mass fractions ranging from 0.005 to 5 wt%. It is observed that with the increase in nanoparticles mass fraction from 0.005 to 5 wt% the dynamic viscosity of nanofluid increases from 0.92 to 1.46 mPa s at fixed temperature of 25 °C, respectively. Moreover, it is evident that with the increment of nanoparticles mass fraction from 0.005 to 5 wt% the dynamic viscosity of CuO-loaded nanofluid increases from 0.41 to 0.5 mPa s at the temperature of 70 °C, respectively. Also it is concluded that with the increase of temperature a significant declination in nanofluid dynamic viscosity is resulted. Therefore, these results exhibit that with the increase in temperature from 25 to 70 °C the value of average nanofluid dynamic viscosity decreases around 66% at the condition where the mass fraction of nanoparticles was chosen to be 5 wt%; However, for the condition where the mass fraction is set on 0.005 wt% this enhancement in temperature leads to declination in dynamic viscosity of CuO-loaded nanofluid about 55%. Consequently, It can be concluded that both temperature and CuO nanoparticles mass fraction have intense impact on the dynamic viscosity of CuO/deionized water nanofluid. Although, it has been reported in previous researches that temperature affect viscosity of water-based nanofluid significantly.

Figure 8 represents the value of dynamic viscosity for CuO/ethanol nanofluid at various temperatures of 25, 40, 55, and 70 °C and nanoparticles mass fractions ranging from 0.005 to 5 wt%. It is obvious from the results in this figure that with the increase in nanoparticles mass fraction from 0.005 to 5 wt% the dynamic viscosity of nanofluid enhances from 1.14 to 2.25 mPa s at 25 °C, respectively. In addition, these results clearly exhibit that with the increase in CuO nanoparticles mass fraction from 0.005 to 5 wt%, the dynamic viscosity of ethanol-based nanofluid enhances from 0.48 to 0.69 mPa s at fixed temperature of 70 °C, respectively. Moreover, it is concluded that (similar to those shown in Fig. 7) with the temperature enhancement, dynamic viscosity of ethanol-based nanofluid decreases tangibly. Thus, with the temperature enhancement from 25 to 70 °C the value of nanofluid dynamic viscosity declines around 69% at the condition where the mass fraction of CuO nanoparticles is chosen to be 5 wt%. Furthermore, for those nanofluid contains 0.005 wt% CuO nanoparticles dispersed in ethanol, this enhancement in temperature, (from 25 to 70 °C) leads to 58% declination in dynamic viscosity of ethanol-based nanofluid.

The results of dynamic viscosity for CuO/ethylene glycol nanofluid at various temperatures of 25, 40, 55, and 70 °C and nanoparticles mass fractions ranging from 0.005 to 5 wt% are presented in Fig. 9. These results also show that with the enhancement in nanoparticles mass fraction from 0.005 to 5 wt%, the dynamic viscosity of CuO/ethylene glycol nanofluid increases from 18.05 to 29.51 mPa s at 25 °C, respectively. Furthermore, it is obvious from the results of this figure that with the increase in CuO nanoparticles load from 0.005 to 5 wt%, the dynamic viscosity of ethylene glycol-based nanofluid increases from 7.70 to 10.14 mPa s at fixed temperature of 70 °C, respectively. Also the temperature enhancement leads to a significant reduction in dynamic viscosity of ethylene glycol-based nanofluid. Accordingly, with the increment of temperature from 25 to 70 °C the value of nanofluid dynamic viscosity decreases around 65% for those contain 5 wt% CuO nanoparticles; In addition, for the nanofluids containing 0.005 wt% CuO nanoparticles dispersed in ethylene glycol, this enhancement in temperature reduces the dynamic viscosity of ethylene glycol-based nanofluid around 56%.

Figure 10 presents the value of relative dynamic viscosity of CuO/deionized water nanofluid versus various temperatures and different CuO nanoparticles mass fractions. The results of this figure represent that with the enhancement in CuO nanoparticles mass fraction from 0.005 to 5 wt% and fixed temperature of 25 °C, the value of relative dynamic viscosity increases from 1.03 to 1.64.

Moreover, for the same increment in CuO nanoparticles mass fraction, the value of relative dynamic viscosity enhances from 1.02 to 1.25 at fixed temperature of 70 °C. These results also exhibit that with the increase in temperature the relative dynamic viscosity of nanofluid declines significantly. Thus, for the condition where the mass fraction of nanoparticles is 5 wt%, the enhancement in temperature from 25 to 70 °C leads to declination in the relative dynamic viscosity of nanofluid from 1.64 to 1.25 and for those contains 0.005 wt% CuO nanoparticles; this enhancement in temperature leads to insignificant change in relative dynamic viscosity of water-based nanofluid. It is also evident the effect of CuO nanoparticles load on relative dynamic viscosity of nanofluids is more tangible for those contain higher than 0.1 wt% CuO nanoparticles; furthermore, the effect of temperature on relative dynamic viscosity of water-based nanofluids is more significant at higher nanoparticles loads.

