We study the effect of activation of clinoptilolite specimens by the solutions of HCl, H2SO4 , NaOH, and NH4Cl with their subsequent thermal treatment for the sorption capacity in silver ions. It is shown that the highest sorption capacity is observed for the clinoptilolite activated by a sodium-hydroxide solution. It was established that, in all cases, the increment of sorption capacity observed upon attainment of a temperature of 200°С is insignificant. The rate of sorption of silver ions by clinoptilolite preliminarily activated by reagents is higher than the initial rate (without activation) by an order of magnitude. We also established the influence of the temperature of treatment of chemically activated clinoptilolite on the sorption rate of silver ions. It was shown that their absorption by clinoptilolite occurs according to the mechanisms of ion exchange and sorption.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

At present, the solution of corrosion problem remains one of priority problem in various branches of industry. The contemporary trends of protection against electrochemical and biological corrosion are connected with the development of protective materials with the certain anticorrosive and antimicrobial additions. In this case, it is also necessary to take into account the ecological aspects, i.e., to use ecologically safe materials [1, 2].

In recent years, the development of ecologically safe means of anticorrosive protection is more and more connected with the application of silver in ionic and free (in the form of nanoparticles) states in which it has the strongest antimicrobial action. Silver nanoparticles immobilized in the polymer or as a component of the coating materials provide corrosion protection and enhance the antibacterial resistance of the metals [3,4,5,6,7]. Silver and copper nanoparticles are used as components of nanocomposites based on polyethylene [8]. For the protection of aluminum alloys against biocorrosion, it was proposed to use sol-gel coatings alloyed with silver particles encapsulated in silicon oxide [9]. Acrylate silver dispersions and polymeric composite materials based on these dispersions are now extensively used, in particular, as materials with antibacterial properties [10].

The efficiency of anticorrosive materials containing silver in one or another form increases if they are immobilized in porous fine-grained materials, which play the role of carriers. They guarantee the possibility of preservation of silver in the ionic and fine-grained forms and provide a large area of its contact with corrosive media. Note that natural zeolites and, in particular, clinoptilolite are characterized by high porosity and ionexchange properties required for sorption and preservation of silver.

High susceptibility of zeolites to cation exchange makes them promising materials for the development of ecologically safe inhibitors of the cathodic corrosion of metals [11]. However, the inhibiting activity of natural zeolites is insufficiently high and, hence, their modification with ions of various metals proves to be a promising method for the improvement of anticorrosive properties of zeolites [12,13,14]. At the same time, natural clinoptilolite reveals a noticeable antibacterial action [15, 16].

The results of investigations of the modification of natural zeolite-containing rocks with silver ions and the antibacterial properties of the obtained materials were described in [17]. It was indicated that the absorption of silver ions by zeolite can be realized according to different mechanisms: ion exchange and sorption. Therefore, parallel with the term “ion-exchange capacity,” it is customary to use the term “sorption capacity.” Clinoptilolite modified with silver ions exhibits a strong antibacterial action, in particular, against Staphylococcus aureus, Pseudomonas aeruginosa, Candida albicans, etc. However, in all cases, the researchers used zeolites from different deposits, which differ by the content of the main component, i.e., clinoptilolite, and by the kind and contents of antiions.

It is known that the thermal, electromagnetic [18], or chemical activations of clinoptilolite make it possible to increase the sorption capacity for different cations. However, the data on the influence of activation of this kind on the capacity of clinoptilolite with respect to silver ions is quite poor.

The aim of the present work is to study the modification of preliminarily chemically and thermally activated clinoptilolite with silver ions for the controlled production of materials with the required silver contents.

Experimental Procedures

For our investigations, we used clinoptilolite (TU U 20.5-43073742-002:2019) from the Sokyrnytsya Deposit (Zakarpats’ka Oblast, Ukraine). The natural zeolite rock contains clinoptilolite (65–80%) as the main component and also admixtures of montmorillonite, calcite, and quartz. Therefore, in order to decrease the influence of admixtures (whose contents may vary) on the results of investigations, we performed preliminarily mechanical crushing of clinoptilolite (with an initial size of 2–3 mm). Since the hardness of montmorillonite and calcite is lower than the hardness of clinoptilolite, the rock particles are subjected to mechanical break at the sites of localization of these components. After grinding of the rock in a ball mill down to sizes < 1.5 mm, we rejected the finest fraction (0–0.25 mm) containing the maximum amount of admixtures. Then the remaining zeolite (0.25–1.5 mm) was ground once again. The investigated fraction of clinoptilolite was as large as 0.056–0.063 mm.