Figure 11 exhibits the value of relative dynamic viscosity of CuO/ethylene glycol nanofluid versus various temperatures and various CuO nanoparticles mass fractions. The results of this figure also represent that with the enhancement in CuO nanoparticles load from 0.005 to 5 wt% and fixed temperature of 25 °C the value of relative dynamic viscosity enhances from 1.04 to 1.72.

Moreover, for this increase in CuO nanoparticles mass fraction, the value of relative dynamic viscosity increases from 1.02 to 1.33 at fixed temperature of 70 °C. These findings also present that with the temperature enhancement the relative dynamic viscosity of nanofluid decreases significantly similar to those obtained for water-based nanofluid. Thus, for the nanofluid with nanoparticles mass fraction of 5 wt%, the enhancement in temperature from 25 to 70 °C leads to significant declination in the relative dynamic viscosity of nanofluid, (from 1.72 to 1.33), and for those contain 0.005 wt% CuO nanoparticles, this enhancement in temperature leads to change in relative dynamic viscosity of nanofluid from 1.04 to 1.02. It is also concluded that the effect of CuO nanoparticles load on relative dynamic viscosity of nanofluids is more significant for nanoparticles loads higher that 0.1 wt%. Moreover, the impact of temperature on relative dynamic viscosity of ethylene glycol-based nanofluids is more significant at higher nanoparticles mass fractions.

The value of relative dynamic viscosity of CuO/ethanol nanofluid versus various temperatures and various CuO nanoparticles mass fractions is presented in Fig. 12.

The results of this figure also represent that with the enhancement in CuO nanoparticles load from 0.005 to 5 wt% at fixed temperature of 25 °C the value of relative dynamic viscosity enhances from 1.08 to 2.12. In addition, for the increase in CuO nanoparticles mass fraction from 0.05 to 5 wt% the value of relative dynamic viscosity enhances from 1.02 to 1.46 at fixed temperature of 70 °C. It means with the increase in temperature the relative dynamic viscosity of nanofluid declines significantly similar to those presented in Figs. 9 and 10. Therefore, for the nanofluid with nanoparticles mass fraction of 5 wt%, the enhancement in temperature from 25 to 70 °C leads to significant decrease in the relative dynamic viscosity of nanofluid from 2.12 to 1.47 and for those contain 0.005 wt% CuO nanoparticles, this enhancement in temperature leads to an insignificant change in relative dynamic viscosity of nanofluid. It is also obvious that the effect of CuO nanoparticles mass fraction on relative dynamic viscosity of nanofluids, is more significant for nanoparticles loads higher that 0.1 wt%; furthermore, the impact of temperature on relative dynamic viscosity of ethanol-based nanofluids is more tangible at higher nanoparticles mass fractions.

3.2.1 Effect of temperature

As shown in Figs. 7, 8 and 9, the viscosity is considered as a function of the CuO nanoparticles mass fraction at constant temperature and it is concluded that with the increase of nanoparticles load the value of nanofluid dynamic viscosity increases significantly. Furthermore, when CuO nanoparticle is dispersed in basefluids, (deionized water, ethanol, and ethylene glycol), the viscosity is measured to be constant at various shear rates declaring Newtonian behavior of CuO-loaded nanofluids. Figures 10, 11 and 12 represent the relative viscosity of the CuO-loaded nanofluid declines with the increase of temperature. Due to the random motion of nanoparticles in basefluids, with the increase of these random motions high impact on hydrodynamic and thermal properties of nanofluid is resulted. According the findings presented by Koo et al. [41], as the temperature increases, the magnitude of nanoparticle random motions enhances and this leads to higher momentum transfer between fluids’ layers by means of nanoparticles. Thus, it is expected that with the increase in temperature more momentum transfer by means of nanoparticles movement is resulted which leads to lower intra-molecular forces and, consequently lower dynamic viscosity of nanofluids.

3.2.2 Effect of nanoparticles mass fraction

In addition the results presented in Figs. 10, 11 and 12 exhibit that with the increase in CuO nanoparticles mass fraction, the relative dynamic viscosity of nanofluids enhances. This enhancement is attributed to the number of nanoparticles random motions, (which is enhanced by increasing nanoparticles load), as well as the solid nanoparticles content in basefluids. The results also illustrate that with the increase in the mass fraction of CuO nanoparticles from 0.005 to 5 wt% the relative dynamic viscosity of CuO/water nanofluid increases about 59, 45, 34 and 22% at temperatures of 25, 40, 55, 70 °C, respectively. Moreover, for CuO/ethanol and CuO/ethylene glycol nanofluids this enhancement in relative dynamic viscosity is 96, 76, 61 and 44% and 65, 52, 38 and 30%, respectively.

3.2.3 Effect of basefluids type

According to the results presented in Figs. 10, 11 and 12 it is concluded that the effect of temperature and basefluid type is more significant on relative dynamic viscosity at CuO nanoparticles mass fraction higher than 0.1 wt%. It is seen that the value of relative viscosity of CuO/ethanol, CuO/ethylene glycol, and CuO/water nanofluids are same at low temperature and nanoparticles mass fraction with maximum 4% difference. The results of relative dynamic viscosity for CuO-loaded nanofluid declared that for ethanol-based nanofluid maximum viscosity measurement was observed at high nanoparticles mass fraction and for water-based nanofluid minimum relative dynamic viscosity was obtained. Interfacial nanolayers of basefluid components surround the CuO nanoparticles’ surface lead to significant positive impact on nanofluid relative dynamic viscosity as well as nanofluid thermal conductivity [42,43,44,45]. On the other hand, with the enhancement in nanolyer thickness the average velocity of nanoparticles movement, (Brownian motion), declines due to the larger nanoparticles mean diameter. Therefore, in CuO/ethanol nanofluid more interfacial interaction is resulted leading to higher relative dynamic viscosity while for CuO/water lower interfacial interaction between nanoparticles surface and water molecules are resulted.

4 Correlation

It is mentioned in the previous researches that relative dynamic viscosity of nanofluids can be estimated by various parameters including nanoparticles load, temperature, basefluid and nanoparticles physical properties [46]. Moreover Brownian velocity of nano-sized component can be estimated by using the following equation:

where T, ρ, D, and κ are temperature, (K), nanoparticle density, (kg/m3), nanoparticle mean diameter, (m), and Stefan Boltzmann constant, (5.670367 × 10−8 W/m2 K4), respectively. According to this relation the magnitude of nanoparticles’ random velocity increases with the increase of temperature and also decreases with the increase of nanoparticles density or mean diameter. In order to obtain the momentum that can be transferred by means of nanoparticles, the following equation can be used in which the nanoparticles’ transferred momentum can be obtained by multiplying nanoparticles density, (ρnp), and magnitude of Brownian velocity, (\(\nu_{Brownian, np}\)).

Accordingly, for basefluid components the above relation can be used as follow in which the momentum transferred by basefluid component can be obtained by multiplying Brownian velocity of basefluid molecules, (\(\nu_{Brownian, bf}\)) to the basefluid density, (ρbf).

In order to compare the momentum transferred by means of nanoparticles and basefluids molecules, the following relation is defined as function of nanoparticles density and mean diameter as well as basefluid density and molecular diameter.

It is concluded from Eq. 9 that with the increase of nanoparticles density and decrease in nanoparticles mean diameter, the value of β coefficient increases; furthermore, the same results are obtained for basefluid with larger molecular diameter and lower density.

To predict the relative dynamic viscosity of CuO-loaded nanofluids at various temperatures, CuO nanoparticles mass fractions and basefluids type, a hybrid group method of data handling (GMDH)-type neural network was used to estimate the correlation based on mentioned parameters [47]. Therefore, a correlation as function of temperature, (°C), nanoparticles mass fraction, (wt%), and β coefficient was derived by using GMDH Shell DS software. (R2 = 0.99):

where the constant values were obtained as follow:

In order to assess the validity of proposed correlation and find the deviation of calculated data from those obtained experimentally, the following equation was used for calculating the margin of deviation:

Figure 13 shows Margin of Deviation, (M.D.), for CuO/deionized water at various nanoparticles mass fractions and temperatures. These results clearly exhibit that the deviation of calculated data from experimental values are majorly less than 10%. In addition, these findings declare that with the increase of temperature up to 70 °C the value of M.D. reach to minimum values and the calculated data are higher than experimental values, (M.D. < 0). These results also declare that for CuO nanoparticles mass fractions of 0.1 and 0.5 wt%, margin of deviation decreases significantly. However, for lower and higher mass fractions the value of M.D. increases up to 10%. This figure implies the proposed model can predict the relative dynamic viscosity of CuO/deionized water nanofluid at the temperature range of 25–70 °C and nanoparticles mass fractions range of 0.005–5 wt% with maximum deviation of 10%.