Zeolite was chemically activated with subsequent drying (activation) at different temperatures. Chemical activation was carried out by using 0.1 N solutions of HCl, H2SO4 , NaOH, and NH4Cl taken in the following mass ratio: clinoptilolite : reagent = 1 : 10. Modification was carried out for 30 min and then zeolite was separated by filtering and washed with distilled water up to the attainment either of a stable pH value (for acids and alkalis) or of the absence of chlorine ions in washing water. After washing, zeolite was dried (thermally activated) at a temperature of 20–300°C up to the attainment of a stable mass. Further, clinoptilolite with a mass of 10 g was modified in 100 cm3 of a 0.1 N AgNO3 solution under the conditions of permanent intense stirring [19]. In the course of modification of zeolite, we potentiometrically measured the concentration of silver ions in the solution. An F-30 millivoltmeter was used as a measuring instrument and Ag-selective (ESS-01) and silver-chloride (EVL-1M) electrodes were taken as measuring and reference electrodes, respectively. The reference electrode worked in contact with corrosive media through an electrolytic cell of the original structure filled with a 1 N KNO3 solution. Zeolite was modified up to the attainment of a stable value of potential of the Ag-selective electrode.

Modified zeolite was washed with distilled water under the conditions of intense stirring up to the complete absence of Ag+ ions in water. The concentration of silver ions in washing water was taken into account in finding the number of Ag+ ions sorbed by zeolite. Prior to each test, the Ag-selective electrode was calibrated in AgNO3 solutions (0.001–0.1 mole/dm3).

The concentration of Na+ , K+ , Ca2+ , and Mg2+ ions in the modifying solution was found with the help of a PAZh-3 flame photometer.

The sorption capacity of clinoptilolite was determined by analyzing the decrease in the concentration of silver ions in the solution. The chemical composition of modified zeolite was determined with the help of energydispersion X-ray (EDX) microspectral analysis by using an INCA Energy-350 instrument integrated in the system of a Zeiss EVO-40XVP scanning electron microscope.

Results and Discussion

By the EDX method, we determined the contents of exchange cations (Na+ , K+ , Ca2+ , and Mg2+ ) in the original specimen of clinoptilolite. They were as follows [wt.% (mEq/g)]: 1.39 (0.604) Na+ ; 2.89 (0.74) K+ ; 1.56 (0.78) Ca2+ , and 0.54 (0.45) Mg2+ . The total content of exchange cations was equal to 2.57 mEq/g. According to the technical certificate of zeolite from the Sokyrnytsya Deposit, its total cation-exchange capacity is equal to 1.8–2 mEq/g. Hence, the mechanical enrichment of the clinoptilolite rock enables one to increase its cation-exchange capacity by ∼22% as a result of the removal of admixtures that do not contain exchange cations.

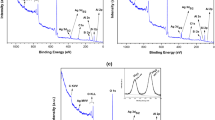

The chemical activation of clinoptilolite by the indicated reagents enables one to increase the static sorption capacity of zeolite with respect to silver ions (Fig. 1).

The ion-exchange capacity of the original clinoptilolite for silver ions noticeably (by a factor of 4.4) increases upon the attainment of treatment temperatures higher than 100°С: from 0.19 to 0.42 mEq/g. This is explained by its dehydration, i.e., by the separation of physically bound water. If the activation temperature is equal to 300°С, then the ion-exchange capacity becomes as high as 0.84 mEq/g.