Figure 14 shows the values of M.D. for CuO/ethanol at various CuO nanoparticles mass fractions and temperatures. The deviation of predicted data from those obtained experimentally is majorly less than 10%. Moreover, these results express that with the temperature enhancement up to 70 °C margin of deviation decreases to the minimum values. Moreover for the CuO nanoparticles mass fractions ranging from 0.05 and 0.5 wt%, M.D. is found at minimum value. Subsequently, for mass fractions lower than 0.05 wt% and higher than 0.1 wt%, the value of M.D. increases up to 10%. Thus, this data presents that the proposed correlation can predict the vales of relative dynamic viscosity for CuO/ethanol nanofluid at the temperature range of 25–70 °C and nanoparticles mass fractions range of 0.005–5 wt% with maximum deviation of 10% similar to those obtained for CuO/deionized water nanofluid.

The results of Margin of deviation for CuO/ethylene glycol at various CuO nanoparticles mass fractions and temperatures are presented in Fig. 15. These results (similar to those of Figs. 13, 14) represent that the deviation of estimated relative dynamic viscosity from experimental data is majorly less than 10%. In addition, with the temperature enhancement up to 70 °C, the margin of deviation decreases to the minimum values for nanoparticles mass fractions below 1 wt%. These findings also declare that for CuO nanoparticles mass fraction of 0.5 wt%, M.D. is found to be at minimum value. Subsequently, for mass fractions lower and higher than 0.5 wt% the value of M.D. increases up to 10% significantly. Therefore, these results present that the proposed correlation can predict the values of relative dynamic viscosity for CuO/ethylene glycol nanofluid at the temperature range of 25–70 °C and nanoparticles mass fractions range of 0.005–5 wt% with maximum deviation of 10% similar to those presented in Figs. 13 and 14.

4.1 Validation of model

In this part of research experimental data were collected from the previous results of other scholars, for validation of the presented correlation CuO-loaded nanofluids (see Table 2). According to the findings presented in this table, the experimental values were obtained from previous researches in which oxide nanoparticles were used for preparation of nanofluids; therefore, the experimental values for relative dynamic viscosity of SiO2/EG, Co3O4/EG, ZnO/EG nanofluid were gathered at various nanoparticles mass fractions and temperatures, and the corresponding data were obtained by using the correlation presented in this study, (Eq. 10). It is concluded that for SiO2/EG nanofluid, the proposed correlation predicts the relative dynamic viscosity of the mentioned nanofluid with margin of deviation less than 10%. In addition, the findings presented in this table, show that for Co3O4/EG, ZnO/EG nanofluids this correlation can calculate the relative dynamic viscosity of nanofluids with M.D. less than 20%. Moreover the values for M.D. decrease with more nanoparticles mass fractions and Eq. 10 can predict relative dynamic viscosity of other oxides-based nanofluid within the temperature range of 25–40 °C and nanoparticles’ mass fractions range of 0.02–0.25 wt% properly.

4.2 Sensitivity analysis

The sensitivity analysis is provided in order to investigate the influences of various parameters including nanoparticles load, temperature and basefluid type. The sensitivity analysis can be used to indicate which independent parameters influence the relative viscosity of nanofluid significantly. Therefore, the sensitivity analysis is performed on proposed correlation of this study by applying ± 15, ± 20, ± 25%, and ± 30% change in nanoparticles mass fraction, temperature, and β coefficient, (which represent type of basefluid and microscopic momentum transfer by nanoparticles and basefluids components). For instance, sensitivity analysis for ± 15 change in temperature of 40 °C, CuO nanoparticles mass fraction of 0.1 wt%, and β coefficient equals to 0.002565 can be obtained according to the following equation:

Figure 16 shows the results of the sensitivity analysis for relative dynamic viscosity of nanofluid versus temperature, nanoparticles mass fraction, and β coefficient. It is evident from the results of this figure that nanofluid relative dynamic viscosity is more sensitive to β coefficient which represents basefluid type comparing to other two independent parameters i.e. nanoparticles mass fraction and temperature.

5 Conclusion

The effects of temperature, nanoparticles mass fraction and basefluid types were studied on viscosity of CuO-loaded nanofluids for the first time [51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77]. CuO nanoparticles were dispersed by using ultrasonic processor in deionized water, ethanol, and ethylene glycol as the basefluids, separately. CuO nanoparticles were prepared by means of precipitation method. Viscosity measurements were performed on samples with nanoparticles mass fractions ranging from 0.005 to 5 wt% and temperature range of 25 to 70 °C.

TEM analysis was performed on dried nanoparticles showing morphology synthesized CuO nanoparticles with average nanoparticles mean diameter ranging from 10 to 50 nm and semi-spherical shape. The results of DLS analysis also confirmed the results of nanoparticles size obtained by TEM analysis in mentioned basefluids; and aslo Zeta-Potential tests exhibited the high stability of the nanoparticles through the basefluids.

By adding CuO nanoparticles to basefluids (deionized water, ethanol, and ethylene glycol), the relative viscosity of nanofluids increases. With the increase in nanoparticles mass fraction higher than 0.1 wt%, the impacts of both nanoparticles mass fraction and temperature would be more significant; while for nanoparticles mass fraction lower than 0.1 wt%, no tangible change in relative dynamic viscosity of nanofluid is seen. In addition, these results declare that viscosity of nanofluids remains constant at various shear rates, which indicates Newtonian behavior of nanofluid at various nanoparticles load and temperature.

According to experimental data it was also evident that with the increase in temperature, relative dynamic viscosity of nanofluid decreased significantly. Finally, a correlation was proposed in this study based on GMDH-type neural network method that the relative dynamic viscosity of nanofluid was correlated by using CuO nanoparticles mass fraction, temperature, and physical properties of the basefluid and nanoparticles.

References

Abdollahi A, Salimpour MR (2016) Experimental investigation on the boiling heat transfer of nanofluids on a flat plate in the presence of a magnetic field. Eur Phys J Plus 131(11):414

Dehghani Y, Abdollahi A, Karimipour A (2018) Experimental investigation toward obtaining a new correlation for viscosity of WO3 and Al2O3 nanoparticles-loaded nanofluid within aqueous and non-aqueous. J Therm Anal Calorim. https://doi.org/10.1007/s10973-018-7394-5

Dehkordi BAF, Abdollahi A (2018) Experimental investigation toward obtaining the effect of interfacial solid-liquid interaction and basefluid type on the thermal conductivity of CuO-loaded nanofluids. Int Commun Heat Mass Transf 97:151–162

Karimipour A, Ghasemi S, Darvanjooghi MHK, Abdollahi A (2018) A new correlation for estimating the thermal conductivity and dynamic viscosity of CuO/liquid paraffin nanofluid using neural network method. Int Commun Heat Mass Transf 92:90–99

Salimpour MR, Abdollahi A, Afrand M (2017) An experimental study on deposited surfaces due to nanofluid pool boiling: comparison between rough and smooth surfaces. Exp Therm Fluid Sci 88:288–300

Abdollahi A, Salimpour MR, Etesami N (2017) Experimental analysis of magnetic field effect on the pool boiling heat transfer of a ferrofluid. Appl Therm Eng 111:1101–1110

Akbari OA, Toghraie D, Karimipour A, Safaei MR, Goodarzi M, Alipour H, Dahari M (2016) Investigation of rib’s height effect on heat transfer and flow parameters of laminar water–Al2O3 nanofluid in a rib-microchannel. Appl Math Comput 290:135–153

Attari H, Derakhshanfard F, Darvanjooghi MHK (2017) Effect of temperature and mass fraction on viscosity of crude oil-based nanofluids containing oxide nanoparticles. Int Commun Heat Mass Transf 82:103–113

Darvanjooghi MHK, Esfahany MN (2016) Experimental investigation of the effect of nanoparticle size on thermal conductivity of in situ prepared silica–ethanol nanofluid. Int Commun Heat Mass Transf 77:148–154

Darvanjooghi MHK, Esfahany MN, Faraj SHE (2017) Investigation of the effects of nanoparticle size on CO2 absorption by silica–water nanofluid. Sep Purif Technol. https://doi.org/10.1016/j.seppur.2017.12.020

Darvanjooghi MHK, Pahlevaninezhad M, Abdollahi A, Davoodi SM (2017) Investigation of the effect of magnetic field on mass transfer parameters of CO2 absorption using Fe3O4–water nanofluid. AIChE J 63(6):2176–2186

Karimipour A, Esfe MH, Safaei MR, Semiromi DT, Jafari S, Kazi S (2014) Mixed convection of copper–water nanofluid in a shallow inclined lid driven cavity using the lattice Boltzmann method. Phys A 402:150–168

Karimipour A, Nezhad AH, D’Orazio A, Esfe MH, Safaei MR, Shirani E (2015) Simulation of copper–water nanofluid in a microchannel in slip flow regime using the lattice Boltzmann method. Eur J Mech B/Fluids 49:89–99

Choi SU, Eastman JA (1995) Enhancing thermal conductivity of fluids with nanoparticles. Argonne National Lab, Lemont

Eastman J (1999) Novel thermal properties of nanostructured materials. Argonne National Lab, Lemont

Mishra PC, Mukherjee S, Nayak SK, Panda A (2014) A brief review on viscosity of nanofluids. Int Nano Lett 4(4):109–120

Chopkar M, Sudarshan S, Das P, Manna I (2008) Effect of particle size on thermal conductivity of nanofluid. Metall Mater Trans A 39(7):1535–1542