The preliminary chemical activation of clinoptilolite for 30 min makes it possible to increase the ionexchange capacity of zeolite in the entire temperature interval. For a drying temperature of zeolite equal to 20°C, the increase in the ion-change capacity of clinoptilolite in the case of its activation by the solutions of NH4Cl, H2SO4 , HCl, and NaOH (as compared with the nonactivated specimens) is equal to 0.26; 0.36; 0.36, and 0.47 mEq/g, respectively. In other words, the zeolite capacity becomes 2.37; 2.89; 2.89, and 3.47 times higher than for the nonactivated substance.

It is worth noting that, for the purposes of washing of zeolite after its activation in a NaOH solution, it is necessary to use more water than in the other cases (by 25–30%).

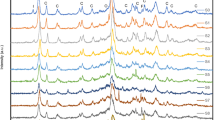

The kinetics of sorption of silver ions by the original and chemically activated clinoptilolite are somewhat different. Indeed, the content of silver ions in the nonactivated zeolite fairly smoothly varies for ∼ 10 min (Fig. 2). The initial ion-exchange rate is equal to 9.26 ·10–4mole/(sec·dm3) (per unit volume of zeolite). The fraction used for the investigations was very fine (< 0.063 mm) and, therefore, the procedure of evaluation of the integral area of the surfaces of clinoptilolite particles required to determine the rate of heterogeneous process is incorrect.

At the same time, the rate of sorption of silver ions by chemically activated clinoptilolite is higher by an order of magnitude. The rates of sorption (ion exchange) with participation of zeolite chemically activated in solutions of NH4Cl, H2SO4 , HCl, and NaOH are as high as 6.12 ·10–3; 7.5 ·10–3; 7.65 ·10–3, and 9.12 ·10–3 mole/(sec·dm3), respectively. For the first 60 sec after activation, we observe the absorption of more than 80% of the entire amount of sorbed ions. Therefore, in the time dependences of the content of Ag+ ions for activated zeolite specimens, we observe a sharp inflection as early as in the first or second minute of the process (Fig. 2a).

As the temperature of treatment (drying) increases from 20 to 100°С, the sorption capacities of clinoptilolite specimens chemically activated in solutions of NH4Cl, H2SO4 , HCl, and NaOH become equal to 0.78; 0.86; 0.99, and 1.16 mEq/g, respectively. Moreover, the increments of sorption capacity of these zeolite specimens with respect to silver ions are equal to 0.33; 0.31; 0.44, and 0.5 mEq/g, respectively. As compared with nonactivated zeolite, the ion-exchange capacities of the activated specimens at a temperature of 100°С become 1.86; 2.05; 2.33, and 2.76 times higher, respectively.

At a temperature of 150°С, when we observe a significant, as compared with 100°С, increase in the capacity of the original clinoptilolite, the capacity of chemically activated clinoptilolites, on the contrary, increases insignificantly. Thus, the content of silver ions in nonactivated zeolite increases from 0.42 to 0.74 mEq/g.

At the same time, the increments of capacity of clinoptilolite specimens activated in solutions of NH4Cl, H2SO4 , HCl, and NaOH in the same temperature range are equal to 0.1; 0.12; 0.07, and 0.09 mEq/g, respectively.

A subsequent increase in temperature within the range 150–300°С causes an insignificant increase in the capacity of chemically activated zeolite for silver ions (see Fig. 1). In particular, the increments of the sorption capacity of specimens treated in solutions of NH4Cl, H2SO4 , HCl, and NaOH were equal to 0.14; 0.163; 0.095, and 0.115 mEq/g, i.e., 13.7; 14.2; 8.2, and 8.6% of the total capacity of clinoptilolite specimens, respectively.

The rates of sorption of Ag+ ions by zeolite specimens thermally activated at a temperature of 300°С increase in all cases (even for the original specimen) (Fig. 2b). Thus, it becomes equal to (mole/(sec·dm3)): 4 ·10–3; 1.18 ·10–2 ; 1.28 ·10–2 ; 1.52 ·10–2 , and 1.85 ·10–2 for the original zeolite specimen and specimens activated by solutions of NH4Cl, H2SO4 , HCl, and NaOH, respectively. In other words, by analogy with a temperature of 20°С, the rate of sorption of silver ions by activated zeolites is higher than for the nonactivated zeolite by an order of magnitude.