Esfe MH, Hajmohammad H, Toghraie D, Rostamian H, Mahian O, Wongwises S (2017) Multi-objective optimization of nanofluid flow in double tube heat exchangers for applications in energy systems. Energy 137:160–171

Ghasemi S, Karimipour A (2017) Experimental Investigation of the effects of temperature and mass fraction on the dynamic viscosity of CuO-paraffin nanofluid. Appl Therm Eng 128:189–197

Afrand M, Toghraie D, Ruhani B (2016) Effects of temperature and nanoparticles concentration on rheological behavior of Fe3O4–Ag/EG hybrid nanofluid: an experimental study. Exp Therm Fluid Sci 77:38–44

Esfe MH, Afrand M, Rostamian SH, Toghraie D (2017) Examination of rheological behavior of MWCNTs/ZnO-SAE40 hybrid nano-lubricants under various temperatures and solid volume fractions. Exp Therm Fluid Sci 80:384–390

Gravndyan Q, Akbari OA, Toghraie D, Marzban A, Mashayekhi R, Karimi R, Pourfattah F (2017) The effect of aspect ratios of rib on the heat transfer and laminar water/TiO2 nanofluid flow in a two-dimensional rectangular microchannel. J Mol Liq 236:254–265

Sajadifar SA, Karimipour A, Toghraie D (2017) Fluid flow and heat transfer of non-Newtonian nanofluid in a microtube considering slip velocity and temperature jump boundary conditions. Eur J Mech B/Fluids 61:25–32

Zadkhast M, Toghraie D, Karimipour A (2017) Developing a new correlation to estimate the thermal conductivity of MWCNT-CuO/water hybrid nanofluid via an experimental investigation. J Therm Anal Calorim 129(2):859–867

Esfe MH (2018) The investigation of effects of temperature and nanoparticles volume fraction on the viscosity of copper oxide-ethylene glycol nanofluids. Periodica Polytech, Chem Eng 62(1):43

Aberoumand S, Jafarimoghaddam A (2017) Experimental study on synthesis, stability, thermal conductivity and viscosity of Cu–engine oil nanofluid. J Taiwan Inst Chem Eng 71:315–322

Shima P, Philip J, Raj B (2010) Synthesis of aqueous and nonaqueous iron oxide nanofluids and study of temperature dependence on thermal conductivity and viscosity. J Phys Chem C 114(44):18825–18833

Duangthongsuk W, Wongwises S (2009) Measurement of temperature-dependent thermal conductivity and viscosity of TiO2–water nanofluids. Exp Therm Fluid Sci 33(4):706–714

Murshed S, Leong K, Yang C (2008) Investigations of thermal conductivity and viscosity of nanofluids. Int J Therm Sci 47(5):560–568

Chandrasekar M, Suresh S, Bose AC (2010) Experimental investigations and theoretical determination of thermal conductivity and viscosity of Al2O3/water nanofluid. Exp Therm Fluid Sci 34(2):210–216

Zadeh AD, Toghraie D (2018) Experimental investigation for developing a new model for the dynamic viscosity of silver/ethylene glycol nanofluid at different temperatures and solid volume fractions. J Therm Anal Calorim 131(2):1449–1461

Nwosu PN, Meyer J, Sharifpur M (2014) A review and parametric investigation into nanofluid viscosity models. J Nanotechnol Eng Med 5(3):031008

Hosseini SM, Moghadassi A, Henneke DE (2010) A new dimensionless group model for determining the viscosity of nanofluids. J Therm Anal Calorim 100(3):873–877

Chen H, Ding Y, He Y, Tan C (2007) Rheological behaviour of ethylene glycol based titania nanofluids. Chem Phys Lett 444(4–6):333–337

Nielsen LE (1970) Generalized equation for the elastic moduli of composite materials. J Appl Phys 41(11):4626–4627

Sahooli M, Sabbaghi S, Saboori R (2012) Synthesis and characterization of mono sized CuO nanoparticles. Mater Lett 81:169–172

Teng T-P, Hung Y-H, Teng T-C, Mo H-E, Hsu H-G (2010) The effect of alumina/water nanofluid particle size on thermal conductivity. Appl Therm Eng 30(14):2213–2218

Esmaeili Faraj SH, Nasr Esfahany M, Jafari-Asl M, Etesami N (2014) Hydrogen sulfide bubble absorption enhancement in water-based nanofluids. Ind Eng Chem Res 53(43):16851–16858

Esmaeili-Faraj SH, Nasr Esfahany M (2016) Absorption of hydrogen sulfide and carbon dioxide in water based nanofluids. Ind Eng Chem Res 55(16):4682–4690

Kim W-G, Kang HU, Jung K-M, Kim SH (2008) Synthesis of silica nanofluid and application to CO2 absorption. Sep Sci Technol 43(11–12):3036–3055