In general, for a treatment temperature of 300°С, the following values of sorption capacity with respect to silver ions were attained (mEq/g) : 0.84 for the original zeolite and 0.98, 1.4, 1.15, and 1.33 for zeolites activated in solutions of NH4Cl, H2SO4 , HCl, and NaOH. The most pronounced effect observed in the case of application of NaOH solutions can be possibly explained by a weak dealumination of zeolite as a result of the interaction of Al2O3 with the alkali.

The results of the EDX analysis show that, the specimens of chemically activated clinoptilolite modified with Ag+ ions do not contain sodium ions. Almost all sodium ions are replaced with hydrogen protons under the action of sulfuric and hydrochloric acids and ammonium chloride. This is confirmed by the analysis of the corresponding solutions for the content of sodium ions. Under the action of a NaOH solution, sodium ions are not replaced in zeolite. However, in the case of modification with silver ions, they are completely replaced. At the same time, the contents of other cations (K+ , Ca2+ , and Mg2+ ) depends, first of all, on the nature of activating reagent (Fig. 3). Under the action of both acids and NH4Cl, as in the case of sodium ions, we observe the replacement of magnesium ions in the major part of the specimens. In this case, under the influence of NaOH solutions, the degree of replacement of magnesium ions varies within the range 11–33%.

For the degree of replacement of K+ and Ca2+ ions, we did not reveal any clear regularities of its variations depending on the nature of reagent. This quantity varies from 5.8 to 35.7%.

By analyzing the composed balance for the contents of Na+ , K+ , Ca2+ , Mg2+, and Ag+ ions (via the number of equivalents per 1 g of zeolite), we made a conclusion that the number of equivalents of Na+ , K+ , Ca2+ , and Mg2+ ions participating in ion exchange is larger than the number of equivalents of Ag+ ions in the samples of modified zeolites. Thus, as a result of activation of zeolite by a NaOH solution with subsequent modification in a solution of silver nitrate, the content of silver ions becomes equal to 0.87 mEq/g, whereas the integral amount of substituted Na+ , K+ , Ca2+ , and Mg2+ ions constitutes 1.01 mEq/g. Hence, it is possible to assume that a part of the indicated ions participates in exchange processes in the course of their interaction with activating reagents and, possibly, a certain part is replaced with silver ions.

The results of the EDX analysis demonstrate that the process of ion exchange (sorption of Ag+ ions) on different particles of clinoptilolite is nonuniform and, therefore, the contents of silver ions can be different. Thus, the particles of zeolite preliminarily modified in a NH4Cl solution contain 48.6–70.8 mg of silver per 1 g of zeolite. The process of sorption of silver ions on zeolite samples modified, e.g., in a NaOH solution is much more uniform. Hence, the silver content varies within the range 82.9–94.4 mgAg/g. In this case, the integral content of silver ions in the process of modification is equal to 143 mgAg/g.

At the same time, it was established that, in the course of holding, the obtained zeolite specimens with higher contents of Ag+ ions acquired dark color. This color is typical of finely divided silver. On this basis, we can make a conclusion that Ag+ ions penetrate into zeolite by two mechanisms: ion exchange and sorption. Moreover, sorbed silver nitrate is preserved in the structure of clinoptilolite because it is not desorbed in the course of washing of modified zeolite with distilled water.

The presence of finely divided silver in the specimens activated in NaOH solutions is confirmed by the fact that, under the action of nitric acid, the clinoptilolite particles become lighter and silver ions appear in the solution. The SEM images of particles indirectly confirm the presence of finely divided silver on the clinoptilolite surfaces. Indeed, the particles are covered with a friable spongy film (Fig. 4).

The accumulated results demonstrate that the preliminary chemical activation of natural clinoptilolite enables one to get significant contents of silver ions in clinoptilolite (even up to 143 mgAg/g). Hence, there exist preliminary technological background (conditions of chemical activation, thermal treatment, etc.) for the controlled modification of natural clinoptilolite with Ag+ ions. This enables us to guarantee efficient antibacterial action of modified clinoptilolite on certain cultures of microorganisms. Thus, in particular, the antimicrobial action is confirmed for Pseudomonas aeruginosa bacteria (blue pus bacillus) and Candida albicans yeast.

Conclusions

The procedure of activation of natural clinoptilolite by solutions of HCl, H2SO4 , NaOH, and NH4Cl with subsequent treatment at different temperatures enables one to guarantee its required static capacity with respect to silver ions in a broad interval; its value can be as high as 1.33 mEq/g (143 mg/g). This confirms the possibility of controlled modification of clinoptilolite under certain conditions (the choice of chemical activators, temperature of treatment of zeolite, etc.) aimed at getting the required content of silver ions, which is important for the creation of corrosion inhibitors and significantly broadens the possibilities of application of clinoptilolite in other fields. The modification of chemically and thermally activated clinoptilolites with silver ions is characterized by a high rate and, therefore, the duration of the process constitutes only 15–20 min, which provides its high productivity. The obtained specimens of clinoptilolite modified with silver ions have noticeable bactericidal properties, which makes it possible to use them for the creation of new compositions aimed at the biocorrosion protection of various structures. The procedures of chemical activation of zeolite and its modification with silver ions, as well as the product obtained as a result, are not harmful for people and environment because the concentrations of reagent solutions are low and, moreover, these solutions can be easily neutralized.

References

Z. V. Slobodyan, Z. M. Il’nyts’kyi, L. A. Mahlatyuk, R. B. Kupovych, and I. V. Semenyuk, “Ecologically safe inhibitors of the corrosion activity of lubricoolants,” Fiz.-Khim. Mekh. Mater., 54, No. 4, 48–51 (2018); English translation: Mater. Sci., 54, No. 4, 496–500 (2019).

I. M. Zin’, O. V. Karpenko, T. Ya. Pokyn’broda, N. I. Korets’ra, M. B. Tymus’, L. Kwiatkowski, and S. A. Kornii, “Inhibition of the corrosion of carbon steels by trehalose lipid surfactants,” Fiz.-Khim. Mekh. Mater., 54, No. 4, 31–38 (2018); English translation: Mater. Sci., 54, No. 4, 477–484 (2019).

A. M. Atta, G. A. El-Mahdy, H. A. Al-Lohedan, and A. O. Ezzat, “Synthesis and application of hybrid polymer composites based on silver nanoparticles as corrosion protection for line pipe steel,” Molecules, No. 19, 6246–6262 (2014); doi:https://doi.org/10.3390/molecules19056246.

R. Zeng, L. Liu, S. Li, Y. Zou, F. Zhang, Y. Yang, H. Cui, and E. Han, “Self-assembled silane film and silver nanoparticles coating on magnesium alloys for corrosion resistance and antibacterial applications,” Acta Metallurg. Sin., 26, No. 6, 681–686 (2013).

J. Narenkumar, P. Parthipan, J. Madhavan, K. Murugan, S. B. Marpu, A. K. Suresh, and A. Rajasekar, “Bioengineered silver nanoparticles as potent anticorrosive inhibitor for mild steel in cooling towers,” Environ. Sci. Pollut. Res. Int., 25, No. 6, 5412–5420 (2018).

A. M. Atta, H. A. Allohedan, G. A. El-Mahdy, and A-R. O. Ezzat, “Application of stabilized silver nanoparticles as thin films as corrosion inhibitors for carbon steel alloy in 1 M hydrochloric acid,” J. Nanomater. (2013), Article ID 580607; https://doi.org/10.1155/2013/580607.

A. S. Johnson, I. B. Obot, and U. S. Ukpong, “Green synthesis of silver nanoparticles using Artemisia annua and Sida acuta leaves extract and their antimicrobial, antioxidant and corrosion inhibition potentials,” J. Mater. Environ. Sci., 5, No. 3, 899–905 (2014).

L. A. Tamayo, P. A. Zapata, N. D. Vejar, M. I. Azócar, M. A. Gulppi, Х. Zhou, G. E. Thompson, F. M. Rabagliati, and M. A. Páez, “Release of silver and copper nanoparticles from polyethylene nanocomposites and their penetration into Listeria monocytogenes,” Mater. Sci. Eng., Ser. C, 40, No. 1, 24–31 (2014); https://doi.org/https://doi.org/10.1016/j.msec.2014.03.037.