Koo J, Kleinstreuer C (2004) A new thermal conductivity model for nanofluids. J Nanopart Res 6(6):577–588

Feng Y, Yu B, Xu P, Zou M (2007) The effective thermal conductivity of nanofluids based on the nanolayer and the aggregation of nanoparticles. J Phys D Appl Phys 40(10):3164

Özerinç S, Kakaç S, Yazıcıoğlu AG (2010) Enhanced thermal conductivity of nanofluids: a state-of-the-art review. Microfluid Nanofluid 8(2):145–170

Xie H, Fujii M, Zhang X (2005) Effect of interfacial nanolayer on the effective thermal conductivity of nanoparticle-fluid mixture. Int J Heat Mass Transf 48(14):2926–2932

Yu W, Choi S (2003) The role of interfacial layers in the enhanced thermal conductivity of nanofluids: a renovated Maxwell model. J Nanopart Res 5(1–2):167–171

Esfe MH, Razi P, Hajmohammad MH, Rostamian SH, Sarsam WS, Arani AAA, Dahari M (2017) Optimization, modeling and accurate prediction of thermal conductivity and dynamic viscosity of stabilized ethylene glycol and water mixture Al2O3 nanofluids by NSGA-II using ANN. Int Commun Heat Mass Transf 82:154–160

Atashrouz S, Pazuki G, Alimoradi Y (2014) Estimation of the viscosity of nine nanofluids using a hybrid GMDH-type neural network system. Fluid Phase Equilib 372:43–48

Żyła G, Fal J (2017) Viscosity, thermal and electrical conductivity of silicon dioxide–ethylene glycol transparent nanofluids: an experimental studies. Thermochim Acta 650:106–113

Mariano A, Pastoriza-Gallego MJ, Lugo L, Mussari L, Piñeiro MM (2015) Co3O4 ethylene glycol-based nanofluids: thermal conductivity, viscosity and high pressure density. Int J Heat Mass Transf 85:54–60

Esfe MH, Saedodin S (2014) An experimental investigation and new correlation of viscosity of ZnO–EG nanofluid at various temperatures and different solid volume fractions. Exp Therm Fluid Sci 55:1–5

Akbari OA, Afrouzi HH, Marzban A, Toghraie D, Malekzade H, Arabpour A (2017) Investigation of volume fraction of nanoparticles effect and aspect ratio of the twisted tape in the tube. J Therm Anal Calorim 129(3):1911–1922

Esfe MH, Afrand M, Rostamian SH, Toghraie D (2017) Examination of rheological behavior of MWCNTs/ZnO-SAE40 hybrid nano-lubricants under various temperatures and solid volume fractions. Exp Therm Fluid Sci 80:384–390

Esfe MH, Saedodin S, Bahiraei M, Toghraie D, Mahian O, Wongwises S (2014) Thermal conductivity modeling of MgO/EG nanofluids using experimental data and artificial neural network. J Therm Anal Calorim 118(1):287–294

Toghraie D, Chaharsoghi VA, Afrand M (2016) Measurement of thermal conductivity of ZnO–TiO2/EG hybrid nanofluid. J Therm Anal Calorim 125(1):527–535

Esfe MH, Yan WM, Afrand M, Sarraf M, Toghraie D, Dahari M (2016) Estimation of thermal conductivity of Al2O3/water (40%)–ethylene glycol (60%) by artificial neural network and correlation using experimental data. Int Commun Heat Mass Transf 74:125–128

Afrand M, Toghraie D, Karimipour A, Wongwises S (2017) A numerical study of natural convection in a vertical annulus filled with gallium in the presence of magnetic field. J Magn Magn Mater 430:22–28

Esfahani MA, Toghraie D (2017) Experimental investigation for developing a new model for the thermal conductivity of silica/water-ethylene glycol (40%–60%) nanofluid at different temperatures and solid volume fractions. J Mol Liq 232:105–112

Esfe MH, Rostamian H, Toghraie D, Yan WM (2016) Using artificial neural network to predict thermal conductivity of ethylene glycol with alumina nanoparticle. J Therm Anal Calorim 126(2):643–648

Akbari OA, Afrouzi HH, Marzban A, Toghraie D, Malekzade H, Arabpour A (2017) Investigation of volume fraction of nanoparticles effect and aspect ratio of the twisted tape in the tube. J Therm Anal Calorim 129(3):1911–1922

Mashayekhi R, Khodabandeh E, Bahiraei M, Bahrami L, Toghraie D, Akbari OA (2017) Application of a novel conical strip insert to improve the efficacy of water–Ag nanofluid for utilization in thermal systems: a two-phase simulation. Energy Convers Manag 151:573–586

Gravndyan Q, Akbari OA, Toghraie D, Marzban A, Mashayekhi R, Karimi R, Pourfattah F (2017) The effect of aspect ratios of rib on the heat transfer and laminar water/TiO2 nanofluid flow in a two-dimensional rectangular microchannel. J Mol Liq 236:254–265

Semironi DT, Azimian AR (2010) Molecular dynamics simulation of liquid–vapor phase equilibrium by using the modified Lennard-Jones potential function. Heat Mass Transf 46(3):287–294

Akbari OA, Toghraie D, Karimipour A (2016) Numerical simulation of heat transfer and turbulent flow of water nanofluids copper oxide in rectangular microchannel with semi-attached rib. Adv Mech Eng 8(4):1687814016641016

Esfe MH, Saedodin S, Wongwises S, Toghraie D (2015) An experimental study on the effect of diameter on thermal conductivity and dynamic viscosity of Fe/water nanofluids. J Therm Anal Calorim 119(3):1817–1824

Afshari A, Akbari M, Toghraie D, Yazdi ME (2018) Experimental investigation of rheological behavior of the hybrid nanofluid of MWCNT–alumina/water (80%)–ethylene-glycol (20%). J Therm Anal Calorim 132(2):1001–1015

Esfahani NN, Toghraie D, Afrand M (2018) A new correlation for predicting the thermal conductivity of ZnO–Ag (50%–50%)/water hybrid nanofluid: an experimental study. Powder Technol 323:367–373

Esfe MH, Hajmohammad H, Toghraie D, Rostamian H, Mahian O, Wongwises S (2017) Multi-objective optimization of nanofluid flow in double tube heat exchangers for applications in energy systems. Energy 137:160–171

Alrashed AA, Karimipour A, Bagherzadeh SA, Safaei MR, Afrand M (2018) Electro-and thermophysical properties of water-based nanofluids containing copper ferrite nanoparticles coated with silica: experimental data, modeling through enhanced ANN and curve fitting. Int J Heat Mass Transf 127:925–935

Karimipour A, Bagherzadeh SA, Goodarzi M, Alnaqi AA, Bahiraei M, Safaei MR, Shadloo MS (2018) Synthesized CuFe2O4/SiO2 nanocomposites added to water/EG: evaluation of the thermophysical properties beside sensitivity analysis & EANN. Int J Heat Mass Transf 127:1169–1179

Karimipour A, D’Orazio A, Goodarzi M (2018) Develop the lattice Boltzmann method to simulate the slip velocity and temperature domain of buoyancy forces of FMWCNT nano particles in water through a micro flow imposed to the specified heat flux. Phys. A 509:729–745

Safaei MR, Karimipour A, Abdollahi A, Nguyen TK (2018) The investigation of thermal radiation and free convection heat transfer mechanisms of nanofluid inside a shallow cavity by lattice Boltzmann method. Phys. A 509:515–535

Goodarzi M, D’Orazio A, Keshavarzi A, Mousavi S, Karimipour A (2018) Develop the nano scale method of lattice Boltzmann to predict the fluid flow and heat transfer of air in the inclined lid driven cavity with a large heat source inside, two case studies: pure natural convection & mixed convection. Phys. A 509:210–233

Esfe MH, Arani AAA, Karimipour A, Esforjani SSM (2014) Numerical simulation of natural convection around an obstacle placed in an enclosure filled with different types of nanofluids. Heat Transf. Res. 45(3):279–292

Karimipour A, D’Orazio A, Shadloo MS (2017) The effects of different nano particles of Al2O3 and Ag on the MHD nano fluid flow and heat transfer in a microchannel including slip velocity and temperature jump. Phys. E 86:146–153

Esfandiary M, Mehmandoust B, Karimipour A, Pakravan HA (2016) Natural convection of Al2O3–water nanofluid in an inclined enclosure with the effects of slip velocity mechanisms: Brownian motion and thermophoresis phenomenon. Int J Therm Sci 105:137–158

Rahman MM, Eltayeb IA (2013) Radiative heat transfer in a hydromagnetic nanofluid past a non-linear stretching surface with convective boundary condition. Meccanica 48(3):601–615

Rashidi MM, Freidoonimehr N, Hosseini A, Bég OA, Hung TK (2014) Homotopy simulation of nanofluid dynamics from a non-linearly stretching isothermal permeable sheet with transpiration. Meccanica 49(2):469–482

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abdollahi, A., Karimi Darvanjooghi, M.H., Karimipour, A. et al. Experimental study to obtain the viscosity of CuO-loaded nanofluid: effects of nanoparticles’ mass fraction, temperature and basefluid’s types to develop a correlation. Meccanica 53, 3739–3757 (2018). https://doi.org/10.1007/s11012-018-0916-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11012-018-0916-1