E. A. Gonzáleza, N. Leivaa, N. Vejarc, M. Sancyb, M. Gulppia, M. I. Azócara, G. Gomeza, L. Tamayoe, X. Zhoud, G. E. Thompsond, and M. A. Páez, “Sol-gel coatings doped with encapsulated silver nanoparticles: inhibition of biocorrosion on 2024-T3 aluminum alloy promoted by Pseudomonas aeruginosa,” J. Mater. Res. Technol., 8, No. 2, 1809–1818 (2019).

O. V. Hres’, S. V. Holovan’, E. V. Lebedev, and V. F. Matyushov, “Acrylate silver dispersions and composite polymeric materials base on these dispersions,” Ukr. Khim. Zh., 75, No. 1, 63–67 (2009).

V. I. Pokhmurskyi, I. M. Zin, S. A. Kornii, Ya. I. Zin, and B. P. Kosarevych, “Theoretical and experimental prerequisites of the application of nanoporous ion-modified zeolites aimed at improvement of the protective properties of organic coatings,” Nanostrukt. Materialoznav., No. 1, 78–87 (2013).

N. M. Ahmed, H. S. Emira, and M. M. Selim, “Anticorrosive performance of ion-exchange zeolites in alkyd-based paints,” Pigment Resin Technol., 40, No. 2, 91–99 (2011); https://doi.org/https://doi.org/10.1108/03699421111113747.

S. A. S. Diasa, S. V. Lamaka, C. A. Nogueira, T. C. Diamantino, and M. G. S. Ferreirab, “Sol-gel coatings modified with zeolite fillers for active corrosion protection of AA2024,” Corr. Sci., No. 62, 153–162 (2012).

V. Pokhmurskii, L. Bily, Y. Zin, and M. Voloshyn, “Inhibition of the corrosion of aluminum alloy by a composition of ionexchange pigments,” Fiz.-Khim. Mekh. Mater., 51, No. 5, 43–47 (2015); English translation: Mater. Sci., 51, No. 5, 638–643 (2016).

V. D. Rybachuk, О. А. Ruban, and N. I. Filimonova, “Microbiological substantiation of the choice of concentration of antimicrobial substances in the composition of a powder based on natural zeolite (clinoptilolite),” Ukr. Biofarm. Zh., No. 1 (58), 4–9 (2019).

S. K. Pavelic, J. S. Medica, D. Gumbarevic, A. Filosevic, N. Przuli, and K. Pavelic, “Clinoptilolite safety and medical applications in vivo. Critical review on zeolite,” Front. Pharm., No. 9, 1–1350 (2018); https://doi.org/https://doi.org/10.3389/fphar.2018.01350.

L. Petrik, R. Missengue, O. Fatoba, M. Tuffin, and J. Sachs, Silver/Zeolite Nano-Composite-Based Clay Filters for Water Disinfection, Report to the Water Research Commission. WRC Report No. KV 297/12, Gezina ( 2012).

A. S. Hrabarovska, Z. O. Znak, and P. P. Olenych, “Investigation of the activation of natural clinoptilolite by ultrahigh-frequency electromagnetic radiation,” Khim. Tekhnol. Rechov. Zastos., 1, No. 2, 21–26 (2018).

Z. O. Znak, A. S. Hrabarovska, O. I. Zin, and A. V. Dyadenchuk, “Modification of thermally activated natural clinoptilolite with silver ions,” Visn. Cherkasy Derzh. Tekh. Univ., Tekh. Nauky, No. 4, 79–87 (2019).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 56, No. 4, pp. 93–99, July–August, 2020.

Rights and permissions

About this article

Cite this article

Znak, Z.О., Коrnii, S.А., Маshtaler, A.S. et al. Production of Nanoporous Zeolites Modified by Silver Ions with Antibacterial Properties. Mater Sci 56, 536–543 (2021). https://doi.org/10.1007/s11003-021-00461-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-021-00461-1